Showing 352 items

matching peel

-

Ballarat Tramway Museum

Ballarat Tramway MuseumSlide - 35mm slide/s - set of 10, Campbell Duncan, Jan. 1971

Set of 10 Ferraniacolor slides - cardboard mounts taken on either 10/1/71 or 16/1/71. .1 - Birney No. 30, Golden Square line, inbound near Cathedral with car yard in background. .2 - ditto, with Cathedral gardens in background. .3 - single trucker, with two SEC roof adverts, entering Nolan St enroute to North Bendigo. Shows the driver sitting in a side on shot. A 4 square store in the background, with a fading advert for "Peeled Tomatoes". .4 - No. 6 turning from Nolan St into McCrae St with 4 square store in background. .5 - No. 26 at Quarry Hill with cemetery in background. .6 - No. 6 at the North Bendigo Terminus .7 - No. 26 outbound to Eaglehawk on the Railway Overbridge, Mt Korong Road. .8 - No. 17 (inbound to City and Quarry Hill) and another bogie crossing at a loop on the Eaglehawk line. Both trams have SEC roof adverts. The driver of the outbound car is boarding the tram. Based on .9, it is No. 3 at Long Gully. .9 - No. 3 waiting at Long Gully Loop . .10 - No. 26 at Quarry Hill terminus, with destination of Eaglehawk.In ink on slide: .1 - "1/2 mile out on Golden Square line - 10/1/71 (Sun)." .2 - "1/2 mile out on Golden Square line - 10/1/71" .3 - "Has just rounded curve near lake Weeroona on North Bendigo line - 10/1/71 (Sun)." .4 - "16/1/71" .5 - " 10/1/71 (Sun)." .6 - "North Bendigo terminus, 16/1/71 (Sat)" .7 - "10/1/71 (Sun) c 3pm" .8 - "Cross Eaglehawk line - 10/1/71 (Sun)." .9 - "Jackson St Loop on E'Hk line awaiting up - 10/1/71 " .10 - "Quarry Hill terminus Bendigo - - 10/1/71"tramways, trams, bendigo, golden square, high st, nolan st, north bendigo, quarry hill, long gully, railway bridge, tram 30, tram 6, tram 26, tram 17, tram 3 -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Top Hat and Bowler Hat, Woodrow & Sons, Early 20th century (.1 Top Hat)

This top hat, with the initials J.H.H., belonged to John Hunter Henderson, a doctor who practised in Warrnambool from 1904 to 1939. For many years he was a member of the Warrnambool Hospital Board of Management. On his retirement in 1939 he went to live in Melbourne where he died aged 81. The John Hunter Henderson fund was established at the Warrnambool Hospital to develop the training facilities for medical and nursing staff. The bowler hat belonged to his driver (name unknown) and it is presumed that he drove a horse and buggy in the early years of the 20th century. These items are of considerable significance as they are associated with Dr Henderson, a long-serving doctor in Warrnambool and they show the status and comparative affluence of doctors in the first half of the 20th century. .1 This is a black top hat with the crown covered in beaver fur or felt of some kind. The upturned brim is slightly worn on one edge. The crown has a black corded band with a bow on one side. There is a stud with an air hole on the crown. Inside there is a brown leather lining with information on the maker on the inside base and a crown image. .2 This is a bowler hat made of black felt with lining on the edges of black cotton material. The brim is slightly turned up on the sides. The crown has a black corded band with a bow at one side. There is a circle of air holes on the side of the hat. Inside there is leather lining with some information on the maker on the inside base. .3 This is a hat box lid with a leather covering over cardboard. It is a spherical shape with some side damage where the leather is peeling. There is a leather strap handle with a metal buckle. There are remnants of travel labels pasted on to the lid. .4 This is a hat box made of leather with a metal lock on one side. It has remnants of paper travel labels on the sides. Inside the box is an insert made of maroon-coloured cardboard for storing the top hat. This insert has a leather strap to stabilize the hat. There is a name on the base of the box written on a piece of adhesive plaster. .1 J.H.H. Woodrow & Sons Hat Manufacturers to H.M. the King 13 Market St Manchester, 8 Castle St Liverpool, 45 Piccadilly London, 42 Cornhill, London, 11 Gordon St Glasgow, 40 Westmoreland St Dublin, Made in England Lincoln, Stuart & Coy Proprietary Limited Flinders St Melbourne .2 The Tropical Hat .3 Midland Railway .4 Dunedin, F.H.Moreton doctor john henderson, warrnambool, history of warrnambool, top hat -

Ballaarat Mechanics' Institute (BMI Ballarat)

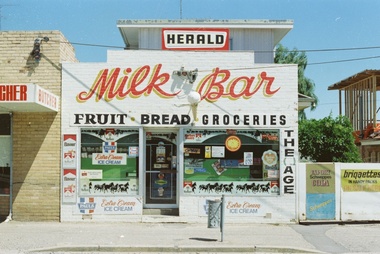

Ballaarat Mechanics' Institute (BMI Ballarat)Landsborough St Milk Bar, Geoff Wallis, 1970s

This photograph is held in the Ballaarat Mechanics' Institute Audio Visual Collection. Please contact BMI for all print and usage inquiries. Ballarat artist and educator Geoff Wallis took a series of photographs of Ballarat Milk Bars in the 1970s. This is one of his favourites. He notes: “My ‘local’ is not the pub that stands on a corner only 100 metres from my home but the milk bar that is across the road from the pub in Peel Street North. It is an extraordinary example of the milk bar fulfilling its time-honoured role of being every suburb or town’s Aladdin’s Cave. It is well worth a visit. I photographed this milk bar in 1979 when it was a much more conventional shop and then continued on taking photographs of all the milk bars I could locate around Ballarat. The photographs were to be the starting point for an artistic project but this didn’t eventuate. Though my motivation was primarily artistic I was also interested in milk bars as familiar and essential parts of daily life. Their accoutrements of Peters Ice Cream cones, newspaper headlines, and colourful signage made them distinctive features of the townscape. Milk bars had been part of my life from when I first was sent to ‘the shop’ as a little boy clutching a ration card. My parents bought a milk bar in Camberwell when I was nine and though I only lived there for a year, it is still vivid in my mind. Lollies, comics, ice cream, milkshakes -- all the treasures essential for a happy childhood -- awaited any child who pushed through the door. Though milk bars were once scattered throughout the city, competition from many sources is making them an endangered species.”ballarat, milk bar, shop, landsborough, herald, groceries -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Black & White Photograph/s, late 1920's

Yields information about a vehicle the Electric Supply Co of Victoria used to provide additional services in Ballarat in the face of bus competition. See page 59 of Golden City and its Tramways for further information.Black and white photograph contained within Reg. Item 2488, page 55, of ESCo or Ballarat Tramways motor bus, with the destination of Mt. Pleasant on the side. Driver W. Irwin? Handwritten caption by H.P. James. Note Item Not formally Numbered. Image btm2507i2 shows position on page relative to items 2507 to 2512. For a copy photograph of this image, see Reg Item 3813. High Res Images added 15/3/2011. Digital scan of a negative in the Wal Jack Collection added 21/4/2019 as image btm2510i4Handwritten in Pencil under the photograph is "Here is an interesting picture. Note the driver he is W. Irwin who gave me these pictures for which I am very grateful. The bus petrol engine International type was formerly in the possession of, one, Cruickshanks, an independent driver with a permit from the council to run between The Point of Pictures?, Ness St, Mt Pleasant via Bond St, Peel St. to City but the Electric Supply Coy purchased the vehicle and ran it from 1927 to 1929 (unpayable). The most use it was put to was on Mt Pleasant, but it ran also to High School as replacement for trams on Sebas if an electric tram was derailed. Perhaps the most unique trips it ever made was between Forest St. Wendouree to the Aerodrome, 1929, on the occasions of any ?? flight. Again Mr Irwin was the driver (& made two trips)"tramways, trams, esco, motor buses, mt pleasant, cruickshanks -

Eltham District Historical Society Inc

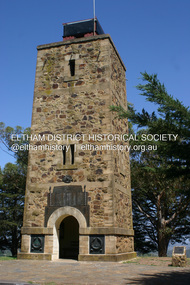

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, Shire of Eltham War Memorial, Kangaroo Ground, 28 January 2008

The Eltham Shire War Memorial, a tower of remembrance, was built with public donations to commemorate the memory of the fallen soldiers from the shire who enlisted in the 1914-1918 war. The tower is reminiscent of the peel-towers or watchtowers that lined the English-Scottish border from the mid 14th century to around 1600 and is constructed from locally quarried stone. This uncommon and picturesque war memorial, which affords an excellent view of the surrounding district was unveiled by His Excellency the Governor-General (Lord Stonehaven) on November 11, 1926. In July 1922 a deputation of returned soldiers from Panton Hill, presumably the Panton Hill branch of the Returned Sailors and Soldiers Imperial League of Australia (RSSILA), proposed to Eltham Shire Council that the monument should be a cairn of local stone “sufficiently high to form a prominent and conspicuous landmark, and crowned with some suitable device”. Eltham Shire Councillor and President of the Panton Hill branch of the RSSILA, Basil Hall, was credited with being the first to suggest a tower, and with organising a Memorial Park committee to raise funds for the monument in the Memorial Park. A meeting for those interested in the establishing a War Memorial monument in the park was held in January 1924 and the Eltham Shire War Memorial League was formed for this purpose. It appears that the broad and rounded cairn that had been recently built was considered by the League a temporary affair, and not the substantial cairn-as-monument, sufficiently high to form the conspicuous landmark, which had been envisaged by the Panton Hill RSSILA. A design competition was held for the monument. The chairman of the League, Councillor Basil Hall, suggested that the site of the memorial in Kangaroo Ground would lend itself to something rugged, instead of polished stone. By April 1924 thirty designs for a memorial had been received from which three designs were selected and of those, the design by the shire engineer Mr McCormack, for a 70ft tower suitable for construction in rough stone, was chosen. Artist Harold Herbert suggested that a peel tower-like design reminiscent of those along the English-Scottish border would be fitting for the site. Herbert drew up a rough sketch that was approved of, and later, Melbourne architect Percy Meldrum volunteered to draw up the design from sketch to architectural drawings. By January 1925 the Soldiers’ Memorial League had adopted Meldrum’s design for a 50ft high tower. Meldrum had also offered his design and supervision of construction free of charge. The Shire provided the stone to the builders, which was a gift quarried from land owned at Kangaroo Ground by Dr Ethel and Professor William Osborne The Shire of Eltham War Memorial, a tower of remembrance, and honour board were unveiled on November 11, 1926, by the Governor General Lord Stonehaven. At this stage a temporary honour roll was painted on the panels on either side of the tower entrance. In September 1930 bronze plates were added above the portal with the names of men who fell in the 1914-18 war. On November 16, 1951, the Governor of Victoria, Sir Dallas Brooks re-dedicated the war memorial tower and unveiled the names of men who gave their lives in the 1939-45 war. Two additional bronze plaques which recognise service in the armed conflicts of Korea, Borneo, Malaya, and Vietnam were unveiled November 11, 2001, by the Governor of Victoria, John Landy, A.C., M.B.E. The tower was first used for fire spotting activities following the Black Friday bushfire in January 1939 in response to a request from Mr R.D. Ness, secretary of the Kangaroo Ground bush fire brigade, who asked Council that the tower be used as an observation tower for detecting bush fires, and asked Council to arrange a telephone to be installed. It was suggested that if the Shire were to appoint a caretaker for the Memorial Park, his duties could also include raising the alarm in the event of a fire. Later in 1939 Council applied for a radio transmitter, which the Forestry Commission planned to install at vantage places throughout the state. The first dedicated fire spotter appointed from December1948, was Mr Smith of Warrandyte. A prefabricated glazed cabin was installed in 1974, which involved the removal of the original stone structure around the rooftop exit door. A new fire spotting cabin, which included the latest technology, was installed soon after the 2009 Black Saturday fires and is manned by CFA personnel on high fire danger days. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p123This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. While published in the book in black and white, this collection features the original colour digital photographs. nillumbik now and then (marshall-king) collection, garden hill, kangaroo ground, memorial park, shire of eltham war memorial -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Grater

François Boullier of France and Isaac Hunt of England both took credit for inventing the cheese grater in the 1540s. Ingredient supplies, mainly milk, ebbed and flowed in both France and England, as they have in the United States during this coronavirus pandemic. Boullier originally aimed to use up an overabundance of cheese in Paris. An avoidance of meat led French farmers to convert their meat herds (often boys) to dairy-producers (girls), which led to more milk and even too much milk, which led to a market flooded with cheese. Boullier made his first cheese grater out of pewter to grate hard, sometimes dried out cheeses, which turned them into a sort of condiment. Pewter is known as a rather soft metal, and Boullier’s original grater is reportedly on display in a museum in Le Havre, France. Isaac Hunt wanted to stretch cheese due to a shortage in England, so he grated and melted it for Welsh rarebit and other dishes. Grating cheese allowed more even distribution of the cheese to melt it in cooking and still does. During the Great Depression of the 1930s, Philadelphia cheesemonger and entrepreneur Jeffrey Taylor also wanted to stretch cheese for to bulk up cheese features, including vegetables, to make them look like more filling food during difficult economic times. Taylor read about Boullier’s invention and made his own by sharpening the holes of a metal shower drain. For the last century, many companies have tried to improve the cheese grater and invent a new “latest” one that we all must-have. Graters are now made of all sorts of materials including bamboo, wood, and various metals. Some are decorated with clowns’ heads, some are shaped like plastic frogs, while others bear knuckle protectors. They vary in size, shape, and function. Grating slots come with different angles and shapes of slots and can grate everything from zucchini, onions and cheese, to cooked eggs, coconut, potatoes, cabbage, and lemon and orange peel, and possibly even create wood shavings. Smaller graters grate ginger and garlic. https://www.cheeseprofessor.com/blog/antique-cheese-gratersThe grater has been used for hundreds of years and has proved its worth in the kitchen throughout history.Grater metal (3 parts) Tripartite with hinges for folding.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, grater -

National Wool Museum

National Wool MuseumPainting, The White Farm, 2020/21

The farm buildings that Linda Gallus has studied and painted are on the farmland adjoining the Leura Park properties in Curlewis, on the Bellarine Peninsula. The current owner of the property told Linda that he bought the farm in 1994. He has used it for both sheep and cattle grazing since purchasing the property. When the farmer bought the land all the buildings on the property were painted white for sale, despite the fact they were very old. The shearing shed was in use up until the time of sale but was in a bad state of disrepair. The roof, stumps and floor required replacing. The building was no longer in use after the sale, so the shearing shed gradually fell into further disrepair. The previous owner had also used the property for growing potatoes, crops and livestock, mainly sheep. Linda’s fascination with the property came when she caught a glimpse of the white chimney over the hill driving towards Point Lonsdale, which still stands proud today on the roof of the old shearing shed. The owner kindly allowed her to visit the property over the past few years to capture the buildings using photography and painting. During this time many of the buildings have fallen. Linda calls it The White Farm as there are remnants of that original white paint on the outside of most of the buildings giving it a strange and rather beautiful patina. The structures are wonderful remnants of the history of the Bellarine. Linda first spotted the old shearing shed when she was driving home to Clifton Springs from Geelong. It was the white chimney on the shearing shed that stood out behind the rolling grassy hills. It was intriguing – bright white and still in good condition, unlike the rest of the building. After further investigation Linda got to know the owner of the property and visited it frequently to draw, take photos and paint. There is a variety of lovely old buildings on the property, but it was the shearing shed that held extra fascination for Linda. The most intriguing thing for Linda was that the buildings were all painted white at some stage and now the patina of peeling paint and bleached timber brought a wonderful mood and feeling to the farm. This is what she has tried to capture in this series of 11 paintings. Most of the buildings are falling, so Linda felt an urgency to capture them using acrylic paint on canvas in order to commemorate them forever.Acrylic Paint on Canvas. The images both feature a falling down shearing shed as the central focus. The wood of the shearing shed is a central theme of importance. The old buildings were painted white for sale despite being in a state of structural instability. After time this same painted wood has been left with an interesting complex patina like film on the surface which the artist has taken great care to capture. Image 1 is titled ‘Another gust of Wind’. It shows the exterior of the shearing shed which is in the process of collapsing from the forces of mother nature. In the background of this painting another of the buildings in the ‘White Farm’ complex is visible, in addition to blue skies and overgrown green grasses. Image 2 is titled ‘Green Trough’. It features the interior of the same collapsing shearing shed. The image is painted as though the viewer is peering through a crack of the external wall. Internally a green trough is seen hanging on an internal fence. Unlike everything else in the shearing shed, the trough appears new and in good condition. It provides a strong juxtaposition to the rest of the shearing shed, and the larger surrounding ‘White Farm’ complexbellarine peninsula, the white farm, shearing shed -

National Wool Museum

National Wool MuseumTextile - Blanket, Eagley Mill, 1955-59

This blanket was owned by the Rosenberg family from the late 1950s onwards. It was the donor Denise’s blanket. Born May 1958, her late mother Elfie kept it safe for many decades after Denise had outgrown it. Elfie returned the blanket to Denise 20 years ago, in its current near new condition. Jacques Rosenberg and Elfie née Naparstek, Denise’s parents, met in Melbourne in the Summer of 1950. They both survived being young and Jewish in Europe during the Second World War. Jacques grew up in France and Elfie in Germany, she was a child of the Kindertransport. They married in 1952 and by 1958 had a son and two daughters. Denise, the youngest daughter, donated the blanket on behalf of the Rosenberg family to the National Wool Museum in 2021. The Kindertransport was a program designed to facilitate the immigration of Jewish children from Nazi Germany before the outbreak of the Second World War. The United Kingdom took in nearly 10,000 predominantly Jewish children from Germany, Austria, Czechoslovakia and Poland. The children were placed in British foster homes, hostels, schools and farms. Tragically, these children were often the only members of their families to survive the tragedies that were to unfold in Europe. Fortunately, Elfie’s parents did survive World War Two by sneaking out of Germany and into the south of France. After Elfie and her sister Serry were Kindertransported, they met up with Salma and Risla Naparstek in Paris in 1947 before migrating to Australia. This blanket originates from the Eagley Mill. They manufactured woollen, worsted and knitwear products from their mill located in Collingwood. Part of Foy & Gibson, the mill had frontages measuring almost two miles within the area bounded by Little Oxford, Wellington, Stanley and Peel Streets in Collingwood. This was the largest manufacturing plant for wool in the Southern Hemisphere at the time. It was also one of the oldest. The first machines for knitting men’s socks were installed in 1896. The site ultimately went into receivership while under new ownership in 1968 and is now high-end real estate. More information about the Mill can be read via Unimelb digitised collection. https://digitised-collections.unimelb.edu.au/bitstream/handle/11343/21262/269411_UDS2010852-85.pdf?sequence=18&isAllowed=y 38”x45” (965 x 1145mm) cream wool blanket. The blanket has white stitching around its edge. Embroidered in the centre of the blanket is a koala eating leaves with accompanying flowers on either side of the marsupial. In the bottom right corner of the blanket a small square label from the Eagley Mills is stitched. This label includes the images of a Sphinx head, a pyramid and a baby’s crib.Eagley / ALL / WOOL / 38”x45” / AWARDED THE CERTIFICATE OF / THE ROYAL INSTITUTE OF / PUBLIC HEALTH & HYGIENE LONDONkindertransport, eagley mill, blanket -

Melbourne Tram Museum

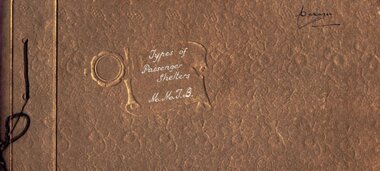

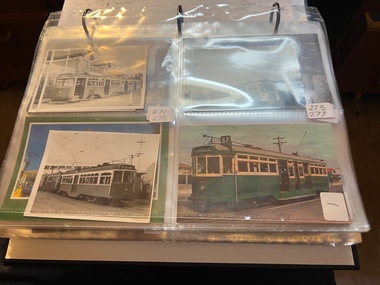

Melbourne Tram MuseumAlbum - Photo Album, Melbourne & Metropolitan Tramways Board (MMTB), "Types of Passenger Shelters MMTB", mid 1930's?

Photo Album - brown cards covers, containing 12 heavy card sheets bound with a brown cotton cord titled "Types of Passenger Shelters MMTB". Ten sheets have two photos of shelters except for the last one giving location and cost. Sheet 1 - Two shelters at Wattle Park 2 - Batman Ave and Peel St; Flemington Road with cable trams in the background. 3 - Victoria Parade and Smith St; Ballarat Road and Gordon St Footscray 4 - Dandenong Road and Hawthorn Road Caulfield; photos of the standard shelter, 6 Number, for St Kilda Road, Alfred Hospital and Gisborne St East Melbourne. 5 - East Kew terminus; Camberwell Road and Smith Road 6 - Oakover Road and Gilbert Rd Preston, Flemington Road at Abbotsford St North Melbourne 7 - Swanston St and Grattan St Women's Hospital with a Bundy clock and street fire alarm in the view; Victoria Parade Fitzroy opposite Eye and Ear hospital with a W class tramcar and the Eastern Hill fire station in the background. 8 - Two photos of the shelter at the corner of William St and Collins St Melbourne. 9 - Toorak Terminus; Rennie and Nicholson St Coburg 10 - Market St terminus City. Images taken from the website production 16-1-2019 - see - http://www.hawthorntramdepot.org.au/papers/shelteralbum.htm On inside back cover is a Kodak label "Scroll" with "3" entered in ink. Date unknown, thought to be mid 1930's - see Reg item 3361 of the construction of William St shelter post 1933.in black ink "Manager" in top right hand corner.trams, tramways, shelters, mmtb, wattle park, victoria parade, st kilda rd, flemington rd, toorak, camberwell, market st, coburg, footscray, preston, caulfield -

Melbourne Tram Museum

Melbourne Tram MuseumAlbum - Robert Thomson Slide Collection, "Melbourne 1970 - 1979", 1970 - 1979

Photo - see pdf file for further information. Number Brief Description RT264 Elizabeth St, at Bourke St, with the construction of the State Savings Bank building (State Bank Galleria) underway. Bourke St Mall also under construction, Note tram warning Sign, tram 1065 - "West Maribyrnong" - route 57 RT265 St Kilda Road, tram 778 - "City" -route 59 RT266 St Kilda Road, tram 569 - "East Malvern Darling Road" -route 3 & tram 819 - "Glen Iris" - route 6 RT267 Swanston St, tram 538 - "City" - route 2A RT268 St Kilda Junction, tram 924 - "City" - route 5 RT269 St Kilda jct, tram 280 - "St Kilda Beach" - route 15 RT270 St Kilda Road, tram 507 - "City" - route 72 RT271 Nicholson St Gertrude St - tram7 - "East Preston Tyler St" - route 88 RT272 West Coburg, tram 778 - "Domain Rd" - route 55 RT273 Wests Road, tram 750 - "Moonee Ponds" - route 22 RT274 St Kilda Rd, tram 8 - "Special" RT275 Nicholson St Victoria Pde, tram 10W - "Special" RT276 L Class Queens way, "City" - route 54 RT277 Bourke St at Spring St, tram 998 - "East Coburg" - route 88 RT278 Nicholson St MMTB Bus, bus 562 - "Garden City via Port Melb" - route 2 RT279 Church St Burwood Rd Jct, tram 9 - "Special" RT280 Riversdale Rd at Camberwell Depot - "Burwood" - route 74 RT281 Balaclava Junction - tram 819 - "Kew Cotham Rd" - route 69 RT282 East Brunswick Terminus, tram 4 - "City Spencer St" - route 96 RT283 Peel St - tram 927 - "Special" RT284 East Brighton Terminus - tram 563 & tram 926 - "City" - route 64 RT285 Dandenong Rd Hawthorn Rd, tram 346 - route 64 RT286 Bourke St at Spring St, tram 34 - "North Fitzroy Park St" - route 97 RT287 Route 69 Terminus St Kilda - tram 369 - "Kew Cotham rd" - route 69 RT288 Route 78 Terminus St Kilda, tram 498 - "North Richmond" - route 78 RT289 Track relay, Fitzroy St, St Kilda RT290 Fitzroy St, St Kilda Demonstrates the work of Robert Thomson in photography, collection and/or production of slidesAssembled album in a black presentation folder of 27 colour slides, collected or produced by Robert Thomson. All photographs have been scanned and placed on the Museum's G drive. A list of all photographs with details has been compiled. melbourne, tramways, trams, track construction, elizabeth st -

Melbourne Tram Museum

Melbourne Tram MuseumAlbum - Robert Thomson Slide Collection - box 15, 1989

Photo - see pdf file for further information. Number Date Brief Description RT341 14-4-1974 PCC1041 at Wattle Park RT342 17-4-1974 St Kilda Road Extension – was High St and Brighton Road RT343 31-3-1975 PCC 1041 at Moonee Ponds Junction RT344 1989 SW6 914 Truganini Road, single line RT345 Jan 90 Z59 westbound in La Trobe St route 89 RT346 Apr 89 W 380 Albert Road with A283 on St Kilda line over bridge (Tours database provides a date of 25-6-1989 for an ARHS tour) RT347 1989 Truganini Rd duplication work RT348 1989 Truganini Rd duplication work RT349 1989 Truganini Rd duplication work’ RT350 Jan 90 SW5 763 Balaclava Junction RT351 Apr 1989 W2 533 Overhead test car Victoria Parade and B class RT352 Apr 1989 W2 533 overhead test car Port Melbourne line RT353 Apr 1989 ditto at Port Melbourne station RT354 Jan 1990 11W scrubber in William St RT355 1986 Transport Art tram SW5 731 - Painted by Lesley Dumbrell RT356 Apr 89 SW6 869 leaving Malvern depot RT357 Apr 89 W1 431 on tour – Truganini Road RT358 Apr 89 W1 431 at East Brighton terminus RT359 Apr 89 W380 and W1 431 on tour Albert Road South Melbourne RT360 Apr 89 W1 431 East Malvern Darling Road RT361 c1989 L 104 William St and Z95 at La Trobe St RT362 c1989 L 104 Peel St RT363 Jan 1990 SW6 921 Balaclava Junction RT364 Apr 1989 B2 2007 Victoria Parade RT365 Apr 1989 B2 2007 Mont Albert terminus RT366 Apr 1989 B2 2007 Bundoora line Plenty Road RT367 Apr 1989? Z3 209 and B2 200) at Bundoora terminus RT368 Apr 1989? B2 2009 and Z2 111 at Bundoora terminus RT369 Apr 1989 W5 839 and W1 431 Truganini Road RT370 Apr 1989 W1 380 Albert Road and B2 on over bridge RT371 Apr 1989 SW6 923 Dandenong Road Demonstrates the work of Robert Thomson in photography, collection and/or production of slidesAssembled album in a black presentation folder of 30 colour slides, collected or produced by Robert Thomson. A list of all photographs with details has been compiled. melbourne, tramways, trams, tram 1041, wattle park, st kilda road, tram 914, tram 59, truganini road, tram 380, st kilda light rail, tram 283, tram 763, balaclava junction, tram 533, port melbourne, tram 11w, william st, transporting art, tram 869, tram 431, tram 104, east malvern, east brighton, peel st, victoria parade, mont albert, bundoora, tram 2007, tram 209, tram 2009, tram 111, tram 839, albert road, tram 923, dandenong road -

Bendigo Historical Society Inc.

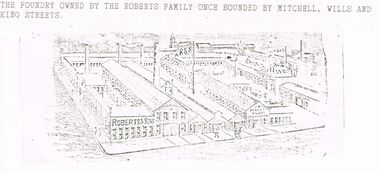

Bendigo Historical Society Inc.Document - CORNISH COLLECTION: DOCUMENTS RELATED TO VARIOUS CORNISH ENTERPRISES IN BENDIGO

Documents and copies of photos related to various Cornish enterprises in Bendigo: a. Line drawing (faint) of foundry owned by the Roberts family (Mitchell, Wills and King streets); b. copy of article from unknown source re United Iron Works with details of the firm and Roberts principals - William Roberts, Abraham Roberts and Arthur Roberts - with copies of photographic portraits (Bartlett Bros.) - bad copy with LH side of text partly illegible; c. copy of article titled 'Goyne's Battery Gratings re John Goyne and history of the business (submitted by person living at ''Rosemundy'', Goynes Road, Epsom - Goyne's home then on 20 acres); d. Photograph of old Robinson photo of Bendigo Stamper Grating Factory, Epsom and five men posed in front of large timber building (badly cut photo with LH edge missing. original photo (9 x 13) of ''Former Bendigo Cornish Fuse Factory'' (handwritten inscription on reverse) taken in recent times (hint - car in driveway); f. copy from un-named book of J Nankervis's Ham and Bacon Curing Factory, Golden Square - drawing of the establishment and a photos of winning display of small goods at the Bendigo Show (no date); g. copy from un-named book of photo of premises of A J Williams, Lily and McKenzie Streets - wooden structure with sign indicating Hardware Merchants and ??Mines Furnisher?? , showing three horse-driven small wagons (delivery?); h. copy of photo of Cornish store(1880s) at White Hills - mention of Frederick Stuckenschmidt (married Miss Mary Smith), William Mathews (original owner?) - corner brick building with family posed outside alongside horse and light cart;. reproduction of exhibit in Bendigo Spring Show, 1915 , the ''Made in Bendigo Exhibition'' - first prize awarded to Messrs H M Legg & Co. Progress Jams, preserves, tomato sauce, tomatoes products, candied peels etc. (folded and small tear).bendigo, buildings, early bendigo businesses, bendigo stamper grating factory. epsom. j. nankervic ham and bacon curing establishment. golden square. bendigo cornish fuse factory. cornish stores. messrs h. m. leggo and co. abraham roberts. arthur roberts. william roberts. goyne's battery gratings. -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photograph - Colour, Ballarat School of Mines and Industries, Ballarat Students Representative Council Executive Board, 2015, 03/12/2015

The board was started in 1959 with the opening of the E.J. Tippett Recreation Hall (formerly the Ballarat School of Mines Museum).Photographs of the Ballarat School of Mines and Industries, Ballarat Students Representative Council Executive . The board includes the President, Secretary, Treasurer and Sports Secretary. Photos also include members of the 2015 reunion who are written on the board.ballarat school of mines students representative council executive, src, e.j. tippett recreation hall, widdop, bethune, witcher, weir, coutts, hart, mcdonald, waybury, titheridge, jones, williams, rodger, levings, reimann, tay, delosa, peel, brauer, costa, hunter, nachiapham, muntz, tapscott, skene, atkins, weybury, anderson, mullins, collier, nash, dobie, johnson, rogers, tulloch, thorne, chung, elshaug, day, sordello, pittard, dower, lynch, cutter, agrums, penna, grubb, davis, tiheridge, baker, court, cooper, tucker -

The Beechworth Burke Museum Research Collection

The Beechworth Burke Museum Research CollectionCard (Series) - Index Card, George Tibbits, Camp Street (Cnr Camp & High Streets), Beechworth, 1976

George Tibbits, University of Melbourne. Faculty of Architecture, Building and Town & Regional PlanningIndex system that support the research for Beechworth : historical reconstruction / [by] George Tibbits ... [et al]Arranged by street names of BeechworthEach index card includes: street name and number of property, image of property, allotment and section number, property owners and dates of ownership, description of the property according to rate records, property floor plan with dimensions.beechworth, george tibbitsbeechworth, george tibbits -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill -

Ballarat and District Irish Association

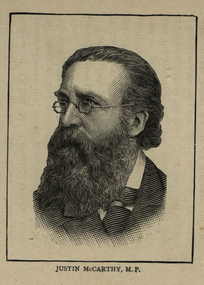

Ballarat and District Irish AssociationImage, Justin McCarthy M.P., 1864

McCarthy, JUSTIN, Irish politician, journalist, novelist, and historian, b. at Cork, November 22, 1830; d. at Folkestone, England, June 24, 1912. He was the son of Michael McCarthy, and was educated at a private school in his native city. At the age of eighteen he obtained a position on the literary staff of the "Cork Examiner". In 1853 he went to Liverpool as a journalist; in 1860 became Parliamentary reporter of the London "Morning Star", which he edited later (1864-68). From 1868 till 1871 he lectured with great success throughout the United States of America and was one of the assistant editors of the New York "Independent". On his return to England he contributed frequently to the "Nineteenth Century", the "Fortnightly Review", and the "Contemporary Review", and for many years was leader writer for the London "Daily News". From 1879 till 1896 he was a member of the British Parliament, representing the Irish constituencies of County Longford, Derry City, and North Longford. In November, 1880, he joined the Irish Land League, which won so many victories for the Catholic peasantry; two years later he became chairman of the National Land and Labor League of Great Britain. In 1886 he revisited the United States. From 1890 till 1896 he was chairman of the Irish Parliamentary party in succession to Parnell, having previously been vice-chairman for many years. His courtesy and moderation won him the respect of all parties in Parliament. Though participating so actively in the political life of Ireland, McCarthy took more interest in letters than in politics. His first novel, "The Waterdale Neighbors", appeared in 1867, and was followed by about twenty others, many of which are still popular. Of these the chief are: "Dear Lady Disdain" (1875); "A Fair Saxon" (1873); "Miss Misanthrope" (1877) and "The Dictator" (1893). Other publications were: "Con Amore", a volume of essays (1868), and biographies of Sir Robert Peel (1891), Leo XIII (1896), and Gladstone (1897). McCarthy's popularity as a writer depends rather on his historical writings, which are always lucid, forceful, and wonderfully free from party spirit. Of these works the most important are: "History of our own Times" (7 vols., London, 1879-1905), dealing with the events from the year 1830 to the death of Queen Victoria and supplemented by "Reminiscences of an Irishman" (1899); "A short History of our own Times" (1888); "The Epoch of Reform, 1830-1850" (London, 1874); "History of the Four Georges" (4 vols., 1884-1901), of which vols. 3 and 4 were written in collaboration with his son, Justin Huntly McCarthy well-known as a novelist and play-writer; "Ireland and her Story" (1903); "Modern England" (1899); "Rome in Ireland" (1904). Failing health and old age could not induce McCarthy to lay down his pen, and even as late as November, 1911, he published his "Irish Recollections", describing with his wonted charm the events of his earlier life. He was an ardent advocate of Catholic rights, and, though he had been indifferent for many years, in his old age he returned to the practices of his religion. A.A. MACERLEAN [http://oce.catholic.com/index.php?title=Justin_McCarthy, accessed 3/12/2013]Image of a bearded man wearing glasses. He is Justin McCarthy, M.P.ballarat irish, justin mccarthy, cork -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

Melbourne Tram Museum

Melbourne Tram MuseumAlbum - Charles Craig - part 2 of 2, 1950s to 1970s

Photo - see pdf file for further information. Number Brief Description CC271 Y1 610 and another at Camberwell depot CC272 Ditto CC273 Y1 613 at Batman Ave CC274 Y1 611 Peel St North Melbourne CC275 Y 469 Camberwell depot CC276 Ditto CC277 Postcard – L104 – MMTB CC278 L103, Hawthorn Road CC279 L103, Hawthorn Road CC280 L103 Dandenong Road CC281 L103 and w5 847 Dandenong Road CC282 L104 on Preston Workshops traverser CC283 Flinders St station with Ws CC284 Flinders St looking south along St Kilda Road to Shrine CC285 Postcard – Nu Color vue – Flinders St CC286 Postcard – Valentines – Flinders St No. 13 CC287 Postcard – Rose Series – 13595 – has been trimmed CC288 Postcard – Rose Series – 10660 – Princes Bridge and Flinders St yard CC289 Postcard – Rose but has been trimmed of Flinders St CC290 Postcard – same as CC285 CC291 SW6 914 and another car in Swanston St by Flinders St CC292 SW6 903 and bus 436 with Flinders St Station in background CC293 W5 776 at Flinders St Station CC294 W2 596 at Flinders St Station CC295 L101 and W2 Swanston St by Ian Brady CC296 Postcard - Biscay BG 250 – A 281 - CC297 W5 779 Maribyrnong River CC298 SW5 787 Queensbridge St CC299A Duplicate copy CC299 Ditto CC300 W5 812 St Kilda Junction CC301 W5 721 Carnegie? - CC302 W5 817 Elliot Ave – see also CC150 CC303 CW5 682 CC304 CW5 682 Dandenong Road CC305 SW6 855 Power St Hawthorn CC306 Argus photo same as CC8A CC307 Freight car 19 leaving South Melbourne depot CC308 Freight car 19 at South Melbourne depot CC309 Cleaner 7 CC310 W2 295 and 8 at South Melbourne Depot CC311 Cleaners 5, 8 and 7 and S or T at South Melbourne depot CC312 Freight car 17 with crew member CC313 Cleaners 5, 8 and 7 along with a tower truck and another road motor CC314 Wheel Transport car 16 at Preston CC315 Cleaner 7 CC316 Cleaner 6 Brunswick Depot R Hudson and Bob Prentice CC317 SW6 867 in Swanston at Flinders CC318 SW6 850 at Chapel and Brighton Road CC319 SW6 914 at Batman Ave CC320 SW6 963 and W5 826 in Collins St near Spencer St CC321 Sw6 923 RAAF tram CC322 Same image at 318, but better has initials T McC (Tom McCaw) CC323 Sw6 963 In Collins at Spencer St CC324 SW6 947 in Collins at Spencer St CC325 Ditto with crew CC326 SW6 850 at Preston Workshop – Argus photo CC327 SW5 843 at Swan and church, severely derailed – Herald photo CC328 SW6 886 in Victoria Parade near La Trobe CC329 SW6 948 turning from Union St into Maribyrnong Road – single curve CC330 W5 731 CC331 SW5 on a 4D – Herald WT photo CC332 Sw6 867 Swanston St with driver carrying handles etc CC333 SW6 954 – Truganini Cres CC334 SW6 915 illuminated for Christmas, the CDA father Xmas special CC335 SW6 850 on route 77 side on view CC336 Sydney R class 1845 on trailer in a busy road CC337 Sydney R class 1845 on trailer CC338 Ditto CC339 Ditto – on trailer turning from a local street CC340 MMTB Emergency van CC341 Ditto CC342 Welding truck – Hopkins and Leeds CC343 Welding truck – Hopkins and Leeds CC344 Welding truck in Hopkins St Footscray CC345 Negative – Hobart tram 103 CC346 Launceston tram CC347 Trackwork – East Kew CC348 Trackwork and a W2 East Kews CC349 SW6 892 and trackwork – East Kew CC350 W4 670 – FRONT ON CC351 W3 654 – Brunswick Depot CC352 W3 666 – St Kilda Road and High St Demonstrates the work of Charles Craig in photography and collection of prints.Assembled album in a black presentation folder of 80 photographs from the Charles Craig Collection - 31 sleeves - part 2 of 2. All photographs have been scanned and placed on the Museum's G drive. A list of all photographs with details where possible has been compiled. Victorian Provincial, Launceston, Hobart and Sydney tram photos have been transferred to other Museums, image files retained.melbourne, tramways, tramcars, trams, charles craig -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMemorabilia - Wood Sample, about 1871

The American wooden ship Eric the Red was named after the Icelandic Viking Eric 'the Red-Haired' Thorvaldsson, who was the first European to reach the shores of North America in 980 A.D. The ship Eric the Red was owned by the Sewall family of Bath, Maine, between 1873 and 1877 it operated in the coal trade between Britain and America. It then operated on the South American guano/ nitrates trade, before again trading between Europe and New York. On this voyage the Eric the Red had been chartered to carry a full cargo of American merchandise including many exhibits bound for the international exhibition to be held in Melbourne in 1880. Eighty-five days out from New York with 23 crew and two passengers, the Eric the Red approached Cape Otway nearing the end of its long voyage. At 1 am on 4 September the weather was hazy with a moderate north-westerly wind, Captain Jacques Allen had all sail set except for the mizzen-royal and the cross jack sails doing 8 knots, and was steering by the light to keep 5-6 miles offshore and clear of Otway Reef. Returning to the deck after consulting his charts the ship bumped as it ran onto the Otway Reef. It struck a second time and then a heavy sea carried away the wheel ropes and the man at the wheel. A third bump carried away the rudder, and shortly after this the ship completely broke up - within twelve minutes it had disappeared but for floating wreckage and cargo. Captain Jacques Allen recounted that: "The mizzen topmast fell with all the rigging, but strange to say, not a man was hurt by it, although they were all standing about. As soon as I found out there was no hope I said to Ned Sewell, the owner's son, and the third mate on board "Stick to me, and hang on to this mizzen mast". I peeled off everything I had on except my drawers thinking I would be able to swim better without my clothes; and Sewell and myself, clinging to the mast, were washed overboard...It was a fearful sea; I have never seen anything like it". Attempting to swim to a more substantial raft of wreckage, and losing touch with young Sewell in the process, Captain Allen struck out: " Just as I left the spar my drawers got down my legs, and entangled them, and down I went. I managed to clear one of my legs and on coming up I managed to get hold of some floating timber. There was a clear space of water between this timber and the deck, except for the spare royal yard, and I again started, but the surf struck me and I went over and over. I managed to get hold of the spare yard, and after holding on to it for some time I managed to get to the deck. When I was pulled on to it I could not move, being so numb and cramped with the cold. The men had some blankets and other things which they had got from the passengers' room in the deck house, and they wrapped me in these. Shortly after I got onto the wreck we made out the steamer's lights, and as soon as she was within hearing distance the men haled. This must have been about half-past four the Captain of the Dawn sent two of his boats to cruise about, and at daylight, they picked us up off the wreck. We had drifted about four miles from the reef where the ship struck, all those who were rescued were more or less bruised. One man had two or three ribs broken, and another had some fingers crushed off. My left foot is very much hurt, and I am black and blue from head to foot. I never knew such ten minutes as that of the wreck, and I thought the time had come for me to 'hand in my checks'. The ship was worth about £15,000, and neither it nor the freight was insured one dollar". (Argus 14/9/1880). Three of the crew and one of the passengers had been swept away and drowned. Fortunately for those clinging to the remains of the shattered hull and floating wreckage, the steamer SS Dawn passed close by and the crew heard the distressed cries of the survivors. Boats were lowered and the survivors were rescued. The Dawn stayed in the area for several hours searching for more survivors. One body was found washed up at Cape Otway and was buried in the lighthouse cemetery. The captain and crew of the Dawn later received rewards and thanks from the United States consul for their efforts. The hull and cargo were sold for £410, and large rafts of floating wreckage and cargo washed up all over the Victorian coast. A section of the hull lies buried in the sand at the Parker River beach, an anchor is on the rocks at Point Franklin, a second anchor is on display at the Cape Otway lighthouse and parts of the ship are on display at Bimbi Park and the Apollo Bay museum. Various wreckage is located in a concentration off Point Franklin, but suitable diving conditions are rare due to waves and strong currents. At the time of the wreck parts of its were salvaged and used in the construction of houses and sheds around Apollo Bay, including Milford House (since burnt down in bush fires), which had furniture and fittings from the ship, and the dining room floor made out of its timbers. A ketch the Apollo was also built from its timbers and subsequently used in Tasmanian waters.The Eric the Red is historically significant as one of Victoria's major 19th-century shipwrecks. The wreck led to the provision of an additional warning light placed below the Cape Otway lighthouse to alert mariners to the location of Otway Reef. The site is archaeologically significant for its remains of a large and varied cargo and ship's fittings being scattered over a wide area. The site is recreationally and aesthetically significant as it is one of the few sites along this coast where tourists can visit identifiable remains of a large wooden shipwreck and for its location set against the background of Cape Otway, Bass Strait, and the Cape Otway lighthouse. (Victorian Heritage Database Registration Number S 239, Official Number 8745 USA) Wood sample from the wreck of the ship Eric the Red the wood is dark in colour and is very light in weight. Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwreck-artefact, eric-the-red, zaccheus-allen, sewall, 1880, melbourne-exhibition, cape-otway, otway-reef, wood-sample, s.s.-dawn -

Federation University Historical Collection

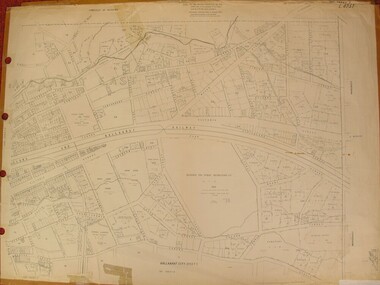

Federation University Historical CollectionPlan, Ballarat East, 1957, 1957

Dr George Clendinning and others were trustees of the Church of England (St Paul's) A number of enlargements of the Ballarat East maps. .4) Bakery Hill, Humffray Street, Victoria Street, Ballarat Youth Council .5) Specimen Vale, Victoria Street, Eureka Street, Housing Commission .10) - Tomber Reserve, York Street, Spencer Street, Bennett Street, Wilson Street, Rodier Street, Richard Street, Fussell Street, Turpie Street, Stockade Street, Ballarat Rifle Range Lal La Street, Clayton Street, Eureka Street Sheet 2 - Yarrowee Creek, High Street, Dinney's Dam, Binney Street, Oliver Street, Humffray Street, Morres Street, Finch Street, Scotts Parade, Rice Street, HOrnby Street, Queen Street, Newman street, King Street, Napier Street, Sim Street. Sheet 3 - Russell Square, Victoria Street, Orphan Asylum, Ballarat Orphanage, Lofven Street, Haines Street, Yarrowee Creek, Ching Who Coey, Chinese, Stawell Street, Rice Street, Lane Street, Humffray Street, Nelson Street, Coffield Street, Morres Street, Western Highway, Rodier Street, Scott Parade, Canterbury Street Sheet 4 - Orphan Asylum, Ballarat Orphanage School, Fortune Street, Scotts Parade, Water Street, Ritchie Street, Humffray Street, Brophy Street, Thompson Street, Victoria Street,Humffray Street Church of England Reserve, Strickland Parade. Mount Xavier Recreation Reserve, Charlesworth Street Catholic Church Reserve. Sheet 5 - Western Highway, Mount Street, Fortune Street, Finlay Street, Jones Street, Ryan Street, Water Street, Brandbury Street, Humffray Street. Sheet 6 - Barkly Street, Ebden Street, Grenville Street, Cameron Street, Peel Street, Young Street, Victoria Street, Steinfeld Street, Haymes Street, Bond Street, Anderson Street, Eastwood Street, Mair Street, East Street, Haymes Crescent Sheet 7 - Murphy Street, Queen Street, Dyte Parade, Princes Street, Midland Highway, York Street, Dodds St, Wilson St Otway Street, Specimen vale, King Street, Gray Street, Little Dodds Street, Eureka Street. Sheet 9 - Richards Street, Fussell Street, Stockade Street, Orphan Asylum, Ballarat Orphanage, Elford Street, Russell Street, Ross Street, Charlesworth Street, Lalor Street, Stockade Street, Wilson Street, York Street, Eureka Street Sheet 10 - Eureka Street, York Street, Elford Street, Wilson Street, Mount Street, Turpie Street, Timber Reserve, Mount Xavier Sheet 11 - Yarrowee Creek, Humffray Street, Barkly Street, Morton Street, Cobden Street, Morton Street Wesleyan Church, Pryor Street, Albion Street, Bradshaw Street, Ballarat Woollen Mills, Tannery, Mount Pleasant. Sheet 12 - Magpie Street, Grant Street, Gladstone Street, Cobden Street, Fraser Street, Grenfell Street, Robertson Street, Bond Street, Barkly Street, Vine Street, Sovereign Hill, Ballarat Observatory, Pearce Street, Bond Street. Sheet 13 - Murphy Street, Larter Street, midland Highway, Geelong Road, gales Street, Lal Lal Street, Clayton Street, Dodds Street, Elsworth Street Sheet 14 - Eureka Street, Eureka Stockade Memorial Park, Eureka Stockade Reserve. York Street, Joseph Street, Kline Street, Charlesworth Street, Chamberlain Street, Trevor Street, Belford Street, Queen Street, Murray Street, Eureka Tiles, Orphan Asylum, Ballarat Orphanage. Sheet 18 - Scotts Parade, Stawell Street, Fortune Street, Victoria STreet, Railway Line, Haines Street, Eureka Street, Elford STreet, Brophy Street, York Street, Clayton Street, Elsworth Street, Barkly Street, Humffray Street, Midland Highway, Princes Street ballarat youth council, ballarat east, bakery hill, humffray street, victoria street, st paul's anglican church, humffray street state school -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined