Showing 1077 items

matching after fire

-

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Newspaper - JENNY FOLEY COLLECTION: BENDIGO FIRE BRIGADE

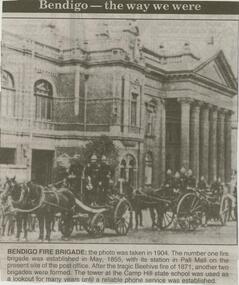

... fire brigade: the photo was taken in 1904. The number one fire... of the post office. After the tragic Beehive fire of 1871, another two ...Bendigo Advertiser ''The way we were'' from 2000. Bendigo fire brigade: the photo was taken in 1904. The number one fire brigade was established in May, 1855, with its station in Pall Mall on the present site of the post office. After the tragic Beehive fire of 1871, another two brigades were formed. The tower at the Camp Hill state school was used as a lookout for many years until a reliable phone service was established. The clip is in a folder.newspaper, bendigo advertiser, the way we were -

Emerald Museum & Nobelius Heritage Park

Emerald Museum & Nobelius Heritage ParkIncense Burner, Early 19th century

... with the recovery after Ash Wednesday 1983 fires... back from Japan by a friend of Noni Smith after World War 2 ...Nancy Hawley requested one of a pair come to the Emerald Museum . It was brought back from Japan by a friend of Noni Smith after World War 2. Noni Smith was Mr Murphy's nurse for many years Noni died at the age of 90 years . She was principal of Emerald Primary School. She was very involved with the recovery after Ash Wednesday 1983 firesJapanese Incense Burner Circa early 19th centuryFloral Bowl with Figured Legs and Topjapanese insense burner -

Victoria Police Museum

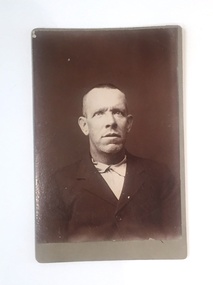

Victoria Police MuseumPhotograph, Criminal photograph Albert McNamara, 1902

... guilty of manslaughter, after he allegedly set fire to his home... and found guilty of manslaughter, after he allegedly set fire to his ...In 1902 Albert E McNamara was convicted for arson and found guilty of manslaughter, after he allegedly set fire to his home, killing his young son. Police alleged McNamara set the house alight as part of an insurance fraud scheme. His wife and other children escaped unharmed, however his young son was killed in the fire. He was executed in 1902 at Melbourne Gaol. Black and white photograph mounted on cardmelbourne gaol, criminal photograph, arson, manslaughter, mcnamara, execution, capital crimes -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Booklet, Anglo-Irish Colonists in Australia, 1970s

... This is a certificate issued by the Victorian Country Fire...) Sizeland’s retirement from the Warrnambool Fire Brigade after more ...This is a certificate issued by the Victorian Country Fire Authority to John Sizeland, a member of the Warrnambool Urban Fire Brigade. The date is 13th April 1977 and the certificate marked John (Jack) Sizeland’s retirement from the Warrnambool Fire Brigade after more than 37 years’ service (the certificate is exact – 37 and five-twelfths years). In our collection we have Jack Sizeland’s Fire Brigade uniform and accessories. This certificate is of interest because it documents the years of service of a Warrnambool identity, John Sizeland. This is a 1977 certificate issued by the Country Fire Authority to John Sizeland. It is a white sheet with a blue tinge around the edges. It has the emblem of the Country Fire Authority, the name of the Authority in a cream, yellow and black ornate setting and printing in black and yellow. There are three signatures (blue ink) on the certificate. Three signatures – P. Ea….., C. Howe, J. Allen warrnambool urban fire brigade, john sizeland, history of warrnambool -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, 'Maitland', 1 Bedford Avenue, Surrey Hills, c 1900, 1900

... . This was the only surviving photo in the family after the fire. Courtesy... in 1986. This was the only surviving photo in the family after ...Maitland' was built in 1889 for Thomas Zeplin, who was a Professor of Music. He owned all the land bound by Union Road, Wilson and Montrose Streets and the railway line. 1 Bedford Avenue stayed in family ownership until purchased by Camberwell Council in 1986, initially for a car park. However it was renovated to become part of Surrey Hills Neighbourhood Centre. It was opened on 23 November 1990. No 3 Bedford Avenue was built for Thomas Zeplin's daughter and named 'Mervyl' or 'Merryl'. Mrs Brodecky (donor) was the great-granddaughter of Thomas Zeplin. The 2 girls are granddaughters of Thomas Zeplin. Electoral roll information: 1972 & 1977: Albert Vojteck Brodecky, manager, 1 Bedford Avenue. 1977: Ray Nanette Brodecky. There are 2 copies. Thomas had this built for his son and family. The house was occupied by his family, though sometimes rented out. His great-grand-daughter Mrs. A. Brodecky sold to the Camberwell Council in 1986. This was the only surviving photo in the family after the fire. Courtesy: Mrs. A. BrodeckyBlack and white photo of 2 houses taken from the street front. On the LHS is a Victorian double-fronted single-storey villa of Hawthorn brick construction, with wrought iron lacework to the veranda, slate roof and picket fence, with an established garden. Next door at No 3 is a double-storey Victorian terrace with a similar fence and building materials. There are 2 young girls standing in front between the properties.maitland, bedford avenue, 1900, surrey hills neighbourhood centre, victorian style, mervyl, merryl, mr thomas zeplin, mrs nanette brodecky, mr albert vojteck brodecky -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Photograph, Schwerkolt Cottage showing Old Well, Toilet and Old Water Tank, 1962

... . The wine cellars and other buildings fell down years ago after... years ago after the bush fires burnt the wooden supports. You ...Photo sent to Mary Jack, Pittsburgh USA, by Charles Schwerkolt. Accompanying text by Charles - 'This is the end facing Ernie's old house which was burnt down last year. There is also the remains of the old well. The old smoke house used to be down there also. All these things have disappeared a long time ago. The house is the only thing that remains of the Schwerkolt property. The wine cellars and other buildings fell down years ago after the bush fires burnt the wooden supports. You will notice the toilet has about 3 boards off the top. The old water tank is hiding the back.Black and white photo of Schwerkolt Cottage showing Old Well, Toilet (with boards missing) and Old Water Tank. Thin Black Border.schwerkolt, charles clarence victor, whalen, rosalie, jackschowsky, mary elizabeth, schwerkolt cottage -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Box, Tin Box McGennan

... after a fire in 1876. In 1896 McGennan established a Box... on the Hopkins River. He rebuilt the boating establishment after a fire ...Peter McGennan (1839-1920) arrived in Warrnambool in the 1870s and established a cooperage in Kepler Street and a boating business on the Hopkins River. He rebuilt the boating establishment after a fire in 1876. In 1896 McGennan established a Box and Case Factory in Davis Street (Merrivale Drive), importing timber from New Zealand, using chartered vessels and his own ships which included the ‘Speculant’. The box factory was a successful venture employing over 30 men until it was destroyed by fire in 1923. Peter McGennan was involved in the establishment of the Warrnambool Cheese and Butter Factory at Allansford and the Warrnambool Woollen Mill. He was a Director of the latter company until his death. Members of the McGennan family were also important business people in Warrnambool, being involved in the hotel business and civic affairs for many years. The tin box may have been used to house family papers or business documents during Peter McGennan’s life and it was used to house his estate papers after his death. Many of these documents are in the collection of the Warrnambool &District Historical Society.This box is of some importance as it belonged to a prominent Warrnambool businessman and his family. It has social significance as an example of the type of storage items used early in the 20th century to hold documents etc.This is a rectangular tin box with the black paint on the outside peeling and yellow paint inside. There is a metal lock which has no key. There is a small handle on the top added to the tin surface. The name ‘P.J.McGennan’ is painted on the front side in yellow paint.‘P.J.McGennan’ A typed label on faded yellow adhesive tape ‘Estate P.J.McGennan’ peter mcgennan, p j mcgennan, peter mcgennan metal box, mcgennan box factory, mcgennan warrnambool -

Melton City Libraries

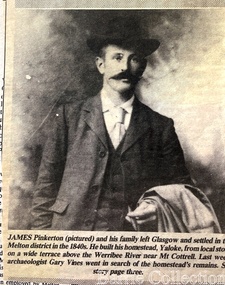

Melton City LibrariesNewspaper, James Pinkerton, 1991

... in 1840.44 After a fire in 1848, the Pinkerton family moved further... in 1840.44 After a fire in 1848, the Pinkerton family moved further ..."James Pinkerton, described by fellow settler Isaac Batey as ‘a fine old Scotish [sic] gentleman’, and his wife Margaret established ‘Chamois Ponds’ on Kororoit Creek in the Keilor district in 1840.44 After a fire in 1848, the Pinkerton family moved further west to a holding called Yaloke, on the Werribee River in the Melton district.45 Today, the Surbiton Park water treatment plant operates on part of the Yaloke run. The Pinkerton family is remembered in Melton in part due to the historic graves of the original settler, Margaret Pinkerton, and four of her grandchildren, which were marked by a memorial cairn in 1931. Changes to sewage flood zoning in the area in the 1990s necessitated that these burials be relocated. Members of the Melton & District Historical Society oversaw a project to relocate the Pinkerton graves and cairn 200 metres from their original site to their current resting place at Mount Cottrell. This relocation ceremony took place on 8 November 1992, with the participation of local school students and with Pinkerton descendants playing a central role. This occasion also marked the opening of the Pinkerton Forest Project, which saw 50 hectares of degraded woodland in Surbiton Park protected for regeneration".Photograph of Jame Pinkerton featured in the the Telegraphlocal identities, pioneer families -

Kew Historical Society Inc

Kew Historical Society IncPhotograph - Denmark Street, Kew, 1972

... of O'Shaughnessy's 'Kew Hotel', and after the destruction by fire... was the original location of O'Shaughnessy's 'Kew Hotel', and after ...The Engineer's Department of the former City of Kew had an extensive collection of photograph of sites in Kew requiring documentation to inform public works. It also kept images of engineering practice in other parts of Melbourne, and overseas, that could be used as models for local activity. Many of these photographs (and plans) were donated to our collection in the 1980s. A number of the photographs are annotated, either on the image itself or on the reverse.This photograph, and others sourced from the City Engineer's Department of the former City of Kew, qualifies as an important record of local streets, public works, street beautification, and engineering techniques of the period. Original black and white photographic positive of automobiles and buildings in Denmark Street, Kew, immediately before the road enters Kew Junction. On the left is McKeon Motors and a retailer of Insulwool, while in the distance is the pharmacy on the corner of High Street and Princess Street (later demolished during the widening of Kew Junction). Notable are the bluestone guttering and what appears to be vacant land on the apex of the triangle of land bounded by High Street South, Denmark Street and Barkers Road. This site was the original location of O'Shaughnessy's 'Kew Hotel', and after the destruction by fire of the latter, the location of a service station. [It is now the site of the Cresco Reserve].Annotation verso: "Indicating the existence of a vehicular entrance at Denmark St abuttal of No.188 High St prior to reconstruction of channeling &c 1972."denmark street -- kew (vic.), kew junction, luestone gutters, mckeon motors, insulwool -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Trophy, Rifle Club, 1909

... soldiers under heavy fire. After the Boer War Geary continued... heavy fire. After the Boer War Geary continued to serve ...This shield was awarded in 1909 by the Rifle Clubs of South Western Victoria for a rifle-shooting competition. Rifle Clubs operated in Warrnambool from 1860 and possibly earlier and in 1904 a union of rifle clubs in the Warrnambool district was formed - the South Western District Rifle Clubs' Union. Edward Geary was a member of the Mounted Rifles, G Company in the 1890s and served as a sergeant in the Boer War, 1899-1900. He was commended by the founder and commandant of the Victorian Mounted Rifles, Colonel Tom Price, for his bravery in South Africa rescuing wounded soldiers under heavy fire. After the Boer War Geary continued to serve in the Mounted Rifles local unit (later called Australian Lighthorse). He was also a long-time member of the Warrnambool Rifle Club and won this trophy as a member of a Lighthorse unit. This shield is of interest as an example of the early 20th century trophies awarded by the Warrnambool district Rifle Clubs. Gun Clubs and Rifle Clubs have been existing in the Warrnambool district since the 1860s. This is a small wooden shield, lightly polished on the front surface. It has silver-coloured metal plates attached by metal pins to the front of the shield in the form of a scroll, two fern or laurel leaves, printed information and a crown with two crossed rifles. At the back is a metal clip to enable the shield to stand up. 'The Warrnambool Citizens Challenge Shield for Competition by Teams, 1909, of Rifle Clubs in the S.W. District of Victoria won by No.1 Sq. XI, A.L.H. Handicap 65, Total Score 579, Arm. Sgt. E. Geary 88'warrnambool rifle club, edward geary, south western district rifle clubs union, warrnambool history -

Sunshine and District Historical Society Incorporated

Sunshine and District Historical Society IncorporatedSports Uniform (Netball) - TOTTENHAM NORTH PRIMARY SCHOOL, 'Ryder' Brand T-Shirt, Early to mid 1980's

... and was built on a South Road, Braybrook site purchased in 1929. After... site purchased in 1929. After a fire in February 1961 ...This Netball uniform from circa 1986 was worn by a girl named Rebecca when she attended the Tottenham North Primary School. Tottenham North Primary School was opened on 29 May 1953 and was built on a South Road, Braybrook site purchased in 1929. After a fire in February 1961 the pupils were sent to the Powell and Curtin Street schools in Yarraville, and to the Maidstone and Sunshine East schools. The new building was officially opened on 22 August 1962 by A. McDonell, Director of Education, and it had sixteen classrooms, an art/craft room, and an assembly hall. Sporting achievements by the pupils included the 1963 football premiership and the 1968 cricket premiership. Over the years it has been called Tottenham Primary, Tottenham Crossing Primary, and Maidstone Primary. The different names resulted because of mergers with other local primary schools as the number of primary aged children in the Braybrook and Tottenham area changed. The school on South Road is now named Dinjerra Primary School. Dinjerra supposedly means 'out west' in the dialect of the original indigenous people of the area. Dinjerra Primary School is now the only neighbourhood government primary school in Braybrook Tottenham. The above information was sourced and compiled from: 1. 'Vision and Realisation - A Centenary History of State Education in Victoria - Volume 3', Education Department of Victoria 1973. 2. The Dinjerra Principal's website article at: http://www.dinjerra.vic.edu.au/91/Message-from-the-Principal.The netball uniform serves as a historic reminder that a school named Tottenham North Primary School once existed. The uniform also provides us with information of the colours used on these types of sports uniforms, and of the design of the School Logo.Two items of Netball Uniform. (a) Skirt - Maroon coloured wrap around sports skirt. (b) T-shirt - Yellow, Size 14 'Ryder' brand children's T-shirt, with maroon coloured triangular shaped School Logo printed on the front.TNPS. TOTTENHAM NORTH P.S. 4703 - (Printed inside triangle)sports uniform, netball skirt, netball t-shirt, tottenham north primary school, south road braybrook, tottenham primary school, maidstone primary school, tottenham crossing school, dinjerra primary school, tottenham north state school, state school 4703 -

Kew Historical Society Inc

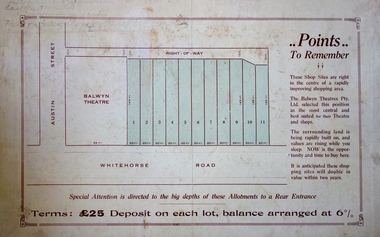

Kew Historical Society IncPlan - Subdivision Plan, Balwyn Theatre and Shop Sites, circa 1927-28, c.1927-28

... , this first Balwyn Theatre was destroyed by fire after a break... Theatre was destroyed by fire after a break-in. Following the fire ...The Kew Historical Society's map collection includes a substantial number of real estate subdivision plans, mainly of Kew but also of surrounding suburbs in Melbourne. Most of the subdivision plans date from the 1920s and 1930s when the districts old homes and local farmland were being split up to accommodate residential growth in the postwar period. These early plans were assembled by a local firm, Jas R Mather & McMillan, which had an office in Cotham Road. Many of the plans, and sometimes photos, were annotated by the agents. The ‘new’ Balwyn Picture Theatre was built and owned by Balwyn Theatres Pty Ltd in ca. 1928. By 1930, this first Balwyn Theatre was destroyed by fire after a break-in. Following the fire, a new cinema was constructed. This plan for a Cinema and eleven shops presumably dates from 1927/28 when the Company announced that this location in Whitehorse Road ‘was the most central and best suited [area] for their Theatre and shops’.Subdivision plans are historically important documents used as evidence for the growth of suburbs in Australia. They frequently provide information about when the land was sold as well as evidence relating to surveyors and real estate and financial agents. The numerous subdivision plans in the Kew Historical Society's collection represent working documents, ranging from the initial sketches made in planning a subdivision to printed plans on which auctioneers or agents listed the prices for which individual lots were sold. In a number of cases, the reverse of a subdivision plan in the collection includes a photograph of a house that was also for sale by the agent. These photographs provide significant heritage information relating house design and decoration, fencing and household gardens.The photograph may also be aesthetically significant depending on the importance of the photographic atelier.Subdivision plan showing the Balwyn Theatre and its adjoining shop sites in Whitehorse Road Balwyn. The 11 shop sites were noted for their depth (133 ft - 145 ft. [Map.0041]balwyn theatre -- balwyn (vic.), subdivisions -- balwyn (vic), subdivision plans -

Warrnambool and District Historical Society Inc.

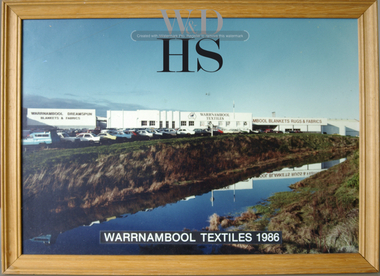

Warrnambool and District Historical Society Inc.Photograph - Framed aerial photograph of Warrnambool Woollen Mill, Circa 1970

... to the directors of the Warrnambool Woollen Mill Company. After being... to the directors of the Warrnambool Woollen Mill Company. After being ...In 1869, the Warrnambool Meat Preserving Company commenced their business on the site, where it operated until 1875 when it was sold to the directors of the Warrnambool Woollen Mill Company. After being destroyed by fire in 1882 it wasn’t until 1910 that the Warrnambool Chamber of Commerce was approached by Marcus Saltau and Peter McGennan to invest in a new mill. The original directors were James Dickson, P J McGennan, Robert Swinton, M Saltau, and J W Younger. In 1955 the Warrnambool Woollen Mill formed a partnership with the Wangaratta Woollen Mills. Dunlop bought the mill in 1968. From that time until its closure in 2000 it had a number of different owners, the last being the Smith Family Industries. The Mill site holds significance for Warrnambool as the site was one of the earliest industries established in the town. The Warrnambool Woollen Mill operated for close to 100 years and in that time forged a strong link with the people of Warrnambool. Its product held a significant position in the marketplace.Aerial colour photograph of the Warrnambool Woollen Mill and surrounding area including carparks. The Merri River crosses from lower left to upper right. Playing field, Jetty Flat, in upper right hand corner and Harris Street bridge in lower left. Aspect is looking easterly. Photo glued to white card mount with text in black underneath. Timber frameWarrnambool Woollen Mill A division of Dunlop Olympic Limited. Manufacturers of Warrnambool/Dreamspun blankets, rugs and fabrics. Registered office South Warrnambool, Victoria. 3280. Australia. P.O. Box 484 Telephone (055)624166. Telex 55820warrnambool, warrnambool woollen mill, woollen mill, dunlop olympic, marcus saltau, p j mcgennan, james dickson, robert swinton, j w younger, dreamspun -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Photograph - Photograph, framed Warrnambool Woollen Mill

... to the directors of the Warrnambool Woollen Mill Company. After being... to the directors of the Warrnambool Woollen Mill Company. After being ...In 1869, the Warrnambool Meat Preserving Company commenced their business on the site, where it operated until 1875 when it was sold to the directors of the Warrnambool Woollen Mill Company. After being destroyed by fire in 1882 it wasn’t until 1910 that the Warrnambool Chamber of Commerce was approached by Marcus Saltau and Peter McGennan to invest in a new mill. The original directors were James Dickson, P J McGennan, Robert Swinton, M Saltau, and J W Younger. In 1955 the Warrnambool Woollen Mill formed a partnership with the Wangaratta Woollen Mills. Dunlop bought the mill in 1968. From that time until its closure in 2000 it had a number of different owners, the last being the Smith Family Industries. The Mill site holds significance for Warrnambool as the site was one of the earliest industries established in the town. The Warrnambool Woollen Mill operated for close to 100 years and in that time forged a strong link with the people of Warrnambool. Its product held a significant position in the marketplace.Colour photograph of the Warrnambool Woollen Mill and surrounding area including carparks. The Merri River crosses from lower left to mid right. Aspect is looking easterly. Photo glued to white card mount with text in black underneath. Timber frameWarrnambool Woollen Mill A division of Dunlop Olympic Limited. Manufacturers of Warrnambool/Dreamspun blankets, rugs and fabrics. Registered office South Warrnambool, Victoria. 3280. Australia. P.O. Box 484 Telephone (055)624166. Telex 55820 warrnambool, warrnambool woollen mill, woollen mill, dunlop olympic, marcus saltau, p j mcgennan, james dickson, robert swinton, j w younger, dreamspun -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Placemats, 75th Anniversary Warrnambool Textiles, 1984

... to the directors of the Warrnambool Woolen Mill Company. After being... to the directors of the Warrnambool Woolen Mill Company. After being ...In 1869, the Warrnambool Meat Preserving Company commenced their business on the site, where it operated until 1875 when it was sold to the directors of the Warrnambool Woolen Mill Company. After being destroyed by fire in 1882 it wasn’t until 1910 that the Warrnambool Chamber of Commerce was approached by Marcus Saltau and Peter McGennan to invest in a new mill. The original directors were James Dickson, P J McGennan, Robert Swinton, M Saltau, and J W Younger. In 1955 the Warrnambool Woollen Mill formed a partnership with the Wangaratta Woollen Mills. Dunlop bought the mill in 1968. From that time until its closure in 2000 it had a number of different owners, the last being the Smith Family Industries.These coasters were part of the 75th Anniversary celebrations.A common item which has significance as it has links to one of Warrnambool's longest operating businesses.A boxed set of six coasters which are metal coloured gold. Each has an outline of Australia with text Buy Australian and the Australian flag. there is text below the outline. The backs are dark blue felt. Buy Australian Warrnambool Textiles A paper insert has " In recognition of your Safety Performance.75th Anniversary Warrnambool Textiles 1909-1984.warrnambool, warrnambool woollen mill, warrnambool woollen mill 1975 -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Calendar, Warrnambool Woollen Mill 1972, 1971

... to the directors of the Warrnambool Woolen Mill Company. After being... to the directors of the Warrnambool Woolen Mill Company. After being ...In 1869, the Warrnambool Meat Preserving Company commenced their business on the site, where it operated until 1875 when it was sold to the directors of the Warrnambool Woolen Mill Company. After being destroyed by fire in 1882 it wasn’t until 1910 that the Warrnambool Chamber of Commerce was approached by Marcus Saltau and Peter McGennan to invest in a new mill. The original directors were James Dickson, P J McGennan, Robert Swinton, M Saltau, and J W Younger. In 1955 the Warrnambool Woollen Mill formed a partnership with the Wangaratta Woollen Mills. Dunlop bought the mill in 1968. From that time until its closure in 2000 it had a number of different owners, the last being the Smith Family Industries. this calendar is an advertising item associated with the Woollen Mill.A common item associated with a long running Warrnambool business.Large 6 page calendar for 1972 with coloured photographs of vintage cars.with Warrnambool Woollen Mill logo underneath with months [printed in black on yellow at the bottom of each page. Metal strip at top.Printed in New Zealand by tanner Couch Ltdwarrnambool,, warrnambool woollen mill 1972 -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - VICTORIA HILL MARONG RD BENDIGO HERITAGE DAY BROCHURE 2010, 2010

... the history and restoration of the 1860s miners cottage after Black... miners cottage after Black Saturday fire. Restoration Loans from ...Victoria Hill Marong Rd Bendigo (Opposite the Gold Mines Hotel) Heritage Day Brochure 2010. Victoria Hill Guided Tours James Lerk (Bendigo Historical Society) George Ellis (Bendigo Cornish Association) Rod Orr (Bendigo Field Naturalists Club) David Bannear (Heritage Victoria) Presentations: Rod Fraser The Geology of Victoria Hill and Bendigo, Kurt Walder German Heritage Ballerstedts-miners from the Hartz Mountains crushing battery, Rod Orr Mining and the Environment in Bendigo, Michele Matthews (BRAC) Sir John Quick the Forgotten Father of Federation spent his youth in the shadow of Victoria Hill, David Bannear ''Things Forgotten'' - the Archaelogy of Bendigo, Carol Holsworth the Chinese and Victoria Hill area, John Kelly Inquests held at the Gold Mines Hotel, George Ellis The Cornish miners of the Ironbark and Long Gully area, Amanda Jean The Ironbark Heritage Study. Coath Cottage Open Day owner Andrew Ward and Restorer Gary Hill explain the history and restoration of the 1860s miners cottage after Black Saturday fire. Restoration Loans from the City of Greater Bendigo.bendigo, gold mining, heritage day 2010 -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Financial record - Ledger Woollen Mill, Circa 1910

... to the directors of the Warrnambool Woolen Mill Company. After being... to the directors of the Warrnambool Woolen Mill Company. After being ...In 1869, the Warrnambool Meat Preserving Company commenced their business on the site, where it operated until 1875 when it was sold to the directors of the Warrnambool Woolen Mill Company. After being destroyed by fire in 1882 it wasn’t until 1910 that the Warrnambool Chamber of Commerce was approached by Marcus Saltau and Peter McGennan to invest in a new mill. The original directors were James Dickson, P J McGennan, Robert Swinton, M Saltau, and J W Younger. In 1955 the Warrnambool Woollen Mill formed a partnership with the Wangaratta Woollen Mills. Dunlop bought the mill in 1968. From that time until its closure in 2000 it had a number of different owners, the last being the Smith Family Industries. This register contains a list of names addresses and occupations of share holders from the period 1910 to 1944.This register provides a comprehensive listing of people who owned shares in the Warrnambool Woollen Mill in the period directly after its beginnings. It is interesting to note that the majority of share owners in the earlier days were from Warrnambool and District while entries in the later years are from further afield.Dark green cloth hard cover with tan point and spine. One red and one black label on spine with gold lettering. Pages are numbered as one number to the opened page. Entries for the most part are written in black ink. Two printed sheets from The Stock Exchange of Melbourne and National Securities are inside the front cover. W.M. Co. Share Transfer Register on labels on spine.warrnambool woollen mill, history of warrnambool, ledger warrnambool woollen mill, share register warrnambool woollen mill -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Booklet, Warrnambool Woollen Mill 1951-53, 1953

... to the directors of the Warrnambool Woolen Mill Company. After being... to the directors of the Warrnambool Woolen Mill Company. After being ...In 1869, the Warrnambool Meat Preserving Company commenced their business on the site, where it operated until 1875 when it was sold to the directors of the Warrnambool Woolen Mill Company. After being destroyed by fire in 1882 it wasn’t until 1910 that the Warrnambool Chamber of Commerce was approached by Marcus Saltau and Peter McGennan to invest in a new mill. The original directors were James Dickson, P J McGennan, Robert Swinton, M Saltau, and J W Younger. In 1955 the Warrnambool Woollen Mill formed a partnership with the Wangaratta Woollen Mills. Dunlop bought the mill in 1968. From that time until its closure in 2000 it had a number of different owners, the last being the Smith Family Industries. This report contains the financial reports for the three years from 1951-1953.This report shows records of the Woollen Mill which was one of the most important industries in Warrnambool for nearly 100 years. As such it has links to many local families and organisations.Light brown paper cover with black text underlined in red. Bound in black tape. Accountants’ name along bottom of cover in black.warrnambool, warrnambool woollen mill, warrnambool woolen mill, -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Document Warrnambool Woollen Mill, Loose sheets Production analysis 1937-1938, 1937

... to the directors of the Warrnambool Woolen Mill Company. After being... to the directors of the Warrnambool Woolen Mill Company. After being ...In 1869, the Warrnambool Meat Preserving Company commenced their business on the site, where it operated until 1875 when it was sold to the directors of the Warrnambool Woolen Mill Company. After being destroyed by fire in 1882 it wasn’t until 1910 that the Warrnambool Chamber of Commerce was approached by Marcus Saltau and Peter McGennan to invest in a new mill. The original directors were James Dickson, P J McGennan, Robert Swinton, M Saltau, and J W Younger. In 1955 the Warrnambool Woollen Mill formed a partnership with the Wangaratta Woollen Mills. Dunlop bought the mill in 1968. From that time until its closure in 2000 it had a number of different owners, the last being the Smith Family Industries. These sheets provide data relating to sales of various different blankets in colours and sizes and where sales occurred . All the capital cities are listed with quantities and customer numbersThe woollen mill was one of the major industries of Warrnambool for nearly100 years. This document is one of many in the collection of the Warrnambool and district historical society which gives an insight into the scale and type of production during the 20th century.Rectangular bundle of loose pages with card on either side and held together with string. Pages are lined and typed with data and also have two small holes and one elongated hole stamped between the smaller ones.Analysis Season 1937-1938 written in red pencil on front card. 'These sheets stocked in 25 patterns by peacock Bros Pty Ltd Melbourne Sydney Adelaide Perth and Brisbane. When ordering this pattern specify No D5' printed on each of the paper sheets.warrnambool, warrnambool woollen mill, woolen mill, dunlop olympic, marcus saltau p j mcgennan james dickson, robert swinton j w younger, wangaratta, dreamspun -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Administrative record - Minute book Glenleigh Fabrics Pty. Ltd, Circa 1955

... to the directors of the Warrnambool Woolen Mill Company. After being... to the directors of the Warrnambool Woolen Mill Company. After being ...In 1869, the Warrnambool Meat Preserving Company commenced their business on the site, where it operated until 1875 when it was sold to the directors of the Warrnambool Woolen Mill Company. After being destroyed by fire in 1882 it wasn’t until 1910 that the Warrnambool Chamber of Commerce was approached by Marcus Saltau and Peter McGennan to invest in a new mill. The original directors were James Dickson, P J McGennan, Robert Swinton, M Saltau, and J W Younger. In 1955 the Warrnambool Woollen Mill formed a partnership with the Wangaratta Woollen Mills. Dunlop bought the mill in 1968. From that time until its closure in 2000 it had a number of different owners, the last being the Smith Family Industries. Directors listed for this period 1956 -1965 include Mr Fletcher Jones, E.E Ladner, N. K. Morris, C. J. McIntyre, J Bennett, J Dickson.. W. S Crowe was manager and Mr E.M Dempster was secretary.The minutes record the decision- making process of one of the major industries of Warrnambool for a significant period of the Woollen Mill’s operation.Heavy black card binder held with thick cloth binding. 1557 Pages with some loose pages at the back of the folder.Kalamazoo Loose leaf Books. Size 42. warrnambool,, glenleigh fabrics pty. ltd., warrnambool woollen mill -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Ledger, Warrnambool Woollen Mill, Mid 20th century

... to the directors of the Warrnambool Woolen Mill Company. After being... to the directors of the Warrnambool Woolen Mill Company. After being ...In 1869, the Warrnambool Meat Preserving Company commenced their business on the site, where it operated until 1875 when it was sold to the directors of the Warrnambool Woolen Mill Company. After being destroyed by fire in 1882 it wasn’t until 1910 that the Warrnambool Chamber of Commerce was approached by Marcus Saltau and Peter McGennan to invest in a new mill. The original directors were James Dickson, P J McGennan, Robert Swinton, M Saltau, and J W Younger. In 1955 the Warrnambool Woollen Mill formed a partnership with the Wangaratta Woollen Mills. Dunlop bought the mill in 1968. From that time until its closure in 2000 it had a number of different owners, the last being the Smith Family Industries. This ledger relates to the operations of the mill in the period 1941-1943. It record items such as quantities and hours of wool being spun, combed, woven, carded. it also records the amount of waste from the processes and the quantities held in the warehouse of blankets, bales of wool, rugs. An item which has a strong connection to one of Warrnambool's longest running businesses and one of its largest. Thousands of local people over the years have been employed there and have an attachment to the woollen mill.It gives an insight into the daily runnings of the business.Black card covered exercise book which is divided into various sections. Pages are lined and it has approximately 150 pages. -

Warrnambool and District Historical Society Inc.

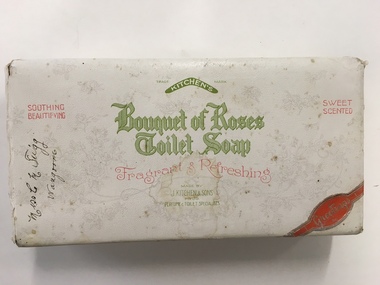

Warrnambool and District Historical Society Inc.Box, Bouquet of Roses Toilet Soap, Mid 20th century

... fire destroyed their premises. However after rebuilding... luck plagued them again after two years when fire destroyed ...The business of Kitchen and Sons began in 1856 when John Kitchen began to make tallow candles in their backyard in Emerald Hill but had to move two years later due to it being an offensive trade. Bad luck plagued them again after two years when fire destroyed their premises. However after rebuilding , the expanded and moved to Footscray ten years later. Over the next 30years the business expanded further employing upwards of 300 people and became one of the leading manufacturers of soaps, candles and associated products in Australia and New Zealand. They were makers of long standing brands such as Velvet soap and Solvol and by the mid 1920's were employing about 1400 people. It was around this time that they merged with the Lever Co of Sydney and after absorption of other soap companies over the next 40 years , the company became known as Lever & Kitchen in 1962. This box contained gift soaps and probably belongs to the period prior to 1924. Miss C M Trigg of Wangoom was the owner. A common item with links to a district family.White card box with overlapping lid which is covered in white paper with green and red text. A red banner across right bottom corner. Light grey floral pattern as background.Miss C M Trigg Wangoom written in black ink on left corner. Made by J Kitchen & Sons Pty Ltd.warrnambool, warrnambool history, wangoom, c m trigg wangoom -

Warrnambool and District Historical Society Inc.

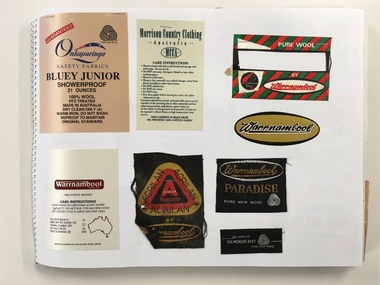

Warrnambool and District Historical Society Inc.Booklet, Scrap Book Warrnambool Woollen Mill, Late 20th century

... to the directors of the Warrnambool Woolen Mill Company. After being... to the directors of the Warrnambool Woolen Mill Company. After being ...In 1869, the Warrnambool Meat Preserving Company commenced their business on the site, where it operated until 1875 when it was sold to the directors of the Warrnambool Woolen Mill Company. After being destroyed by fire in 1882 it wasn’t until 1910 that the Warrnambool Chamber of Commerce was approached by Marcus Saltau and Peter McGennan to invest in a new mill. The original directors were James Dickson, P J McGennan, Robert Swinton, M Saltau, and J W Younger. In 1955 the Warrnambool Woollen Mill formed a partnership with the Wangaratta Woollen Mills. Dunlop bought the mill in 1968. From that time until its closure in 2000 it had a number of different owners, the last being the Smith Family Industries.This book contains a large number of labels some of which would have been sewn to the corner of the many blankets which were manufactured over the long history of the Woollen Mill.Some are cloth of a satin type. Some state care instructions and some have been made under other name brands such as Myer, Patersons and Nile. There is also a range of types of blankets such as travel and picnic rugs, baby blankets.Some are pure wool, others are a blend of synthetic and wool, mohair. In the latter stages of its operation, under the ownership of the Smith family , recycled woollen product was produced.This is an interesting collection of labels which were produced and collected over a long period of time and therefore provide a valuable insight into different styles and variety of the blankets produced by the Warrnambool Woollen mill which played a large part in the social and employment history of the city for nearly all of the 20th century. The different styles and colours provide a snapshot of design and artistic styles of the period. Large Spirax folder with yellow and white check patterned cover with dark blue writing.A Warrnambool label in gold,black and white is glued to front cover . Back cover is grey heavier card. The white pages have a large number of labels which relate to the Warrnambool Woollen Mill . Some are stapled and others are glued.Genuine drawing cartridge 48 sheets . Made in Indonesia.warrnambool, warrnambool woollenmill,warrnambool blankets warrnambool blankets labels, -

Wooragee Landcare Group

Wooragee Landcare GroupPhotograph, 28th April 2004

... National Park and had survived after a bush fire in 2003 had burned... National Park and had survived after a bush fire in 2003 had burned ...This photograph was taken at Wooragee Hall on Wednesday the 28th of April 2004 called 'Queries about Quolls' and shows a Quoll Presentation by Andrew Murray at Mt Pilot, Chiltern Mt Pilot National Park. The photograph shows (L - R) Jerry Alexander, Unknown, Unknown, Mary Prowse, Tony Prowse. The event was hosted by the Wooragee Landcare Group and was led by Andrew Murray (of Parks Victoria), President of the South-East Forest Spotted-tailed Quoll Working Group and one of Victoria's leading authorities in quolls. As the name of the event would suggest, this session provided attendees with insight and general information on quolls, including the characteristics of quolls, the habitat of quolls and the techniques that can be used when searching for quolls which was part of a wider project aimed at protecting the endangered species of the tiger quoll, also known as the spotted-tailed quoll, an animal that once inhabited Mount Pilot-Chiltern National Park. This particular photo shows a group of attendees looking at a typical quoll nesting site in a rock crevice. According to an article included in the Wooragee Landcare group coordinators annual report 2004 and 2005 album (record 00001), Andrew Murray had been tasked to train a team of Department of Sustainability and Environment staff and volunteers from the local area (Beechworth and Wooragee) in the detection skills needed to establish whether the tiger quoll still inhabited the Mount Pilot-Chiltern National Park and had survived after a bush fire in 2003 had burned through the area where they would normally have been found. The Tiger Quoll is the largest of the quoll species. Largely resembling a cross between a possum and a cat, the quoll is distinctive due to the white spots that are often found all over its brown fur.This photograph is significant as it provides evidence of a project undertaken by the Wooragee Landcare Group to educate themselves and members of the public on the tiger quoll in the early 2000s in an attempt to better understand and protect the species. The Wooragee Landcare Group has been instrumental in the co-ordination of programs relating to biodiversity protection in the local area, providing great assistance to landholders.Landscape coloured photograph printed on gloss paperReverse: WAN NA 0ANA2N0 AN2 0 1636 / [PRINTED] (No.4) / 918wooragee, wooragee hall, wooragee landcare, wooragee landcare group, quoll, spotted-tailed quoll, tiger quoll, queries about quolls, south east forest spotted-tailed quoll working group, andrew murray quolls, mount pilot chiltern national park, quoll species, endangered quoll, andrew murray, beechworth, landcare group, mount pilot -

Forests Commission Retired Personnel Association (FCRPA)

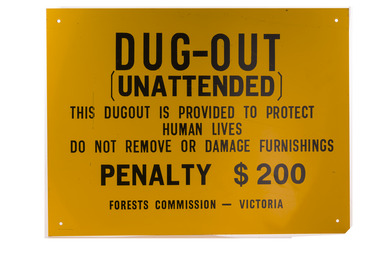

Forests Commission Retired Personnel Association (FCRPA)Dugout sign, Post 1966

... that remained in the forest after the 1939 fires. Many remote logging... that remained in the forest after the 1939 fires. Many remote logging ...Considered in terms of both loss of property and loss of life, the Black Friday bushfires on 13 January 1939 were one of the worst disasters to have occurred in Australia and certainly the worst bushfire up to that time. The fires burnt 2 million hectares, 69 sawmills were destroyed, 71 people died, and several towns and sawmills were entirely obliterated. Among those killed were four men from the Commission The subsequent Royal Commission conducted by Judge Leonard Stretton has been described as one of the most significant inquiries in the history of Victorian public administration. Its recommendations led to sweeping changes. In addition to building dams and water points, the Stretton Royal Commission recommended expanding and controlling the use of bushfire dugouts at forest sawmills. Well-constructed dugouts had saved the lives of many sawmill workers and their families during the 1939 bushfires. But in some locations, they had proved fatal. Dugouts became mandatory for those few sawmills that remained in the forest after the 1939 fires. Many remote logging coupes and FCV roading camps also had dugouts. The local District Forester was required to make annual pre-season inspections of all dugouts on State forests and those within the Fire Protected Area (FPA). Some were built privately on private land. Most were primitive construction with a log or corrugated iron roof covered with earth. A hessian bag often hung at the entrance to keep the heat and smoke out. But they were dark and damp with snakes and other creepy crawlies often lurking inside. By 1940-41 there were 19 new dugouts constructed by the Commission and a further 128 by forest licensees. Ten years later there were 8 new Commission dugouts and 21 new ones built by other interests. By 1960-61 the rate of new builds was declining but the Commission still managed 103 dugouts while 127 were looked after by others. However, as the forest road network improved and gave all-weather access to modern two-wheel-drive vehicles the reliance on dugouts receded.Large metal sign that was positioned near forest dugoutsbushfire, forest signs, forests commission victoria (fcv) -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

... to work after the glaze firing. For example – adding precious...! After firing your work will be in the student finished work ...The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

... to work after the glaze firing. For example – adding precious...! After firing your work will be in the student finished work ...The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

... to work after the glaze firing. For example – adding precious...! After firing your work will be in the student finished work ...The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate