Showing 89 items

matching commercial equipment

-

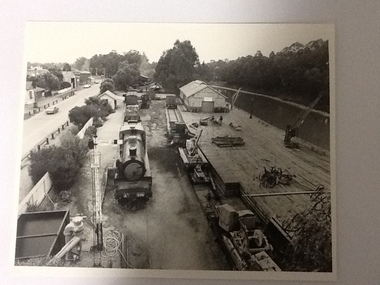

Port of Echuca

Port of EchucaBlack and white photograph, approximately 1983

Original held by Mr. Mike Rosel. Relates to series of images, reg. No P000027, P000028.2, P000029.3, P000030.2, P000031, P000032Photograph shows Port of Echuca from a slight height looking lengthways (north ward) with the steam train carriages and the wharf dominating the view. Murray river on the right, Murray esplanade on left with Star hotel visible and Federal Ale sign of the northern fence beyond the hotel. Sawmill is a commercial concern (steam visible above roof). Steam train marked A2 and 996 on the front of the engine. Various equipment , including manual cranes, visible on and around the wharf. Cargo shed is clearly visible on the wharf.Black and white photograph of the Port of Echuca from a slight height looking lengthways, (north) with steam train and wharf dominating the view. Murray river on the right and Murray Esplanade on left. Cranes and cargo shed clearly visible with other wharf machinery running along the side of the wharf. Star Hotel visible on the far left of the photograph. Saw mill (in background) is still a working operation.On train "A2" and "996". "Federal Ale" sigh on the fence beyond the Star Hotel.port of echuca, sawmill, steam trains, echuca wharf, rosel, mike -

Bendigo Military Museum

Bendigo Military MuseumEquipment - CLINOMETER & CASE, Made in Australia D up arrow D, 1) 1943; .2) 1944

.1) Clinometer Mortar MKIII, brass,machined, with curved graduated markings. Centre is a bock with bubble in cross hairs. .2) Heavy leather case with ends sewn in. Rear has 2 leather keepers for a belt. Case shuts via strap & brass button..1) “TARGET - F TOUCH 1943 'A.3457'” .2) CASE. “MOR CLINO MKI (scratched on '3389') RB up arrow DCD 1944”instruments - measuring, containers - commercial, military history, clinometer -

Bendigo Military Museum

Bendigo Military MuseumContainer - CONTAINER, OIL, Possibly WW1 - WW2 and on

Oil bottle for 303 Rifle. Brass cylinder with screw out top with oil scoop. .1) Brass cylinder for oil with black sealing washer. .2) Brass screw top with oil scoop attached.OA stamped on screw top Tick (symbol) on side of cylindercontainers - commercial, metal craft- brassware, military history - equipment, oil container -

Bendigo Military Museum

Bendigo Military MuseumAccessory - TANK, FILM, est WWI

... . Refer 1317P, 1320P, 1321. photography-processing equipment ...The item was part of Jack Grintons film processing. This one he bought after the War. He served as No 1043, 38th Batt AIF 1916-19. Part of the Grinton collection which included hundreds of negatives and developed photos that he took during the war. In England prior to France he spent many evenings processing his own photos. Refer Cat No 1280 for service details. Refer 1317P, 1320P, 1321.Wooden box with lid, three spools and two handles for winding film.On lid: "Made by Eastman Kodak, Rochester. NY USA. Patents: August 3 1902, May 21 1907. May 23 1905, Sep 17 1907. Jun 1908. 3 1/2 inch ODEL-B-2"photography-processing equipment, containers - commercial, grinton -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, mechanical hand whisk c1940, c1940

... Manufacturing Company was an early manufacturer of large commercial ...An eggbeater is a hand-held device with a crank on the side geared to one or more beaters. The user grips the handle with one hand and operates the crank with the other, creating the rotary action. A hand-turned rotary egg beater was patented by J.F. and E.P. Monroe in 1859 in the US. This egg beater patent was one of the earliest bought up by the Dover Stamping Company, whose Dover egg beaters became a classic American brand. The Monroe design was also manufactured in England. In 1870, Turner Williams of Providence, R.I., invented another Dover egg beater model. The Hobart Manufacturing Company was an early manufacturer of large commercial mixers. A mechanical egg beater with a wooden handle and steel gears and crank c1940cooking, kitchen equipment, dairy, cakes, housework, early settlers, pioneers, baking, nutrition, blacksmiths, market gardeners, cake mixers, moorabbin, cheltenham, bentleigh, brighton, monroe e.p., monroe j.f., egg beaters, williams turner, dover stamping compant ltd., hobart manufacturing company ltd. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, china meat platter, c1900

Wedgwood was founded on 1 May 1759 by Josiah Wedgwood and in 1987 merged with Waterford Crystal to create Waterford Wedgwood, an Ireland-based luxury brands group. After the 2009 purchase by KPS Capital, Wedgwood became part of a group of companies known as WWRD Holdings Ltd, an acronym for "Waterford Wedgwood Royal Doulton." In 1765, Josiah Wedgwood created a new earthenware form which impressed the then British Queen consort Charlotte of Mecklenburg-Strelitz who gave permission to call it "Queen's Ware"; this new form sold extremely well across Europe. Wedgwood developed a number of further industrial innovations for his company, notably a way of measuring kiln temperatures accurately and new ware types Black Basalt and Jasper Ware. Wedgwood's most famous ware is jasperware. It was created to look like ancient cameo glass. It was inspired by the Portland Vase, a Roman vessel. Wedgwood had increasing success with hard paste porcelain which attempted to imitate the whiteness of tea-ware imported from China. High transportation costs and the demanding journey from the Far East meant that the supply of chinaware could not keep up with increasingly high demand. In 1812 Wedgwood produced their own bone china which, though not a commercial success at first eventually became an important part of an extremely profitable business. An oval white china platter with blue flowers and fruit. Back is marked WEDGWOOD CHRYSANTHEMUMOn base ; CHRYSANTHEMUM / i / W / 7 / WEDGWOOD china, pottery, crockery, england, moorabbin, bentleigh, cheltenham, kitchenware, wedgwood josiah -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySaw Logging, circa early 1900's

This item can be seen as a hand piece belonging to a logger or farmer spanning over one hundred or more years. The equipment was made to perfection as a hand tool and has not been improved upon since its introduction into the logging industry or farming fraternity. It can be used by one person or two (husband and wife or father and child). Its versatility is ageless. It can be used for domestic clearing of the paddocks, or for domestic fire places and stoves or commercial logging up until the 2000s (introduction of specific logging trucks that cut and treat the trees in one process).This item is very significant to the rural and logging regions within the Kiewa Valley. It has been used for domestic wood cutting and for industrial logging in the mid to late 1900s. It was used when clearing land for the SEC Hydro scheme and to allow for the introduction of the Mount Beauty construction workers' village (later developed into the town) The great advantage of this saw was that it uses only muscle power and can be located where ever a lumber "Jack" or property owner can venture. either by foot or by horse.This saw is a Warranted Superior One/Two Man Logging Saw. It has 68 teeth and is 42 inches long. At a position of one inch (2.5cm) from the end is a hole one inch down from the leading edge. There is another hole 45 cm in front of the handle. Both these holes are for a "helper handle" which when in use renders this logging saw fit for a two man operation. This is a cross cut saw for cutting down vertical trees (horizontal cut) The handle is made from wood and fastened to the blade by three heavy duty screws. The one helper handle stands 150mm high and has a 150mm wooden hand grip.The central screw has 25mm manufacturers' identification logo stamped "WARRANTED SUPERIOR".one or two man cross cut saws, forestry, timber industry -

Orbost & District Historical Society

Orbost & District Historical Societydentist's chair, approx. 1860's - 1890's

... This item is an example of early dentistry equipment. chair ...Until the arrival of 'specialist' dentists in the mid-nineteenth century, dental care was provided by the medical profession and druggists, who were eventually registered under two British Acts, the Colonial Medical Act (1858) and the Colonial Dentists Act (1878). Many isolated communities had problems gaining access to dentists, and were often served by dentists on a part-time basis, mainly providing extraction and denture servicesThis item is an example of early dentistry equipment.Portable dentist's chair from around 1900's. Leather headrest and seat, wood frame, with metal bolts to allow chair to recline.chair furniture-commercial dentistry -

Orbost & District Historical Society

Orbost & District Historical Societybottle

... domestic writing-equipment stoneware Front bottom - Commercial ...An ink bottle was made of glass or ceramic and typically sat on a desk. The writer would dip the pen (or quill) into the bottle to put more ink on the pen. Because they sat on a desk, ink bottles were often decorative. We have mostly dispensed with ink bottles and quills. This item is an example of early stationery equipment commonly used.A cylindrical brown glazed ceramic ink bottle with a neck narrowing to a pouring lip and cork. Label is blue.Front bottom - Commercial.bottle ink-bottle ceramic domestic writing-equipment stoneware -

Orbost & District Historical Society

Orbost & District Historical Societyink bottle, first half 20th century

An ink bottle was made of glass or ceramic and typically sat on a desk. The writer would dip the pen (or quill) into the bottle to put more ink on the pen. Because they sat on a desk, ink bottles were often decorative.We have mostly dispensed with ink bottles and quills. This item is an example of early stationery equipment commonly used in schools, households and commercial enterprises.A cylindrical brown glazed ceramic ink bottle with the neck narrowing to a pouring lip.Towards the bottom : WYATT MOTTS LANCELEY -

Cheese World Museum

Cheese World MuseumRetailing equipment, Hamilton Beach Mfg Co, Milkshake mixer

The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. This milkshake maker is part of the collection of items given into the care of the Cheese World Museum. Uebergang catalogue No.N42 A single beater electric commercial milkshake maker with black lead, mounted on a white 'artificial marble' base with four rubber stops; and straight-sided aluminium mixing container. An extendable metal column (to H44cm) with a side clip attached is used to hold the container. The electric motor is housed in a slotted round metal casing.Hamilton Beach Mfg Co. Builders, Racine, Wisc. Made in USA. Pats Pending. Volts 220-50c. No.4N14412Aallansford, hamilton beach manufacturing company, usa, milkshake maker, milk, retailing equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Ship Log, 1880-1890

The John E. Hand & Sons Company was founded in Philadelphia in 1873, quickly gaining a reputation as competent manufacturers of nautical instruments and compass adjusters. In fact, John Enos Hand, the company founder, is recognised as the first man in America to adjust a compass aboard an iron ship. The Hand Company built navigational equipment for all varieties of floating vessels, and operated a chain of retail outlets with “service stations” in numerous port cities, including Baltimore and New Orleans, until 1956. Service stations sold Hand instruments as well as other nautical paraphernalia and provided compass adjusting services. Additionally, John E Hand and his two sons, John L Hand and Bartram Hand, were inventors in their own right who patented design improvements for numerous instruments that were employed in the company’s work. Commercial and private contracts dominated the firm’s business until the late 1930s when the United States military began preparations for World War II. Although the Hand Company never completely abandoned its involvement with private industry, after World War II, military contracts monopolised their business. The Company obtained contracts with the Navy, Coast Guard and Marines to develop new instruments, and to build military-engineered nautical equipment. Of note are the wrist compass, developed for the Navy beginning in the 1950s, and the Mark VII Model 5 Navy Standard Binnacle. Although it moved numerous times, the Hand Company headquarters and factory remained in the Delaware Valley, occupying several buildings in Philadelphia and southern New Jersey. Maintaining its central office in Philadelphia well into the 1900s, the factory was moved to Atco, New Jersey around the turn of the twentieth century and subsequently to Haddon field, New Jersey. It moved one last time in the 1960s to Cherry Hill, New Jersey. In 1997, California-based Sunset Cliffs Merchandising Corporation purchased the Hand Company and all its assets for $100,000. "HAND" brand taffrail log by John F. Hand and Sons Co. Register is enclosed in log, has a glass front and 3 dials on an enameled surface, the first dial registers the miles up to 100, the second registers the units up to 10 mile, the third registers quarters of a mile. The item is rocket shaped with a three blade rotor and a rope ring attachment at one end; the rotor will spin when a rope is attached, allowing the apparatus dials to measure the ship's speed when it is dragged behind a ship. Diagram of the 'Hand' trademark with a compass card in the middle, inscription reads "John F Hand and Sons Co" and "PHILA-BALTO" ( Abbreviation for: Philadelphia / Baltimore) flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, bartram hand, john enos hand, john f. hand and sons co, john l hand, john hand & sons instrument makers, john hand & sons of philadelphia, marine instrument, marine service station, mechanical ship log, nautical instrument, nautical navigation, navigational equipment, scientific instrument, ship log, ship log register, ship’s speed, sunset cliffs merchandising corporation, speed log, rocket log, harpoon log, taffrail log, taff rail log -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Guillotine, c. 1880's

This guillotine is a hand operated machine specifically designed to cut through multiple sheets of paper or card. It has a very heavy and sharp single blade knife mounted between vertical guides or runners. The main users of a machine like this is in by the printing and publication binding industry. Book binding companies use a guillotine to evenly trim the pages of a book after it has been bound. The way the guillotine is used is - paper or card is stacked squarely on the flat table and pushed firmly against the back guide - the handle below the table at the front of the machine is wound around, which brings the back guide forward, pushing the paper stack forward and positioning the centre of the stack below the vertical frame - the upper wheel is wound around, which brings the clamp and firmly in position on top of the paper, to hold it very firmly - the large wheel on the side of the machine is turned around to lower the long sharp blade down onto the pages and cut them through. The sharp edge of the blade is protected somewhat from becoming blunt; a block of wood sits in the table under the stack of paper An early model of a guillotine was patented in 1837 by Thirault, who built a model with a fixed blade. Guillotines similar in principal to this one were patented by Guillaume Massiquot in 1844 and 1852. Over the years many improvements have been made and operation has moved from man power to electricity. Oscar Friedheim Ltd. was the importer and wholesaler of a large range of machinery and equipment for the printing and bookbinding industry. He sold most of his equipment under his own name. On this guillotine or paper cutter he refers to the origin of the guillotine’s manufacture only as “German Manufacrure”. A reference book “Commercial Bookbinding: a description of the processes and the various machines used" by Geo. Stephen, 1910, recommends Oscar Friedheim, amongst others, for the supply of “reliable cutting machines for hand or power”. It also recommends Oscar Friedheim’s for a wide range of other printing machinery and processes. OSCAR FRIEDHEIM LIMITED, LONDON Oscar Friedheim Ltd. was established in 1884 and operated from Ludgate in London. The company was an importer and wholesale supplier in the 1880’s, offering machinery and equipment for the printing and packaging industry for the UK and Ireland. The company became incorporated in 1913. An advertisement of 1913 includes a telegraphic code plus two telephone numbers for Oscar Friedheim Ltd and invites readers to call at the Ludgate, London, showrooms to see the machines working. The company later became Friedheim International Ltd. The book titled “Friedheim, A Century of Service 1884-1984 by Roy Brewer, celebrates Oscar Friedheim’s achievements. Friedheim International currently operates from Hemel Hempstead, on the northern outskirts of London UK. It promotes itself as “… the leading supplier of finishing, converting and packaging machinery to the printing, graphic arts, and highly varied packaging industries in the UK and Ireland. The company’s policy is simple – “employ the best people, work with the best equipment manufacturers in the world, and treat our customers as partners!” The company still sells guillotines. The guillotine is significant for its ability to represent aspects of the printing trade in Warrnambool and in a typical port town circa 1850 to 1910. It represents communication methods and processes used in the time before electrically powered equipment became common in industry.Guillotine (or paper cutter), hand operated. Metal framework with vertical guides, stand and metal mechanical parts including wheels and gears. Table with back guide; handle below front of table winds to move the back guide. A wheel at top of machine winds to adjust pressure of the clamp on the work on the table below it. The cutting blade fits between vertical guides; a timber insert in the table below the blade helps minimise the loss of sharpness of the blade. A handle on the side of the machine turns a large spoked wheel, which rotates a large gear, causing the blade to move up and down. Makers details are on a small oval plaque with embossed maker’s details is screwed onto main body. Maker is O Friedheim, London, and the machine is of German manufacture, circa late 1880’s.Maker’s plaque inscribed "O. FRIEDHEIM / London / German Manufacture"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, printing machinery, printer’s guillotine, paper guillotine, paper cutter machine, oscar friedheim ltd london, friedheim international ltd, bookbinding industry, printing industry -

Federation University Historical Collection

Federation University Historical CollectionEquipment - Postage Meter, Pitney Bowes, Post Office Franking Machine, c 1970

This franking machine was used in the mail room of SMB and also in the mail room at University of Ballarat. Pitney Bowes is a global technical company, known for its postage meters and other mailing equipment and services. It was founded in 1920 when the company of Arthur Pitney, founded in 1902, merged with the company of Walter Bowes, founded in 1908. The name at merger became Pitney Bowes Postage Meter Company. They produced the first commercially available postage meter.White, brown and black Pitney Bowes model 6300 Franking Machine in a black carry case. Includes power lead and blue soft cover. Yellow card with instructions fro Supervisor of Mail Centre Code No. 6331 Serial No. 18412 Yellow sticker for SMBballarat school of mines, university of ballarat, post office, mail, franking machine, postage meter, arthur pitney, walter bowes -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Hand operated embossing document press, 1910

... of commercial office equipment used in the 19th and 20th century ...The woollen mill was a vital part of Warrnambool for all but 22 years of the town’s history since it's the establishment in 1847 when the first land sales were held and white settlement began. In 1869 the Warrnambool Meat Preserving Company began operations on the mill site, in 1875, shareholders of the then defunct Warrnambool Meat Preserving Company happily sold the land and buildings on the Merri river to Warrnambool Woollen Mill Company Ltd for £5,000. The site was sold again in 1876 to grazer Robert Hood of Sherwood, who was chairman of directors of the failed company, which couldn’t raise sufficient capital to keep the works operating. The entrepreneurial Hood then used the existing plant to turn his own wool into tweed cloth. But just as the mill was starting to show a profit, a fire destroyed the building and plant on the night of 25 March 1882. So again, the mill was operational for six short years. Insurers only paid a fraction over 10% of the damage, Hood couldn't raise sufficient capital to rebuild on his own, and so the site lay unused until 1910. In 1908 Marcus Saltau and Peter John McGennan convinced the Warrnambool Chamber of Commerce to invest in a secondary industry with local capital. A public meeting in September 1908 agreed to raise £40,000, electing Saltau chairman of directors, a post he held for 34 years. A year later, using mostly local money, the Warrnambool Woollen Mill Company dispatched its first manager, John E. Bennett, to buy a plant and recruit 20 experienced staff from the Yorkshire woollen industry in December 1909. Another year more, the new mill was officially opened on 14 November 1910 by Marcus Saltau as company chairman and town mayor. Eighteen months on, in May 1912, the mill paid its first half-yearly dividend of 2 ½%. It was now working two shifts, with a year's orders to fill. In 1914 the mill ordered its own generator, providing the town with electricity and effectively doubling its plant size by October 1915, six months after Gallipoli. Thereafter, government orders for cloth and military supplies assured the mill’s success right through the First World War and on until 1923. A plant upgrade in 1922 for machinery to make worsted fabric drained profits, which, with a fall in demand, led to a loss in 1925. Profits were restored by the 1930s, despite the Depression, mostly due to tight management and robust marketing. Production boomed again during the Second World War, but soon foreign competition bit into profits, forcing the company to consolidate operations. The ‘50s and ‘60s were golden years for the mill. Security and growth gave the company confidence to trial Australia’s first electric blanket in 1958 and to install Swiss Sulzer looms in 1965. Over time, the building facades took on the modern look that the mill presented until it closed. The Dunlop company bought the mill in 1968, fending off a challenge from Onkaparinga in South Australia, and continued to expand by adding Wendouree Woollen Mill in the same year and Dream-spun Textiles a decade later, in 1979. Soon after that purchase, however, the mill began its slippery slide into decline. Dunlop sold to its former rival bidder Onkaparinga Woollen Co. Ltd in 1982, which in turn was taken over by Macquarie Worsted's only a year later, in 1983. Operations remained stable for a decade until 1994 when the Macquarie Group signaled that its newly rationalised operations left no room for the Warrnambool investment. The final operator of the mill was The Smith Family charity group, which ran the site by agreement with the Warrnambool City Council and a state government grant in that same year, 1994. The mill became more of a fabric recycler than a manufacturer. The site was sold to private operators in February 2003 and rezoned four months later to allow for the mixed housing development. The embossing press is significant for its association with the Warrnambool Woollen Mills 1910-1968, a major employer in the Warrnambool district. The press is also significant as an example of commercial office equipment used in the 19th and 20th century.Press, metal, for Company seal of Warrnambool Woollen Mill, stamping their brand as Western District Worsted Mills Pty Ltd. Metal is black with red and gold floral markings. Inscription of stamp reads "WESTERN DISTRICT WORSTED MILLS PROPRIETRY LIMITED" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, warrnambool woollen mills, western district worsted mills proprietry limited, worsted fabric, printing press, logo printing press, stamp printing press, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Diving compressor and helmet, 1944

... that developed diving equipment and breathing equipment and worked... company that developed diving equipment and breathing equipment ...Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water pumps, refrigeration equipment, and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards, and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12 bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering, and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air, and under the sea (including mine rescue, tunneling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A.Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman's fortunes began to decline as an aging Sir Robert Davis failed to invest, or change the company's business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire-fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998). (For information regards the diving helmet & Frank King see Notes Section at the end of this document)The items are very significant as a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. The company that made the equipment was a leading inventor,developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job. Frank Kings' diving helmet and compressor (communication pipe stored separately). Compressor is hand cranked. US Navy diving helmet, Mark V. Two maker's plates attached. Made in 1944.On rear "WATER SUPPLY" On front 'PATENT" " Logo: Images (Lion, Crown, Horse, Shield within an oval) "SIEBE, GORMAN & Co. Ltd. SUBMARINE ENGINEERS, LONDON.flagstaff hill, warrnambool, maritime museum, great ocean road, us navy diving helmet, commonwealth government salvage, diving helmet, marine salvage, frank king, diver, siebe. gorman & co ltd, submarine equipment, diving equipment, communication under water, hand cranked, diving compressor -

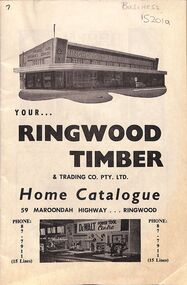

Ringwood and District Historical Society

Ringwood and District Historical SocietyPamphlet, Two catalogues from Ringwood Timber & Trading circa 1960s

Two catalogues of goods to sell, from Ringwood Timber & TradingEditorial of 15201b includes a short history of the company. In 1937, Mr S Coopersmith and son, Frank (the present Managing Director) started a fruit case manufacturing business in North Melbourne under the name of The Cooper Case Co. The business flourished, and in 1940, recognising the possibilities in and around Ringwood, an old bush sawmill and an area of land on the Maroondah Highway, were secured. Subsequent purchases have since increased this area to approximately 15 acres. It was decided to widen the activities and scope of the business and two new firms were formed. Cooper Sawmilling Co., which operated a modern sawmill, and Ringwood Timber & Trading Co., which handled the output of the sawmill and introduced builders' and general hardware lines to meet the demands of this rapidly expanding area. As Ringwood grew, so too did the organisation which was created to serve it. The principals studied timber and hardware merchandising trends overseas, and after considerable investigation the new building on Maroondah Highway was completed in 1956. Today, acclaimed as one of the most modern mills and hardware stores in the Southern Hemisphere, combining up to date machinery and handling equipment together with unique drive-in facilities and a self-selection centre. Ringwood Timber & Trading Co. are proud to offer a service unparallelled to home builders. In conformity with modern commercial practice the various firms have since been incorporated under the Victorian Companies Act and the latest accounting methods and office equipment have been installed to provide an efficient and virile administration to control the entire manufacturing and trading activities. We have a staff of over 220 personnel, each trained in their particular field to provide you, our valued client, with expert advice, quality merchandise and second-to-none service to enable you to fulfil every need in and around your home. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, china shaving mug / scuttle, c1950

Shaving soap scuttles are distinguished from shaving mugs by having a separate area for hot water. The hot water is for dipping a shaving brush into to make a lather with the soap which is then applied to the skin before using the razor. Vintage scuttles are often elaborately decorated. Between 1880 and 1920 is the original time period for the occupational shaving mug. Most men owned a shaving mug, either at home or at a barber shop. Mugs purchased for home use typically were purchased through local stores, had more variety in style but usually went without a name. Barber shops sold mugs with the owners’ names on them partly because they thought that shaving rash came from sharing the same soap. In reality, the rash was not a result of soap but of unsterilized razors. Transfer ; The Duryea Motor Wagon was among the first standardized automobiles and among the first powered by gasoline. Fifteen examples were built by the Duryea Motor Wagon Company of Chicopee, Massachusetts, between 1893 and 1896. Their enterprise followed the first commercially available automobile which was patented by Karl Benz on January 29, 1886, and put into production in 1888. The Duryea Motor Wagon remained in production until 1917. The Duryea brothers entered their horseless carriage in many shows and races. A china shaving mug / scuttle with a car transfer. The mug has a wide spout to hold / insert the shaving brush , a perforated tray opening at the top to hold the soap and a bulbous base for the hot water. car transfershaving equipment, safety razors, cheltenham, early settlers, moorabbin, shaving soap sticks, shaving brushes, shaving scuttles, shaving rash, infectious diseases, barber shops, -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - KERR'S CYCLE AND SPORT SHOP, c.1940

Black and white photograph. Interior at bicycle shop. Sports equipment, prams. Mounted on grey board. History of object: James Lerk 2000 'Interior of Kerr's Cycle and Sports Shop, Hargreaves St, Bendigo. Now part of the Hargreaves Mall. Photograph c.1940. Photographed for Bendigo Advertiser 11.1.2001buildings, commercial, kerr's cycle & sport shop -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - GRAHAM HOOKEY COLLECTION: COMMERCIAL BANK OF AUSTRALIA PAPER BAGS

Six paper bags of the Commercial Bank of Australia Limited for deposits $10 of ….cents coins. Three small paper bags of the Commercial Bank of Australia limited for deposits of $ 2 of 5 cents coins.numismatics, equipment, bags -

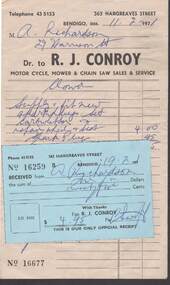

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - R.J.CONROY Account, 1971

The Bendigo business R.J. Conroy was a bicycle agency in the 1940s. Elliott Bros of Bendigo Pty Ltd was started in 1980 by three brothers Hayden, Daryl and Noel Elliott. They purchased the motorcycle dealership known as RJ Conroy from Dick Conroy. In 1990 Elliott Bros built a new premises with a huge showroom on Wattle Street in Bendigo to display their huge and diverse range of motorbikes, ATV's, chainsaws, lawnmower, brush cutters, garden tractors and all the power equipment necessary for domestic and commercial garden maintenance.Docket and Receipt, R.J.Conroy to Motor Cycle , Mower & chain Saw sales & service Mr. A. Richardson, 29 Harrison Street. Dated 11/2/1971 & 19/2/1971 for the sum of $4.95 receipt document, docket -

Creswick Campus Historical Collection - University of Melbourne

Creswick Campus Historical Collection - University of MelbourneEquipment, Card Sorting Key to the identification, properties and uses of the principal commercial Australian timbers

... of the principal commercial Australian timbers Equipment ...Timber box with sliding lid containing punched cards with photograph on rearEquipmentCSIRO -

Clunes Museum

Clunes MuseumDocument - INVOICE, CIRCA 1891

THE INVOICES WERE RECEIVED FROM MR. J.R. BLAIR OF ST. KILDAAN INVOICE MADE OUT TO THE WESLEY CHURCH FROM WEICKHARDT & CO. FOR PLUMBING EQUIPMENT FOR REPAIRS TO ROOF AND TANK FOR 5 POUNDS THREE (5.3.0)local history, document, commercial, weickhardt & co. -

Geelong Naval and Maritime Museum

Geelong Naval and Maritime MuseumTeacup

The Orungal was originally built in Glasgow in 1923 for the Khedival Mail Steamship & Graving Dock Company of Egypt and named the S.S. Fezara. Due to the effects on steamship companies of the Great Depression including the steep costs of building new ships and increases in running costs and port charges, no new passenger ships had been ordered in Australia since before World War One. To meet demand for passenger berths, the Fezara (5826 tons) along with its sister ship the Famaka (5856 tons, renamed Ormiston), were chartered by the Australasian United Steam Navigation Company Ltd (A.U.S.N.Co.) in 1927. Both the A.U.S.N.Co and the Khedival Mail Steamship Co. were part of the P&O Group. The Orungal operated in this role as an interstate passenger and mail steamer between 1927 and 1940, being used mainly on the Melbourne to Queensland and Western Australian runs, with 240 single class berths. Following the outbreak of World War Two six of the nine large passenger liners servicing mainland Australian passenger and mail trades were requisitioned by the Government to ferry equipment, troops and supplies. Some of them were converted to armed merchant cruisers and used for patrol work and escort duties in the Indian and Pacific Oceans. The Orungal had originally been requisitioned by the government along with the Zealandia on 25 June 1940, to transport troops to Darwin, but was returned to commercial service because "of her unsuitability", perhaps too slow for the demands of the work. Despite being rejected for patrol and convoy duties the Orungal still had a vital role as one of only three passenger liners left to service the mainland Australian trade. Following its requisitioning by the Government shortly after war broke out, it had been fitted out with defensive armament. On its final voyage arriving at Port Phillip Heads from Sydney, Captain Gilling was attempting to enter the Heads ahead of a worsening south-westerly storm and, with a minefield known to have been laid in the area, had been warned by the Navy not to deviate from the swept channel. The captain and crew held fears that in the stormy seas a mine may have been carried away. In the worsening weather a blur of lights at Barwon Heads was mistaken for Port Lonsdale, and the Orungal steamed ashore onto Formby Reef, just east of the entrance of the Barwon River - instead of passing safely through the middle of the Rip. At the Marine Board Inquiry Capt. Gilling - who had been master of the Orungal since 1926 - stated that after becoming uneasy about his position and changing course to starboard one point: " At 10.21 pm I ordered the engine room to stand by and gave instructions for the patent log to be hauled in and for the sounding-gear to be got ready. Approximately two minutes later, in a flash of lightning, I saw land off the port beam. I immediately recognised it as Barwon Heads, and ordered the helm to be put hard to starboard, but the vessel struck before she had time to answer the helm" Barwon Heads and Ocean Grove residents were startled to hear the shrill blast of the ship's whistle, followed by the bright flares and explosions of signal rockets. The Queenscliff lifeboat crew, who had responded to the tragic collision between the Goorangai and another passenger liner the Duntroon in Port Phillip Bay less than 24 hours earlier, were later praised for their efforts in safely taking off all the passengers and crew. Most of the passengers were asleep at the time of the wreck, and were woken up by the commotion, the ship shaking "from stem to stern" and stewards ordering them to lifeboat stations in driving rain. It was a dramatic time with the ship siren wailing and distress rockets being fired. It was reported that "When it was found the ship was safe, the passengers all went to the music room. There they sang and danced for several hours. The ship's orchestra played merrily, and amateur performers among the passengers clowned, danced and sang to keep the laughter going. In the early hours of the morning passengers went to their cabins, most of them to sleep soundly while the keel grated on the rocks". At dawn the Queenscliff lifeboat arrived at the scene having been launched at 2.30am, and cautiously approached the ship which was being "battered by mountainous seas". By 5am oil from a burst oil line was helping to calm seas around the Orungal sufficiently enough for the lifeboat to approach, and all the passengers and crew were taken off in several trips by the lifeboat. A Court of Inquiry later found that the wreck was caused by an abnormal set of current to the north-west and cleared the officers and crew of neglect of duty. The sight of a huge liner almost on the beach saw an unprecedented amount of traffic as people drove an estimated 10,000 cars, using some 60,000 gallons of fuel in a time of strict petrol rationing, to see the spectacle. Salvage operations began in an attempt to refloat the vessel, scheduled for the high tide on 15 December 1940. However, during these operations, at 2.30 am on 13 December 1940, a major fire broke out, believed to have been caused by spontaneous combustion in the boiler room. The ship was soon ablaze, with smoke pouring from its hatches and ventilators, and at mid-morning the magazine exploded fiercely. Of the 60 men working aboard the vessel two were severely burned and had to be taken to Geelong Hospital. The gathered spectators witnessed the eerie sight of the ship's hull glowing red when night fell. The well-known building demolition contractor Whelan the Wrecker bought the salvage rights, and methodically proceeded to dismantle the ship and its fittings. The drama was not yet over for the wreckers when - without warning - the burnt-out hulk was 'attacked' by RAAF for strafing practice. Salvage rights were transferred to another private owner in 1963. By 1945 the combined effects of the exposed location, fire and salvage had seen what was left of the wreck disappear beneath the waves. The site today is marked by two of the four Scotch type boilers sitting upright and exposed at low tide, just north-east of the small boats channel at the entrance to Barwon Heads. Large sections of steel hull plating and framing, and impressively large pieces of ships structure and machinery including masts, booms, deck winches, propeller shaft, flywheel, and a thrust block lie scattered about and make the site an interesting shallow dive. It is interesting to compare the site of the Orungal with the intact remains of similar large passenger ships scuttled in deep water in the Ships' Graveyard, such as the Milora and Malaita. The site is subject to waves and surge, and is best dived on flat calm days The teacup originated from the SS Orungal and was likely used heavily in the ship's life as a passenger, mail and cargo carrier around Australia. The teacup is significant for its connections to SS Orungal and of this ships connected story of being sunk in extraordinary circumstances in the local region. A.U.S.N. Co. Ltd. Teacup salvaged from SS Orungal ss orungal, fezara, world war two, barwon heads, ocean grove -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

City of Ballarat Libraries

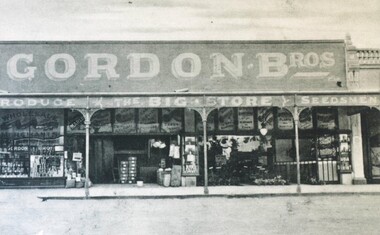

City of Ballarat LibrariesPhotograph, Gordon Brothers Seedsmen Store, Ballarat circa 1916

This store was located at 35-37 Armstrong Street North. Out the front is a display of garden equipment and seeds. The site was later occupied by Greenfields.building, commercial, gordon brothers, armstrong street north -

Monash University Museum of Computing History

Monash University Museum of Computing HistoryFerranti Sirius mainframe computer, 1961

The Ferranti Sirius is an electronic second-generation transistor computer and is one of three remaining examples of this machine left in the world. It was an important addition to the computing facilities at Monash University in the early 1960s and provided access for computer programming and research for many early computer professionals, academics and teachers. The Ferranti Sirius computer was built in a period of rapid growth in computing technology. The first stored program computers appeared in the late 1940s and used individual designs with valve technology. By the mid-1950s valve technology was replaced by transistors and the first mass produced commercial computers became available. The Ferranti Sirius was announced in 1959 and offered a “small” academic computer. It was designed and built by the English company Ferranti Ltd and sold through a local office of the company in Melbourne. The Sirius was manufactured at the Ferranti Ltd.’s West Gorton, England factory from 1959 to 1963 and, in all, the company produced probably 22 installations although only 16 were actually recorded as sold; this included one at Ferranti’s Bureau in London and one at Ferranti’s Melbourne Bureau. Only 7 were exported and 4 of these 7 were located in Melbourne, Australia. All four were associated with computing at Monash University – the Sirius in the MMoCH collection was purchased by Monash University in 1962, a smaller Ferranti Sirius was used on the Caulfield campus (prior to amalgamation with Monash University) from 1963, the Ferranti company had its own Ferranti Sirius initially temporarily installed at Clayton campus in 1962 and then placed in their office in Queens Road, Melbourne. A fourth computer was purchased by ICIANZ (now Orica) in 1962 and was transferred to Clayton campus in 1967. Only two of these Melbourne examples have survived; one in the MMoCH collection and one at Museums Victoria. There is an example of the Ferranti Sirius in the Science Museum Group collection in the UK as well. The Ferranti Sirius in the MMoCH collection was the first computer purchased by Monash University and it was shipped to Australia to be installed by November 1962. The University had a similar model computer on loan from Ferranti Ltd during the first part of the year and it was returned to the office of the company in Queens Road, Melbourne once the University’s own machine was installed. The computer was placed on site at Clayton campus, Monash University. The computer operated from 1962 until 1972 when it was officially decommissioned. The Ferranti Sirius was sold to Mr Paul Stewart in late 1974 and removed from Monash University. Mr Stewart later donated the computer back to the University in 1988 and it was transferred to the collection of the Monash Museum of Computing History after 2001. The Ferranti Sirius is an electronic second-generation transistor computer and is one of three remaining examples of this machine left in the world. It was an important addition to the computing facilities at Monash University in the early 1960s and provided access for computer programming and research for many early computer professionals, academics and teachers. The Ferranti Sirius is of scientific (technological) significance as one of the early transistor digital computers that transitioned computing from first-generation valve computers to second generation commercial installations. This example of the Sirius is of historical significance in its role as a part of the Computer Centre, Clayton campus, Monash University which provided computing facilities in Melbourne in the early 1960s when there were few installations available for academic, administrative and commercial users. Staff and students were able to undertake investigative research and learn programming techniques. The Computer Centre encouraged the use of the computer across all disciplines and this provided the base to establish computer science as a subject offering and, later, a new department in the University. This growth in computer education eventually culminated in the establishment of the Faculty of Information Technology, Monash University. The Ferranti Sirius in the collection at Monash Museum of Computing History has a main unit with a CPU and memory combined with input/output equipment and one extra cabinet of memory. The Central Processing Unit is a floor-standing unit which contains the computer circuits, power supplies and has a decimal digit display panel and a normal clock. A moveable control panel is placed in front of the Unit (Currently set on a recreated desk/filing cabinet support in the display). The Sirius base unit uses acoustic delay line memory with 1000 word store. An additional 3000 word memory cabinet is set adjacent to the CPU and can be connected to increase the memory. The computer is supported by a range of input/output devices. There is a Ferranti Paper tape reader, located on desk in front of CPU. Red label on front “Ferranti tape reader. Type TR 5. Serial No. 477”. Adjacent to the CPU is a set of Simplified tape editing equipment in three pieces which includes a (1) Table unit with switches on front face. Metal tag on reverse reads “Creed & Co. Model No. S4060. Serial No. 1457. Original Customers Marking GRP7 V706”. The table has a numbered internal tag “Table Serial No. 198579. (2)Creed teletype set on table unit. Metal tag on reverse “Creed & Co. Model No. 75RPR K4M4. Serial No. 5897 Made in England”. (3)Creed paper tape reader set on table unit. This set of equipment could read paper tape and print it, or copy paper tape while allowing it to be edited, or allow a programmer or data preparation person to type and punch a new program or data. It has no electrical connection to the computer. Paper tapes were usually torn off and carried across to the computer. There is also another table unit with switches on front face and changeable setting switch on front right side which holds a Ferranti Westrex paper tape punch set. Label on reverse “Teletype Code BRPE11” This was the Computer’s only output device. BRPE-11 is a teletype model number. -

Numurkah & District Historical Society

Numurkah & District Historical SocietyEquipment - Wooden school rulers x 4

Wooden 12 inch / 30cm school rulers with increments in inches and centimetres both sidesBank of ES & A / Commercial Savings Bank of Australia Limited / Drink a Pint of Milk a Day / Standard school Ruleeducation, school, measuring, ruler