Showing 454 items

matching valves

-

Federation University Historical Collection

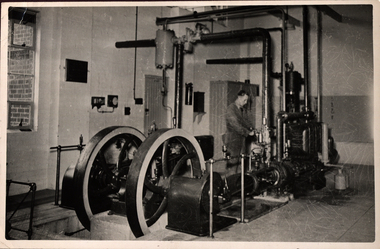

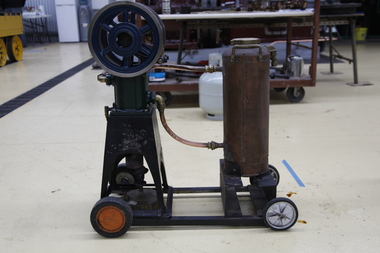

Federation University Historical CollectionPhotograph - Photograph - Black and white, Ballarat School of Mines Model Steam Engine

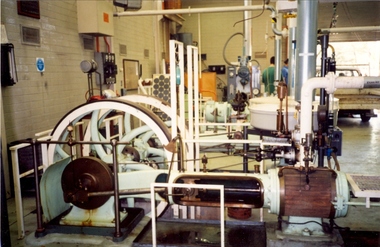

The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.Black and white photograph of the Davey Paxman Experimental Steam Engine installed at the Ballarat School of MInes. steam engine, model steam engine, davey paxman, thomas bath, experimental steam engine -

Federation University Historical Collection

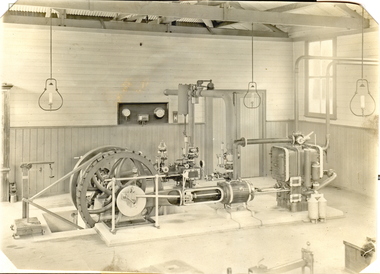

Federation University Historical CollectionPhotograph, Ballarat School of Mines Davey Paxman Experimental Steam Engine, c1902

The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only. Black and white photograph of an experimental steam engine which was produced for the Ballarat School of Mines. It was designed for experimental purposes, such as testing of efficiency, etc. The laboratory which housed the steam engine was lit with gas lighting. davey paxman experimental steam engine, model steam engine, davey paxman, steam, thomas bath, thermodynamics -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, Westinghouse Brake & Saxby Signal Co. Ltd, "Compressed Air Brakes for Tramways", May. 1929

Forty One page book with dark red cover titled "Compressed Air Brakes for Tramways", published by Westinghouse Brake and Saxby Signal Co. May 1929. Cover - cloth texture laminated paper cover, dark red on outside, with embossed title and publishing details and Westinghouse logo embossed on rear cover. Forty printed pages sewn at three points into cover with page 41, tipped onto right hand edge of page 40, with a blind perforated strip to enable the sheet to be used as an Enquiry form to obtain a price regarding tram brake equipment. Covers compressed air brake systems in general for tramways, including layout drawings, straight air brake, braking ratio, brake cylinder sizing, reservoirs, air compressor type E13, DH16, E13, Governors ES16, Brake Valve No. 13, 9, brake cylinder, sand ejectors, reservoirs drain cocks, with an appendix describing the automatic brake system for use with trailers. Manual No. DP12."Colin Rutledge" stamped on top of page 1.trams, tramways, westinghouse, tramcar brakes, compressors, governors, equipment -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron Hand Kerosene, mid to late 1900s

The 1950's saw a revolution in small appliances for use in the average household. This hand held self heating(kerosene) iron was introduced as a time saving and more convenient iron for pressing clothes and other cloth fabrics. It replaced irons needing a separate fire source to heat the ironing plate. These irons continued to be in service, even when electricity was available in cities and larger rural towns (domestic electric steam irons were invented in 1938). This item was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation.In the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing remained for an extended period covering the 1960s to 1970s. Kerosene products, such as this kerosene iron was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival and the ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This Coleman kerosene iron has a solid steel chrome plated(press) base with a painted (blue) wooden handle. The handle is stud fastened onto an oblong shaped rolled steel handle frame and screwed (two screws) onto the base plate. Both the heating plate and the top securing plate are shaped similar to a river boat. The main housing enclosing the heating element is enamel coated(blue in colour) steel and has a half hole for lighting the kerosene at the rear end. Behind the handle and protruding upwards is a stainless steel fully enclosed container (bowl shaped) for the main supply of kerosene to the burner or generator(enclosed within the main body of the iron. The bowl has an air valve and inlet for pressurised air intake (hand pump) On the bottom rear of the fuel bowl there is a screw regulated fuel pump. The fuel heated base plate provides the heat for this advertised "self heating iron(instant lighting). See KVHS 0347B- Instruction sheet; KVHS 0347C- Wrench; and KVHS 0347D Fuel can.Stamped on the base plate of the handle, front region "COLEMAN LAMP & STOVE CO." below this "WICHITA KAN" below this"TORONTO CAN". In the middle of the handle base and in larger print "COLEMAN Instant-Lite" At the rear location in large print "MODEL 4" in smaller print below "MADE IN U.S.A." below this "PAT#1718473"household appliances, alternative non electrical ironing appliances, domestic appliances, kerosene appliances -

Melbourne Tram Museum

Melbourne Tram MuseumBook, Melbourne & Metropolitan Tramways Board (MMTB), Electric System /Instructions to Drivers in Electric Car Operation", 1948

Book - 52 pages, side stapled book within grey Rexene covers. Titled "Melbourne and Metropolitan Tramways Board /Electric System /Instructions to Drivers in Electric Car Operation" Dated 1948. Printed by Regent Press Pty Ltd, 457 Plenty Road, Preston. Provides in a Q & A format, instructions to drivers in electric car operation, sketches of various types of controllers, braking system description, emergency braking, safety cars, manual lap valves, the air system, an addendum page 26A dated 22/10/1952 about emergency braking for four motor cars, hand braking, lighting system and general duties, and what to do if the tram breaks down. On pages 44 to 48 - a long list of don'ts, notes regarding the traffic code and reference index for defects. Pages 1 and 2 have been removed along a perforated line - would have been an acknowledgement sheet. Book has No. 4727 on top of page 3. See Reg Item 6115 for another copy.Has pencil notes on inside cover and pages for controllers on inside of rear page. Some questions have been highlighted by a red pencil.trams, tramways, mmtb, drivers, training, instructions, motormen -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured objects, Cigarette lighter metal, 20thC

A cigarette lighter is a portable device used to generate a flame. It consists of a metal or plastic container filled with a flammable fluid or pressurized liquid gas, a means of ignition, and some provision for extinguishing the flame. A spark is created by striking metal against a flint, or by pressing a button that compresses a piezoelectric crystal (piezo ignition), generating an electric arc. In naphtha lighters, the liquid is sufficiently volatile, and flammable vapour is present as soon as the top of the lighter is opened. Butane lighters combine the striking action with the opening of the valve to release gas. The spark ignites the flammable gas causing a flame to come out of the lighter which continues until the top is closed (naphtha type), The Beney Company was founded by Robert Ernest Beney of London, England. R. E. Beney invented and marketed the first Beney mechanical lighter in 1919. Beney also designed and manufactured numerous luxury lighters and striker boxes for Alfred Dunhill of London as well as Hermes of Paris. In 1938, Beckenham based Beney Lighters was acquired, adding utility lighters and precision tools to the company's (Winn & Coates) ever growing list of products. The biggest selling line manufactured by Beney was the Economic Gas Lighter which hung on the side of housewife's gas cookers and was also used for lighting Bunsen burners in laboratories. In 1939-1940 the company moved its administration to the Beney Lighter premises in Beckenham after the Head Office at Trinity Square along with many company records were destroyed in a 'doodlebug' flying bomb attack. Beney Ltd. continued producing lighters at least through the late 1954. A green metal cigarette lighter that used fuel and a striking action arm to produce a flame .base: BENEY / COMPANION / PATENT 568897 / BRITISH MADEtobacco, cigarettes, cigarette lighters, fuels, moorabbin, cheltenham, bentleigh, early settlers, beney pty ltd, beckenham england -

Puffing Billy Railway

Puffing Billy RailwayHeinrici Hot Air Motor, 1900s

Louis Heinrici, Germany, circa 1900 a small Stirling type hot air engine in which a body of air is worked constantly, being alternately heated and cooled during each revolution of the crankshaft. Heinrici hot air engines are of the valveless, closed cycle type, generally called Stirling cycle engines, after Robert Stirling, the Scottish Presbyterian minister who pioneered their development in the early 1800's. They operate by alternately heating and cooling a quantity of air, called the working fluid, contained in the engine's internal spaces. Heat is applied externally and passes through the cylinder wall, heating the working fluid, which is then expanded against a piston to do mechanical work. After heating and expanding, the working fluid is moved to a cool space where it cools and contracts before being returned to the hot space for the cycle to repeat. It has a displacer (just a loose piston), below and in the same cylinder as the power piston to which it is connected via cranks and linkages so as to lead by 90degrees of crankshaft angle. The displacer space and the piston space are connected by the annular gap around the loose fitting displacer so that the working fluid moves between these spaces and changes volume by the appropriate ratio as the engine rotates. Because they have no valves and experience no sudden pressure changes, Stirling engines are noted for quietness and reliability. Heinricis use air at atmospheric pressure for their working fluid, but for higher specific output (power for size) and better efficiency, modern Stirling cycle engines use pressurised gas- air, nitrogen, helium or hydrogen.Historic - Hot Air Engine - MotorHot Air Motor made of Steel with two drive wheels. a small Stirling type hot air engine in which a body of air is worked constantly, being alternately heated and cooled during each revolution of the crankshaft. Heinrici Motorheinrici hot air motor, puffing billy -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Foghorn, 20th century

A marine foghorn gives an audible navigational signal to warn vessels of dangers, hazards and the presence of other vessels in fog conditions. The foghorn signal is a series of long and short sounds with short or long pauses between them. These common signals conform to a code called the International Regulations for Preventing Collisions at Sea and provide such information as whether the vessel is under sail or motor, large or small, aground or at anchor. The designs of foghorns vary but they all use a column of air to make a loud sound. Some use vibrating plates or metal reeds, others force air through holes in a revolving cylinder or disc, sounding like a siren, and some use a clockwork mechanism to open the valves that let the air into the horn. They are usually built to meet particular specifications e.g. U.S.C.G. (US Coast Guard). This Tyfon plunger foghorn has a horizontal handle attached to a vertical rod that moves up and down inside a cylinder. When the handle is plunged down, in a similar way to a bicycle pump, the air is forced out of the bottom of the cylinder into a pipe with a bell-shaped horn on the end, making a loud, low sound. The wider base of the cylinder helps to keep it stable. The original type Tyfon foghorns were manufactured in about 1910 by Kochums Mechanical Workshop (Kockums Mechanical Werkstad, Ltd.), Malmo, Sweden. The company was established in 1840, became a Limited company in 1866, and established a shipyard at the Port of Malmo, Sweden, in 1870. The civilian ship production in Malmo ceased in 1987. As well as building ships the company built large industrial and agricultural machinery and maritime goods.this replica foghorn represents the design of a Swedish, Tyfon model 1910. It is an example of the type of safety equipment used on marine vessels to signal other vessels and signal to land. Replica foghorn; portable marine, plunger operation. It has a brass cylinder and adjustable brass horn. The plunger handle and base are wooden. Inscriptions are on the plaque on the horn and moulded into the air intake. Facsimile of a Kockums of Malmo, Sweden, Tyfon model 1910 Fog Horn.Impressed into the attached plaque "KOCKUMS MLK. VERKSTAD / MALMO SWEDEN" and "TRADE TYFON MARK" Also added to the plaque individually "288938" Molded around the circumference of the air intake "TYFON PATENT"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, foghorn, fog horn, tyfon foghorn, kockums mlk verkstad, malmo sweden, replica, warning signal, safety equipment, ship's equipment -

Federation University Historical Collection

Federation University Historical CollectionTool - Object, E. Thomas & Williams Limited, Cambrian Lampworks, Kop Staszic Carbide Lamp

Carbide lamps, or acetylene gas lamps, are simple lamps that produce and burn acetylene (C2H2) which is created by the reaction of calcium carbide (CaC2) with water. Acetylene gas lamps were used to illuminate buildings, as lighthouse beacons, and as headlights on motor-cars and bicycles. Portable acetylene gas lamps, worn on the hat or carried by hand, were widely used in mining in the early twentieth century. A mining or caving lamp has calcium carbide placed in a lower chamber, the generator. The upper reservoir is then filled with water. A threaded valve or other mechanism is used to control the rate at which the water is allowed to drip into the chamber containing the calcium carbide. By controlling the rate of water flow, the production of acetylene gas is controlled. This, in turn, controls the flow rate of the gas and the size of the flame at the burner, and thus the amount of light it produces. Staszic is a coal mine located in Katowice , in the district Giszowiec, Poland This type of lamp generally has a reflector behind the flame to help project the light forward. An acetylene gas powered lamp produces a bright, broad light. Many cavers prefer this type of unfocused light as it improves peripheral vision in the complete dark. The reaction of carbide with water produces a fair amount of heat independent of the flame. In cold caves, carbide lamp users can use this heat to help stave off hypothermia. When all of the carbide in a lamp has been reacted, the carbide chamber contains a wet paste of slaked lime (calcium hydroxide). This is emptied into a waste bag and the chamber can be refilled. (http://en.wikipedia.org/wiki/Carbide_lamp, accessed 06/05/2015)Metal Carbide Mining lamp with light reflector and hook.miners lamp, mining lamp, statszic, poland, carbide, mining -

Ballarat Tramway Museum

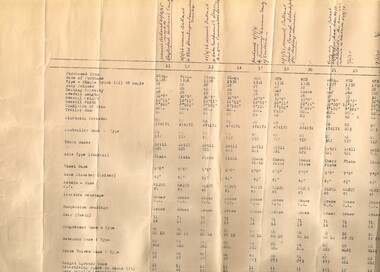

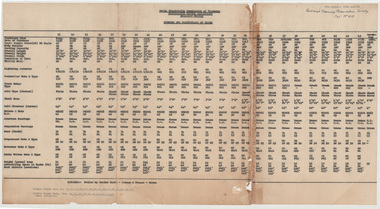

Ballarat Tramway MuseumDocument - List, State Electricity Commission of Victoria (SECV), Details of Ballarat Trams - marked up

Demonstrates the source of the tramcars for both Ballarat. Gives details on equipment, sizes and seating capacity of the tramcars as at August 1964 with hand written notes about the acquisition and disposal of some of the tramcars.Printed List of trams and their details for Ballarat Trams ( similar to item 3430.1), dated 5-September-1966, titled "Numbers and Particulars of Trams". Handwritten notes have been made for the acquisition dates for the tramcar and disposal details of the vehicle along the top edge. 3430 - Ballarat - typed carbon copy - two sheets, were taped together. Gives details of where purchased from , date of purchase, type, body builder, seating capacity, overall length, overall height, overall width, condition of tram, trolley base, Lightning arrester, controller make and type, Truck Maker and type, type of truck, axle type, wheel base, axle diameter, motors type and maker, Motor horsepower, Armature bearings, suspension bearings, gear teeth, Air compressor make and type, Brake Valves make and type, Governor make and type, Weight in tons and details of advertising space in racks. At base has typed (original) list of trams of the two types, single truckers and bogie trams. List of trams includes the scrubber and No. 20 which was scrapped prior to system closure. Handwritten notes have been made for the Acquisition dates for the tramcar and disposal details of the vehicle along the top edge.tramcars, ballarat, sec, disposal, sale of trams, acquisitions -

Churchill Island Heritage Farm

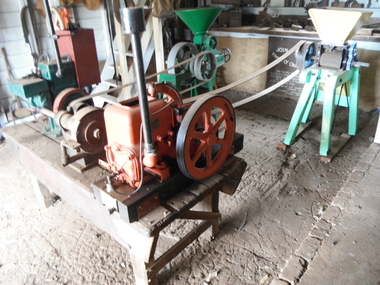

Churchill Island Heritage FarmFunctional object - Stationary engine, red, 1925

“Sundial 2hp engine, open crank, 600rpm, serial number 6420.” These small 4 stroke engines were widely used on Australian farms through the 20th century to power chaffcutters, grinders, saws, lighting plants, pumps, shearing plants, milking machines and cream separators easing much of the drudgery of farm work. They were also used in garages and workshops and by bush fire brigades. The engine was made by H.V.McKay Massey Harris. At one time Hugh Victor McKay’s Sunshine Harvester Works was the largest factory in Australia but in 1930, to ensure survival during the Great Depression, elected to merge with the Australian arm of a Canadian firm, Massey Harris. The Sundial is fitted with twin flywheels, making it a compact and convenient power source as either wheel could double as a drive wheel. Its connecting rod, crankshaft and flywheel spokes are covered, a safety measure that was not standard at the time. These engines were advertised as simple, dependable, low in price and cheap to run. They had the additional advantage that a bolt-on kit was made by the manufacturer to convert them to run on kerosene. ‘The engine's output is two horsepower (1.5 kW) at 600 rpm. The compression ratio is 5:1 and the spark plug is activated by a high tension magneto. The fuel tank holds 3.3 litres and the cooling water hopper holds 6.6 litres. Cylinder bore is 101 mm and piston stroke is 115 mm.’ In a catalogue of HV McKay Massey Harris agricultural machinery published in March 1942, the engine is described as follows: 'The cylinder head is of the hot, turbulent type, giving the finest fuel atomisation and heat distribution. The carburettor, of special design, has an automatic air valve controlling the amount of air. The supersensitive, high speed, flyball-type governor provides an ample range of speed.'Typical of units used on local farms. RepresentativeSundial 2 h.p. engine, open crank 600 rpm Seral number 6420, red. Attached to yellow grain grinderSunshine McKay, 1939 Serial no. 6420farm machinery, stationary, machine operated, belt driven -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - List, State Electricity Commission of Victoria (SECV), "Numbers and Particulars of Trams" - Ballarat, 5/08/1964

Yields information about the dimensions and equiipment on Ballarat Tramcars operated by the SEC.Typed List of tramcars and their details for Ballarat dated 5-August-1964, titled "Numbers and Particulars of Trams". Prepared by Les Denmead, typed by PB. Ballarat - typed carbon copy - two sheets, are taped together. Gives details of where purchased from , date of purchase, type, body builder, seating capacity, overall length, overall height, overall width, condition of tram, trolley base, Lightning arrester, controller make and type, Truck Maker and type, type of truck, axle type, wheel base, axle diameter, motors type and maker, Motor horsepower, Armature bearings, suspension bearings, gear teeth, Air compressor make and type, Brake Valves make and type, Governor make and type, Weight in tons and details of advertising space in racks. At base has typed (original) list of trams of the two types, single truckers and bogie trams. List of trams includes the scrubber and No. 20 which was scrapped prior to system closure. See also 8721 and 8722 for other versions - different dates and 8690 for a Bendigo list. Note: Framed copies of both Ballarat and Bendigo are held in the depot. Some changes have been made to the tramcars since the preparation of this sheet and there are some errors and differences. See also Reg Item 6879 for an annotated version.In black ink, top right hand corner - "Ballarat Tramway Preservation Society Cat No. 613"tramcars, ballarat, equipment, lists, data -

Federation University Historical Collection

Federation University Historical CollectionArticle - Article - Women, Ballarat School of Mines: Women of Note; Jeanette Perkins, First Female Geology Student, (1927 - )

Jeanette Perkins was born in 1927 at Ballarat. She attended Alfredton State School and Pleasant Street State School before completing her secondary schooling at Ballarat High School (BHS). During her later years at BHS Perkins decided that she wanted to become a geologist, but was ineligible for university when she failed Leaving Certificate maths. She attended an interview with the principal (Heseltine) at the Ballarat School of Mines (SMB) and announced that she wanted to be a geologist. Heseltine was, according to Perkins, aghast: he informed her that there had never been a female geologist at SMB and they didn't want one. But Perkins persisted. Only then did Heseltine reluctantly enrol her in the School's Applied Chemistry Course which offered the most geological subjects, moreover, it was the only one he considered available to a 'mere' female. After graduating Perkins was employed as a metallurgical chemist with M.B. Johns Valves, Ballarat. In 1949 she married Alfred Watson. In 1951 Jeanette and Alf Watson moved to Melbourne where she commenced work as a metallurgical chemist at the Maribyrnong Ordnance Factory while studying geology part time: Alf returned to study at the University of Melbourne. Once again, Watson set a precedent by becoming the first female student to study geology part-time at the Melbourne Technical College. Increasing demands brought about by her growing family, she turned to part-time lecturing second and third year stratigraphy and palaeontology at RMIT. In 1957 the Watsons moved to the Mary Kathleen Uranium Mine in NW Queensland where he was appointed electrical design engineer. After their return to Melbourne in 1960, Jeanette taught herself to SCUBA dive and quickly developed a passion for the sport and the marine environment. She taught senior science to secondary students for 10 years whilst working towards a Masters degree. In 1991 Jeanette Watson was awarded a Doctorate from Deakin University.women of note, ballarat school of mines, alfredton state school, pleasant street state school, ballarat high school, leaving certificate maths, interview with principal, heseltine, geologist, applied chemistry course, no female geologists, metallurgical chemist, married 1949, melbourne, ordinance factory, part time study, melbourne technical college, rmit, part time lecturer, scuba diving, science teacher for ten years, masters degree, doctorate, deakin university -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Foghorn, Late 19th century

A foghorn is a device that uses sound to warn of navigational hazards like rocky coastlines, or boats of the presence of other vessels, in foggy conditions. The term is most often used with marine transport. When visual navigation aids such as lighthouses are obscured, foghorns provide an audible warning of rocky outcrops, shoals, headlands, or other dangers to shipping. An early form of fog signal was to use a bell, gong, explosive signal or firing a cannon to alert shipping. From the early 20th century an improved device called the diaphone was used in place of these other devices, The diaphone horn was based directly on the organ stop of the same name invented by Robert Hope-Jones, creator of the Wurlitzer organ. Hope-Jones' design was based on a piston that was closed only at its bottom end and had slots, perpendicular to its axis, cut through its sides, the slotted piston moved within a similarly slotted cylinder. Outside of the cylinder was a reservoir of high-pressure air. Initially, this air would be admitted behind the piston, pushing it forward. When the slots of the piston aligned with those of the cylinder, air passed into the piston, making a sound and pushing the piston back to its starting position, whence the cycle would be repeated. This method of producing a low audible sound was further developed as a fog signal by John Northey of Toronto and these diaphones were powered by compressed air produced by an electric motor or other mechanical means that admitted extremely powerful low-frequency notes. The example in the Flagstaff collection is an early cased and portable diaphone used on pleasure or sailing craft. By manually turning the crank handle air is produced and fed into valves that direct air across vibrating metal reeds to produce the required sound. in foggy weather, fog horns are used to pinpoint a vessels position and to indicate how the vessel is sailing in foggy conditions. One blast, when sailing on starboard tack and two blasts, when sailing on a port tack and three dots, when with wind is behind the vessel. Since the automation of lighthouses became common in the 1960s and 1970s, most older foghorn marine installations have been removed to avoid the need to run the complex machinery associated with them, and have been replaced with an electrically powered diaphragm or compressed air horns. The example in the collection is significant as it was used in the early 19th century for sailing vessels was important but these portable crank fog horns have also been superseded by modern electric varieties. Therefore the item has a historical connection with sailing and maritime pursuits from our past.English Rotary Norwegian Pattern nautical foghorn within a boxed pine varnished case with exposed corner dovetailing, original leather carrying strap, brass side crank, and original copper trumped horn. Card accessory with Directions for Use in both English and French.Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, foghorn, maritime technology, maritime communication, marine warning signal, portable foghorn, bellows foghorn, crank handle, robert hope-jones, john northey -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Colour photograph, Davey Paxman Experimental Steam Engine in the Mount Helen Workshop, c1994

The Davey Paxman Experimental Steam Engine was purchased by the Ballarat School of Mines as the result of a bequest from Thomas Bath.The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.davey paxman experimental steam engine, model steam engine, steam, thermodynamics laboratory, thomas bath, bequest -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryEquipment - Resuscitator Unit, c. 1960

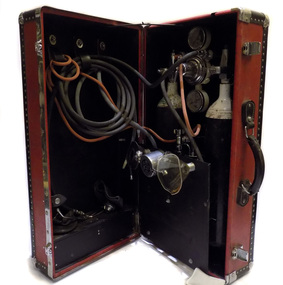

Mechanical resuscitation devices, such as the Pulmotor and Lungmotor, were popular in the early part of the twentieth century. Their use waned in the 1920s as significant bodies like the British Medical Research Council and American Red Cross refused to endorse them. The most popular of the resuscitators to emerge in the 1930s was the E&J (Ericson and Johnson) resuscitator. The device was soon widely available, vigorously promoted with support from many medical practitioners. They were soon to be found in hospitals, emergency services like the ambulance and fire brigade, and voluntary life-saving organisations. In Australia, Norman James, director of anaesthesia at the Royal Melbourne Hospital, developed an interest in equipment for ambulances and the resuscitation of drowning victims. Little in the way of practical, portable equipment was available to either the ambulances or the voluntary life-saving organisations, such as Surf Life Saving Australia (SLSA); American resuscitators, like the E&J, were expensive and bulky to import. James designed a simple portable resuscitation device for local use after being approached by Jack Conabere, secretary of the Elwood Life Saving Club (ELSC). The resulting Royal Melbourne Hospital resuscitator, or the R.M. resuscitator as it was marketed, was a simpler, manual version of those available overseas. It was gas driven with a plunger, marked “Press”, and a safety valve. The small working unit attached directly to the facemask. Once the patient was positioned facedown and the airway cleared of debris, the mask was placed firmly over the face. The plunger allowed gas to flow and lung inflation; releasing the plunger allowed expiration. This simple resuscitator was marketed by Commonwealth Industrial Gases (CIG) and became very popular in Australia with volunteer and professional rescue organisations. It represents one of the many innovations in resuscitation equipment that resulted from cooperation between volunteer life savers and medical practitioners. Norman James worked closely with Jack Conabere and the Government Pathologist to develop the equipment. ELSC was the first life saving club to use the resuscitator on the beach. While conducting an early training exercise on 23 December 1951, they used it to successfully resuscitate a man who had drowned after capsizing his home made yacht. The R.M. resuscitator was also used in more inventive ways. At Fairfield Hospital in Melbourne, a group of physiotherapists and doctors did some innovative work with polio patients, teaching them glossopharyngeal (or “frog”) breathing, as a means of becoming less dependent on ventilators. In 1981, the Australian Standards Association stated that the RM head failed to meet its revised standards and it was withdrawn from the market. Red leather suitcase with black leather trim with metal studs. There are clip locks for locking the suitcase in the closed position. The suitcase contains equipment for oxygen resuscitation. There is a space allocated for two oxygen cylinders, however there are no cylinders present.Embossed into metal plaque: The C.I.G. / Oxy-viva / PORTABLE UNIVERSAL OXYGEN RESUSCITATORresuscitation, portable, surf life saving australia, royal melbourne hospital, rm resuscitator -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Falkiner Electric Road Train in front of George Leighton's Wodonga Store and Bakery Wodonga 1914

This image of the Ralph Falkiner’s Mueller Petrol-Electric Road Train was taken in Wodonga in February 1914. Imported from Germany by Mr Ralph S Falkiner in late 1913, the train’s inventor, Major W A Mueller with two assistants, came to Melbourne to assemble then commission the train. The train cost Mr Falkiner about £13,000 plus £4,591 import duties. The Falkiner family were sheep breeders in the Western Riverina and he hoped to use the road train primarily to convey wool to the railways for despatch to Sydney. The train was 216 feet long, weighed 43.5 tons with a top speed loaded of 6-8m/h and petrol consumption up to two gallons per mile. Its first Australian journey was to haul 50 tons of cargo to Edmondson & Co at Wagga Wagga, 277 miles away. The journey from Melbourne was plagued with problems including broken cylinders and crank shaft and overheating as it was not designed for Australian climatic conditions. Three months after leaving Melbourne it arrived in Wodonga. A series of problems between Springhurst and Wodonga, including broken cylinders and valves caused an eight day delay. Some of the cargo was off-loaded in Albury, then after repairs the train continued on to Wagga where it arrived in May 1914. After unloading there, the road train was taken to Mr Falkiner's Groongal Station, near Hay and subsequently made several long trips into drought-stricken areas or the Western Riverina. Eventually the dream collapsed when the engines gave out after the train bogged in the sticky black soil of the Hay plain with 251 bales of wool on board. The train was finally railed back to Melbourne and stored but destroyed when the warehouse burnt down. In this photo, the road train is drawn up outside the Wodonga Stores and Bakery owned and operated by George Leighton. Mr Leighton began his business opposite the Terminus Hotel in Sydney Street, Wodonga in 1885. His business included a general store, stocking groceries, ironmongery, drapery, crockeryware, boots and shoes as well as a bakery. He was very actively involved in the community and served on the Wodonga Council for 18 years including three terms as Wodonga Shire President in 1901 – 02, 1910-11 and 1913-14. He was also Chairman of the Wodonga Waterworks Trust for several terms. Mr. Leighton also took a prominent part in the movement to establish a Public Library in Wodonga. His other involvements including being a Founder of the Wodonga Lodge of Freemasons, Honorary Treasurer of the Wodonga Bulldogs Football Club and Secretary of the Wodonga Racing Club. Mr Leighton passed away in Wodonga in 1916.This image is significant because it records a rare event in Wodonga and an experiment in Australian road transport.Black and white images of the Falkiner Road Train in Wodonga and on its first journey from Melbourne to Wagga, NSW It is taken in front of the Wodonga Stores and Bakery operated by George Leighton in Sydney Street, Wodonga.falkiner electric train, early road transport, high street wodonga, george leighton -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pump, circa 1930's - 1940's

This pump is an Ajax Type L2 Series A model, made and sold by McPherson’s Pty Ltd of Melbourne circa 1930’s to 1940’s, is a mechanical, hand operated, constant flow pressure pump. It would have been used to pump fluids from one area to another, for example from a dam to a tank or used as a bilge pump on a small vessel, mounted on the vessel’s bulkhead, floor or deck. This type of hand pump is sometimes called a ‘Reciprocating Suction Pump’. It has a mechanical pumping action of the lever moves the piston inside the pump up and down. The water is lifted from below the pump through the inlet pipe and into the pump’s cylinder. This action causes the lower valve to close and the piston’s valve opens and the pressure within the pump forces the water out of the pump through the exit pipe. The limitation of this type of pump is that it can only raise the water a maximum of about 7 metres from beneath the ground and yields 24-26 Litres per minute. This type of pump could be used for many purposes such as pumping water or fuel. McPherson’s 1940’s advertisement proclaims “For all jobs on the land – irrigation, spraying, tank, plumbing, fire-fighting – there’s a suitable “Ajax” pump. Send us the details of you pumping problem. Our Expert’s advice will help you choose the right pump – the one that will give you most years of PROFITABLE PUMPING.” (The Australasian (Melbourne) Sat. 26th October 1940.) McPherson’s Pty Ltd, the manufacturer, advertised a similar pump to this one in The Australasian (Melbourne) in 1936, calling it the Ajax Double Acting Hand Pump. In 1942 another advertisement advised that a representative for a fire-fighting equipment supplier was visiting the western district of Victoria. The company could now supply double-action two-spray Ajax pumps at lower prices than similar pumps the district had recently purchased from Adelaide. McPHERSON’S FOUNDER and COMPANY TIMELINE 1860 – Thomas McPherson, a Scottish immigrant (c. 1853 ), founded McPherson’s in Melbourne, supplying pig iron (lead ingots imported as ballast in ships) to local manufacturers. 1882 – Thomas McPherson established a warehouse in Collins St Melbourne and included tools, steam fittings and machinery in his wares. The business expanded to include steam saw mills and became known as Thomas McPherson and Sons (William Murray and Edward). 1888 – Thomas passed away and his sons inherited the business. In 1896 William Murray became the sole proprietor after his brother Edward’s death. 1900 – The firm expanded, establishing Acme Bolt Company to manufacture nuts and bolts. 1912 – McPhersons Pty Ltd established a machinery warehouse and showroom in 554-556 Collins St Melbourne. McPherson’s went on to establish branches in Sydney (1911), Adelaide (1921) and Perth (1930) 1917 - McPherson’s supplied ‘dog spikes’ for the transcontinental railway, running from Eastern to Western Australia. 1918 – A tool works set up in Kensington, Melbourne, manufacturing Macson lathes and made machine tools that previously had to be imported. 1924 – The Bolt Works was transferred to a new building in Melbourne. McPhersons began making pumps. 1929 – McPherson retired. His son (Sir) William Edward McPherson (known as ‘WE’), was born in Hawthorne, Melbourne, in 1898. After his education he began work in his father’s Melbourne hardware and machinery business He took over as governing director when his father retired. 1929-1932 – McPherson’s supplied thousands of tons of rivets from its Richmond (Melbourne) Bolt Works for the construction of the Sydney Harbour Bridge. 1936 – McPherson’s Pty Ltd is advertising Ajax Pumps in newspapers 1934 – McPhersons purchased the property adjoining the warehouse in Collins Street, and during 1935-1936 built a new office and showrooms on the site of 546-445 Collins St. 1939 - McPherson’s acquired the Tool Equipment Co. Pty. Ltd and Associated Machine Tools Australia Pty Ltd was formed to separate McPherson’s machine-tool manufacturing and merchandising interests. 1939 – Ajax Pump Works, a foundry and pump manufacturing plant, was established in Tottenham, Melbourne, and the Ajax Bolt and Rivet Co Pty Ltd began manufacturing in New Zealand. 1944 - McPherson’s became a public company, McPherson’s Ltd. 1948 - The Ajax Pump Foundry opened at Kyneton, Victoria and in the post war years it grew to became a large manufacturer. 1980’s – Ajax Pumps brochure lists the address as 6 Buckhurst St, South Melbourne, Vic 3205 with the Telephone number 03 669 3588 1988 - Ajax Pumps acquired the Forrers Company, which was established in 1921. Manufacturing in Ipswich, Queensland, specialising in submersible sewage pumps. 1991 – KSB Ajax was formed, bringing together the companies KSB and Ajax Pumps 1993 – Manufacturing was moved to state-of-the-art premises in Tottenham, Victoria 2001 - The Forrers facility was moved to Tottenham. 2007 - Company name KSB Ajax Pumps was changed to KSB Australia Pty Ltd. 2009 - KSB Australia opened a branch in Townsville, Queensland. 2011 - KSB Australia moved to its dedicated Water and Waste Water Competence Centre in Bundamba, Queensland. DISPLAY OF THIS AJAX PUMP This pump was installed at Flagstaff Hill Maritime Village as part of a working display in the village by the Friends of Flagstaff Hill, in acknowledgement of the dedicated involvement of one of its long serving members, Bob Crossman. The display was officially opened 31st March 2018 and incorporates a restored Furphy Tank and Water Pipe Stand. The pump is used to draw water from the lake, through the water stand pipe and into the reconditioned Furphy Tank. This Ajax pump made by McPherson’s Pty Ltd is significant for its association with McPherson’s, a prominent manufacturer of hardware in Victoria. McPherson’s is famous for supplying ‘dog-spikes’ for the transcontinental railway (eastern to western Australia, 1917) and rivets for the Sydney Harbour Bridge (1929-1932). The Ajax pump is also of significance because of its association with McPherson’s Governing Director (Sir) William McPherson, former premier and treasurer in Victoria 1928-1929. The former McPherson’s Pty Ltd building in Collins Street Melbourne is now on the Victorian Heritage Register VHR H0942 This pump is representative of mechanical pumps popular in the early to mid-1900’s and still used today. Hand operated pressure pump, double acting. Cast metal case, painted red, with steel hose attachments and long metal lever. Pump is bolted to wooden plank. Model of pump is AJAX, Type L2, Series A pump. Embossed on lower section of pump "L2 - 10", "L2 - -1", "AJAX" “(?) –2-1” Embossed on lower handle “3-7” “L – 4” Embossed on attached plate “FOR SPARE PARTS / TYPE L2 / SERIES A / PUMP ASSEMBLED BY T R” Manufactured by McPherson’s Pty Ltd of Melbourne circa 1930’s - 1940’s.flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ajax pump works tottenham melbourne, ajax pump factory kyneton, william edward mcpherson, thomas mcpherson of melbourne, mcpherson’s pty ltd melbourne, acme bolt company, tool equipment co. pty. ltd, associated machine tools australia pty ltd, ajax bolt and rivet co. pty ltd new zealand, forrers company ipswich queensland, ksb ajax pumps, ksb australia pty ltd, macson lathes, tool manufacturer early to mid- 20th century, ajax double acting hand pump, ajax type l2 series a pump, qisjax pumps, water pump 1940’s, fuel pump 1940’s, hand operated constant flow pressure pump, reciprocating suction pump, agricultural hand pump, plumber’s hand pump, portable hand pump -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - DRAINAGE PROBLEMS - MINERS SENSATIONAL EXPERIENCE AT THE VICTORIA QUARTZ

Handwritten notes from a Bendigo Advertiser report, Thursday June 16th 1910. Management had for some time been apprehensive that the flooding in the deep mines to the south would affect them. Lansell's 180 took the precaution of baling. On the Tuesday night the men at the Victoria Quartz had a sensational experience. The storage dam at 3324 ft level receives the overflow from the flooded mines to the south. The level connects with the 3310 level at the Big 180. The water flows uninterrupted into thestorage dam which has a capacity of about 270 tanks. The dam had been emptied on Tuesday morning and work continued until 10 pm that night. The platman noticed that the water was coming down the shaft in a regular torrent. They didn't take much notice as they thought it was a leakinig outlet valve on the ascending tank. At 11 pm the releiving shift came down the shaft and said that the dam at 3,324 ft must be overflowing. The velocity of the water pouring down the shaft increased and the men made a hurried exit from the bottom of the shaft which is down 310 ft from the 4.254 ft plat (a total depth of 4,564 ft). An inspection of the dam at the 3324 ft level found it to be overflowing. By morning (Wednesday) the shaft had filled, and the water rose to 7 ft in the plat at 4254 feet. Mining inspector hgave orders that men were not to go below the 3324 ft level. Baling continued without cessation at the Big 180 all day and could not lower the water. Drilling machines etc and a powerful air winch at the 4254 ft plat are under water. An inspection made of the 3100 ft level at the 180 mine where the workings are connected with the New Chum & Victoria showed that water was running strongly from that mine proving that the inrush was due to flooded water from the southern deep mines to the south. Document from Albert Richardson Collection of mining history. Document from Albert Richardson Collection of mining history.document, gold, drainage problems, new chum drainage scheme, miners sensational experience at the victoria quartz, bendigo advertiser 16/6/1910 page7, lansell's 180, big 180, new chum & victoria -

Parks Victoria - Maldon State Battery

Parks Victoria - Maldon State BatteryBox, tool

Used to store tools and other assorted items associated with Maldon State Battery..1 storage box with compartments and lid, painted green, made from wood, leather and are chains attatched from box to lid, trapeze shape, .3 grooves on top of box parallel to wooden supports on lid, latch, nails and bolts attatching wood and inner compartments, leather straps on innner lid and inside main compartment for holding tools, main compartment contains torn newspapers, severed cloths, pieces of rock, pipe peices made of metal and plastic, assortment of metal pieces, paint lids, green bucket with grease, food packaging, tap/valve, metal mesh, leather and plastic pieces, 2 keys/padlocks, nails, nuts, assortment of tools, wooden pieces, wooden handle for screwdriver, broken chair, chalk, pieces of ceramic (Bendigo pottery) , pocket handle with inscription, bottle lids, plastic container, rope/belt for machines, piece of belt, broken canvas strap, peices of broken dark brown glazed textured pottery, large circular threaded joins, large elboiw threaded elbow joins .2 upper left compartment containing brush head, sandpaper and assorted rusty metal objects .3 upper middle compartment containing rusty weighing hook, rusty bolt and scrap metal .4 upper right compartment containing broken tan pottery, rusty threaded T join, unknown green paper with inscription .5 lower left compartment containing white cotton waste, assorted circular rusty metal objects, assorted rusty nails and washers, orange lid with insciption, nut and bolt .6 lower left middle compartment containing unknown assorted metal objects, peice of broken clamp and felt .7 lower right middle compartment containing large rusty nuts and unknown rusty metal objects .8 lower right compartment containing assorted threaded rusty circular metal objects, rusty nut and bolt, metal pump part, rusty mobil oil tin 20litres, old newspaper scraps, -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncAlbum - Hume Reservoir Australia Album - Detail plan and explanation, Department of Public Works, N.S.W, 1927

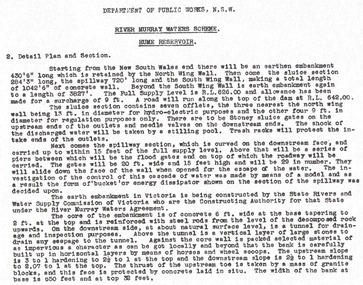

This set of photos is from a leather bound album bearing the inscription "HUME RESERVOIR AUSTRALIA" plus 'The Rt. Hon. L. C. M. S. Amery, P. C., M .P.' all inscribed in gold. It was presented to The Rt. Hon. L. C. M. S. Amery, P. C., M. P, Secretary of State for Dominion Affairs on the occasion of his visit to the Hume Reservoir on 2nd November 1927. This album is of local and national significance as it documents the planning and development of the Hume Reservoir up to 1927. It was the largest water reservoir in the British Empire. The album records the pioneering engineering work that went into its construction.2. Detail Plan and Section. Starting from the New South Wales and there will be an earthen embankment 430 feet 6 inches long which is retained by the North Wing Wall. Then come the sluice section 284 feet 3 inches long, the spillway 720 feet long and the South Wing Wall, making a total length of 1,042 feet 6 inches of concrete wall. Beyond the South Wing Wall is earth embankment again to a length of 3,827 feet. The Full Supply Level is R.L.626.00 and allowance has been made for a surcharge of 9 feet. A road will run along the top of the dam at R.L.642.00. The sluice section contains seven offlets, the three nearest the north wing wall being 13 feet in diameter for hydro-electric purposes and the other four 9 feet in diameter for regulation purposes only. There are to be stony sluice gates on the upstream ends of the outlets and needle valves on the downstream ends. The shock of the discharged water will be taken by a stilling pool. Trash racks will protect the intake ends of the outlets. Next comes the spillway section, which is curved on the downstream face, and carried up to within 15 feet of the full supply level. Above that will be a series of piers between which will be the flood gates and on top of which the roadway will be carried. The gates will be 20 feet wide and 15 feet high and will be 29 in number. They will slide down the face of the wall when opened for the escape of the water. The investigation of the control of this cascade of water was made by means of a model and as a result the form of “bucket” or energy dissipater shown on the section of the spillway was decided upon. The earth embankment in Victoria is being constructed by the State Rivers and Water Supply Commission of Victoria who are the Constructing Authority for that State under the River Murray Waters Agreement. The core of the embankment is of concrete 6 feet wide at the base tapering to 2 feet at the top end and is reinforced with steel rods from the level of the decomposed rock upwards. On the downstream side, at about natural surface level, is a tunnel for drainage and inspection purposes. Above the tunnel is a vertical layer of large stones to drain any seepage to the tunnel. Against the core wall is packed selected material of as impervious a character as can be got locally and beyond that the bank is carefully built up in horizontal layers by means of horses and wheel scoops. The upstream slope is 3-to-1 hardening to 2½-to-1 at the top and the downstream slope is 2½-to-1 hardening to 2.07-to-1 at the top. The thrust of the upstream toe is taken by a mass of granite blocks, and this face is protected by concrete laid in situ. The width of the bank at base is 650 feet and at top 32 feet.hume reservoir australia, river murray waters scheme, hume weir diagrams, hume plan details -

Puffing Billy Railway

Puffing Billy RailwayLister Auto Truck

The Lister Auto-Truck was a small monowheel tractor built for moving light loads around factories, railway yards and similar sites. They were built by R A Lister and Company of Dursley, Gloucestershire, well known for their range of small stationary engines The Auto-Truck was one of several monowheel tractors to appear in the 1920s and '30s, with the availability of small, reliable petrol engines, as developed for motorcycles and the stationary engines for which Lister were already known. These were tricycle vehicles, with the single leading wheel used for both drive and steering. Their simple construction carried most of the mechanism on this wheel as a single unit, the chassis with the trailing wheels being little more than a trailer for balance. Simplicity was a key feature. The engines were single-cylinder and air-cooled. Ignition was by magneto, rather than requiring a battery and electrical system. One of these designs was produced in the 1920s by George Grist of the Auto Mower Co., Norton St Philip, Somerset. The engine was a JAP 600 cc four-stroke air-cooled sidevalve, a typical small engine of the time. The Auto Mower Co. were Lister agents and when Lister heard of this 'Auto-Truck' they bought one for use in their own factory. It was used to carry heavy engine castings from the foundry to the machine shop. Lister customers saw them and there was such interest in wanting to buy them that Lister negotiated with Auto Mower to build them under licence. Although Lister were already well known for their small petrol stationary engines, these were heavy cast-iron engines with water hopper cooling and unsuitable for vehicle use. Lister remained with the JAP engine for the Auto-Truck. The Auto-Truck was designed for use in factories or other places with smooth surfaces of concrete or tarmac. This allowed the use of small solid-tyred wheels with only simple suspension, making the vehicle simple, cheap and lightweight. They had little ability on soft surfaces though and could even topple over if driven carelessly across slopes. Their design was a compromise between the top-heavy nature of the tall engine grouping above its wheel and a well thought-out chassis for stability. The bearing between them was a large diameter ring roller bearing, mounted at the lowest part of the chassis. This gave rigidity and stability, even after long wear. A ring of rolled channel girder was attached to the engine group and rollers on the chassis carried the load upon this. On early Auto-Trucks this bearing is set very low, in line with the chassis members, and is covered by thin steel plates. The front panel of the engine cover is distinctive with large ventilation holes and a Lister signature cut through it. Strangely this panel is made of thick cast iron, providing substantial weight high on the engine and only adding to its top heaviness. To improve visibility of moving vehicles in noisy factories, this panel was often painted white, the rest of the vehicle being Lister's usual brunswick green. The driver was seated on a Brooks bicycle saddle, which in recognition of the lack of vehicle suspension, was carried on the end of a cantilevered bar that acted as a leaf spring. A wide handlebar on the engine group was used for steering. A squeeze bar the width of this handlebar engaged the clutch. Controls included a hand throttle, a gear lever with two forward and one reverse gears, and a large handbrake lever. The engine unit rotated freely for a full 360° rotation. When used in reverse, the Auto-Truck could either be driven from the saddle, looking backwards over the driver's shoulder; or they could dismount, swivel the engine unit around and control it as a pedestrian-controlled truck from behind. Under the engine cover were two equal diameter tanks, a fuel tank for petrol and a shorter oil tank. Engine and chain-drive lubrication used a total-loss oil system, controlled by a small pump and needle valve. Info Ref: Lister Auto-Truck - Wikipedia https://en.wikipedia.org/wiki/Lister_Auto-TruckHistoric - Industrial monowheel tractor for moving light loads around factories, railway yards and similar sites.The Lister Auto-Truck - small monowheel tractor Made of steel with three wheels. Powered by a J.A.P single cylinder petrol motor which is Hand Cranked to start.Lister puffing billy, lister, lister auto truck, monowheel tractor -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Diving Compressor, Siebe Gorman & Co. Ltd, 1880-1890

This compressor was part of the E.G. Ward Collection. It is connected to the diving suit and boots also in our collection. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water-pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12 bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunneling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr. E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The compressor is a very significant item as it gives a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. Siebe & Gorman the company that made the equipment was a leading inventor, developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job during the early days of marine exploration.A single cylinder divers' pump by Siebe Gorman & Co Ltd, London, eccentric hand cranked in brass mounted mahogany case with instructions to the underside of the lid, brass covered pressure gauge and air outlet, brass makers plaque to the front, water inlet and outlet to the rear, green painted lifting rings. Machinery has some blue painted areas on the metal.Plate on the back 'WATER SUPPLY" "WATER OVERFLOW" "WATER DRAIN-IN" Pressure gauge dial "BOURDON'S PRESSURE GAUGE" STEBE GORMAN & CO. LONDON", "LBS PRESSURE" "FEET OF SALT WATER" Plate on the front " PATENT, Siebe Gorman & Co Ltd Submarine Engineers" below emblem (Lion, Crown, Horse)flagstaff hill, warrnambool, flagstaff-hill, maritime-museum, diving compressor, london, siebe gorman & co ltd, marine technology, life saving, deep sea diving, maritime museum, maritime village, manine history -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Diving Suit, boots and weight, 1900

This diving suit with helmet, boots and weight is part of the E.G.Ward collection, along with the diving compressor and a photograph of a diver in this equipment. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12-bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunnelling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A.Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire-fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The items are very significant as a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. The company that made the equipment was a leading inventor,developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job.Diving suit including helmet, boots and a weight. Diving suit is made of canvas with knitted cuffs. The helmet is metal. The boots have a thick sole and thick leather upper that is held on with leather straps and buckles. The toe of the boot is heavy metal. The weight is worn next to the trunk of the diver and it has an inscription to mark the front. It is worn with straps and buckles holding it in place. Royal Navy Admiralty Pattern 6 bolt No 3 light Siebe Gorman light diving helmet circa 1960 used by the Royal Navy before and after World War 2"Siebe Gorman & Co Ltd Marine Engineers London. Patent" with "E G Ward" on front and back plate. On weight "FRONT"flagstaff hill, warrnambool, diving suit, siebe gorman and co ltd., siebe gorman and co ltd marine engineers london, marine engineers, diving helmet, diving boots, diving weight, marine diving, maritimemuseum, maritime village, maritime history, marine technology, life saving, deep sea diving -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Diving compressor and helmet, 1944