Showing 259 items

matching drink bottle

-

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Bottle Labels, n.d

... drink Set of 6 bottle labels, 'Henty Raspberry Cordial', red ...Set of 6 bottle labels, 'Henty Raspberry Cordial', red background, green, white, black lettering; green and white sailing ship top right.henty cordial, drink, soft drink -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Bottle Labels - Jeffrey Bros, Casterton, n.d

Thomas Jeffrey established the Jeffrey Cordial Factory in Casterton in 1876 in Mcpherson Street.Set of 16 bottle labels Jeffreys Bros. Jusfrute Passion soft drink. Red label, depiction of passionfruit, black, white and yellow print.jeffrey bros, jeffrey cordial factory, casterton, trade -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Bottle Label, Jeffrey Cordial Factory, n.d

Thomas Jeffrey established the Jeffrey Cordial Factory in Casterton in 1874.Bottle label, 'Jeffrey Bros Superior Creme Soda'. Orange and royal blue background, royal blue and white print.soft drink, jeffrey bros, cordial, soda, casterton, local industry -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionMemorabilia - Labels, n.d

Strip of 27 self adhesive bottle labels, Casterton Country Made Soft Drinks & Cordial, Jeffreys Bros. White labels, royal blue print. -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Bottle Label, n.d

... soft drink industry food and drink Bottle label, Portland ...Bottle label, Portland Aerated Waters, ½ and ½ fruit juice cordial. Red, blue, yellow label, circle with lighthouse, garland of mixed fruits. Black, white print.cordial, aerated water, soft drink, industry, food and drink -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Bottle Labels, n.d

... Bros Casterton soft drink Set of 18 bottle labels, Jeffreys ...Set of 18 bottle labels, Jeffreys Bros. Jusfrute orange soft drink. Blue label, ½ orange and lemon, black and dark green print.cordial factory, jeffrey bros, casterton, soft drink -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Bottle Labels, n.d

... Casterton food and drink Bottle label, Jeffreys Bros. Superior Grape ...Bottle label, Jeffreys Bros. Superior Grape fruit. Yellow and green background, green and white print.cordial, jeffrey bros, casterton, food and drink -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Bottle Labels, n.d

... Aerated Waters food and drink Bottle label, Portland Aerated ...Bottle label, Portland Aerated Waters, Clove Cordial. Red, blue, yellow label, circle with lighthouse, black, white, yellow print.cordial factory, portland aerated waters, food and drink -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionDomestic object - Shasta Bottle (7 Fl oz), n.d

... Front: 'Shasta 7 Fl oz Refrishing Drinks' Back... PRESERVATIVE ADDED BOTTLED BY SHASTA SOFT DRINKS PORTLAND VICTORIA ...Portland Aerated Waters clear glass Shasta bottle 7 fl. oz. Pyro label.Front: 'Shasta 7 Fl oz Refrishing Drinks' Back: 'ARTIFICALLY COLOURED AND FLAVOURED PRESERVATIVE ADDED BOTTLED BY SHASTA SOFT DRINKS PORTLAND VICTORIA' Base 'ISM 708 3 SYMBOL' - impressed -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Shasta Bottle (850ml) - Portland Aerated Waters, n.d

Portland Aerated Waters clear glass Shasta bottle 850ml, Pyro label. Measurements 29cm x Diameter top 2.3cm x bottom 8cmFront: 'Shasta 850ml Refreshing Drinks' Back: "ARTIFICALLY COLOURED AND FLAVOURED PRESERVATIVE ADDED BOTTLED BY PORTLAND AERATED WATERS, 13 OSWARD ST., PORTLAND, VICTORIA' -

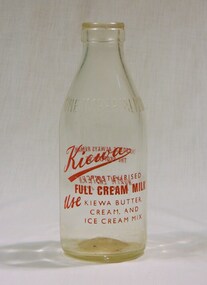

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle - Ginger Beer, early to late 1900's

... non alcoholic drink taylor ginger beer bottle reuseable ...This glass ginger beer bottle was manufactured and used early to late 1900's, until the time that cheaper containers were invented(plastic bottles). This bottle was so constructed to be easily moved within the ginger beer processing plants from the brewing vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1990s the bottle slowly became phased out of production however boutique suppliers still preferred thick glass to contain any explosive action. Two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. were the main suppliers for the Victorian State. In the period when this bottle was manufactured and used the major ginger beer brewing plants for the whole of Victoria were located in Melbourne because this was where its greatest consumer base was there and most rural areas were supplied by domestic sources (mother brewing ginger beer for the children). The Kiewa Valley and its region was one rural area which until road invrastructure was enhance covered the ginger beer thirst by local family production. As the population expanded considerably in the late 1940's (SECV Hydro Scheme) with a greater demand for "soft" drinks" being established supplies from larger towns and cities were call for. Each bottle was "branded" during manufacturing to show the contents were from a reputable supplier (H Taylor) and where it originated from. These bottles were recyled by the manufacturer as a way to cut production costs. This method of recycling the bottles back to the specific manufacturer has (except for South Australia)been overtaken by a no cost recycling collection by councils (funded by their communities). This method by passes the user cost principle as the bottles are processed as non generic. The uneconomical "on cost" which was replaced by the "throw away" less costly plastic containers however did not provide the keen domestic brewer of the "beer" with a reusable bottle. This heavy gauged glass ginger beer bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the filling production line. The method of pouring ginger beer into the bottle has been part of the "production line". This bottle has a one and a half pint capacity and is made from "light green" coloured glass(a protection against light penetration). This thick glass bottle, to contain ginger beer, required its thickness because of the extensive handling (man and machine) before final consumption. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck. Ginger beer was a "soft drink" of great demand. On the middle portion of this bottle is a large elongated circle within it and following the spherical line is "H. TAYLOR" ans a star separates this from "MELBOURNE" rounding out the bottom curviture. Within these words are the large initials "T H" . The "T" superimposed onto the "H". On the base and covering the whole bottom is the letter "T". At the opposite side to the manufacturers logo is "THIS BOTTLE CANNOT BE SOLD OR USED BY ANY OTHER PERSON & IS NOT COMPLETE WITHOUT STOPPER" glass bottle, non alcoholic drink, taylor ginger beer bottle, reuseable bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Ginger Beer, circa mid to late 1900's

... bottle soft drink bottles cordial bottles Around the bottom side ...This glass ginger beer bottle was manufactured and used early to late 1900's, until the time that cheaper containers were invented(plastic bottles). This bottle was so constructed to be easily moved within the ginger beer processing plants from the brewing vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1990s the bottle slowly became phased out of production however boutique suppliers still preferred thick glass to contain any explosive action. Two major glass bottle works companies, e.g. Australian Glass Manufacturers and the Melbourne Glass Bottle Works Co. were the main suppliers for the Victorian State.In the period when this bottle was manufactured and used the major ginger beer brewing plants for the whole of Victoria were located in Melbourne because this was where its greatest consumer base was there and most rural areas were supplied by domestic sources (mother brewing ginger beer for the children). The Kiewa Valley and its region was one rural area which until road invrastructure was enhance covered the ginger beer thirst by local family production. As the population expanded considerably in the late 1940's (SECV Hydro Scheme) with a greater demand for "soft" drinks" being established supplies from larger towns and cities were call for. Each bottle was "branded" during manufacturing to show the contents were from a reputable supplier (PHIBBS Bros) and where it originated from. These bottles were recycled by the manufacturer as a way to cut production costs. This method of recycling the bottles back to the specific manufacturer has (except for South Australia)been overtaken by a no cost recycling collection by councils (funded by their communities). This method by passes the user cost principle as the bottles are processed as non generic. The uneconomical "on cost" which was replaced by the "throw away" less costly plastic containers however did not provide the keen domestic brewer of the "beer" with a reusable bottle.This heavy gauged glass bottle (Ginger Beer) has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the production line. The method of pouring ginger beer into the bottle has been part of the "production line" process of automation. This bottle has a capacity to hold 250ml of ginger beer and is made from "clear" glass. The marority of ginger beer bottles produced in this time frame where made with a "green" tint in them.This tinting helped reduce the sunlight effecting the contentsAround the bottom side of the bottle and blown into the glass is "THIS BOTTLE IS THE PROPERTY OF PHIBBS BROS, ALBURY" above this, in "running script" and sloping up from left to right is "Phibbs Bros" and underneath parallel to it "ALBURY". On the base of the bottle is molded a big "L 289" underneath this "M" and below this "AGM".ginger beer bottle, soft drink bottles, cordial bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle - Ginger Beer, mid to late 1900's

... This bottle was used in a period when "soft" drink ginger beer ...This bottle was used in a period when "soft" drink ginger beer was "brewed" not only in homes but also in specific breweries. Most rural areas had families which produced their own ginger beer. Medium to large towns and cities had ginger beer "factories". These factories had large "on bottle" advertising who the producer was. This producer advertising was firmly infused into the bottle and not on removable labels (late 1900's on wards). Regional breweries had a strong following, similar to State beer producing breweries. The competition between breweries of ginger beer was regional and not state or international. Return of bottles was not a sign of saving the environment or becoming eco- friendly but a requirement to keep production costs low. This is highlighted by "This bottle Remains the Property", in other words return when empty. Up to the end of the second World War Australian "soft drink" demand was for local produce. The American invasion of other flavours of "soft drink" came in the 1950's. Multi -Corporations producing non alcoholic beverages at lower production costs reduced local manufacturers considerably. This however had little effect on semi isolated rural areas where home brews flourished.This bottle shows the impact that small regional towns had and still have on semi isolated rural communities(Kiewsa Valley). With better communications (radio/television/newspapers) and a better transport connections specialised breweries such as the Wangaratta Brewery had an extensive customer "hinterland" to serve. The "canny" rural population would be able to reuse this bottle for their own specific purpose. Because of the long distances between Kiewa Valley residences and the major towns available to them, the issue of adaptability of any purchases made was always closely linked to their long term usefulness.This bottle is made from thick clear glass and has a capacity of one and a half pints. It has a flat top with a wooden screw stopper (internal thread). On one side "THIS BOTTLE REMAINS THE PROPERTY OF WANGARATTA BREWERY PTY LTD" On the top rim of bottle on both sides "17". On the bottom of the base are "AGM" AND "346"ginger beer bottle, soft drink bottles, cordial bottles, wangaratta drinks -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomMillbank filter bag, M & Co

Personal issue equipment during World War 2 and Vietnam War eras. It did not purify water but stopped one from drinking mud. The filtered water was run in to a water bottle containing sterilizing tablets.Light green cotton bag. Fitted with brass eyelets in top corner for use as hanging point.Manufacturer's stamp: "M & Co. 1945, Defence broad arrow, CAT No A.F. 0005" -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle - Beer, 1950s - 1960s

... . bottle beer richmond brewery drink richmond Bottom sides ...Beer came in bottles sold at licensed premises either locally or in larger cities visited during shopping expeditions.The shape of the bottles changed. The bottles were re cycled remaining the property of the manufacturer who paid for them. History of the Richmond Brewery, Richmond.Historical: Change of bottles - shape, glass, embossing. Collected by bottle collectors. Aesthetic: Display showing embossing & shape especially if in good condition.Clear glass bottle used for beer. Bottom half has straight sides. The top half tapers to the opening where a metal crimp fits. It has a crown seal. The glass is joined on two sides longitudinally. It is heavily embossed, in capital letters, around the base of the side around its circumference and at the base.Bottom sides: 'The property of Richmond N.S. Brewing Co. Pty. Ltd.' Base: 'R.B.' and underneath these letters 'R.'. and in between and much smaller S.3.bottle, beer, richmond brewery, drink, richmond -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle - Spirits

Spirits came in bottles sold at licensed premises either locally or in larger cities visited during shopping expeditions. The shape, embossing and size of bottles varied. Small bottles of whisky or gin were used as a comforting drink for the sick. The embossed squares pattern was used on bottles containing medicine or poison.Historical: Change of bottles - shape, size, glass, embossing Aesthetic: Display showing embossing, shape and size.Small clear glass with mottled pattern and embossed with 4 rows of small squares around the bottom. On 1 side the glass is clear and shaped as a rectangle joined to a circle sitting on top of the rectangle. The opening is heavily embossed for a screw top. The sides are straight for three quarters of the way up then sharply taper to the neck before the lip and opening. Embossed on the base. The shape of the bottle is rectangular with curved ends. Common seal: 'A' followed by 'GB36' or '6836' followed by 'M'spirits, medicine, whisky, gin -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle - Milk, 1959

... capacity. bottle milk drink container dairy farm kiewa cow Glass ...This is a milk bottle from the local dairy in Kiewa. It is an old style bottle in imperial measure(ended 1974). This has good historical value, as milk is no longer made in bottles and we do not use imperial measurements anymore. This item is significance for historic reasons, shows local dairy items used. There are not many bottles from this local dairy from this period, and is it is in good condition. . Social significance, shows what items local families used. Research significance. These bottles are not in use anymore as we do not have imperial measurement, so good for research that explains this topic. Therefore has good interpretive capacity.Glass milk bottle. One imperial pint.Glass molded inscription of ONE IMPERIAL PINT. In red text on front Kiewa, (in script) / PASTUERISED / FULL CREAM MILK/ USE KIEWA BUTTER/ CREAM / AND ICE CREAM MIX . In red text on back THIS BOTTLE ALWAYS REMAINS/THE PROPERTY OF/NORTH EASTERN/DAIRY CO. LTD. On bottom of bottle, molded AGM 2 x M F1959 in the middle of botton 5 / 48 bottle, milk, drink, container, dairy, farm, kiewa, cow -

Warrnambool and District Historical Society Inc.

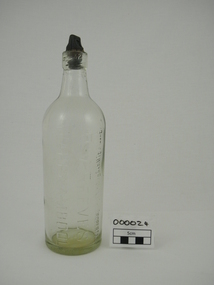

Warrnambool and District Historical Society Inc.Container - Reeves' Cordial Bottle, Early 20th century

The Reeves family emigrated from Dublin arriving in Geelong around 1845. The established their cordial business in Warrnambool in mid 19th century and operated well into the 20th century.The Reeves family were one of a number of drink manufacturers which operated in Warrnambool in the late 19th century and 20th century. Clear glass cylindrical bottle with neck. The dark grey stopper has an internal screw with rubber seal.Embossed on side of bottle "This bottle always remains the propertyof /R.V. REEVES/WARRNAMBOOL." Lined measure mark on side of bottle. "32" either side of lip.Manufacturers marks on bottom.reeves, warrnambool, cordial bottle -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - Bottle, Reeves Dry Ginger, Circa late 20th century

Ralph Reeves purchased an established cordial factory in the early 1900’s from the estate of J Fletcher. It was operated by the Reeves family, firstly Reginald, followed by his son-in-law Murray Moon until the latter part of the 20th century. A common object familiar to a large number of people in the Warrnambool area with links to one of Warrnambool’s longest established family businesses.Two clear glass bottles with rib pattern and circles at bottom of neck. Transfer label with small white circles and one larger red one. Top is white with orange writing. Contains Dry Ginger.Enjoy Reeves’ ice cold on the front, Bottled by R.J Reeves Warrnambool. Preservative added artificially coloured. Net contents 7 FL. OZ. warrnambool, reeves, reeves soft drink, reeves cordial. -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - Bottles, Syphon R.J Reeves, Early to mid 20th Century

Ralph Reeves purchased an established cordial factory in the early 1900’s from the estate of J Fletcher. It was operated by the Reeves family, firstly Reginald, followed by his son-in-law Murray Moon until the latter part of the 20th century.A common object familiar to a large number of people in the Warrnambool area with links to one of Warrnambool’s longest established family businesses. Two clear glass. Cylindrical with 12 ribs. Chrome metal top with lever and spout. Logo etched on front of bottles Inscriptions and Markings: “R. J. Reeves” engraved on side of lid. “R. J. Reeves Warrnambool in oval surrounding RJR. This syphon remains the property of R. J. Reeves Warrnambool and its use by others is prohibited.British syphon company Limited London.warrnambool, reeves, soda syphon, reeves soft drink, reeves cordial. -

Orbost & District Historical Society

Orbost & District Historical Societybottle, C 1970's -1990's

Dross Drossou sold his cordial manufacturing business to Phillips and Stone, a Bairnsdale company, in 1948. Phillips & Stone continued to manufacture soft drinks at Orbost until the early 1970s when the factory became a distribution centre. It closed as a distribution centre in 1978 and later served as the headquarters of the Orbost State Emergency Service. The site of the Cordial Factory now forms part of the carpark at the rear of the Orbost Newsagency. (John Phillips) This bottle is an example of a product manufactured/distributed by a local industry no longer existing.A narrow-shouldered, clear glass bottle with white and red lettering. The neck is threaded (cap is missing). It is labelled "P & S 850ml; Phillips and stone; refreshing drinks. BAIRNSDALE AND ORBOST. Manufactured by Phillips & Stone Bairnsdale & Orbost E2361. Preservative added. Artificially coloured and flavoured."glass-bottle container phillips-and-stone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910’s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. The bottle’s shine has been worn from around 3/4 of its body, indicating that it has been resting horizontally on an abrasive surface, perhaps in the ground or on a river or sea bed. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. Brown, brown glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ nipple-liker bump in the centre. Bottle is straight from base to half height then tapers to a shoulder over the next quarter, than almost straight up to the mouth. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker, ginger beer bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This turn-moulded glass bottle is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. There is a portion of cork in the bottle’s mouth and dry remnants in the bottle’s base. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This hand made, green glass bottle is representative of bottle making before mass production and is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. There is a portion of cork in the bottle’s mouth and dry remnants in the bottle’s base. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. The bottle’s shine has been worn from around 3/4 of its body, indicating that it has been resting horizontally on an abrasive surface, perhaps in the ground or on a river or sea bed. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This turn-moulded glass bottle is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. The shine has been worn from three-quarters of the body of the bottle. There are particles adhered to the inside of the bottle. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Stoneware Demijohn, Bendigo Pottery , 1905-1950

... for Sharpe Bros, brewers of non-alcoholic drinks such as Dandelion ...This demijohn was made by Bendigo Pottery for Sharpe Bros, brewers of non-alcoholic drinks such as Dandelion Ale, Ginger Beer and cordial. Sharpe Bros began in New Zealand and expanded to Australia in the early 20th century. The company was taken over by Cadbury Schweppes in 1972.An item made during the first half of the 20th century by a Bendigo pottery as a container made for the Sharpe's brewery in Victoria to contain their non alcoholic drinks for retail sale.Glazed stoneware bottle with dark brown glaze to top section, one gallon size, narrow neck glazed stoneware stopper and wire handle missing. SHARPE BROS. AUSTRALIA & NEW ZEALAND Text printed in black on body: 'This bottle is the absolute property of and must be returned to Sharpe Bros. Australia and New Zealand.flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, bottle, stoneware bottle, sharpe bros., drink, non alcoholic drinks, bendigo pottery, demihohn -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wooden Rolling Pin, First half of 20th Century

A rolling pin is a simple tool used to flatten dough. The first civilisation known to have used the rolling pin was the Etruscans. Their advanced farming ability, along with a tendency to cultivate many plants and animals never before used as food and turn them into sophisticated recipes, were passed to invading Greeks, Romans, and Western Europeans. Thanks to the Etruscans, these cultures are associated with gourmet cooking. To prepare their inventive foods, the Etruscans also developed a wide range of cooking tools, including the rolling pin. Although written recipes did not exist until the fourth century B.C., the Etruscans documented their love of food and its preparation in murals, on vases, and on the walls of their tombs. Cooking wares are displayed with pride; rolling pins appear to have been used first to thin-roll pasta that was shaped with cutting wheels. They also used rolling pins to make bread (which they called puls) from the large number of grains they grew. Natives of the Americas used more primitive bread-making tools that are favoured and unchanged in many villages. Chefs who try to use genuine methods to preserve recipes are also interested in both materials and tools. Hands are used as "rolling pins" for flattening dough against a surface, but also for tossing soft dough between the cook's two hands until it enlarges and thins by handling and gravity. Tortillas are probably the most familiar bread made this way. Over the centuries, rolling pins have been made of many different materials, including long cylinders of baked clay, smooth branches with the bark removed, and glass bottles. As the development of breads and pastries spread from Southern to Western and Northern Europe, wood from local forests was cut and finished for use as rolling pins. The French perfected the solid hardwood pin with tapered ends to roll pastry that is thick in the middle; its weight makes rolling easier. The French also use marble rolling pins for buttery dough worked on a marble slab. Glass is still popular; in Italy, full wine bottles that have been chilled make ideal rolling pins because they are heavy and cool the dough. Countries known for their ceramics make porcelain rolling pins with beautiful decorations painted on the rolling surface; their hollow centres can be filled with cold water (the same principle as the wine bottle), and cork or plastic stoppers cap the ends. Designs for most rolling pins follow long-established practices, although some unusual styles and materials are made and used. Within the family of wooden rolling pins, long and short versions are made as well as those that are solid cylinders (one-piece rolling pins) instead of the familiar style with handles. Very short pins called mini rolling pins make use of short lengths of wood and are useful for one-handed rolling and popular with children and collectors. Mini pins ranging from 5 to 7 in (12.7-17.8 cm) in length are called texturing tools and are produced to create steam holes and decorations in pastry and pie crusts; crafters also use them to imprint clay for art projects. These mini pins are made of hardwoods (usually maple) or plastic. Wood handles are supplied for both wood and plastic tools, however. Blown glass rolling pins are made with straight walls and are solid or hollow. Ceramic rolling pins are also produced in hollow form, and glass and ceramic models can be filled with water and plugged with stoppers. Tapered glass rolling pins with stoppers were made for many centuries when salt imports and exports were prohibited or heavily taxed. The rolling pin containers disguised the true contents. The straight-sided cylinder is a more recent development, although tapered glass pins are still common craft projects made by cutting two wine bottles in half and sealing the two ends together so that the necks serve as handles at each end.Tiny rolling pins are also twisted into shape using formed wire. The pins will not flatten and smooth pastry, and the handles do not turn. The metal pins are popular as kitchen decorations and also to hang pots, pans, and potholders. https://www.encyclopedia.com/sports-and-everyday-life/food-and-drink/food-and-cooking/rolling-pinThe use of the rolling pin to make thin pastry or pasta.Wooden rolling pin with some damage on cylinder section.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, rolling pin, cooking, pastry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, Late 19th century or early 20th century

Glass manufacturing has evolved over thousands of years. Glass making has been traced back to 3500 BC in Mesopotamia. The earliest known glass objects were beads, perhaps made by accident while working with metal. In the late Bronze Age, several civilizations discovered how to make vessels and glass bottles by wrapping threads of melted glass around cores of sand or clay. Later, moulds were used to form dishes and table wares. Around the 1st century BC, glassblowing was discovered. This made glass containers less expensive than pottery. Mould-blown glass, the process of blowing a piece of molten glass into a wooden or metal mould, was invented during the 1st century AD. This technique was faster with more consistent results. It paved the way for mass production. It wasn’t until the late 1800s that the production process to become more efficient. In 1887, a company in England created a semi-automatic process that could produce up to 200 bottles an hour. This process has been refined to the point where modern machines can yield more than 600 containers per minute. Blown vs. Manufactured Glass Bottles Nowadays, glass bottles, jars, and cups are usually manufactured on a bigger scale than is found in individual glassblowing studios. If we still depended on hand-blown glass for all of our glass containers, we would see some major differences in the process of creating bottles and jars. First, there's the time. Hand blowing glass takes a significant amount of time, even for one simple container. In contrast, hundreds of jars per minute can be made using modern technology. This leads to the second advantage: price. Because of the automated and streamlined process, the price for manufactured containers is much lower than that of hand-blown glass. Third, manufactured bottles will be much more consistently uniform than bottles blown by hand. Automated glass manufacturing produces nearly identical batches of jars. Glass blowing is awesome for unique, beautiful pieces of art. But for lots of lower priced and uniformly shaped containers, automatic manufacturing is the preferred method to create glass bottles and jars. https://www.containerandpackaging.com/resources/glass-bottles-brief-history The invention and development of glass for domestic items including bottles, has been nothing short of revolutionary. The use of glass bottles, that could be easily washed, led to improved hygiene, and mass manufacturing of drinks of all types, including milk, cordial and alcoholic beverages.Green Glass Bottle Possibly a ginger beer bottle.Concave indentation at the base. Also on base are two raised lumps. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, glass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSoda Syphon, 1900-1930’s

This soda syphon (or siphon) was distributed by John Fletcher of Warrnambool, and made by the British Syphon Mfg. Co. Ltd. of London between the 1900s-1930s. It comprises a multi-sided clear glass bottle, an internal glass tube and a metal release valve and spout on the top. It was used to dispense pressurised, effervescent soda water. It was often used as an alternative to water or added to fruit juices and cordials. The text on this bottle states that it remains the property of the retailer, John Fletcher, and must be returned to him. Customers were asked for a deposit on the bottle, which would be refunded when the bottle was exchanged or continued as the deposit on a fresh bottle. Returned bottles would be cleaned and recharged with the gas and sold again. Soda syphon are bottles, glass or metal, with a release valve and spout on the top. The valve lever on the top of the syphon, when depressed, causes the gas in the syphon to force the water up through the tube and out of the spout. The bottle’s mechanism gives the water an effervescent quality to make bubbly drinks such as sparkling mineral water, soda water and sparkling water. ABOUT JOHN FLETCHER John Fletcher bought the Union Cordial Factory in Koroit Street, Warrnambool that was previously owned by John Davis. Fletcher operated the factory as J Fletcher, John Fletcher and Fletcher’s. He eventually sold his business and stock in 1930 to Ralph Reeves, who may have continued using Fletcher’s supply of drink containers before renewing them with stock showing his own brand. The soda syphon is representative of drink containers used in the later 19th and early 20th century. It also represents the system of returnable, recyclable containers. Soda syphon (or siphon). Glass bottle, clear, multi sided, tapered from a heavy glass base to a narrower shoulder, with glass tube at centre connected to metal pump mechanism at the top. Has elaborate frosted label for J. Fletcher of Warrnambool. Made by the British Syphon Mfg. Co. Ltd. London. Bottle remains the property of John Fletcher, Warrnambool.Metal syphon has impressed "J FLETCHER" and logo "S S" in centre of two concentric circles with text between circles "BRITISH SYPHON MFG. CO. LTD. LONDON". Etched into glass "J. FLETCHER / WARRNAMBOOL", "TRADE "[stylised] F" / MARK", "SODA WATER", "THIS SYPHON IS THE PROPERTY / OF JOHN FLETCHER / WARRNAMBOOL AND CONNOT BE / AND CONNOT BE LEGALLY USED BY OTHERS / BRITISH SYPHON CO. TLD. LONDON / - - - - "flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john fletcher, fletcher, john fletcher of warrnambool, soda siphon, soda syphon, british syphon mfg co ltd of london, soft drinks, soda drinks -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSoda Syphon

This soda syphon was made in England, UK, from metal, glass and synthetic materials. The pump mechanism on top of the bottle includes a soda bulb. When this bulb is pierced the soda inside is released and it aerates the contents of the bottle as they are dispensed through the tap on top.Soda syphon (or siphon) covered in diamond shape synthetic material, with used soda bulb fitted. Tap appears jammed. Inscription on top of bottle. Made in England. Size 'C'. Includes inscriptions for place made, size and instructions."Never fill syphon above red line", "Made in England", "Size C", "Shake syphon well while piercing bulb"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, soda syphon, soda siphon, drink dispenser, drink aerator