Showing 71 items

matching marine industry

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlaque - Nameplate, Circa 1886

The brass letter “A” is from the starboard bow of the FALLS OF HALLADALE, a 2085-ton iron-hulled and four-masted sailing ship that was wrecked near Peterborough on 14 November 1908. Two companion pieces, the letters “S” and “D”, are also in the Flagstaff Hill Maritime Village collection of shipwreck artefacts (as registered numbers 748 and 6596). The ship’s name originally appeared in these impressively large brass letters across the stern and both port and starboard bows of the vessel. The FALLS OF HALLADALE was built in 1886 by Russell & Co at their Greenock shipyards on the River Clyde. She was the seventh of nine similar cargo carriers produced for the owners of the Falls Line, Wright, Breakenridge & Co of Glasgow. All nine ships were named after waterfalls in Scotland. First was the FALLS OF CLYDE in 1878, then the FALLS OF BRUAR in 1879 (lost in 1887), the FALLS OF DEE in 1882 (sunk in 1917), the FALLS OF AFTON in 1882, the FALLS OF FOYERS in 1883 (disappeared in 1898), the FALLS OF EARN in 1884 (wrecked in 1892), the FALLS OF HALLADALE in 1886 (wrecked in 1908), the FALLS OF GARRY in 1886 (wrecked in 1911), and the last of the fleet, the FALLS OF ETTRICK (lost in 1906). The FALLS OF CLYDE is still afloat as an exhibit at the Hawaii Maritime Center in Honolulu. Russell & Co delivered the owners full-bottomed, economical ships of 1800 to 2000 tons, practically designed to minimise loss of speed while increasing seaworthiness and carrying capacity. The sturdily constructed FALLS OF HALLADALE had iron masts and wire rigging, allowing her to maintain full sail even in gale conditions, and square “warehouse-type” bilges to accommodate maximum bulk cargo on her long-haul voyages. This class of ship remained commercially competitive into the twentieth century despite the advantages of coal-fired steamships. When the 22 years old FALLS OF HALLADALE finally foundered on Victoria’s Shipwreck Coast in 1908, the Melbourne Court of Marine Inquiry held it was entirely due to Captain D.W. Thomson’s navigational error, rather than any technical failure of the Clyde-built ship. The shipwreck of the FALLS OF HALLADALE is of state significance — Victorian Heritage Register No. S255. The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).A brass letter “A”, from the shipwreck FALLS OF HALLADALE, raised along the central axis to form three dimensional effect, in unrestored and fair condition. Of dull grey-green metal, bent and with irregularly worn edges, it has been subjected to amateur cleaning on the front face, with some remaining greenish copper oxidation and surface pitting. The rear face is uncleaned with a layer of sedimentary concretion, orange-red staining from the iron hull, and green copper oxidisation. Three sediment-filled bolt collars on the rear face are part of the original casting.warrnambool, shipwreck coast, flagstaff hill, shipwrecked coast, flagstaff hill maritime village, flagstaff hill maritime museum, shipwreck artefact, maritime museum, great ocean road, brass lettering, falls of halladale, 1908 shipwreck, russell & co., ship's nameplate, letter, letter a -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlaque - Nameplate, Circa 1886

The brass letter “D” is from the starboard bow of the FALLS OF HALLADALE, a 2085 ton iron-hulled and four-masted sailing ship that was wrecked near Peterborough on 14 November 1908. Two companion pieces, the letters “S” and “A”, are also in the Flagstaff Hill Maritime Village collection of shipwreck artefacts (as registered numbers 748 and 6595). The ship’s name originally appeared in these impressively large brass letters across the stern and both port and starboard bows of the vessel. The FALLS OF HALLADALE was built in 1886 by Russell & Co at their Greenock shipyards on the River Clyde. She was the seventh of nine similar cargo carriers produced for the owners of the Falls Line, Wright, Breakenridge & Co of Glasgow. All nine ships were named after waterfalls in Scotland. First was the FALLS OF CLYDE in 1878, then the FALLS OF BRUAR in 1879 (lost in 1887), the FALLS OF DEE in 1882 (sunk in 1917), the FALLS OF AFTON in 1882, the FALLS OF FOYERS in 1883 (disappeared in 1898), the FALLS OF EARN in 1884 (wrecked in 1892), the FALLS OF HALLADALE in 1886 (wrecked in 1908), the FALLS OF GARRY in 1886 (wrecked in 1911), and the last of the fleet, the FALLS OF ETTRICK (lost in 1906). The FALLS OF CLYDE is still afloat as an exhibit at the Hawaii Maritime Center in Honolulu. Russell & Co delivered the owners full-bottomed, economical ships of 1800 to 2000 tons, practically designed to minimise loss of speed while increasing seaworthiness and carrying capacity. The sturdily constructed FALLS OF HALLADALE had iron masts and wire rigging, allowing her to maintain full sail even in gale conditions, and square “warehouse-type” bilges to accommodate maximum bulk cargo on her long-haul voyages. This class of ship remained commercially competitive into the twentieth century despite the advantages of coal-fired steamships. When the 22 years old FALLS OF HALLADALE finally foundered on Victoria’s Shipwreck Coast in 1908, the Melbourne Court of Marine Inquiry found it was entirely due to Captain D.W. Thomson’s navigational error, rather than any technical failure of the Clyde-built ship. The shipwreck of the FALLS OF HALLADALE is of state significance — Victorian Heritage Register No. S255. The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).Large brass letter “D”, from the shipwreck FALLS OF HALLADALE, dented but in generally good unrestored condition. Front face of dull grey-green metal showing reddish oxide stain and some cream-coloured concretisation. Rear face has not been brushed clean and displays more encrustation.The four bolt collars for fixing letter to ship are filled with sediment.warrnambool, shipwreck coast, flagstaff hill, shipwrecked coast, flagstaff hill maritime village, flagstaff hill maritime museum, shipwreck artefact, maritime museum, great ocean road, brass lettering, falls of halladale, 1908 shipwreck, russell & co., ship nameplate, nameplate, letter, letter d -

Flagstaff Hill Maritime Museum and Village

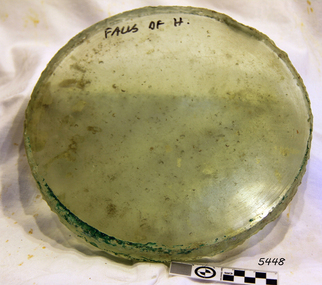

Flagstaff Hill Maritime Museum and VillageFunctional object - Porthole Glass

The iron-hulled, four-masted barque, the Falls of Halladale, was a bulk carrier of general cargo. She left New York in August 1908 on her way to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual beautiful green American slates (roofing tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. Three months later and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29 The Falls of Halladale was a four-masted sailing ship built-in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. The lines flag was of red, blue and white vertical stripes. The Falls of Halladale had a sturdy construction built to carry maximum cargo and able to maintain full sail in heavy gales, one of the last of the ‘windjammers’ that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new, raised catwalk-type decking allowed the crew to move above the deck stormy conditions. This idea is still used today on the most modern tankers and cargo vessels and has proved to be an important step forward in the safety of men at sea. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roofing tiles (roof slates), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the night of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on the south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).Porthole Glass, from the wreck of the Falls of Halladale, little encrustation. "Falls of H" written in black texta penporthole glass, flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, falls of halladale, shipwreck peterborough, 1908 shipwreck, great clipper ships, russell & co. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Ship Log, Early 20th Century

In times past the only way to measure a ship’s speed was to throw a wood log into the water and observe how fast it moved away from the ship. In the 16th century, the log was fastened to a rope knotted at set intervals. The log was thrown over the stern (back) of the vessel and a crew member counted the number of knots that were paid out in a set time. From this, they could estimate the vessel's speed through the water. This was known as streaming the log and is also the derivation of the knot as a measurement of nautical speed. Various manufacturers of nautical equipment had sought over the years to perfect the operation of determining a ship's speed and it wasn't until Thomas Walker and his son Ferdinand developed a mechanical system that eventually made this task became easy for marine navigators. Thomas Walker & Son were internationally renowned in the manufacturing of ship logs the founding father, Thomas Walker (1805–1871), an engineer in Birmingham, patented his mechanical log in 1878 which was a recording instrument that attached to a rail at the stern of a vessel connected by a long cord with a rotor which was towed behind the ship. The instrument dial then recorded the distance travelled. Thomas Walker first went into business to manufacture stoves at 58 Oxford Street Birmingham. Walker’s self-feeding stove was widely lauded at the Paris Exhibition of 1855, winning a prize medal and kickstarting the first of many notable innovations for the Walker family's manufacturing business. However, it wasn’t until working on an earlier ship’s log model invented by his Uncle that Thomas Walker became interested in the further development of this device, used to ascertain a ship’s speed. Walker continued to improve on the common log for the company of Massey & Sons and these improvements were deemed revolutionary. This log became a firm favourite of the West India Association (a British-based organisation promoting ties and trade with the British Caribbean), being the most common log in use for two generations. It took until 1861 for Thomas Walker and his son, Thomas Ferdinand Walker (1831-1921) to patent the first Walker log of many. Together, with the introduction of the A1 Harpoon Log two years later, they established the Walker Log Business as a force to be reckoned with. By his passing in 1871, Thomas Walker Snr had not only founded a family business with considerable staying power but also instilled a tradition of public service. Having sat as a representative on the Birmingham Town Council for 15 years and played an active role in public works, he was soon given the nickname of ‘Blue Brick Walker’. Much like his father, Thomas Ferdinand Walker changed the face of the maritime industry. His patent of 1897, the ‘Cherub’ log, was a notable departure from the past providing a far more accurate reading and replacing the majority of logs of the age. They were the first to produce an electric log (Trident) and the Walker factory was one of the first to introduce the 48-hour work week for employees.The ship log was invented and made by a significant marine instrument maker and innovator of machinery. It demonstrates the huge leap taken to improve navigational accuracy at sea with an instrument that was in use for decades.Ships Log, Walker Trident electric motor, in wooden box with instructions inside box. The motor dial with electric cord is still inside box.Inscription "Admiralty patent number 3332" and "Walker Trident Electric Ship Log (Mark III), 15-25 volt". On top of lid, hand written, is "G TAYLOR"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ships log, thomas walker & son, electric ships log, marine navigation, thomas ferdinand walker, ship log -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1940's

Smiths began with a craftsman named Samuel Smith who in 1851 opened a shop in Newington Causeway, London, where he made and sold watches, clocks and precision instruments. Samuel had a son, Samuel Jnr who was apprenticed in his fathers business. Samuel Jnr eventually opened his own business at 85 Strand and later opened other premises at 9 Strand, Trafalgar Square and 68 Piccadilly. In 1899 he turned his business into a private limited company, S. Smith & Son Ltd. Samuel Jnr son, Sir Allan Gordon-Smith, joined him as Manager at 9 Strand in 1903 and laid the foundation of the vast Smiths organisation of the future, leading the company towards the supply of accessories for the then developing motor industry making car clocks and the first speedometers patented in 1904. In July 1914 a new company was formed under the name S. Smith & Sons (Motor Accessories) Ltd., to take over the motor accessory business of S. Smith and Son Ltd. and this became the main company of the group which eventually grew to become Smiths Industries Ltd. The original company S Smith and Sons Ltd., continued as jewelers and clock and watchmakers until 1930 when the company was taken over by Bravingtons retail jeweller chain. In 1931 Smiths decided to enter the domestic clock market and formed a new company, Smiths English Clocks Ltd., as the Clock and Watch division of S Smith & Sons (Motor Accessories) Ltd. This is the start of "Smiths Clocks" because this is when they began to manufacture domestic clocks in quantity. Moreover, they set out to produce these clocks at a price that the average householder could afford. S Smith & Sons (Motor Accessories) was at this time was the main company in the Smiths group of companies and their business developed both in the motor vehicle field and outside it. Smiths began to make automatic pilots for aircraft and, through the acquisition of a majority interest in Henry Hughes & Sons Ltd., entered the field of marine instruments. During the war from 1939 to 1945, Smiths' production expanded. There was a demand for motor, aircraft and marine instruments for the Services and the production of industrial instruments and it is at this time that our item was made. In 1944 many changes were made to the Smiths' organisation. The name of the principal company was changed from S Smith & Sons (Motor Accessories) to S. Smith & Sons (England) Ltd. and four new subsidiary selling companies were set up. These were Smiths Motor Accessories Ltd., Smiths Aircraft Instruments Ltd., Smiths Industrial Instruments Ltd., and Smiths English clocks Ltd. The manufacture of clocks and watches ceased in 1979 and 1983 saw Smiths withdraw from producing items for the motor industry.An item that is now regarded as a vintage, sought by horology collectors worldwide and is in excellent condition. The item is unique in that it was made specifically for ships by the Smith company a well known British clock manufacture. Its provenance is well established and it was made during the world war II era specifically for merchant and naval vessels of the time. Naval brass ships bulkhead clock. The clock face is of white enamel with black Roman numerals, an outer minutes ring and black steel hands. There is a subsidiary seconds dial with sweeping hand just above the centre and a fast/slow adjustment lever above that. There is no manufactures name on the dial. There are a beveled glass and brass hinged lid to the front of the clock. The clock is housed in a heavy brass case with screw holes around the circumference for mounting. There are no markings on the clock or mechanism flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, s smith and sons, clock, maritime clocks, clock makers, bulkhead clock -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Bosun's Chair, ca. mid-20th century

The bosun’s chair is a typical piece of equipment included on board a vessel in the late 19th and early 20th century. The nautical word 'bosun' is an abbreviation of the word 'boatswain' who is the person responsible for the repair and maintenance of the vessel. It could be used when rigging the sails and for rescue at sea, along with a thick rope anchored on shore or a rope between ships. It could also be used to move passengers to and from a ship as well as cargo on, to and from the vessel. A bosun's chair is a simple piece of equipment made from a short plank of wood and a sturdy piece of rope. It looks a little like a child's swing but usually has a pulley system that allows the user to adjust the length of the hanging piece of rope, and in so-doing adjusts the height above the floor or ground or sea. In modern times a harness would also be worn by the bosun’s chair user for safety reasons. Bosun's chairs are also used by window cleaners, construction workers and painters. The bosun’s chair is sometimes just a short plank, or even a canvas sling. The bosun's chair is significant for its association with maritime equipment carried on board a vessel in the late 19th and early 20th century for maintenance and safety purposes. It was occasionally used to save lives. The bosun's chair is also significant as an early version of equipment still used today. Since its invention there have been many safety features added in certain industries such as window cleaning and painting.Bosuns chair, rectangular slab of wood with two holes at both ends through which rope ends are threaded for support and the loops above the seat are tied with sailor's knotting to form a triangle. flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, bosun's chair, bosuns chair, boatswains chair, rigging, maritime equipment, bosun's seat, life saving, marine technology, ship rigging -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Binnacle and Magnetic Compass

In 1947, the scientific instrument manufacturing firms of Henry Hughes & Son Ltd, London, England, and Kelvin Bottomley & Baird Ltd, Glasgow, Scotland, came together to form Kelvin & Hughes Ltd. Hughes Company History: Henry Hughes & Sons were founded in 1838 in London as a maker of chronographic and scientific instruments. The firm was incorporated as “Henry Hughes & Sons Ltd” in 1903. In 1923, the company produced its first recording echo sounder and in 1935 a controlling interest in the company was acquired by S Smith & Son Ltd resulting in the development and production of marine and aircraft instruments. Following the London office's destruction in the Blitz of 1941, a collaboration was entered into with Kelvin, Bottomley & Baird Ltd resulting in the establishing “Marine Instruments Ltd”. Following the formal amalgamation of Kelvin, Bottomley & Baird Ltd and Henry Hughes & Sons Ltd in 1947 to form Kelvin & Hughes Ltd. Marine Instruments Ltd then acted as regional agents in the UK for Kelvin & Hughes Ltd who were essentially now a part of Smith's Industries Ltd founded in 1944 and the successors of S. Smith & Son Ltd. Kelvin & Hughes Ltd went on to develop various marine radar and echo sounders supplying the Ministry of Transport, and later the Ministry of Defence. The firm was liquidated in 1966 but the name was continued as Kelvin Hughes, a division of the Smiths Group. In 2002, Kelvin Hughes continues to produce and develop marine instruments for commercial and military use. (See Note section this document for further information on the company's origins) This model binnacle and compass is a good example of the commercial diversity of navigational instruments made by Kelvin & Hughes after world war 2. It was made in numbers for use by shipping after the second world war and is not particularly rare or significant for its type. Also, it was made no earlier than 1947 as the firms of Kelvin, Bottomley & Baird Ltd and Henry Hughes & Sons Ltd who took over from Smith & Sons were not amalgamated until 1947. It can there for be assumed that this item was made during the company's transitional period to Kelvin & Hughes from Smith Industries Ltd.Mid 20th century ship's binnacle with Kelvin Hughes/ F. Fuselli Genova 8 inch diameter (glass) compass on gimballed ring. Round, teak wood pedestal with mounted brass compensating sphere brackets and painted iron balls one green the other red. Heavy brass helmet style compass cover with hinged front door and removable top for compass viewing and natural lighting. A single handle is located on the side and single burner on the opposite side. Retains an old finish and some wear to the pedestal base. Binnacle marked Serial No 163 "Veritas" Made by Kelvin Hughes Compass marked "Kelvin Hughes & Made in Great Britain Serial No 760 C J"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Hand Trolley, Mid-20th century

A hand trolly can be loaded with heavy objects such as luggage, produce, and equipment and the objects can then be easily wheeled from one place to another. They are used by farmers, railway workers, shipping companies, porters, factory labourers and other industries when heavy loads need to be moved. Hand trolleys were first used in the 18th century by young workers at the docks. The new equipment used leverage and wheels, enabling them to move the same heavy loads that the men were moving. This hand trolley is an example of the hand trolleys used since the 18th century to move heavy loads at the docks and shipyards. It is associated with the maritime industries of shipping, transportation, travel and trade as with the primary production sectors of farming, markets and produce. Hand trolley; an L-shaped handcart with handles at one end, wheels at the other, and a ledge to hold the load. This hand trolley has orange wooden slats and handles, two metal wheels and a black metal frame. It has supporting legs at one end, two metal flanges near the wheels and a support foot at the bottom. There is an inscription on the metal at one side.Stamped into metal: "MSSC"warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, hand trolley, sack truck, trolley, luggage trolley, hand truck, trundler, sack barrow, bag barrow, leverage, marine technology, cargo handling, docks, wharft, shipping, trade -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Machinery Oiler Can, First half of the 20th century

An oil can or oiler is a can that holds oil usually motor oil for lubricating machines. An oil can can also be used to fill oil-based lanterns. An occupation, referred to as an oiler, can use an oil can (among other tools) to lubricate machinery. Oil cans were made by companies like Noera Manufacturing Company and Perfection in the late 19th and early 20th centuries and around this time, oil cans frequently leaked and contributed to fires. In 1957, aluminium oil cans were introduced, produced by companies like the American Can Company. Rocanville, Saskatchewan, Canada is home to a large-scale oil can industry because of the Symons Oiler factory which produced oil cans during World War II.The subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, item a is believed to have been produced in the first half of the 20th century for marine use.Conical oiler can with spout, screw top lid and top hook for hanging, side handle missing.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, conical pot, pot -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Marine Lamp, R C Murray & Co Ltd, 1900 -1930

... used in the marine industry on many ships, the company made ...The item is a kerosene marine ships lamp used onboard ships and smaller vessels for general lighting and navigation the subject lamp was made by a very well known maker R C Murray of Glasgow Scotland. During the research several different addresses were found but nothing on the founder or company history. It appears RC Murray made not only marine lamps but lamps for the railways as well. The company is listed in the Scottish Post Office Directories for 1885 to 1886 as manufacturing tinsmiths, lamp makers, coppersmiths, gas fitters, bell hangers and workers in sheet iron, zinc and brass at street numbers 7, 9 and 11 Carlton Court, Bridge St Glasgow. An additional address is at 37 Cavendish St Glasgow listed for 1910, and also at Pollokshaws Road. The writer assumes the company must have moved sometime between 1886 & 1910 to these addresses. The writer at this time cannot ascertain any more historical information regarding the company or its founder, however, lamps made by RC Murray are now collector's items commanding significant sale prices on many auction websites.A significant item used in the marine industry on many ships, the company made kerosene lamps for other industries as well and was a well-known company in the early part of the 20th century.Marine kerosene ships lamp, round copper handle on top and side top is hinged with catch and lever, protruding near top.Inscribed "RC Murray and Co Limited" "Pollokshaws Road Glasgow S.1." flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, lamp, lantern, brass lamp, nautical object -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Marine Lamp, James Paterson Lamp Manufacturer, 1880s to 1930s

... of the 20th century. A significant item used in the marine industry ...The item is a kerosene marine ships lamp used onboard ships and smaller vessels for general lighting and navigation the subject lamp was made in Melbourne by a known maker James Paterson. The writer at this time cannot ascertain any significant historical information regarding the company or its founder, however lamps made by James Paterson of Melbourne are rare and regarded as collector's items and would command significant sale prices. All that is currently known is that the James Paterson Lamp manufacturing company were located at 30 Little Collins St Melbourne, and were active in Dec 1885 and in 1886 from newspaper articles of the time. Therefore the assumption is that the subject lamp was made in the late 19th to the first quarter of the 20th century.A significant item used in the marine industry on many ships, the company made kerosene lamps for other industries as well and was a well-known Melbourne based company in the late 19th and early part of the 20th centuries.Marine masthead copper ship's lamp with a handle at the top and holders at the side. It has a lamp glass and reflector mounted on a removable fuel tank. It was made in Melbourne by James Paterson.Stamped James Paterson Lamp Manufacturer 30 Little Collins St Melbourneflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, lamp, masthead brass ship's lamp, masthead lamp, james paterson, marine kerosene lamp -

Flagstaff Hill Maritime Museum and Village

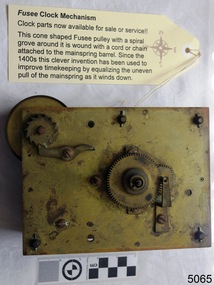

Flagstaff Hill Maritime Museum and VillageMachine - Fusee Clock Mechanism, early 20th Century

The origin of the fusee is not known. Many sources credit clockmaker Jacob Zech of Prague with inventing it around 1525. The earliest dated fusee clock was made by Zech in 1525, but the fusee appeared earlier, with the first spring-driven clocks in the 15th century. The idea probably did not originate with clockmakers, since the earliest known example is in a crossbow windlass shown in a 1405 military manuscript. Drawings from the 15th century by Filippo Brunelleschi and Leonardo da Vinci also show fusee mechanisms. The earliest existing clock with a fusee, also the earliest spring-powered clock, is the Burgunderuhr (Burgundy clock), a chamber clock whose iconography suggests that it was made for Phillipe the Good, Duke of Burgundy about 1430. Springs were first employed to power clocks in the 15th century, to make them smaller and portable.[1][5] These early spring-driven clocks were much less accurate than weight-driven clocks. Unlike a weight on a cord, which exerts a constant force to turn the clock's wheels, the force a spring exerts diminishes as the spring unwinds. The primitive verge and foliot timekeeping mechanism, used in all early clocks, was sensitive to changes in drive force. So early spring-driven clocks slowed down over their running period as the mainspring unwound. This problem is called lack of isochronism. Two solutions to this problem appeared with the first spring-driven clocks; the stack freed and the fusee. The stack freed, a crude cam compensator, added a lot of friction and was abandoned after less than a century. The fusee was a much more lasting idea. As the movement ran, the tapering shape of the fusee pulley continuously changed the mechanical advantage of the pull from the mainspring, compensating for the diminishing spring force. Clockmakers empirically discovered the correct shape for the fusee, which is not a simple cone but a hyperboloid. The first fusees were long and slender, but later ones have a squatter compact shape. Fusees became the standard method of getting constant force from a mainspring, used in most spring-wound clocks, and watches when they appeared in the 17th century. Around 1726 John Harrison added the maintaining power spring to the fusee to keep marine chronometers running during winding, and this was generally adopted. The fusee was a good mainspring compensator, but it was also expensive, difficult to adjust, and had other disadvantages: It was bulky and tall and made pocket watches unfashionably thick. If the mainspring broke and had to be replaced, a frequent occurrence with early mainsprings, the fusee had to be readjusted to the new spring. If the fusee chain broke, the force of the mainspring sent the end whipping about the inside of the clock, causing damage. The invention of the pendulum and the balance spring in the mid-17th century made clocks and watches much more isochronous, by making the timekeeping element a harmonic oscillator, with a natural "beat" resistant to change. The pendulum clock with an anchor escapement, invented in 1670, was sufficiently independent of drive force so that only a few had fusees. In pocketwatches, the verge escapement, which required a fusee, was gradually replaced by escapements which were less sensitive to changes in mainspring force: the cylinder and later the lever escapement. In 1760, Jean-Antoine Lépine dispensed with the fusee, inventing a going barrel to power the watch gear train directly. This contained a very long mainspring, of which only a few turns were used to power the watch. Accordingly, only a part of the mainspring's 'torque curve' was used, where the torque was approximately constant. In the 1780s, pursuing thinner watches, French watchmakers adopted the going barrel with the cylinder escapement. By 1850, the Swiss and American watchmaking industries employed the going barrel exclusively, aided by new methods of adjusting the balance spring so that it was isochronous. England continued to make the bulkier full plate fusee watches until about 1900. They were inexpensive models sold to the lower classes and were derisively called "turnips". After this, the only remaining use for the fusee was in marine chronometers, where the highest precision was needed, and bulk was less of a disadvantage until they became obsolete in the 1970s. Item is an example of clock mechanisms used until 1910 for many different styles of clocks and went out of fashion in the 1970s due to improvements in clock and watch making.Brass fusse clock movement, It has very heavy brass plates and wheels, high-count machined pinions, and a fusee. The mounting of the pendulum is missing and It has a recoil escapement. A fusee is a conical pulley driven through a chain by the spring barrel. As the spring runs down, the chain acts at a larger and larger radius on the conical pulley, equalising the driving torque. This keeps the rate of the clock more even over the whole run. It has motion work to drive an hour hand as well as a minute hand and the centre arbor is extended behind the back plate to drive some other mechanism.Inscription scratched on back"AM 40" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock mechanism, fusee mechanism, horology -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCompass, 1947-1950

Kelvin Company History: The origins of the company lie in the highly successful, if strictly informal, the relationship between William Thomson (1824-1907), Professor of Natural Philosophy at Glasgow University from 1846-1899 and James White, a Glasgow optical maker. James White (1824-1884) founded the firm of James White, who was an optical instrument maker in Glasgow in 1850. He was involved in supplying and mending apparatus for Thomson's university laboratory and working with him on experimental constructions. White was actually declared bankrupt in August 1861 and released several months later. In 1870, White was largely responsible for equipping William Thomson's laboratory in the new University premises at Gilmore hill. From 1876, he was producing accurate compasses for metal ships to Thomson's design during this period and this became an important part of his business in the last years of his life. He was also involved in the production of sophisticated sounding machinery that Thomson had designed to address problems encountered laying cables at sea, helping to make possible the first transatlantic cable connection. At the same time, he continued to make a whole range of more conventional instruments such as telescopes, microscopes and surveying equipment. White's association with Thomson continued until he died. After his death, his business continued under the same name, being administered by Matthew Edwards (until 1891 when he left to set up his own company). Thomson, who became Sir William Thomson and then Baron Kelvin of Largs in 1892, continued to maintain his interest in the business after James White's death in 1884, raising most of the capital needed to construct and equip new workshops in Cambridge Street, Glasgow. At these premises, the company continued to make the compass Thomson had designed during the 1870s and to supply it in some quantity, especially to the Admiralty. At the same time, the firm became increasingly involved in the design, production and sale of electrical apparatus. In 1899, Lord Kelvin resigned from his University chair and became, in 1900, a director in the newly formed limited liability company Kelvin & James White Ltd which had acquired the business of James White. At the same time Kelvin's nephew, James Thomson Bottomley (1845-1926), joined the firm. In 1904, a London branch office was opened which by 1915 had become known as Kelvin, White & Hutton Ltd . Kelvin & James White Ltd underwent a further change of name in 1913, becoming Kelvin Bottomley & Baird Ltd . Hughes Company History: Henry Hughes & Sons was founded in 1838 in London as a maker of chronographic and scientific instruments. The firm was incorporated as Henry Hughes & Sons Ltd in 1903. In 1923, the company produced its first recording echo sounder and in 1935, a controlling interest in the company was acquired by S Smith & Son Ltd resulting in the development and production of marine and aircraft instruments. Following the London office's destruction in the Blitz of 1941, a collaboration was entered into with Kelvin, Bottomley & Baird Ltd resulting in the establishing Marine Instruments Ltd. Following the formal amalgamation of Kelvin, Bottomley & Baird Ltd and Henry Hughes & Sons Ltd in 1947 to form Kelvin & Hughes Ltd., Marine Instruments Ltd then acted as regional agents in the UK for Kelvin & Hughes Ltd who were essentially now a part of Smith's Industries Ltd founded in 1944 and the successors of S Smith & Son Ltd. Kelvin & Hughes Ltd went on to develop various marine radar and echo sounders supplying the Ministry of Transport, and later the Ministry of Defence. The firm was liquidated in 1966 but the name was continued as Kelvin Hughes, a division of the Smiths Group. In 2002, Kelvin Hughes continues to produce and develop marine instruments for commercial and military use. This model compass is a good example of the commercial type of instruments made by Kelvin & Hughes after the world war 2, it was made in numbers for use on various types of shipping after the second world war and is not particularly rare or significant for it's type. Also it was made no earlier than 1947 as the firms of Kelvin, Bottomley & Baird Ltd and Henry Hughes & Sons Ltd who took over from Smith & Sons were not amalgamated until 1947. Given that Smith and Sons is engraved on the compass with Kelvin & Hughes it can be assumed that this compass was made during the company's transitional period to Kelvin & Hughes.Compass, marine or ship's card compass, gimble mounted, with inscriptions. Type is Lord Kelvin 10 inch compass card. Made in Great Britain by Kelvin Hughes Division of S. Smith & Sons (England) Ltd. "LORD KELVIN 10.", "COMPASS GRID", "MANUFACTURED IN GREAT BRITAIN BY", "KELVIN HUGHES DIVISION", "S. Smith & Sons (England) Ltd".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, marine compass, gimble compass, ship's compass, lord kelvin compass, smith and sons england ltd, henry hughes & son ltd london england, kelvin bottomley & baird ltd glasgow scotland, kelvin & hughes ltd, navigation instrument, scientific instrument, william thomson, james white, baron kelvin of largs -

Port Melbourne Historical & Preservation Society

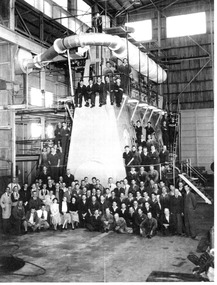

Port Melbourne Historical & Preservation SocietyBook, Glen Stuart, My Time At Engine Works, 26 Oct 2008

Completed by Glen Stuart in 2007 and published by PMH&PS in October 2008, when Glen spoke on the subject at a PMH&PS meeting"My Time At Engine Works" by Glen Stuart. Yellow paperback 48 pages illustrated. A memoir of Glen's working life, building marine engines.industry - manufacturing, transport - shipping, commonwealth engine works, glen stuart -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyBook, Land Conservation Council Victoria, The Gippsland Lakes Land Use Strategy Plan 1978, 1985

A review of public land use in the East Gippsland area, including natural resources, flora and fauna, recreation. Contains photographs, maps statistics.conservation, aboriginals, primary industry -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyBook, Rule, Hilda, East Gippsland Past and Present, 1980

History of Nowa Now for the 'Back to Nowa Nowa' in September 1980. Includes photographs.township, timber industry, settlement -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph, 1980

Colour photograph of the deck of the fishing boat Minawie almost covered with a successful shot of school whiting, estimated as 70 bins. Taken at sea. Lakes Entrance Victoriafishing industry, waterways -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph

Sister ships for MinawieColour photograph of the fishing boats Mako and Yukon ready for launch, built by Pompie, Mordialloc, Victoria.fishing industry, boats and boating, ocean -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph, 1980

Colour photograph of the recovery of the cruiser Idler which had been abandoned at seatopography, fishing industry, ocean, boats and boating -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph, 1980

Colour photograph of the recovery of the cruiser Idler which had been abandoned at seatopography, fishing industry, ocean, boats and boating -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyBook, Australian Narional University, Oil Search in Australia CEB Conybeare, 1980

An account of the history and development on the search for oil in Australia and production up to 1980Small book with orange cover 151 pagesnon-fictionAn account of the history and development on the search for oil in Australia and production up to 1980oil, industry, history -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph, Hancock, 1952

The icrusher came from Sennitts in Sydney and was modified by Kents Engineering. The block ice was manufactured at the ice works in Staughton Street. At this time 1952 the Anchovette had the wheelhouse at the stern.Black and white photograph of fishermen icing fish on the Anchovette in photograph are Jack Corbett, Ted Jackel, Harold Broome. Lakes Entrance Victoriafishing industry, boats and boating -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph, Hancock, 1952

Black and white photograph of fishermen loading ice onto the Anchovette, seated in photograph is Jimmy McNamara Lakes Entrance Victoriafishing industry -

Wodonga & District Historical Society Inc

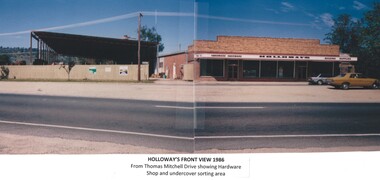

Wodonga & District Historical Society IncPhotograph - Holloways Building Supplies

Eric Holloway began spot milling timber at age of 17. He borrowed fifty pound from an uncle in 1934 to purchase a McCormick Deering tractor and saw bench. He went from farm to farm cutting timber for farmers. For a time, he worked on Shelley Station spot milling with WS Walker and Son. In approximately 1946 Arthur and Eric Holloway established a saw mill at Shelley. Another brother Ernie, a builder and returned soldier, worked with them from time to time. Using timber sawn in the mill he built eight basic houses for the mill workers. The brothers employed many migrants: - Yugoslav, Czechs, Russians, Ukrainians, Serbs as well as other hardworking people. This meant there were families, so Ernie also built and furnished a school at Shelley. Application was made for a teacher from the Education Department. At the Shelley mill the workers used ex-army blitzes, GM trucks (for carting logs) army ducks and a centurion tank for parts. The timber from the mill was trucked to Albury and Wodonga, customers being FA Stowe and Mates Timber. The army was also a big customer with Holloways supplying timber for the army huts that were built at Bandiana. A timber mill that had been built at Tallangatta by State Rivers and Water for the purpose of establishing New Tallangatta, was purchased by Holloway Brothers as an extension of their Shelley operation. In 1954 a new mill was built at Granite Flat on the Omeo Highway and the Shelley operation closed. Ernie Holloway was involved in the building of the mill and accommodation houses in Mitta Mitta. The mill workers travelled from Mitta to work each day. Holloways Building Supplies was established at 49 Tallangatta Rd Wodonga at this time. It was established on four house blocks with a little shed, with more land being acquired as the operation expanded. The brothers realized that it would be more profitable to set up their own timber outlet to supply their customers. Arthur Holloway continued to run the sawmills while Eric Holloway concentrated on the Wodonga business. A hardware store, offices and joinery were built as demand continued for building materials. All the timber arriving in the yard from the mill was hand sorted, providing employment for many. With the milling and timber outlets Holloways provided employment for approximately forty staff. The next generation of the Holloway family became involved. A Hyster forklift was purchased which allowed for bulk handling of the timber. Land was purchased in Sanyo Drive where timber was cleated and dried. Select grade timber, F17 dry framing, builders hardware and tools were sold. Holloways endeavoured to be a one stop shop for framing and fitting out of houses. In 1989 the business was sold to Mt Beauty Timbers who later on sold to Dahlsens. The timber mill was decommissioned. The Holloway family retained the ownership of the premises of 49 Thomas Mitchell Drive leasing to Dahlsens until that operation was moved to Albury in 2013. In 2014 the lease land was sold to two local businesses. Leigh Martin Marine purchased the parcel of land adjoining their business. Lester and Son purchased the remaining block and demolished the premises. A funeral parlour was built on that site.These photos are significant because they document the story of an important Wodonga business.A series of coloured photographs depicting aspects of Holloways Building Supplies business in Wodonga.holloways wodonga, wodonga businesses, timber industry -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaPainting - Painting, Acrylic, Ramon Honisett, Untitled, 1990-2000

Ramon (Ray) Francis Honisett (11.04.1931 - 30.08.2019), Fellow RMIT and medallist specialised in philatelic design, marine and military aircraft painting art and was active in the 1960s - 1990s. Ray Honisett used to live in Rye, in the Mornington Peninsula. According to Gavin Fry's book: The painting likely depicts the Lysaght Endeavour loading at Hastings. "The Lysaght Endeavour and its sister ship Lysaght Entreprise were built in Newcastle in 1973 specifically to serve the regional steel industry on the route Port Kembla - Westernport - Adelaide. Even after being lengthened by 17 metres, the two ships had remarkably short working lines, with both being broken up by 1988."Maritime artLarge framed unglazed landscape format painting predominantly green depicting in foreground a merchant vessel, a roll-on roll-off cargo ship moored at a single quayside on a river or river mouth. The middle ground shows a moderate solid jetty leading to large storage sheds at right. The background appears primarily rural with fields and hills in the distance. The location is probably Hastings Western Port in Victoria - notice the forklifts loading rolls of steel produced at the nearby steel rolling mill - the buildings in the distance. You can see the rolls of steel lined up on the hard stand to the right of the ship. The funnel colours suggest the Australian National Line. The frame incorporates a beige fabric slip with gilt edge the actual dark wood frame also with inset banded gilt edge. The back of the painting is covered with brown paper in places damaged. Hangs on a cotton cord threaded between two screw in eyelet hooks.at lower right corner single uc word in black paint : "HONISETT"tankers, marine painting, maritime art, ramon honisett, ray honisett, anl maritime art prize, acta maritime art prize, hastings, western port, victoria, steel, roll on roll off, forklift, mornington peninsula, artwork-paintings -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

... and generally in coastal areas of Victoria. Marine industries ...The wooden pattern was possibly made for casting a part for Craftman Marine, makers of engines for boats and other machines. It is part of a set that is stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block with a corner cut diagonally. A five-sided shape has been carved into the centre, with one side curved inwards and slightly shallower than the other sides. The cut-out area is painted black. Three holes are drilled in the cut-out side to align the pattern with another piece of work. A wooden slat is fixed across the diagonal side. The back of the pattern has a handwritten inscription, possibly by two writers. The pattern is part of a set of foundry patterns from Briggs Brass Foundry and is connected to Craftman Marine.In black handwriting: "1 # H AL" Handwritten in a different hand: "CRAFTMAN MARINE" Written the the first hand: BRIGGS" (or "BRICK")flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912, craftman marine, craftsman marine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

... and generally in coastal areas of Victoria. Marine industries ...The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; thick square mostly unopainted wooden block with a solid half-cylinder added to the top, which has rounded shoulders. A disc is added to the front, aligned with the curve at the top. The top curve has orange paint and the dial is pink. Three holes are drilled in the back, in a triangular configuration. It is similar in shape to a mantle clock or an early-style radio. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

... and generally in coastal areas of Victoria. Marine industries ...The wooden pattern is part of a set that is stored in a strong wooden crate and may be part of another similar pattern. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; unpainted, square wooden block with a semi-circle of dowel added to the centre of the side with rounded corners. Three short dowel pegs are inserted on one flat side; one below the semi-circle and one near the lower corners in an overall triangle configuration. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

... for the marine industry, ready to supply the needs for once-off or mass ...The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block made from laminated sections of wood painted black. A half-cylinder shape was carved into the long side, and a dowel shape was placed at the lower side. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

... for the marine industry, ready to supply the needs for once-off or mass ...The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; pair of U-shaped carved blocks, unpainted. The blocks have opposing metal pins and holes to hold them together. One block has a disc shape carved into the base. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912