Showing 444 items

matching e.g.

-

Flagstaff Hill Maritime Museum and Village

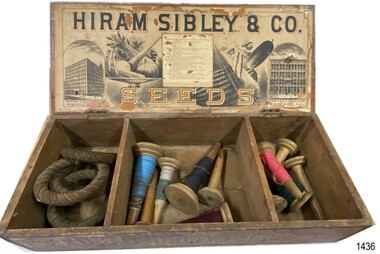

Flagstaff Hill Maritime Museum and VillageContainer - Box for seeds, ca. 1880s

This seed box was made for Hiram Sibley for his seed house business. He sold seeds priced by the weight or the space they took up e.g. bushel. This box allowed for seeds to be divided by type, size or even date. The box was strong and easy to cart and store. It was also a handy item to 'recycle' as a storage container for other items. The Sibley seed box is a desirable collectors' item. A large variety of sizes and shapes are still available today in various stages of condition. Hiram Sibley developed seeds that were strong and the plants that grew from these seeds produced many seeds. Varieties of Sibley seeds and plants are still advertised for sale in modern times. HIRAM SIBLEY (1807-1888) - Hiram Sibley was born in America. He had a natural mechanical ability and became skilled in many trades. He and his partner Don Watson opened a sawmill then a machine shop and foundry. He became involved with Alfred Vale and Samuel Morse and their work on the telegraph. Eventually he became the first president of the Western Union Telegraph Company. Later, after leaving Western Union in the early 1860s, Sibley bought and sold railroads, manufactured sold, ran timber mills, and became involved in farming and seed supply. In this area he used his skills to engineer seeds that were stronger and develop plants that produced more seeds. The production of seeds became his main business. He bought land cheaply and improved to soil so that he could produce seed and grain, and graze herds of cattle. He became the owner of 14 large farms. Hiram Sibley earned the reputation "as the most extensive farmer and seedsman in this country". The business of Hiram Sibley & Co. was conducted his warehouse in Rochester and his seed house in Chicago. One department of the business sold farming equipment, another department imported ornamental plants from overseas countries Sibley went on to invest a large amount of money in a bank, and to be financially involved in the community by making large donations to public services such as a library and a school of music. At one point he was the richest man in Monroe county.This box is significant for its historic connection with Hiram Sibley, who is famous for many reasons, among which is his very profitable business of seed engineering to improve the production of crops. This box also represents the value of containers used for selling products in the 1880s, being re-used for other useful purposes. The box is an example of goods imported for use in Australia. The text and images of the box are an example of 1880s advertisingBox, wooden, with two brass hinges joining lid to base. Base has two wooden partitions, divided into three unequal sized compartments. Lid's underside has label with drawings of buildings and produce, text with maker's name and description of vegetables. Front edge of box has stencilled text and diagrams. Outside lid, and the other three sides, have no inscriptions. Made by Hiram Sibley & Co., USA. (Box is currently used to store quoits 1436.2 and cones of cotton thread 1436.3.)Marked "HIRAM SIBLEY & CO / SEEDS", "WAREHOUSE - "ROCHESTER N.Y. ", "SEED HOUSE - CHICARGO, ILL.", "SEEDS BY WEIGHT & MEASURE", "PUT UP BY / HIRAM SIBLEY & CO. / ROCHESTER, N.Y. AND CHICARGO, ILL."flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, hiram sibley & co, rochester n.y., seeds, wooden seed box, seed box, seedsmen, arable farming, chicargo illinois, seed house, seed engineering, seed distribution, seeds by weight and measure -

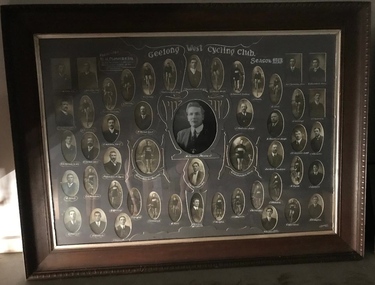

Geelong Cycling Club

Geelong Cycling ClubHonour Board, 1913

Decorative wooden frame surrounding black and white photographs behind photographic mounting card in grey. The inscriptions are hand painted in white with some highlights in gold and blue. “Geelong West Cycling Club/Season 1913/Presented to H.Flowers, Esq/by the members of the above club in appreciation of his valuable services as President/W.O’Shannessy, Com Hcapper/R.Thomson, Com/J.J.McCracken/L.Welsh/W.Fisher/T.A.Grundell, whipp/F.Annear, Treasurer and Hcapper/C.Smith,Whip/H.Preschud, Auditor/J.Smith/H.Foot/A.G.Thomson, Comm/W.Grundell, Com/T.W.Grundell/H.H. Potter/G.Hotchin, Jnr Sec & Capt/H.Flowers, President/J. Tournier, Judge/A. Bradshaw, Judge/G. Dorling/J.Thomson/H.H.Preschud, Ass.Sec’t/H. Fisher, Vice Pres/P.Grundell, Sen. TimeK/C.Bond, C Man & Aud/TJB Grundell, Vice Cp/E.G. Stott, Time Keeper/H. Toyne/J.C. Bennett, Judge/C. Simmons/A. Bond/E. Atkinson/E. Keating/ S. Knight/T. F. Preschud/A. Marr/T.R.Balfour/Track Steward/C. Hudgell/J. O’Loughlin/J.W.Grundell/C.Ovendon/H.Toyne/J. Jarrett/R. Preschud/H. Morrish/S.Balfour, Track Stew/V.Balfour, Track Steward/C.Williams/D.M.Hogan” geelong west cycling club; h.flowers; w.o’shannessy;r.thomson; j.j.mccracken; l.welsh; w.fisher; t.a.grundell; f.annear; c.smith; h.preschud; j.smith; h.foot; a.g.thomson; w.grundell; t.w.grundell; h.h. potter; g.hotchin; h.flowers; j. tournier,; a. bradshaw; g. dorling; j.thomson; h.h.preschud; h. fisher; p.grundell; c.bond; tjb grundell; e.g. stott; h. toyne; j.c. bennett; c. simmons; a. bond; e. atkinson; e. keating; s. knight; t. f. preschud; a. marr; t.r.balfour; c. hudgell; j. o’loughlin; j.w.grundell; c.ovendon; h.toyne; j. jarrett; r. preschud; h. morrish; s.balfour; v.balfour; c.williams; d.m.hogan; -

The 5th/6th Battalion Royal Victoria Regiment Historical Collection

The 5th/6th Battalion Royal Victoria Regiment Historical CollectionAward - AIF 7th Division Band Championship Palestine 1941

7 PLATES AND ONE MISSING AIF 7th Division Band Championship Palestine 2nd March 1941 Won by 2/24 Battalion Bandmaster L/SGT L.G.SKANE DRUM MAJOR L/SGT P.C Russell side drums pte w.h. wilson pte r.k. johnson tenor drum pte. e.w.j. Forrest Bass Drum Pte N.M. Hogan Cymbals Pte E.Brear Buglars Pte GH Rickard PTE M.A. Johnson Suprano Coronet Pte G FERGUSON SOLO Coronets CPL D.W.Duncan PTE H.T PARSONS PTE DH FRAZER REPIANO CORONET PTE RD BLACKBURN FLUGEL HORN PTE. H.J. GAYLORD 2ND CORONETS PTE R.R. MATHER PTE J.W.COOK 3RD CORONET PTE L.J.MCDONALD SOLO HORN PTE D.M.GRAY HORNS PTE W.H.B SINCOCK PTE B HOLM BARITONES PTE M.R. CRICK PTE A.L. WARWICK EUPHONIMS PTE. E.A.SINCOCK PTE H.R CLOGAN TROMBONES PTE H.J SINCOCK PTE G.W. BARRETT BASS TROMBONE PTE E.G. MOFFAT -

Glen Eira Historical Society

Glen Eira Historical SocietyArticle - CAULFIELD CENTRAL RSL

This file contains six items pertaining to the Caulfield Central RSL: 1/A page to which is attached a black-and-white photograph (date, source and photographer unspecified) of the Caulfield Central RSL, outlying garden and Australian flag. Some writing on the rear identifies the subject. 2/A typewritten letter, (1 page) dated 1946 (no date more specific than that specified), from the Chairman & Honorary Treasurer of the Caulfield Central RSL Appeal Committee (name unspecified) to the Mayor of Caulfield (name also unspecified), imploring the latter for a donation of $20,000 dollars for purposes of constructing a Memorial Hall to eulogize servicemen killed during WWII. Some rough working notes on rear side. 3/A flyer, undated (although presumably published in 1950), printed by Peter Isaacson Pty. Ltd., advertising a concert presented by the Ugly Ugly Man (Frank M. Beard) and the Malvern Tramways’ Harmonica Band to be held at Caulfield Town Hall on 06/06/1950 to assist the Welfare Funds of the Caulfield Central RSL and the Sailors, Soldiers and Airmen’s Mothers’ Association. Also contains an advertisement for a drapery business called Tallents. 4/The annual report of the Caulfield Central RSL, for the period 1952 – 1953. Contains announcements of the annual general meeting and annual elections, the President’s report (in which he principally discusses the club’s charity work and sporting activities), the subcommittee staff roster, the sportsmen’s honour roll, the annual accounts (e.g. balance sheet, income & expenditure statement) and the roster of nominees for office in the committee of management election. 5/A typewritten letter, (1 page) dated 26/11/1982, from Max Brian Blair, Treasurer of the Caulfield Central RSL, to Mr. R. Ballantyne, Secretary of the Caulfield Historical Society, thanking him for his donation to the RSL. 6/A photocopy of an article titled ‘RSL pays $30,000 to buy off objector’ (from the Sunday Herald, by Mary-Anne Toy, dated 16/09/1990), about the Caulfield Central RSL paying local resident Mr. Chris White to withdraw his objection to the RSL’s intention to re-allocate its clubrooms, and the consequent response of the relevant authorities.caulfield, caulfield central returned servicemen league (rsl), ex-service organisations, clubs and associations, returned servicepeople, armed forces, soldiers, aged people, senior citizens centres, mayors, city of caulfield, war memorials, blamey thomas general sir, white t. w. group capt., gullett h. b. major, beaurepaire frank sir m.l.c., kennedy j. a. m.l.c., warner a. g. m.l.c., michaelis archie m.l.a., dennett a. h. lt.-col. m.l.a., don john capt. m.l.a., reid h. squire m.l.a., brooks w. r. cr., packer j. t. cr., parton e. m. cr., prior p. l. cr., morris t. w. cr., sinclair a. j. g. cr., sims h. e. cr., smith h. c. h. cr., smith james e. cr., tyers s. w. cr., webster harold cr., yorston j. s. cr., briggs r. jas., disney j. s., donath h., llewellyn evans, goddard s. a. padre, lynch p. j., nilsen oliver j. cr., pidd padre a. t., robinson norman, reece harold j., wootton harold s., wallace gordon w., nelson harold g., halls, concerts, musical events and activities, fundraising events, bands, musical ensembles, sailors soldiers and airmen’s mothers’ association, ‘the ugly ugly man’, beard frank m., malvern tramways harmonica band the, caulfield town hall, tallents, drapers, glenhuntly road, glen huntly road, elsternwick, peter isaacson pty. ltd melbourne, annual reports, financial documents, fisher s. w., finch f., williams f., salmon j. e., mallyon v. k., woods w., mayne t. v., lanyon r. j., rowney w. p., williams j. d., pepper e., bathurst t., patterson r., nuzum e. j., phillips e. v., turner g., hawthorn road, byrne l. j., eva a. r., bunny c. l., hoy c. a., orken a., hiam s. f., rawson n. l., coleman g. h., cohen a. s., mason j., goode l. p., nelson h. g., crosbie m. r., mcsweeney t., westley g. de v., greeves c. g., festivals and celebrations, community services, social services, service clubs, ladies auxiliary, returned servicewomen’s section, blamey house, social sub-committee, sport, sporting clubs, tennis, golf, billiards, table tennis, lawn bowls, thompson peter, cricket, children’s health bureau, family welfare bureau, buley doug mr., tomlins m. i., lang a. r., kendall h. i., ford c., munro w., gordon h., rowe s., green j. h., o’brien j., ring t., anderson g. j., croft r. m., jones p. j., la cerf g., roper i., lawrence f., eustace r. c., hanley a., moore a., strachan w. d., gilbert w. f., blair m. r., scriven e. g., miller j. l., hosking b. e., cheeseman r. n., summers s., croy l. w., mclatchie s., williams stan, hattersly cliff, day alf, rawson noel, johnson alby, banham bill, kersey b., williams s., jones a., witten f., waters r., dash r., meldrum i., grant j., haggar l., nightingale n., hallett r., somers r., young g., rawson n., croft r., barton m., o’grady w., cooper p., manton j., sutcliffe a., maver a., challender d., hunt a., parrott e., leicester j., westwood a., rae alex, smith harry, forbes jimmy, johnson jack, higgins w., fink s., hall s., ross m., anderson h., fleming j., bottoms a., peek e., stark j., mathews e., gursansky l., morres r., alenson j., holland i., wallace p., craig h., lucas j., smith h., bretel l., berryman p., reid a., swann j., tully f., henderson g., fields w., johnson j., gloster p., tennat j., boyd a., butterworth k., chapman k., curran j., elkington a. b., evans w., mckenzie d. a., nicol a. b., thompson w., wanliss t. w., watson g. j., williams g., yeomans p., mcgowan h., o’connor k., atherton r., batson s. s., bull e., fletcher a., gorman s. c., hall w., jellett l., lesar h., mather r., nelson n., ratford d., rowe p., turner w. j., wehsack f., williams s. c., wilson a., carter w., forbes i., purvis l., datson r., jackson e., wolstencroft w., smith c., mitchell r., harward j., gillespie ray, hill wally, parkinson w. g., greeves colin mr., water stan mr., selleck f. p., luckins l., andrews f., young v. l., king e. j., mccutcheon j. o., grenfell d. j., hurley c., shand a. r., yeates l., hogue h., mather j., wardrop j., lyons a. m., ross a. r., bradley t., walker r. n., cox f. c., mornane j. s., fletcher a. e., mcneil j. g., rose n., lyons l. j., trevorrow g., wright d. e., walker r., maxwell j., hutchinson j. c., mclean r., caulfield historical society, ballantyne r. mr., blair max brian, toy mary-anne, ruxton bruce mr., administrative appeals tribunal, caulfield city council, white chris mr., northcote avenue, independent church of australia, marsden ian mr., mccutcheon mr -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, J. G. Brill Company, "The J.G. Brill Company", early 1920's

Green folder gold block printed cover for "The J.G. Brill Company" and associated companies containing the following bulletins. All four pages, unless noted otherwise, printed on art paper, with the company name associated companies and agencies - e.g. Noyes Bros in Australasia. Contain a photo of the truck, a photo of a vehicle using the truck or bogie, line diagram, dimensions and parts diagram and listing. Bulletins 229, 246, 247 and 249 are for window (sash) components seats. Give diagrams and photos of this equipment. 1. No. 220 - The Brill 21E truck 2. No. 221 - Brill No. 50E truck 3. No. 224 - The Brill 27MCB truck 4. No. 225 - The Brill 76E truck 5. No. 227 - The Brill 39E truck 6. No. 228 - The Brill 77E truck 7. No. 229 - The Brill Renitent Post 8. No. 234 - The Brill 78M truck for light weight cars 9. No. 236 - Parts of Brill Short Base Pivotal Truck No. 27G 10. No. 237 - Parts of Brill Short Base Pivotal Truck No. 27F 11. No. 238 - Parts of Brill High Speed Truck No. 27E 12. No. 240 - Two Important Brill full elliptic Spring Trucks - 51E and 68E types. 13. No. 242 - The Brill 79E truck for Birney Safety Cars 14. No. 246 - Brill Reversible seats - Winner and Waylo types - 8 pages 15. No. 247 - Brill Non-reversible seats. 16. No. 249 - The Motorman's seats for Birney Safety cars. (different style of layout). All contained with a 'Shipman's "Common-Sense" Binder', comprising a green cloth covered cardboard, continuous cover, printed end papers, binder clips for inserting documents. Style No. 62848. Gold block front with name of company and Brill logo and on spine of document "Brill Publications" in gold. Has a ESCo date stamp of 3 May 1921 on front page of Bulletin No. 220.On front cover of first Bulletin, date stamp of ESCo, Ballarat "3 May 1921" in purple ink.trams, tramways, 21e trucks, j c brill co, bogies, interurban, birney, brill trucks -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sharpening Steel

A honing steel, sometimes referred to as a sharpening steel, whet steel, sharpening stick, sharpening rod, butcher's steel, and chef's steel, is a rod of steel, ceramic or diamond-coated steel used to restore keenness to dulled blade edges. They are flat, oval, or round in cross-section and up to 30 centimetres (1 ft) long. The steel and ceramic honing steels may have longitudinal ridges, whereas the diamond-coated steels are smooth but embedded with abrasive diamond particles. Non-abrasive honing rods such as smooth ceramic or ribbed steel are able to remove small amounts of metal via adhesive wear. In normal use, the rod is applied to the blade at a slightly higher angle than that of the bevel, resulting in the formation of a micro-bevel. The term "hone" is associated with light maintenance performed on a blade without the effort and precision normally associated with sharpening, so the name "hone" was borrowed. In the 1980s, ceramic abrasives became increasingly popular and proved an equal, if not superior, method for accomplishing the same daily maintenance tasks; manufacturers replaced steels with ceramic (and later, manufactured diamond abrasive) sharpening "steels" that were actually hones. Use Honing steels are used by lightly placing the near edge of the blade against the base of the steel, then sliding the blade away from yourself along the steel while moving it down – the blade moves diagonally, while the steel remains stationary. This should be done with the blade held at an angle to the steel, usually about 20°, and repeating on the opposite side at the same angle. This is repeated five to ten times per side. Steeling It is often recommended that steeling be performed immediately before or after using a knife and can be done daily. By contrast, knives are generally sharpened much less frequently. A traditional smooth honing steel is of no use if the edge is blunt, because it removes no material; instead it fixes deformations along the edge of a sharp blade, technically known as burnishing. There has long been speculation about the efficacy of steeling (re-aligning the edge) vs honing (removing minor deformation with abrasives); studies tend to favour abrasives for daily maintenance, especially in high-carbide-volume "stainless" steels (such as the popular CPM S30V steel, which tends to "tear out" when steeled rather than re-forming an edge.) Small honing steel for outdoor activities Usage trends Steels have traditionally been used in the West, especially in heavy-use scenarios (e.g. butchering, where the edge deforms due to forceful contact with bone). These scenarios also lead Western trends toward blades tempered to a lower level of hardness (and thus lower brittleness). In East Asia, notably Japan, harder knives are preferred, so there is little need for steeling intra-day, as the edge does not deform as much. Instead, the blade is honed as needed on a waterstone. While tradition has kept the practice of steeling alive in Western kitchens, the majority of honing steels sold are abrasive rather than smooth, and knives are harder and more frequently made of stainless steel, which does not respond to traditional steeling techniques as well as high-carbon/low alloy tool steels.The sharpening steel is essential to maintain the sharpness of carving and other knives.Steel knife sharpener with bone handle. Part of a carving set.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sharpening steel, carving set, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Tatting Shuttle, Aero Needles Group Ltd, Mid to late 20th century

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots.The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century.Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". Tatting looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. A shuttle is a small tool that looks like a small boat "sailing" in and out of the thread. Tatting is called "schiffchenarbeit" in German, which means "the work of a little boat". There are two popular types of shuttles. The first has closed ends and a removable bobbin where the thread is wound around - often made from metal or plastic (as is item 8535.1). The second type has a post in the center where the thread is wound (e.g. item 8535.2). The ends of this bobbin are open but snug. Because it is constructed in two pieces, it can be made from materials like bone, ivory or mother of pearl. Shuttles hold a larger amount of thread (as compared with needles) which means fewer ends to weave in. Fishermen in the past are thought to have used large shuttles to weave cord into certain knots whilst making their fishing nets. Their methods were copied by weavers, who innovated by using threads and smaller shuttles to make lace. One type of tatting shuttle produced by "Aero" from the 1930's to the late 1960's was an anodized grey coated aluminium shuttle with a sharp pick at one end. In the 1970's it was superseded by the grey plastic "Aero" which has a removeable bobbin which you can put on the end of the shuttle to make thread winding easier and an embedded crochet hook for joining picots. The "Aero" company developed in Redditch, England - a town renowned as a centre for manufacturing needles. Firms run by Henry Milward and Abel Morrall were based in Redditch and by the 18th century Redditch was manufacturing one million sewing needles per year. Abel Morrall Ltd launched the "Aero" brand in 1936 and greatly expanded the firm's product line to include tatting shuttles and knitting needles. The classic plastic "Aero" tatting shuttle was manufactured in England from the early 1970's until the 1990's. These items are significant as examples of easily accessible handiwork tools that enabled women in the 1930s -1960s to be able to decorate and personalize their household linen and clothing.Shuttle no. 8535.1 is a beige, boat shaped plastic shuttle with enclosed ends, small round central indentations on both sides and an enclosed black removeable bobbin. The shuttle has a grooved point at one end to hold a bobbin and a small metal crochet hook at the other end. Shuttle no. 8535.2 is a beige, boat shaped metal shuttle with pointed ends that are open but snug, small round central indentations and two smaller circular markings (on both sides) and two internal posts with cream thread wound around.Shuttle no. 8535.1 - "AERO" / "ENGLAND" Shuttle no. 8535.2 - "AERO' / "ENGLAND" "39c" (written in ball point pen)flagstaff hill maritime museum and village, flagstaff hill, warrnambool, shipwreck coast, great ocean road, tatting shuttle, aero company, handwork, handwork tool, craft, handcraft, needlework, tatting -

Ringwood and District Historical Society

Ringwood and District Historical SocietyNewspaper - Newspaper cutting, The story of the Ringwood Memorial Clock Tower erected 1928 incl list of Roll of Honour names, 4-Aug-28

Around 1940-42 the clockwork mechanism was wound by hand for payment of 2/6 (25 cents) per week, payable half yearly. The clock tower was removed and re-erected in 2000 at the intersection of Maroondah Highway and Wantirna Road, with a new electric winding mechanism.The story of the Ringwood Memorial Clock Tower erected 1928 at a cost of approx $1700 and unveiled 4-Aug-1928 at the intersection of Maroondah Highway and Warrandyte Road. It commemorates those who served and those who lost their lives in WW1.ROLL OF HONOUR; Addison, W.J.; Allan, A.; Bailey, A.F.; Bolton, E.; Brain, W.; Brown, A.G.; Brown, W.; Brown, C.H.; Browning, D.; Brocksop, P.; Bruce, R.T.; Butler, W.J.; Cairnduff, J.B.; Castles, D.; Chivers, S.R.; Chivers, A.; Clemson, J.K.; Cutts, C.W.G.; Cutts, N.F.L.; Cooper, J.; Dehne, P.C.; Dawes, L.F.; Dawes, F.A.; Dawes, C.A.R.; Foster, A.; Franks, C.V.W.; Ford, T.; Franklin, E.; Fitts, E.; Goodall, R.; Goodall, J.H.; Grant, T.W.; Guy, W.H.; Hannah, J.; Harris, D.B.; Hardidge, B.; Hains, C.L.; Hefferson, R.H.; Hodgetts, L.F.; Hodgetts, W.C.; Homewood, L.; Howship, M.L.; Howship, F.R.; Howship, S.P.; Hubbard, H.; Johnston, W.J.; Johnston, R.A.; Johnston, C.H.; Justice, Rev. T.H.; Kennedy, G.; Kraefft, H.G.; Lang, A.C.; Larkwing, A.H.; Lawlor, J.; Lothian, J.C.; Maggs, C.B.; Martin, E.; McCann, R.; McGillvray, M.; McKinnon, J.; Miles, Sister A.F.; Miles, T.A.; Miles, R.F.; Miles, K.L.; Miles, L.E.; Milner, T.; Miller, S.; Moss, L.S.; Moss, C.B.; Muller, G.W.; Muller, J.H.; Neal, A.G.; Nield, F.N.; Parker, A.; Parker, R.; Parker, F.V.; Parker, T.S.; Paris, C.C.; Peake, A.; Pearson, H.F.; Pollard, J.L.; Ratten, C.J.; Ratten, W.G.; Read, I.; Sanders, J.; Shanks, R.J.; Smith, S.; Smith, P.C.; Smith, C.; Stephenson, R.H.; Stowell, H.A.; Taylor, J.; Thomas, H.O.; Thomas, I.; Thompson, A.R.; Thorpe, J.G.; Tomholt, S.J.; Toogood, E.G.; Venables, W.E.; Walker, J.; Wedge, C.H.; Wedge, J.W.K.; Whitchurch, A.; Wilson, L.J.; Williams, J.A.; Williams, W.G.; Wright, S.; Wright, J.W.C.; DIED ON SERVICE; Johnston, C.H.; McCann, H.J.; Mackinlay, H.W.; Mitchell, L.; Morris, J.; Pollard, H.L.; Palmer, E.R.; Parker, J.J.; Rooney, E.; Schonfelder, A.W.; Thurrowgood, W.; Todd, J.; Thomas, R. -

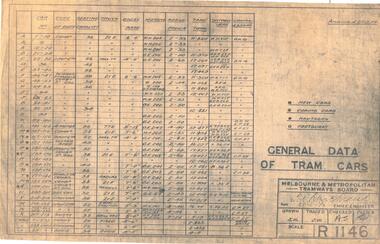

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Folder, Melbourne & Metropolitan Tramways Board (MMTB), "MMTB General Data of Tramcars", compiled to c2005

Set of 60 A3 sheets, comprising a folder of GA Drawings – from Keith Kings, held with black plastic semi elastic black clip or retaining strip. All drawings have been scanned (about 50% were already scanned, e.g. the first sheet) and placed on the Depot Tramcar Mechanical component listing. Order of drawings as received has been retained and listed as follows. R1146 – General Data of Tramcars – 24-9-1924 R11-927 – SW6 and W6 – Advertising Panel Location R11-928 – W7 Advertising Panel Location R9529 – Class W7 GA List of Tramcar GA Arrangement Drawings dated 13/12/1974 Cover sheet – “Melbourne and Metropolitan Tramways Board – Electric Tramcars Index - lists Class, numbers and Drawing Nos. R1266 – Cable Train – Dummy and 4 wheel trailer R3799 – Cable train – Dummy & 4 wheel trailer R3422 – Cable train – dummy & Bogie trailer PMTT 161 – Combination Car R3076 – Class A – Combination Car Dropped ends PMTT – 163 - Bogie car with dropped centre compartment PMTT – 700 – Bogie Car with dropped centre compartment and longitudinal rattan saloon seats R3078 – Dropped Centre bogie car – Maximum Traction R4571 – Dog Transport Car – class C converted PMTT 162 – Summer car (old type) – F class PMTT 164 – Summer car – G class R3079 – Class L R7416 – Class L PMTT 160 – Bogie Closed Car – (O class) R9787 – Class G – All night tram style R3077 – Class G – All night tram style R8999 – Class A tramcar Coburg type Original – S class R5963 - Class A tramcar Coburg type Original – S class (modified) R3093A - Class T R4382 – Class T arrangement for one-man operation Car 178 R3756A – class U R2461 – class W – W class converted to W2 R2460 – class W1 R2459 – class W2 R4646 – class SW2 R9525 – class SW2 R3071 – class W3 R3812 – class W4 R4678B – class W5 R9601 – class CW5 R5818 – class SW5 R12-052 – Class W5 – sliding door conversion R4771A – class SW6 (reversible seats) R6408A – class SW6 (Tubular Fixed Seats) R8617 – class SW6 and W6 R9529 – class W7 R10-129 – Class VR car R8332 – PCC type car R2462 – class X R1811 – types of electric cars – class X Safety car R2463 – class X1 R3080 – Class X2 R2464 – class Y R2465 – class Y1 R10-946 – All electric tram – 1041 R11-333 – class Z1 and Z2 trams R11-387 – class z outside dimensions R11-563 – Class Z tram (101-115) R11-580 - class Z3 tram R12-062 – Class A tram T4000-12 – double ended 6 axle articulated LRV – a possibly arrangement R6928 – PCC Car – double end operation R9980 – Freight car 17 – former V class passenger car See Reg Item 5639 for a similar document.trams, tramways, drawings, tramcars, cable trams, tramcar design, preston workshops, mmtb -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Diving Compressor, Siebe Gorman & Co. Ltd, 1880-1890

This compressor was part of the E.G. Ward Collection. It is connected to the diving suit and boots also in our collection. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water-pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12 bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunneling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr. E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The compressor is a very significant item as it gives a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. Siebe & Gorman the company that made the equipment was a leading inventor, developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job during the early days of marine exploration.A single cylinder divers' pump by Siebe Gorman & Co Ltd, London, eccentric hand cranked in brass mounted mahogany case with instructions to the underside of the lid, brass covered pressure gauge and air outlet, brass makers plaque to the front, water inlet and outlet to the rear, green painted lifting rings. Machinery has some blue painted areas on the metal.Plate on the back 'WATER SUPPLY" "WATER OVERFLOW" "WATER DRAIN-IN" Pressure gauge dial "BOURDON'S PRESSURE GAUGE" STEBE GORMAN & CO. LONDON", "LBS PRESSURE" "FEET OF SALT WATER" Plate on the front " PATENT, Siebe Gorman & Co Ltd Submarine Engineers" below emblem (Lion, Crown, Horse)flagstaff hill, warrnambool, flagstaff-hill, maritime-museum, diving compressor, london, siebe gorman & co ltd, marine technology, life saving, deep sea diving, maritime museum, maritime village, manine history -

Federation University Historical Collection

Federation University Historical CollectionBook, Ballarat School of Mines Council Minute Book, 1949-1956, 16/11/1949 - 04/10/1956

The Ballarat School of Mines was the first technical school in Australasia..1) Hard green covered book with part leather binding. Finance Committee, Council and one Christian Education (or chaplaincy) on sub-committee minutes Dr James Stewart, 1950, pp. 64, 138, 160 G. Baragwanath, carpenter, 1950 G.W. Barrell, 1950, p. 24 V. Belikov, 1950, p. 35 G.W. Cornell, 1950, pp. 37, 44, 78 R.M. Cutter, 1950 H. Edwards, 1950, pp. 14, 15 Arthur Gouday, 1950, p. 29 J.E. Hewitt, 1950, p. 119 D. Kellock, 1950, p. 117 H.H. Kerr, 1950, p. 74 L. Lederman, 1950, obituary, pp. 19, 28 A,W, Lynch, 1950, p. 24 D. Mullins (plumbing), 1950, pp 44, 78 A.M. Praetz, 1950, p. 95 Kevin White, 1950, p. 75 S.E. Williams, 1950 C.M. Chisholm, 1951 N.F. Dewsnap, 1951 F.A. Farr, 1951 R.P. Flower, 1951, p173 L. Garner, 1951, p128 Douglas R. Mills, 1951, p182 F.G. Proctor, 1951 A.J. Andreartha, 1952 B. Bryan, 1952 D. Cotton, 1952 D. Duggan, 1952 Hans Fumberger, 1952, p260, 287 V.C. Jones, 1952, p248 J.R. Lyall, 1952, p206 E.G. Savage, 1952, p228 Geoffrey F. Stevens, 1952 Albert Watts, 1952, p260 K.C. Webb, 1952, p248 Neon Signs, 1953, p310 William Baragwanath, 1953, p324 Ronald G. Barlyn, 1953, p314 C.M. King, 1953, p272 W. Murton, 1953, p340 F. Ritchie, 1953, p303 J. Turnbull, 1953, p274 J.R. Allsop, 1954 David Morris, 1954, p350 W.J. Paterson, 1954, p424 John Peyton, 1954, p348 William Sadler, 1954, p352 Mrs Connors, 1955 Corbould, 1955, p497, 503, 514, 521, 550 A. Causland, 1955, p507 W.W. Leggatt, 1955, p504 B.D. Ngip, 1955, p462 L.K. O'Down, 1955, p460 R. Rowlands, 1955, p508 J.A. Strange, 1955, p501 L. Wilson, 1955, p459 Harry Brew, 1956, p516 H.L. Coburn, 1956, p571 I.R. Gordon, 1956, p541 B.M. Hearn, 1956, p 550 John Miles, 1956, p571 H.A. Patterson, 1956, p553 Ballarat School of Mines Proposed Gymnasium (Corbould Recreation Hall) 364, 403, 445, 452, 458, 523, 531, 540 Ballarat School of Mines Museum, 1950, p38, 105, 112; Aboriginal Relics, P566 poliomyelitis, 1952 Ballarat School of Mines Agrostology, 1952, p242, 312, 360, 362, 370 Ballarat School of Mines Neon Sign, 1953 Ballarat School of Mines Basketball site, 1953 Hickman Street, Ballarat, Deviation near White Flat, 1954 Ballarat School of Mines Bicycle sheds, 1954 Ballarat Technical School, Norman Street, Ballarat, 1954 Ballarat North Technical School, 1956, p521 Ballarat School of Mines Christian Education, 1956, p569 Blacksmithing, 1956, p523 Ballarat School of Mines Museum Future, 1956, p526, 535, 536, 542, 561, 568 Ballarat School of Mines War Museum, 1956, p516, 542 Fossils, 1955, p462 123 grant Street purchase, 1956, p546 model Farm Smith gift, 1956, p561 Shearing, 1955, p504 Repatriation Students, 1856, p 555 .2) Typed and handwritten documents in plastic envelope at back of book on sundry topics.ballarat school of mines, ballarat school of mines council minutes, ballarat school of mines finance committee, ballarat school of mines christian education, chaplaincy, dr james stewart, g. baragwanath, g.w. barrell, v. belikov, g.w. cornell, r.m. cutter, h. edwards, arthur gouday, j.e. hewitt, d. kellock, h.h. kerr, l. lederman, d. mullins, a.m. praetz, kevin white, s.e. williams, c.m. chisholm, n.f. dewsnap, f.a. farr, r.p. flower, l. garner, douglas r. mills, f.g. proctor, a.j. andreartha, b. bryan, d. cotton, d. duggan, hans fumberger, v.c. jones, j.r. lyall, e.g. savage, geoffrey f. stevens, albert watts, k.c. webb, william baragwanath, ronald g. barylyn, c.m. king, w. murton, f. ritchie, j. turnbull, j.r. allsop, david morris, w.j. paterson, john peyton, william sadler, mrs connors, corbould, a. causland, w.w. leggatt, b.d. ngip, l.k. o'down, r. rowlands, j.a. strange, l. wilson, harry brew, h.l. coburn, i.r. gordon, b.m. hearn, john miles, h.a. patterson, ballarat school of mines gymnasium, corbould recreation hall, polio, poliomyelitis, a.j. andrewartha, pandemic, a.w. lynch, 123 grant street ballarat -

Seaworks Maritime Museum

Seaworks Maritime MuseumHonour Board, Melbourne Harbour Trust

Belonged to the Melbourne Harbour Trust Commissionersarge, wooden, rectangular "Roll of Honour" board for the Melbourne Harbour Trust Commissioners. It was their honourary board for employees who went to the 1st World War. comprised of seven panels with names of people carved into them. The centre panel has "in Memorium' in brass lettering and is raised out from the three panels which flank it on either side. The main lettering across the top of the board is made from brass, and is attached to the wood. A circular brass crest is featured in the centre top of the board, which is flanked by carved gum leaves and nuts. The date "1918" is also cast in brass and attached to the lower front right hand side of the board.1918 circa."ROLL OF HONOUR/ THE MELBOURNE HARBOR TRUST COMMISSIONERS/ MHT/ IN MEMORIAM/ R. DEWAR, W. KEARNEY, A.H. TREBLE, R. CURWEN, G.R. PALMER, J. STUBBS, A. ALLISON, T. MCCARRON, W. MCLAUGHLIN, J.D. MCMILLAN, F.S. CLISSOLD, A. STEEGE, W. JORY, C.H. WOOD, H.H. BARKER, J. HEMINGWAY, R.H. CROCKETT, T.W. PARROTT, E.G. STONE, W.H. FRAME, S.H. PARROTT, V.W. PIPER, A.R MCBRIDE/ D. FINLAYSON, S.EVERETT, G.O. LAWRENCE, A. PHILLIPS, A. CAHILL, G.C. HUGHES, G.S BELL, A.D. BROAD, C.W. MILLS, A.C. COOK, A. JONES, A. COCCIARDI, A.N. ROYCE, M. THOMAS, A.WARE, J. RISBRIDGER, A. STEPHENS, G.S. MCCOLL, W.S. TAYLOR, H.A. MILLER, P.J. BURNS, D.B. MACKIE, F. HEARN/ E. SAMBELL, J. STOTT, W. POOLEY, R. JOHNSTON, A.W. FERGUSSON, W.H. SPURR, P.R. STEVENS, D.J. STUART, T. CHAPPLE, W. REED, W.J ALLINGHAM, J. PAGE, J.J. MAIR, C.A PHIPPS, J. WILSON, A.J WILLIAMS, W.L. FOSTER, W.S PENHALLURIACK, R.N. BARBER, E. DOLAN, T. MCGRATH, P. PATERSON, J.W. GRAY/ C.J.H.BARRY, F.L. WATERS, F.E. BUXTON, A.C. NUTTING, E.J BATTEN, C.E. ELLIOTT, C.T. RUFFLE, W.H. STEVENS, J. JOHNSTON, D. BATHIE, J. MCPHERSON, T.W. GIBBON, J.W. BURN, C.H. CHEEK, P.J. EVANS, J. MUCHEMORE, G.N. SADLEIR, W.D. SMITH, C HINCHCLIFFE, A. CARD, F.A. ROBERTS, C.E. TROWBRIDGE, W. ALLAN/ V.T. NICKELS, J.G MEYERS, T.G. MCKEDDIE, W.H EVANS, S. KEWLEY, F. MUIR, F.W. TREGANOWAN, M. GRANT, T.R. HAWWORTH, N. NORRISON, J. MCDONALD, J. SHERIDAN, H.R. GOLDIE, A.A. METHVEN, H.P.H VINVENT, P. RIDDELL, R.W. BARCLAY, P. NASH, A.E. WHYTE, W. DAWSON, J.F LEISTER, J. MCNEILL, H. STAFFORD/ J. PHILLIPS, W.J. PETTETT, W. PRIEST, C. OLSON, G.D. CARRE, L.C.R GAME, I.M COWLISHAW, R.R. SMITH, P. DUSTING, T.H. JONES, W. DOWIE, G.T. BEASELY, J.G BAILEY, F. JORDAN, J. FARRELL, A. DAWE, W.H. STUBBINGS, C.W. STEFFENSON, H. BLACKEBY, H. TATE, J. BASSETT, J. MCLEAN/ IN MEMORIAM, P. FOLEY, A.C. JOHNSON, S. TURNER, C.W FORD, E.F RENNICK, T.G. HOBERG, T. WEIR, W.S HICKS, J. BARRY, H. DANIEL, W. ROADKNIGHT, L.N CLARK, R. DYSON, H.G JOHANSON/ 1914/1918 -

National Wool Museum

National Wool MuseumClothing - 1984 Los Angeles Olympics Men's Opening Ceremony Shirt, c. 1984

On the 1984 Los Angeles Olympic Uniforms donator Doug wrote- During the 1980s the Australian wool industry was at its most prosperous times with record numbers of sheep producing wool receiving ever increasing values due to the success of the Reserve Price Scheme, and the overall guidance of the Australian Wool Corporation (AWC). As a humble technician, my role was a low profile newly created position of “Controller, Technical Marketing” where wool was to be marketed on its technical properties, as distinct from the “Product Marketing Group” which exploited trhe traditional high profile approach of marketing wool;s superior fashion attributes. The Woolmark was the tool central to this approach. When the forthcoming Los Angeles Olympic Games was announced, the Product Marketing Group seized upon the chance to show the world that we could make top fashion garments and display them on our elite athletes on the world stage. A concept was launched using a contemporary top designer, Adel Weiss, with the most exclusive fabrics and knits available, and all with a lot of hype. This launch failed dismally for the following reasons- - The designer did a wonderful job presenting an excellent fashion range on perfect skinny models. The AOC however wanted a uniform which had an obvious Australian appearance when fitted to elite, and frequently muscular, athletes. - The fabrics chosen did not reflect the performance required by travelling athletes, there was no recognition of the need for ‘easy care.’ - There was no recognition given to the problem of measuring, manufacturing and distribution of a range of articles when the selected athlete could be domiciled anywhere in Australia. - There was no appreciation of such historical facts as Fletcher Jones, who had been unofficial suppliers dating back to the 1954 Olympics in Melbourne, and the Fletcher Jones board member, who was also an AWC board member, and was not in favour of the change. The project passed from Product Marketing to Public Relations, a big spending off-shoot of the AWC Chairman David Asimus, and due to the day to day operations of the project was passed to me and PR took care of the financial matters. The first task was to meet with the AOC and find out exactly their requirements. This lead to the production of a design and manufacturing brief, cointaining exact time lines for each event required to ensure an appropriate uniform on every athlete chosen to represent his/her country on the date given for the Opening Ceremony in Los Angeles. Working backwards the timeline becomes- 1. Noted the exact date of the Opening Ceremony. 2. Estimated the date for distributing completed garments to each athlete. 3. Estimated the time span available for measuring each athlete and commence making each component of the ensemble to the individual measurements of each athlete. 4. Decided the date for making the final choice of uniform design concept. 5. Decided the date for distribution of the design brief to selected designers. These five steps were spread out over a two year period. The Commonwealth Games occur midway between each Olympic Games, work on the Olympic uniform commences the week after the Commonwealth Games closing ceremony and MUST be ready by the prescribed day two years hence. The project also had to remain cognisant of trade politics existing within the span of the task, as well as the temperament of designers in general. It is no overstatement to say that in the past every designer in Australia believed they could, and should, be chosen to design the Australian Uniform. The final choice of designer almost always faced criticism from the fashion press and any designer who had been overlooked. However, with the contenders receiving an exacting brief the numbers of serious contenders greatly reduced. The Los Angeles Olympic Uniforms. A further reason for the AWC bid failure to design the LA uniform was that the AOC had already chosen Prue Acton to design it. This was based on her proven performance during previous games as she had a talent for creating good taste Australiana. Her design concepts also considered the effect when they were viewed on a single athlete as well as the impact when viewed on a 400 strong team coming on to the arena. A blazer trouser/skirt uniform in bright gold was chosen for the formal uniform. It was my task to select a pure wool faille fabric from Foster Valley weaving mill and have sufficient woven and ready within the prescribed timeline. The trouser/skirt fabric selected was a 60/40 wool polyester plain weave fabric from Macquarie Worsted. This fabric had a small effect thread of linen that was most attractive when dyed to match some eucalyptus bark Prue had brought back from central Australia. For the Opening Ceremony uniform, Prue designed a series of native fauna, a kookaburra for the men’s shirt and a pleated skirt with a rural scene of kangaroos, hills and plants. This presented an insurmountable printing challenge to the local printing industry as it had an unacceptably large repeat size and the number required (50) was also commercially unacceptable. The solution was a DIY mock up at RMIT and the employment of four student designers. The fabric selected for this garment was a light weight 19 micron, pure wool with a very high twist yarn in alternating S and Z twist, warp and weft. This fabric proved to be the solution to a very difficult problem, finding a wool product which is universally acceptable when worn next to the sin by young athletes competing in the heat of a Los Angeles summer. Modifications to this fabric were developed to exploit its success when facing the same problem in future games. Garment Making- The most exacting garment in the ensemble is the tailored blazer, plus the related trouser/skirt. Unfortunately tailoring athletes that come in various shapes and sizes such as; - Weight lifters develop an enormous chest, arms and neck size. A shirt made to a neck size of 52 would produce a shirt with cuffs extending well beyond the wearer’s hands. - Basketball players are up to 7 feet tall and garments relying ona chest measurement grading would produce a shirt with cuffs extending only to elbow length. - Swimmers develop enormous shoulders and slim hips, cyclists by contrast develop thighs I liken to tree trunks and a uniform featuring tight trousers must be avoided at all cost. Suffice to say many ensembles require specialist ‘one off’ treatment for many athletes. Meanwhile there is a comfortable in between group who can accept regular sizes so you can cater for these by having back up stock with plenty of built in contingencies. Athletes may be domiciled anywhere in Australia, this creates a fundamental problem of taking their measurements. The Fletcher Jones organisation was key to answering this problem due to their presence in every capital city, as well as many provincial towns around Australia. Each athlete on being selected for the Olympic Team was simultaneously requested to visit their nearest Fletcher Jones shop. The standardised measurement data collected was shared with the other manufacturers, e.g. Pelaco Shirts, Holeproof Socks and Knitwear, Maddison Belts, and even Hush Puppy Shoes. As the time for the Games approached the AOC made arrangements for combining meeting of all. Selected available athletes at the Australian Institute of Sport, Canberra, where, among other things, they were fitted and supplied with their uniform. The method evolved as follows.Men’s cream coloured button up, collared shirt. Images of a kookaburra have been printed onto the shirt, a single kookaburra on the left breast and a pair of kookaburras on the reverse of the shirt. The kookaburras are printed in a brown tone to complement the cream colour of the fabric.On tag - FMaustralian wool corporation, 1984 los angeles olympics, olympic uniforms, men's uniforms, sport, athletes -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone in two pieces. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070. Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone vertebrae. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined