Showing 366 items

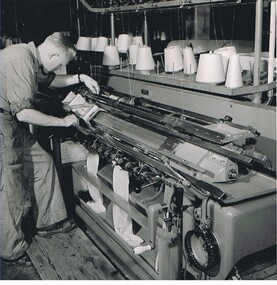

matching machine operated

-

National Wool Museum

National Wool MuseumTextile - Beanie, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Teal knitted ribbed beanie with gathered crown.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Skirt, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. This garment was owned and worn frequently by Assunta herself, as part of an ensemble. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Forrest green skirt shaped with darts and has an elastic waistband. Has a brown silky lining. knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Jumper, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. This garment was owned and worn frequently by Assunta herself, as part of an ensemble. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Forrest green long sleeved crew neck jumper with black horizontal stripes on lower half. Button at the back of neck. knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Cardigan, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. This garment was owned and worn frequently by Assunta herself, as part of an ensemble. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Forrest green cardigan with black edged scallop detailing on collar, button band and faux pockets.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumDocument - Business Card, Tina Knitwear, 1980-2000

Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Standard size cream business card with black embossed lettering.front: TELEPHONE: 596 1489 / TINA KNITWEAR / FOR ALL MEN'S AND LADIES' WEAR / 17 ORCHARD STREET, NORTH BRIGHTON, 3186knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumDocument - Label, Tina Knitwear, 1980-2000

Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Thin paper white label with gold printed text.front: An Original by / Tina Knitwearknitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

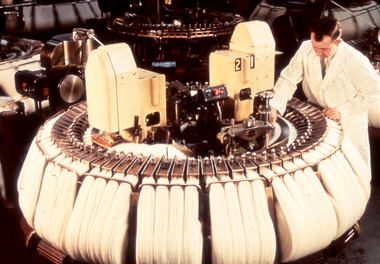

National Wool MuseumPhotograph - Slide, Stuart Ascough, Noble Comb, 1990s

... showing a man in a white coat operating a wool combing machine... factory training combing machine 35mm colour transparency mounted ...This slide is part of a collection of visual resources used by Stuart Ascough while conducting training and technical advice at mills in China, India, Russia and Australia. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing a man in a white coat operating a wool combing machine inside a factory.wool, industry, australia, australian wool board international wool secretariat, factory, training, combing machine -

National Wool Museum

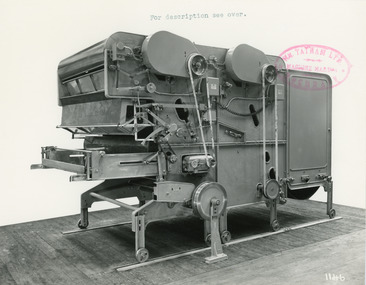

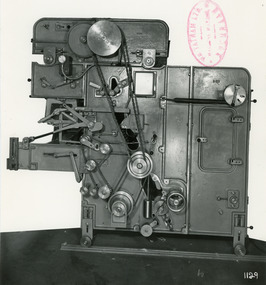

National Wool MuseumPhotograph - Product Photograph, Automatic Feeding Machine

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Automatic Feeding Machine automatically dispenses wool to a carding machine, so that an even, constant supply is received. This eliminated the manual labour previously needed for the initial weighing and feeding of wool. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866, Tatham developed innovative textile machinery and sent their products to Australia and other countries around the world.Two black and white photos of an Automatic Feeding Machine in a landscape format. The first photo is of the front of the machine, the second is of the rear.8037.1 - Front - top margin: For description see over. Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1146 Rear - 78” wide Automatic Feeding Machine having Dual Hoppers in which the first and large section feeds the second Hopper so as to maintain a constant level of material in the latter. The driving of both spiked lattices is by electro-magnetic clutches, the one in the first Hopper being actuated by a sensitive feeler motion in the second, the second spiked lattice however, being controlled, of course, from the Scale Pan. Through a mercury switch. The scale is of our latest super-sensitive pattern mounted diagonally across the Feed. Only the opening doors are used in the actual weighting and the trap doors placed over the scale which close immediately the correct weight is deposited, operate through a solenoid. The machine incorporates many other features and is arranged to divide for facility in cleaning. 8037.2 - Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1147 Rear - Showing opposite side of Dual Automatic Feed illustrated in photo 1146textile machinery, automatic feeding machine, tatham, feeding machine -

National Wool Museum

National Wool MuseumPhotograph - Product Photograph, Patent Automatic Feed Machine

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. An Automatic Feeding Machine automatically and sequentially supplies uncarded wool to carding machines, The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Automatic Feed Machine in a portrait format. Black wiritng on the rear, typed with a typewriter.Front - mid left corner - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1129 Rear - Patent Automatic Feed with Extended Hopper fitted with balanced pressure plate which operates through Variable Speed Device to regulate speed of spiked lattice in accordance with material in Hopper. Electro-Magnetic Clutch Drive to spiked lattice controlled by Mercery Switch on scale arm. Diagonal Scale Pan with improved knife edge suspension. Dual Trap Doors over Pan actuated by Solenoid. Automatic device to slow spiked lattice just prior to weigh being obtained. Ball or roller bearings to main shaft, combs and other parts. Self-aligning bearing to timing shaft etc.textile machinery, tatham, wool manufacture, carding, automatic feeding machine, wool -

Vision Australia

Vision AustraliaPhotograph - Image, Queensland Institute for the Blind matting, cane and mattress workshop, August 1952

... - Snowy Willis oversees the operation of the machine that bores... into brush heads. 4 - Unknown worker operating a coir matting machine ...Fives images of the workshop machinery used by the Queensland Industrial Institute for the Blind in the manufacture of various products. 1 - Pitched brooms being made by Stewart Jewell (left) and Jack Dollier (right). 2 - Unknown worker at a basket station making a cane basket, surrounded by finished examples. 3 - Snowy Willis oversees the operation of the machine that bores holes into brush heads. 4 - Unknown worker operating a coir matting machine. There were apparently 10 such machines in use at the time this image was taken. 5 - Snowy Willis checking the bobbins being filled from a giant spool. In the background are empty bobbins stacked against walls and filled bobbins on spool holders. 6 - Roy Anderson checks the wadding on a recently filled mattress, whilst in the background Ellen McDevitt uses a portable sewing table to sew the ends of a filled mattress.6 x B/W photographs of the workshop machinery used by the Queensland Industrial Institute for the BlindC2-657: 2, Brush shop - pitch set brooms being made by blind workers C2-664: Basket shop - some of the various types of baskets made C2-654: Snowy Willis. Brush shop - a semi automatic brush stock boring machine in operation. C2-666: Matting shop - one of the ten coir matting looms in use. 1960. C2-659: Matting shop - bobbin winder and bobbin bank. C2-655: 15. 2 col wide. Bed shop wadding a fibre mattress. Also showing special sewing machine and movable table used in sewing the mouths of filled mattresses.queensland industrial institute for the blind, stuart jewell, jack dollier, snowy willis, roy anderson, ellen mcdevitt -

Vision Australia

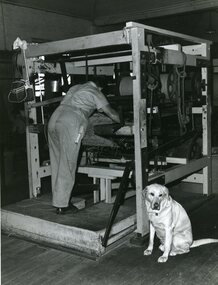

Vision AustraliaPhotograph - Image, QIIB staff with their dogs

... Two workers operating mat making machines... workers operating mat making machines, with their respective guide ...Two workers operating mat making machines, with their respective guide dogs: George Stibbs (wearing overalls and shirt) with Rex, and Arthur Bridges (white singlet and overalls) and his dog.3 x B/W photographs of workers with guide dogsC2-5059 C2-5058 C2-5061, Arthur Bridgesqueensland industrial institute for the blind, george stibbs, arthur bridges, employment -

Tarnagulla History Archive

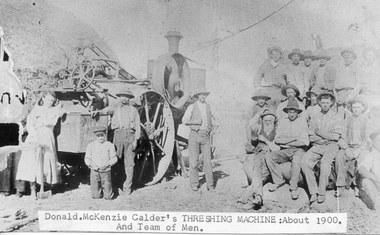

Tarnagulla History ArchivePhotograph, Calder's Threshing Machine, Tarnagulla, circa 1900

... operating his threshing machine, around 1900. Copy photograph. .... A monochrome photograph depicting Donald McKenzie Calder operating his ...Donald Clark Collection. A monochrome photograph depicting Donald McKenzie Calder operating his threshing machine, around 1900. Copy photograph. -

Mont De Lancey

Mont De LanceyFunctional object - Sewing Machine, Wertheim, early 1900's

Wedding gift to Mrs. and Mrs. Wandin Sebire in 1905. From their home in Sebire Avenue Wandin.An antique black painted cast iron treadle sewing machine with gold decoration on the front and mounted on a wooden base with one small drawer on each side and a foot operated treadle below. It has a wooden detachable cover. There are two cotton reels included.Plate reads "Deutsche Nahmaschinen Fabrik. Vormals. Jos. Werthheim : Frankfurt a/m".Stamped Hugo Werthheim.sewing machines, cabinet sewing machines, machines, sewing equipment -

Mont De Lancey

Mont De LanceySewing Machine

Treadle sewing machine in wooden cabinet with a fold out lid, and opening door, and a foot operated treadle below. Gold floral painting on plate and machine body, and a bag of 'feet'."Victor Medium CS Serial Number 173897"sewing machines -

Melton City Libraries

Melton City LibrariesPhotograph, Harvesting, 1950

1950 decade HAY FORK - A local invention. Bill and Arthur Gillespie and Bon Barrie In the early 1950’s Bill Gillespie of Bulmans Lane had been experimenting in developing a machine to improve the collection of hay sheaves at harvesting and stack building time. The ripened crop was cut by a reaper and binder which bundled the storks into sheaves tied with binder twine. The reaper and binder was towed by a tractor by the mid 1940s previously teams of draught horses were used to pull the reaper and binder. A photograph taken at the Barrie farm shows three binders the first being towed with a tractor and the others with horse teams. Two workmen were needed to operate the binder when cutting a crop. The sheaves collected on the binder and released onto the ground and were scattered across the paddocks. Using a conventional two pronged pitch fork the harvest hands collected the sheaves and placed each one cut edge on the ground in an upright position and layered with about 15 sheaves into an apex shape to form was is known as a stook. The shape of the stook allowed for drying and draining of water if rain had occurred. Prior to the invention of the mechanical hayfork this was a laborious task requiring each sheaf to be pitched onto a tray truck and moved to the location of the haystack. The mechanised HAYFORK was operated by one person on tractor greatly reducing the need for gangs of labourers. At harvest time farmers had relied on itinerant teams of workers descending on the district looking for work. The three Barrie brothers on their adjoining farms combined forces to cut their crop at its optimum time while the weather was in their favour. Up to many 20 workers at times formed a team in earlier times. Agricultural university students were also keen to gain practical experience in the field. Each of the brothers had a particular skill, and Tom Barrie was the expert on stack building. The district haystacks had a distinctive shape and could be recognised by their builder. Bill Gillespie’s first operational HAY FORK consisted of a large 13 pronged fork situated forward of the truck cabin. It was attached with iron girders and mounted on the rear of the cabin to the tray of his British Bedford truck. It was constructed in metal and iron and welded in the farmers work sheds. The mechanism was raised and lowered by the driver scooping along the ground to pick up a complete stook to raise high enough to deposit all the sheaves in one stook onto the stack or truck tray. The fork section was released by a rope and operated by the driver in the cabin. This model was trialled on the Barrie farm at Ferris Lane. It proved to be very successful and the Barrie/ Gillespie brothers went on to develop a HAYFORK which attached to a tractor and was operated with a series of levers and was raised and lowered hydraulically. It was detached from the tractor when stacking was completed. In its early days farmers travelling along the Western Highway called at the Barrie farm at Ferris Lane to inspect its construction and operation of the invention. It became a widely adopted by farmers throughout the State. It was being used on Wattie Palmer’s farm on Bridge Road Melton South in 1997. Farming in Melton, hay growing and stack building. agriculture, local identities -

Parks Victoria - Maldon State Battery

Parks Victoria - Maldon State BatteryWasher, Rubber

Probably used as part of operating machinery. Two circular parts with holes in centre to fit onto machine and horseshoes cut out around the edge. 77.1 is much smaller and may be made of leather, whereas 77.2 is rubber and larger. -

Wodonga & District Historical Society Inc

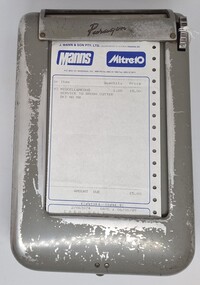

Wodonga & District Historical Society IncFunctional object - Business Docket Dispenser, Lamson Paragon, c1960s

J. Mann and Sons was first established as a farm produce store in 1921. The range of products was extended in the 1930s and included groceries and hardware, as well as the first petrol bowser in Wodonga outside the store. After WWII, the premises were extended and the range of products continued to increase. In the 1960s the Mann Family opened a new supermarket in Wodonga, in addition to the hardware business, providing steel, plumbing and industrial supplies, and they employed over 100 people at one stage. With changes in the retail industry, the Mann Family sold the main hardware business to Bunnings and the produce business to the Kelly brothers in 2006. Paragon, trading at various times as Lancom Paragon, Moore Paragon, Paragon Printing and the South Pacific Print Group, was also based in Wodonga from 1958 until 2010. It began as Lamson Paragon in 1958 but was destroyed by a fire causing £150,000 damage. The factory resumed operations on 24 June 1959.with 30 staff and by 1973 employed 120 and used 80 tons of paper per week. Further develp[ment took place to the factory in 2 stages. In 1977 Moore Corporation of Toronto took over control of the London based parent company Lamson Paragon necessitating a change of name of the Australian company to become Moore Business Systems Australia Limited. After many successful years of operation including expansion to a staff of 240 people, changes to business operations and the loss of several large contracts led to the company entering voluntary administration in March 2010.This machine and docket has local provenance as it came from the 20th century business of J. Mann & Son in Wodonga..The machine was manufactured by Paragon, also operating as Lamcon Paragon and Moore Paragon, which were a major manufacturer in Wodonga from 1958 until 2010.This is a grey rectangular-shaped metal box with rounded edges. The box has four metal studs on the base to keep the box stable. The box has a hinged section to enable paper dockets to be inserted. It also has a turning mechanism for removing the dockets, one at a time from a slot at the top of the machine. The machine includes a docket from Mann Mitre 10 Wodonga operated by J. Mann & Son Pty. Ltd. The dockets provided a duplicate copy for the company as well as the white copy for the customer. The dispenser and dockets were produced by Paragon.At top of dispenser: "Paragon" Across top of docket: "J. MANN & SON Pty. Ltd. (Incorporated in Victoria) TRADING AS: / Manns Mitre 10/ P.O. BOX 141, VIC., 3690. Phone: (060) 24 4813paragon, lamson paragon, moore paragon, mann wodonga, moore business systems australia limited -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - German Hairclippers, Alcoso Company, c1900 - 1950

Hair and beard clipping was frequently carried out at home prior to WW11 and often much later in rural areas. Manual hair clippers were readily available for purchase. The Alcoso company started as steel manufacturers by Alexander Coppel in 1821. Alcoso is an acronym for Alexander Coppel Solingen. They were very successful and opened a second manufacturing facility sometime in the 1850s. They manufactured pipes, rolled steel, wire, tableware, daggers, swords, knives and razors. They started manufacturing razors in the 1850s. The company is most famous for their swords. The Coppel family that Alexander donated millions of marks to charity including building an orphanage, a school for the disadvantaged, and a recreation centre. They headed various social rights groups. They were leading citizens of Solingen. The family was Jewish and the company was Aryanized in 1936. Alexander Coppel and his family were sent to a concentration camp in 1941 along with the remaining Solingen Jews. He died there of starvation in 1942 at the age of 77.This kind of hair clippers were a common household item in the early 20th century. They are representative of an important Jewish company prior to WW2.2 sets of hairclippers made from steel alloy. The arms of the clippers are hinged and can be adjusted with a wing screw. The arms are squeezed together and released. like scissors to operate,On box lid: "Haarschneide-Maschine/ Hairclipper/ "Alcoso"/ Solingen / Tondeuse/ Maquina para cortar el pelo" Translation hair cutting machinehair clippers, alcoso company, alexander coppe, personal items -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncEquipment - Fire Fighting Knapsack, REGA Products Ltd, c1945

The spraying units were manufactured in Australia by REGA Products. Ltd. in 1926. They established themselves as leaders in the production of agricultural and horticultural spraying machines, including smaller knapsacks. Knapsacks were quickly adapted to a range of applications and were widely used by the C.F.A (Country Fire Authority). They were also widely used for defence during World War II. REGA was later purchased by the Garrard family and still operate as part of Garrads Pty Ltd. This sprayer was one of the units used by the C.F. A. in Wodonga. The Country FIre Authority was established in 1945 following a Royal Commission into the 1939 Black Friday fires which recommended a single firefighting authority for country Victoria, bringing together the Bush Fire Brigades, Country Fire Brigades and Forest Commission. The first fire brigade, the Wodonga Urban Fire Brigade was formed in 1891 and registered in May 1893. Since that time its volunteers have provided ongoing support to the Wodonga and District communities through events such as urban fires, bushfires and other emergency situations. This item is representative of the Wodonga Country Fire Authority and its many volunteers.A knapsack sprayer designed to be used for spraying insects. The unit includes brass fittings, leather straps and a spray arm and nozzle attached. It was also adapted to be widely used by firefighters.On front: REGA / C.F.A. Around lid: REGA SPRAYERSrega sprayers, cfa region 24, cfa volunteers, cfa wodonga, wodonga urban fire brigade, fire fighting equipment -

Broadmeadows Historical Society & Museum

Broadmeadows Historical Society & MuseumMachine - Adding Machine

... A manually operated Burrough's adding machine...Burroughs Adding Machines Ltd of Detroit Michigan ...Burroughs Adding Machines Ltd of Detroit Michigan was the first company to occupy a factory at Strathleven. During the European reconstruction in the late 1940's Burroughs built a major new factory at Strathleven in Scotland, initially to assemble machines from US-made parts and later to manufacture the full product range for the British and Commonwealth markets. Most of the post-war calculators and portables found in Australia are from the Strathleven factory.This manually operated calculator predates the rise of the modern computer.A manually operated Burrough's adding machine. It is a greyish green plastic and has a silver handle. It has 8 columns to add manually and has decimal currency. There is a roll of white (slightly yellowed) paper inserted in the top section.Burroughs Machine Limited, Strathleven, Scotland Made in Great Britainburroughs adding machine, office, calculator, detroit, michigan -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Lathe

... flagstaff-hill-maritime-village Lathe large free standing machine ...Lathe large free standing machine with turning mechanics at centre incorporating wooden turning handle at end. Is attached to pulley and operated by steam engine. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - HANRO COLLECTION: NEWSPAPER ARTICLE, 1926

... Black and white photograph of a young man operating... of a young man operating a knitting machine. and two document: copy ...Black and white photograph of a young man operating a knitting machine. and two document: copy of newspaper article from The Argus, Wednesday 5 May 1926, page 20, regarding the Hanro knitting mills establishment in Bendigo. copy of newspaper article from the Brisbane Courier, Saturday 18, December 1926 page 12.organization, business, hanro -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BASIL MILLER COLLECTION: BENDIGO SAYS GOOD-BYE TO THE TRAMS, c1972

13 April 1972. Bendigo Says Good-bye to the Trams. A1 sheet - double sided. Tramway history 1890 - 1972, 2 copies. At the stroke of 5 pm from Eaglehawk Town Hall clock 82 years of history will end as the last tram makes its sentimental journey to the city, while at the Bendigo Cemetery - the Quarry Hill line terminus - another tram will be leaving for its last resting place. Other articles include: Four Eras, of trams. The Trammies, covering Ballarat, Geelong in the form of a poem. 1927 and all that, by Basil Miller, remembering his 45 years of service with the trams. How it all started, The twin communities of Sandhurst and Eaglehawk were relatively early in considering the possibility of operating street tramways within their boundaries. Cabs, Battery Cars, Construction, Strikes, Bendigo 1890 to 1972 - Tramways. Man and his Mates, continued from previous page, Explosion, Touchy Task, A Quickey, Horrors. Electric in 1903, There was excitement galore in the City during April, 1903 - and the Advertiser recorded the progress of the new-fangled electric machine. One man's Memories, Tough times, humour, tragedy and comradeship - they all came flooding back as former Bendigo tramway-man Tom Griffiths recently turned the clock back. Keb Sir Keb Sir? 'Keg sir? Tram off the line,' was the call of the cabbies when a train pulled in at the Bendigo railway station. Altered Shopping Trend, With advent of the electric tram in Bendigo came change in shopping habits.bendigo trams -

Vision Australia

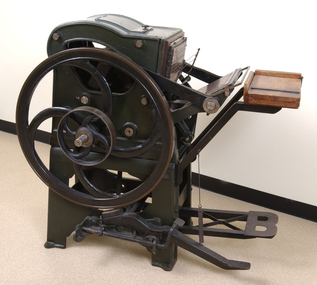

Vision AustraliaMachine - Object, Minnie Crabbe, Braille printing press, 1934

In 1934, the Victorian Association of Braille Writers annual report advised that it had acquired a Crabb-Hulme Braille Printing Press. Two years in development, the Press was designed by Miss Minnie Crabb (the librarian) and built to her specifications by Mr Hulme. Invented to produce ephemeral material quickly, such as programs, catalogues and newsletters, and provided more opportunities for information to be quickly sent out to Braille readers.Steel and cast iron printing press with two wheels on left hand side and two foot levers to operate a wheel on the right hand side.victorian association of braille writers, braille equipment, minnie crabb -

Melbourne Tram Museum

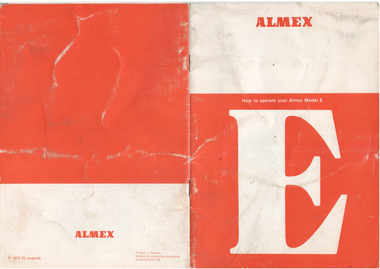

Melbourne Tram MuseumManual, Almex, "Almex - How to operate your Almex Model E", Feb. 1975

Instruction Manual - 16 pages - centre stapled, with photographs for the operation of the Almex Model E ticket machine for the use on Z class trams, from the time of their introduction. See Reg Item 4583 for a Machine from the Camberwell depot.trams, tramways, tickets, ticket machines, z class -

Melbourne Tram Museum

Melbourne Tram MuseumFunctional object - Tramcar component, Melbourne & Metropolitan Tramways Board (MMTB), Cast brass and machined handle - air operated doors, c1940

... with air operated sliding doors. Cast brass and machined handle ...Cast brass and machined handle used on tramcars fitted with air operated sliding doors.trams, tramways, sliding door tramcars, tramcar component, preston workshops -

Melbourne Tram Museum

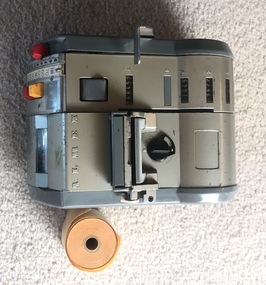

Melbourne Tram MuseumFunctional object - Ticket Machine, AB Almex, Stockholm, Almex, c1975

Ticket Machine - Almex - grey / metallic case with various buttons, levers, number registers for accounting purposes. Use on Z class trams. Has a spare paper roll. See Reg Item 3020 for a manual - "Almex - How to operate your Almex Model E"trams, tramways, tickets, ticket machines, camberwell depot, z class -

Melbourne Tram Museum

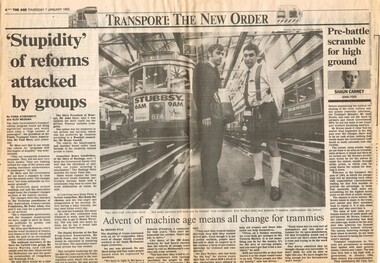

Melbourne Tram MuseumNewspaper, The Age, "Transport: The New Order", "Stupidity of reforms attacked by groups", 7/01/1993 12:00:00 AM

Newspaper cutting (page 4 of The Age, 7-1-1993), about the proposals by the State Government to revise the way the public transport system operated in Victoria including removal of conductors. Has maps or diagrams showing the proposed changes, including shutting of tram and rail lines and calling tenders for replacement services on country rail lines. Includes headlines: "Transport: The New Order" "Stupidity of reforms attacked by groups" "Advent of machine age means all change for trammies" "Pre-battle scramble for high ground" "Brown attacks massive rorts" Has a photo of conductors Ken Walker and Roberto D' Andrea by Michael Clayton Jones at South Melbourne Depot with W5 874 in the background.trams, tramways, ptc, tramways, melbourne, railways, upfield, closure, buses, unions, public transport, tram 874 -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Report, C. N. Govett, A. E. Twentyman, "A story of the Melbourne Cable Tramway System - 11th November 1885 to 26th October 1940", 1973

Report or history Melbourne's cable trams written by Neville Govett and Alf Twentynan, two recognised historians on Melbourne cable trams. The book looks at the Engine Houses, cables in detail, route colours, grips, shunting, the various lines and how they operated, fares, annual reports, notes, and fare collection. Includes information on the operators, See item 1885 for another copy and a full scan of the document.Yields information about the operation and history of Melbourne's cable trams.Report - black comb bound, 230 approx. pages, photocopied from an original, loose sheets foolscap sheets photocopied from an original manuscript by C. N. Govett and A. E. Twentyman - 1973On page 3 in ink "To my friend John, with Best Wishes Neville Govett, 28 Apr 86". On a label on the outside of the comb binding "The Melbourne cable tram system" is a Dymo machine label. trams, tramways, cable trams, mmtb, winding houses, engine houses, operations -

Alfred Hospital Nurses League - Nursing Archive

Alfred Hospital Nurses League - Nursing ArchiveEquipment - Portable electric suction machine, Clements Suction and Pressure Pump

... suction machines for use in hospital operating theatres... suction machines for use in hospital operating theatres ...This equipment was located in the outpatients department (Philip Block) until September 2021 when it was deemed obsolete by Infection Prevention. Hubert Ingham Clements (1886-1969) was an Australian engineer who established his own engineering business in NSW in 1908 manufacturing combustion engines. He became interested in anaesthesia equipment and from the 1920s Clements worked on improving ether apparatus and manufacturing portable suction machines for use in hospital operating theatres. The latter machines were to earn an unrivalled reputation for reliability; many remained in service over thirty years after their date of production. The business became H. I. Clements & Son when his son William joined the company. (https://adb.anu.edu.au/biography/clements-hubert-ingham-12846)Item is an example of equipment from its time period and is of historic significance.Portable Clements Suction & Pressure Pump built by H I Clements & Son Ltd Consists of motor with attached carry handle, attached pressure regulator, attached disposable drainage cannister with tubing and power cable mounted on a trolley with castors.H I Clements & Son Pty. Ltd. Metal Manufacturing label with: Serial Number 1725FS and SAA Certificate Number BCG/4S/60194 on motor (front side) Ward 11 engraved on motor handle AH Biomedical Engineering orange test due sticker and AH Biomedical blue test sticker (reverse side)suction, clements, portable suction, respiratory, pressure pump, surgical drainage