Showing 93 items

matching road making equipment

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Chisel, 1930-1955's

This pointed chisel, made in Melbourne, was used in the making of components for the ship model Sovereign of the Seas. It is part of a collection of objects used by Jim Williams, maker of fine ship models from about 1930-1955. Most of the components for the models, as well as many of the tools, were handmade by Jim Williams. Jim’s family has donated the ship model “Sovereign of the Seas” and many tools, accessories and documents used in the making of this and other ship models have been donated to Flagstaff Hill Maritime Village. Ship model of HMS Sovereign of the Seas, scale model of 17th Century English war ship, was handmade and carved from plans, enclosed in airtight glass case. All components of that model, including even the smallest pulleys, were hand crafted using tools designed and made by Jim. Outstanding details include functional rigging and moving cannons. Please see our record 3732 of the mode Sovereign of the Seas for further details of the ship and the maker. This chisel is connected with the hobby and skill of ship model making that has been crafted as a leisure activity for many generations. The hobby is often chosen by serving and retired mariners who appreciate the connection with maritime history. This chisel was used by local Warrnambool man, Jim Williams, who was employed at Cramond and Dickson clothing store, and then at Fletcher Jones menswear for 27 years. It was used in making components for the model of the historic ship, the Sovereign of the Seas. The Sovereign of the Seas was a historic 17th century English war ship with important maritime heritage. Pointed chisel; dark round wood handle and metal shaft. Made in Melbourne. Chisel blade has an illegible inscription on it. This chisel is part of a collection of tools and accessories once used by Jim Williams, maker of a series of ship models 1930-1955 including “HMS Sovereign of the Seas”.Pressed into the metal "FRANK - - - / MELBOURNE"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ship model sovereign of the seas, jim williams, james bernard williams, ship model hobby, ship model tools, ship model making equipment, ship model making accessories, wood working tool, pointed chisel, chisel made in melbourne, sovereign of the sea, ship model, hobby, ship model tool, tool, chisel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Screwdriver Set, 1930-1955's

This Yankee spiral-ratchet Screw Driver (screwdriver) set was a hand tool with drills, used in the making of components for the ship model Sovereign of the Seas. It is part of a collection of objects used by Jim Williams, maker of fine ship models from about 1930-1955. Most of the components for the models, as well as many of the tools, were handmade by Jim Williams. Jim’s family has donated the ship model “Sovereign of the Seas” and many tools, accessories and documents used in the making of this and other ship models have been donated to Flagstaff Hill Maritime Village. Ship model of HMS Sovereign of the Seas, scale model of 17th Century English war ship, was handmade and carved from plans, enclosed in airtight glass case. All components of that model, including even the smallest pulleys, were hand crafted using tools designed and made by Jim. Outstanding details include functional rigging and moving cannons. Please see our record 3732 of the mode Sovereign of the Seas for further details of the ship and the maker. This set is connected with the hobby and skill of ship model making that has been crafted as a leisure activity for many generations. The hobby is often chosen by serving and retired mariners who appreciate the connection with maritime history. This set was used by local Warrnambool man, Jim Williams, who was employed at Cramond and Dickson clothing store, and then at Fletcher Jones menswear for 27 years. It was used in making components for the model of the historic ship, the Sovereign of the Seas. The Sovereign of the Seas was a historic 17th century English war ship with important maritime heritage. Spiral-Ratchet Screw Driver set, also called an ‘American drill’ or hand drill. 9 parts, Yankee brand, No. 31 set. Made by North Bros. Mfc Co. Philadelphia, Pennsylvania, U.S.A.. Instructions for use are on label. Ratchet screwdriver plus 6 drill bits - sizes 1/16th to 11/64th - contained in a small round wooden tube with lid, label on outside. This Screw Driver set is part of a collection of tools and accessories once used by Jim Williams, maker of a series of ship models 1930-1955 including “HMS Sovereign of the Seas”. “WITH 6 DRILL POINTS / SIZES, 1/16 TO 11/64 includes - - with - - / “Yankee” Spiral-Ratchet Screw Driver No. 31 / Made by NORTH BROS. MFG. CO. PHILADELPHIA P [A?]- / Directions for use – First Insert Drill Point In - / Drill Chuck, and turn the – in Chuck of Screwdriver U.S.A.”flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jim williams, james bernard williams, ship model hobby, ship model tools, ship model making equipment, ship model making accessories, wood working tool, model making tool, screwdriver set, spiral ratchet screwdriver set, yankee screwdriver set, spiral-ratchet screw driver set, american drill, ratchet drill set, ratchet hand drill, ratchet screwdriverset, north bros. mfc co philadelphia pa, tool, sovereign of the sea, ship model, hobby, ship model tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Gauge, 1930-1955's

This gauge was used in the making of components for the ship model Sovereign of the Seas. It is part of a collection of objects used by Jim Williams, maker of fine ship models from about 1930-1955. Most of the components for the models, as well as many of the tools, were handmade by Jim Williams. Jim’s family has donated the ship model “Sovereign of the Seas” and many tools, accessories and documents used in the making of this and other ship models have been donated to Flagstaff Hill Maritime Village. Ship model of HMS Sovereign of the Seas, scale model of 17th Century English war ship, was handmade and carved from plans, enclosed in airtight glass case. All components of that model, including even the smallest pulleys, were hand crafted using tools designed and made by Jim. Outstanding details include functional rigging and moving cannons. Please see our record 3732 of the mode Sovereign of the Seas for further details of the ship and the maker. This gauge is connected with the hobby and skill of ship model making that has been crafted as a leisure activity for many generations. The hobby is often chosen by serving and retired mariners who appreciate the connection with maritime history. This gauge was used by local Warrnambool man, Jim Williams, who was employed at Cramond and Dickson clothing store, and then at Fletcher Jones menswear for 27 years. It was used in making components for the model of the historic ship, the Sovereign of the Seas. The Sovereign of the Seas was a historic 17th century English war ship with important maritime heritage. Gauge; marking gauge, wooden. Wooden handle threaded through hole in wooden block, adjusted along the handle by tightening a wing-nut screw. The end of the handle has a pointed pin fitted for scoring a mark on the work surface to mark timber before cutting. This gauge is part of a collection of tools and accessories once used by Jim Williams, maker of a series of ship models 1930-1955 including “HMS Sovereign of the Seas”.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jim williams, james bernard williams, ship model hobby, ship model tools, ship model making equipment, ship model making accessories, wood working tool, model making tool, drawing instrument, gauge, tool, sovereign of the sea, ship model, hobby, ship model tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Chisel, 1930-1955's

This chisel was specially modified to be used in the making of components for the ship model Sovereign of the Seas. It is part of a collection of objects used by Jim Williams, maker of fine ship models from about 1930-1955. Most of the components for the models, as well as many of the tools, were handmade by Jim Williams. Jim’s family has donated the ship model “Sovereign of the Seas” and many tools, accessories and documents used in the making of this and other ship models have been donated to Flagstaff Hill Maritime Village. Ship model of HMS Sovereign of the Seas, scale model of 17th Century English war ship, was handmade and carved from plans, enclosed in airtight glass case. All components of that model, including even the smallest pulleys, were hand crafted using tools designed and made by Jim. Outstanding details include functional rigging and moving cannons. Please see our record 3732 of the mode Sovereign of the Seas for further details of the ship and the maker. This chisel is connected with the hobby and skill of ship model making that has been crafted as a leisure activity for many generations. The hobby is often chosen by serving and retired mariners who appreciate the connection with maritime history. This chisel was used by local Warrnambool man, Jim Williams, who was employed at Cramond and Dickson clothing store, and then at Fletcher Jones menswear for 27 years. It was used in making components for the model of the historic ship, the Sovereign of the Seas. The Sovereign of the Seas was a historic 17th century English war ship with important maritime heritage. Grooving chisel, metal blade and turned wood handle. Round wooden handle has been bent and cut on one side so that it can be used in small difficult areas. This chisel is part of a collection of tools and accessories once used by Jim Williams, maker of a series of ship models 1930-1955 including “HMS Sovereign of the Seas”.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jim williams, james bernard williams, ship model hobby, ship model tools, ship model making equipment, ship model making accessories, wood working tool, model making tool, chisel, sovereign of the sea, ship model, hobby, ship model tool -

Flagstaff Hill Maritime Museum and Village

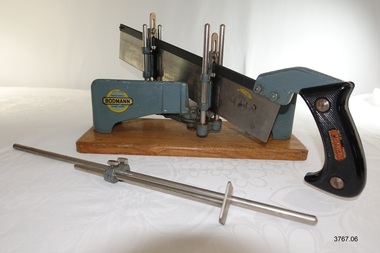

Flagstaff Hill Maritime Museum and VillageTool - Mitre Saw Set, 1930-1955's

This Bodmann mitre saw set was used in the making of components for the ship model Sovereign of the Seas. It is part of a collection of objects used by Jim Williams, maker of fine ship models from about 1930-1955. Most of the components for the models, as well as many of the tools, were handmade by Jim Williams. Jim’s family has donated the ship model “Sovereign of the Seas” and many tools, accessories and documents used in the making of this and other ship models have been donated to Flagstaff Hill Maritime Village. ABOUT the BRAND NAME ON THE SAW - BODMANN and CO, Germany In 1927 the Brisbane Courier Mail described Bodmann and Co of Reinscheid, Germany as "manufacturers of guaranteed tools and hardware. It appears that at least the saw has been re-badges and sold by Bodmann because (1) there are remnants of a label on the saw blade similar in shape to the Bodmann label on the mitre set (2) the removed label reveals the name and logo of "ULMIA Schutz OTT Marke" (3) one of the "Bodmann" labels on the saw handle has been applied in a crooked manner, almost leaving off the last "N". ULMIA is a German manufacturer of high quality woodworking tools. A drawing of a very similar mitre bset with saw can be seen on the ULMIA website. In 2002 the long established company ANKE of Swabian Alb, Germany (makers of cut timber, workbenches and countertops) bought out the name and trademark rights of ULMIA. HISTORY OF SOVEREIGN OF THE SEA (brief) Ship model of HMS Sovereign of the Seas, scale model of 17th Century English war ship, was handmade and carved from plans, enclosed in airtight glass case. All components of that model, including even the smallest pulleys, were hand crafted using tools designed and made by Jim. Outstanding details include functional rigging and moving cannons. Please see our record 3732 of the mode Sovereign of the Seas for further details of the ship and the Jim Williams. This mitre saw set is connected with the hobby and skill of ship model making that has been crafted as a leisure activity for many generations. The hobby is often chosen by serving and retired mariners who appreciate the connection with maritime history. This mitre saw set was used by local Warrnambool man, Jim Williams, who was employed at Cramond and Dickson clothing store, and then at Fletcher Jones menswear for 27 years. It was used in making components for the model of the historic ship, the Sovereign of the Seas. The Sovereign of the Seas was a historic 17th century English war ship with important maritime heritage. Bodmann Mitre Saw set model 348, comprising metal, adjustable mitre saw on timber stand, and metal hand saw with Bakelite handle. The mitre saw is labelled with the trademark of Bodmann, Germany, and stamped with the model number 348. The saw has Bodmann trademark badges on each side of the handle; the text on one of these badges is not quite aligned. The saw blade has remnants of a label under which the stamped logo of ULMIA Schutz OTT Marke is clearly visible. Saw is fitted with two metal guides that slide onto vertical posts on the mitre saw. Metal measuring guide holds the wood job to the correct length. Saw has a protective brown paper wrapper. This mitre saw set is part of a collection of tools and accessories once used by Jim Williams, maker of a series of ship models 1930-1955 including “HMS Sovereign of the Seas”.On mitre saw- 2x logos "REGISTERED / BODMANN / TRADE MARK" and embedded stamp “348”. On saw - Remnant of logo on blade “ULMIA Schutz OTT Marke” with image of a church-like tall building, and 2x , "BEST QUALITY / BODMANN / MADE IN GERMANY” flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jim williams, james bernard williams, ship model hobby, ship model tools, ship model making equipment, ship model making accessories, wood working tool, model making tool, mitre box set, mitre saw, bodmann and co reinscheid, germany, ulna ott of of swabian alb, germany, anke of swabian alb, germany, sovereign of the sea, ship model, hobby, ship model tool, mitre saw set -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Set of Tools, 1930-1955's

This set of handmade tools was made by Jim Williams for his own purposes to make designs and components for the ship model Sovereign of the Seas. It is part of a collection of objects used by Jim Williams, maker of fine ship models from about 1930-1955. Most of the components for the models, as well as many of the tools, were handmade by Jim Williams. Jim’s family has donated the ship model “Sovereign of the Seas” and many tools, accessories and documents used in the making of this and other ship models have been donated to Flagstaff Hill Maritime Village. Ship model of HMS Sovereign of the Seas, scale model of 17th Century English war ship, was handmade and carved from plans, enclosed in airtight glass case. All components of that model, including even the smallest pulleys, were hand crafted using tools designed and made by Jim. Outstanding details include functional rigging and moving cannons. Please see our record 3732 of the mode Sovereign of the Seas for further details of the ship and the maker. This set of handmade tools is connected with the hobby and skill of ship model making that has been crafted as a leisure activity for many generations. The hobby is often chosen by serving and retired mariners who appreciate the connection with maritime history. This set of tools was used by local Warrnambool man, Jim Williams, who was employed at Cramond and Dickson clothing store, and then at Fletcher Jones menswear for 27 years. It was used in making components for the model of the historic ship, the Sovereign of the Seas. The Sovereign of the Seas was a historic 17th century English war ship with important maritime heritage. A set of 6 small, fine wood working and carving tools stored in a ‘Craven A’ cigarette tin. The tools have been handmade by Jim Williams for the purpose of making ship models. This set of tools is part of a collection of tools and accessories once used by Jim Williams, maker of a series of ship models 1930-1955 including “HMS Sovereign of the Seas”. (Also included is a spare handle.)On the tin; “CORK TIPPED / TRADE MARK / CRAVEN “A” / VIRGINIA / CIGARETTES”flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jim williams, james bernard williams, ship model hobby, ship model tools, ship model making equipment, ship model making accessories, wood working tool, model making tool, carving tools, handmade wood carving tools, craven a cigarette tin, sovereign of the sea, ship model, hobby, ship model tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw, 1930-1955's

This fret saw, with its unconventional up-side-down blade, was used in the making of intricate shapes for the ship model Sovereign of the Seas. It is part of a collection of objects used by Jim Williams, maker of fine ship models from about 1930-1955. Most of the components for the models, as well as many of the tools, were handmade by Jim Williams. Jim’s family has donated the ship model “Sovereign of the Seas” and many tools, accessories and documents used in the making of this and other ship models have been donated to Flagstaff Hill Maritime Village. Ship model of HMS Sovereign of the Seas, scale model of 17th Century English war ship, was handmade and carved from plans, enclosed in airtight glass case. All components of that model, including even the smallest pulleys, were hand crafted using tools designed and made by Jim. Outstanding details include functional rigging and moving cannons. Please see our record 3732 of the mode Sovereign of the Seas for further details of the ship and the maker. This saw is connected with the hobby and skill of ship model making that has been crafted as a leisure activity for many generations. The hobby is often chosen by serving and retired mariners who appreciate the connection with maritime history. This saw was used by local Warrnambool man, Jim Williams, who was employed at Cramond and Dickson clothing store, and then at Fletcher Jones menswear for 27 years. It was used in making components for the model of the historic ship, the Sovereign of the Seas. The Sovereign of the Seas was a historic 17th century English war ship with important maritime heritage. Fret saw or coping saw. The fine-toothed, thin metal blade is held in place on the adjustable U shape frame by a swivelling spigot or clip at each end. The handle is turned wood, dark in colour. In this particular saw the blade is set into it upside down, and was used in this way for a specific purpose. This fret saw is part of a collection of tools and accessories once used by Jim Williams, maker of a series of ship models 1930-1955 including “HMS Sovereign of the Seas”. flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jim williams, james bernard williams, ship model hobby, ship model tools, ship model making equipment, ship model making accessories, fret saw, coping saw, wood cutting tool, carpenter's saw, carpentry, sovereign of the sea, ship model, hobby, ship model tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Cherry and Sons, 1890-1920

The subject item is a good example of a large, hand-operated Bentwood box butter churn used to make up to 14 pounds of butter. It was made in Gisborne, Victoria, by the famous manufacturer, E. Cherry, and is known as an Improved Patent No.2 model probably dating from the late 1800s. The Cherry works specialised in making all types of butter churns and equipment for both domestic use on farms and small butter factories during the late nineteenth and early to mid. twentieth centuries. Milk was "separated" to retrieve the cream which was then beaten to make butter. E Cherry began making various models of Cherry butter churns in 1858, Edward Cherry migrated from Herefordshire England to Australia in 1855 with his wife Ann Appleby, nee Davis, and established a joinery workshop at Gisborne, Victoria. He began by making butter churns in his spare time and his product soon became popular allowing him to establish a viable business. A factory was established in 1875 and he started to make churns of all sizes including up to industrial scale. He exported his products to many countries around the world, Edward Cherry died in 1909 and the business was then run by his son George until he died in 1917. E Cherry's other son Thomas (1861-1945) was also involved in the firm maintaining an interest for several years. He had been born in Gisborne and became a senior house medical surgeon at the Melbourne Hospital in 1890. He continued his studies at Kings College London, eventually becoming a renowned bacteriologist and agricultural scientist. A significant item giving an snapshot into how early industrial manufacturing became established in Australia in the production of domestic and industrial dairy equipment.Butter churn wooden manually operated made by Cherry and Sons with rotating lever curved plywood basin and parallel cross beamed horizontally spoken churning apparatus inside with wooden plug at lower side of churn. Label in block transfer "E CHERRY / MAKER / GISBORN / VICTORIA / 2" "IMPROVED PATENT"warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, butter churn, wooden butter churn, e cherry & sons, dairy equipment, gisborne, food preparation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Sander, c. 1930-1955

This burgundy coloured, portable electric belt sander is stored in its own heavy duty cardboard box. It was made in England and, according to the label on the lid of the box, it is a Portrix Sander-Polisher, all-electric, portable, sands wood metal and polishes. Its uses include decorating, carpentry and polishing. It has a complete with electric unit with flex. The price of 75/- (75 shillings) is printed on the label of the box. The model and the brand of the sander have been removed from the manufacturer’s information embossed on the side of the sander. The sander is part of a collection of objects used by Jim Williams, maker of fine ship models from about 1930-1955. Most of the components for the models, as well as many of the tools, were handmade by Jim Williams. Jim’s family has donated the ship model “Sovereign of the Seas” and many tools, accessories and documents used in the making of this and other ship models have been donated to Flagstaff Hill Maritime Village. Please see our record 3732 of the mode Sovereign of the Seas for further details of the ship and the maker.This vintage Portrix sander-polisher represents tools used for the hobby and skill of ship model making that has been carried as a leisure activity out for generations. Ship model making was also a pastime for sailing crew, who often made a model of the ship in which they were sailing. This sander was used by local Warrnambool man, Jim Williams, who was employed at Cramond and Dickson clothing store, and then at Fletcher Jones menswear for 27 years. It was used in making components for the model of the historic ship, the Sovereign of the Seas. The Sovereign of the Seas was a historic 17th century English war ship with important maritime heritage.Belt sander, electric. Portable power tool, Portrix model Sander–Polisher, burgundy coloured body with swivelling, black electric cable, 250V 1 / 4 amp. For sanding wood and metal, and for polishing. (Stored in original box.) Made in England. Part of a collection of tools and accessories used by Mr. Jim Williams to build ship model of the “Sovereign of the Sea” and other models. c. 1930-1955. Moulded into body “ - - - SANDER –POLISHER / 1 / 4 amp. PRODUCT OF - - - MANUFACTURING CO. LTD. 50 CYCLES / MADE IN ENGLAND PAT. PEND. 200/250 volts A.C.” (the Brand and Manufacturer’s name have been removed)flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, portrix sander-polisher, portrix power tool, portrix belt sander, woodworking equipment, ship modelling equipment, jim williams, james bernard williams, ship model, hobby, ship model tool, sovereign of the seas, english war ship -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel leather punch, c1900

This steel leather punch would be used by early settlers in Moorabbin Shire c1900when making and repairing, farm and household leather goods.Early settlers in Moorabbin Shire had to be self sufficient and made and repaired their farm and household equipment. Blacksmiths made the toolsA solid steel leather punchleatherwork, craftwork, moorabbin, bentleigh, cheltenham, early settlers -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionEquipment - Whale Oil Lamp, n.d

Tin wall-mounted whale oil lamp, that also has two feet, making it stable on a flat surface. Asa ? tiger head where the burner exits. Round base, curved stand, hook for hanging. Clear glass chimney. -

Eltham District Historical Society Inc

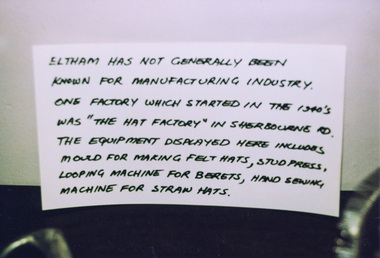

Eltham District Historical Society IncPhotograph, Hat making equipment, Heritage Week at 728 Main Road, Eltham, 1990, 1990

Two Colour photographs of hat making equipment,for Heritage Week display at the Local History Centre (former Courthouse), 728 Main Rod Eltham. (Home of Eltham District Historical Society) The equipment was used at the Hat Factory in Eltham which started in the 1940s. The equipment shown includes a mould for making felt hats, stud press, looping machine for berets and hand sewing machine for straw hats. Sign accompanying the display is hand written and reads: "Eltham has not generally been known for manufacturing industry. One factory which started in the 1940s was "the hat factory" in Sherbourne Rd. The equipment displayed here includes moulds for making felt hats, stud press, looping machines for berets, hand sewing machine for straw hats."heritage week, eltham, courthouse, hat factory, hat mould, activities -

Kiewa Valley Historical Society

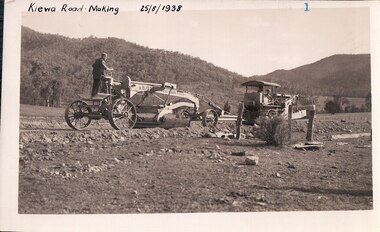

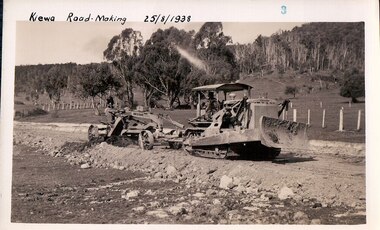

Kiewa Valley Historical SocietyBlack and White photograph of Road Making Machinery, Kiewa Road Making, 25/08/1938

... of this type of mechanical equipment in road making was a huge ...Construction of the main road from South Tawonga to the Bogong High Plains, to provide access to the construction sites for the new Kiewa Hydro Electric Scheme, was commenced early in 1938, the work being undertaken on behalf of the Commission by the Country Roads Board. For the construction work, the Commission purchased three Caterpillar - model R07 - diesel crawler tractors equipped with Kay Brunerei (Brunner) hydraulically operated trailbuilders (angle dozers). This acquisition resulted from a visit to the United States of America in May, 1937 by the Construction Engineer ( Mr. C.H. Kernot) and Assistant Civil Engineer (Mr. J.F. Douglas) where they saw this relatively new type of equipment in use. With the co-operation of the CRB, the Commission demonstrated the operation of these machines at Fishermen's Bend on 6th April, 1938. They were then sent to Kiewa where they commenced operation towards the end of the month. From South Tawonga, the route led immediately across the Western Branch of the Kiewa River necessitating the construction of a bridge 100 feet long. By the end of 1939, the excavation had been 'opened up' for a distance of 19 1/2 miles (approx. 31 km) and of this length, 10 miles (approx. 16 km) had been surfaced.The purchase and use of this type of mechanical equipment in road making was a huge investment, as prior to this most of the work would have been done manually with the use of picks and shovels. Not only were many months of hard manual labour saved, but a very significant amount of time in providing access to the proposed work sites for the new Kiewa Hydro Scheme. This photo is an excellent reminder of how primitive the early machinery was compared to the present but also represents the forward thinking of the State Electricity Commissions engineers in purchasing such innovative equipment . A black and white photograph showing the type of machinery used for road making in the 1930's. It shows a grader being towed by a caterpillar tractor.On the top left hand corner of the photograph , hand written in black ink is the words 'Kiewa Road Making 25/8/1938'. On the right hand side of the photo has been stamped in blue the Number 1. It has been developed on Velox paper (marked on back of photo) with a gloss finish.road making, state electricity commission, caterpillar tractor, kiewa -

Kiewa Valley Historical Society

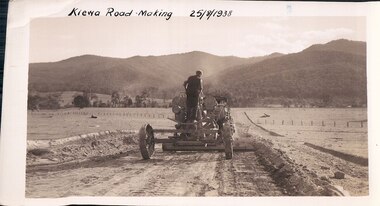

Kiewa Valley Historical SocietyBlack and White photograph of Road Making Machinery, Kiewa Road Making 25/08/1938 No. 2, 25/08/1938

... ) The purchase of this type of mechanical equipment in road making ...Construction of the main road from South Tawonga to the Bogong High Plains, to provide access to the construction sites for the new Kiewa Hydro Electric Scheme, was commenced early in 1938, the work being undertaken on behalf of the commission by the Country Roads Board. For the construction work, the Commission purchased three Caterpillar - model R07 - diesel crawler tractors equipped with Kay Brunerei (Brunner) hydraulically operated trailbuilders (angle dozers). This acquisition resulted from a visit to the United States of America in May, 1937 by the Construction Engineer ( Mr. C.H. Kernot) and Assistant Civil Engineer ( Mr. J.F. Douglas) where they saw this relatively new type of equipment in use. With the co-operation of the CRB, the Commission demonstrated the operation of these machines at Fishermen's Bend on 6th April, 1938. They were then sent to Kiewa where they commenced operation towards the end of the month. From South Tawonga, the route let immediately across the Western Branch of the Kiewa River necessitating the construction of a bridge 100 feet long. By the end of 1939, the excavation had been 'opened up' for a distance of 19 1/2 miles (approx. 31 km.) and of this length, 10 miles (approx. 16 km.) had been surfaced. (see KVHS 0328)The purchase of this type of mechanical equipment in road making was a huge investment, as prior to this most of the work would have been done manually with the use of picks and shovels. Not only were many months of hard manual labour saved, but a very significant amount of time in providing access to the proposed work sites for the new Kiewa Hydro Scheme. This photo is an excellent reminder of how primitive the early machinery was compared to the present but also represents the forward thinking of the State Electricity Commissions engineers in purchasing such innovative equipment.A black and white photograph of road making near Mt. Beauty in 1938. Mount Beauty hills can be seen in the background with cleared land for grazing in the fore ground.Hand printed in black ink at the top of the photograph is 'Kiewa Road Making 25/8/1938'. On the right hand corner has been printed the number 2. It has been printed on gloss Velox paper.road making, state electricity commission, caterpillar tractor, kiewa, secv -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBlack and White photograph of Road Making Machinery, Kiewa Road Making 25/8/1938(No. 3 in a series of 8), 25/08/1938

... of this type of mechanical equipment in road making was a huge ...Construction of the main road from South Tawonga to the Bogong High Plains, to provide access to the construction sites for the new Kiewa Hydro Electric Scheme, was commenced early in 1938, the work being undertaken on behalf of the Commission by the Country Roads Board. For the construction work, the Commission purchased three Caterpillar - model R07 - diesel crawler tractors equipped with Kay Brunerei (Brunner) hydraulically operated trail builders (angle dozers)). This acquisition resulted from a visit to the United States of America in May, 1937 by the Construction Engineer ( Mr. C.H. Kernot) and Assistant Civil Engineer (Mr. J.F. Douglas) where they saw this relatively new type of equipment in use. With the co-operation of the CRB, the Commission demonstrated the operation of these machines at Fishermen's Bend on 6th April, 1938. They were then sent to Kiewa where they commenced operation towards the end of the month. From South Tawonga, the route led immediately across the Western Branch of the Kiewa River necessitating the construction of a bridge 100 feet long. By the end of 1939,the excavation had been 'opened up' for a distance of 19 1/2 miles (approx. 31 km.) and of this length, 10 miles (approx. 16 km) had been surfaced.The purchase and use of this type of mechanical equipment in road making was a huge investment, as prior to this most of the work would have been done manually with the use of picks and shovels. Not only were many months of hard manual labour saved, but a very significant amount of time in providing access to the proposed work sites for the new Kiewa Hydro Scheme. This photo is an excellent reminder of how primitive the early machinery was compared to the present but also represents the forward thinking of the State Electricity Commission's Engineers in purchasing such new and innovative equipment.A black and white photograph of a Caterpillar diesel crawler tractor and a hydraulically operated trailbuilder (angle dozer) making a road in the Mt. Beauty area.Hand written in black ink in the top left hand corner are the words "Kiewa Road Making 25/8/1938". On the upper right hand of the photograph has been stamped the number 3. On the back is stamped the word 'Velox' severaly times, which is the make of the photograhic paper. roadmaking, caterpillar tractor, kiewa, state electricity commission -

Kiewa Valley Historical Society

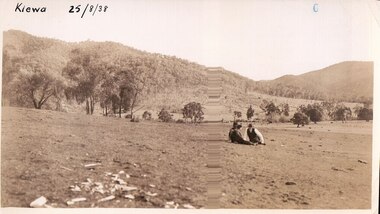

Kiewa Valley Historical SocietyBlack and white photograph of farmland, Kiewa, 25/8/38, circa 1938

This photograph was taken in August, 1938 at the time of road making in the area and some eight years prior to the establishment of Mt. Beauty township. The area was still being used for grazing, and the land was eventually acquired from the local land owners by the State Electricity Commission. The construction of the road, from Tawonga to the High Plains, was commenced in April of this year. This allowed men and heavy equipment to be transported to the work sites for the construction of the Kiewa Hydro Electric Scheme. An important photograph as it shows the upper Kiewa Valley as it was before the establishment of the town of Mt. Beauty. The land had been cleared of natural growth and has been used for grazing cattle. By 1946 housing construction had commenced for the new town of Mt. Beauty and by 1948 street construction in the southern part of the town was completed as far as Hill Street.A black and white photograph taken in the upper Kiewa Valley showing farmland with a group of three unidentified people sitting on the grass.Handwritten in black ink is the inscription 'Kiewa 25/8/1938'. In the right corner of the photograph has been stamped the number 6. On the back in a circle, some 14mm across, are the words 'Kodak Print'. The word Velox is also printed on the back.kiewa, mt. beauty, construction, grazing, secv -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Hat making equipment, Heritage Week at 728 Main Road, Eltham, 1990, 1990

Colour photograph of hat making equipment,for Heritage Week display at the Local History Centre (former Courthouse), 728 Main Rod Eltham. (Home of Eltham District Historical Society) The equipment was used at the Hat Factory in Eltham which started in the 1940s. The equipment shown includes a mould for making felt hats, stud press, looping machine for berets and hand sewing machine for straw hats. Sign accompanying the display is hand written and reads: "Eltham has not generally been known for manufacturing industry. One factory which started in the 1940s was "the hat factory" in Sherbourne Rd. The equipment displayed here includes moulds for making felt hats, stud press, looping machines for berets, hand sewing machine for straw hats."heritage week, eltham, courthouse, hat factory, hat mould, activities -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Royal Doulton, Late 19th to early-20th century

The Royal Doulton company began as a partnership between John Doulton, Martha Jones, and John Watt was an English ceramic and home accessories manufacturer founded in 1815. Operating originally in Vauxhall, London, later moving to Lambeth, in 1882 it opened a factory in Burslem, Stoke-on-Trent, in the centre of English pottery. The business was specialised in making salt-glazed stoneware articles, including utilitarian or decorative bottles, jugs and jars, much of it intended for inns and pubs. The backbone of the business was a wide range of utilitarian wares, mostly stonewares, including storage jars, tankards and the like, and later extending to pipes for drains, lavatories and other bathroom ceramics. From 1853 to 1902 its wares were marked Doulton & Co., then from 1902, when a royal warrant was given, Royal Doulton. The company always made some more decorative items, initially still mostly stoneware, and from the 1860s the firm made considerable efforts to get a reputation for design, in which it was largely successful, as one of the first British makers of art pottery. Initially, this was done through artistic stoneware's made in Lambeth, but in 1882 the firm bought a Burslem factory, which was mainly intended for making bone China table wares and decorative items. An early utilitarian stoneware item made by a well-known company that specialised in making salt-glazed items that later earned a reputation for making stoneware art objects. This ink well is historically significant as it represents the method of hand written communication that was still common up until the mid-20th century, before fountain pens and ballpoint pens took over in popularity and convenience.Ceramic, salt-glazed, mid-brown ink bottle. It has a small round mouth, rounded lip that extends past neck, wide shoulders, straight sides, flat base. Handmade. The surface is matt. there are flecks of dark brown in the clay. The bottle has marks on the side.Noneflagstaff hill, warrnambool, shipwreck coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, shipwreck artefact, writing equipment, writing accessory, office equipment, stationery, domestic, stoneware, clay, ceramic, pottery, inkwell, penny ink well, nib pen, dip pen, ink, hand writing, record keeping, household, business, vintage, blotting paper, ink bottle, dwarf ink, salt glazed -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTextile - Twine, 20th century

Sailmaker's twine is usually stored on a reel. It is wax coated and ready to use. The twine is made from strands of fibres that are plied together. The wax waterproofs the twine and smooths out the fine hairs of the fibres, making it easier to work with. The waxed twine helps prevent the ends of the rope work from fraying. Sailmakers use twine and needles to sew sails and many other canvas items such as bags and covers. Special tools, equipment, benches and seats are needed to work with the large heavy and thick pieces of canvas. Sometimes the sailmaker with have special-purpose tools made for his unique work. The place of work on shore is often called a sailmaker's loft. However, sailmakers also work on the job, on sailing ships and boats. This twine is an example imperative equipment for sailmakers. Sailmaking was an essential trade in the shipping industry of the 17th to 19th and early 20th centuries. Sailmakers were often part of a ship's crew, making repairs as needed and using their skills for other work such as net making.Twine; reel of brown waxed sailmaker's twine.warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, twine, waxed twine, sailmaker's twine, sailmaker's equipment, sailmaking, canvas work -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Cherry and Sons, Circa 1890-1920

The subject item is a good example of a large, hand-operated Bentwood box butter churn used to make up to 14 pounds of butter. It was made in Gisborne, Victoria, by the famous manufacturer, E. Cherry, and is known as an Improved Patent No.2 model probably dating from the late 1800s. The Cherry works specialised in making all types of butter churns and equipment for both domestic use on farms and small butter factories during the late nineteenth and early to mid. twentieth centuries. Milk was "separated" to retrieve the cream which was then beaten to make butter. E Cherry began making various models of Cherry butter churns in 1858, Edward Cherry migrated from Herefordshire England to Australia in 1855 with his wife Ann Appleby, nee Davis, and established a joinery workshop at Gisborne, Victoria. He began by making butter churns in his spare time and his product soon became popular allowing him to establish a viable business. A factory was established in 1875 and he started to make churns of all sizes including up to industrial scale. He exported his products to many countries around the world, Edward Cherry died in 1909 and the business was then run by his son George until he died in 1917. E Cherry's other son Thomas (1861-1945) was also involved in the firm maintaining an interest for several years. He had been born in Gisborne and became a senior house medical surgeon at the Melbourne Hospital in 1890. He continued his studies at Kings College London, eventually becoming a renowned bacteriologist and agricultural scientist. A significant giving an snapshot into how early rural and industrial manufacturing became established in Australia.Rectangular butter churn, a footed wooden box containing an X-shaped wooden interior rack, which is joined to an exterior metal hand crank with turned wood handle, through a hole in the box. Beneath the hand crank is a hole from the interior lined with metal. The lid has a carry handle affixed to the lid on two cross pieces attached to the lid by brass screws.Lettering in black on a transfer "CHERRY & SONS PTY LTD. GISBORNE VICTORIA". Model 00warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, flagstaff-hill-maritime-village, butter churn, gisborne, edward cherry, george cherry, thomas cherry, ann appleby, dairy equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Foot Grip, Frank McDowell, Early 20th century

This foot grip was made and owned by Frederick William McDowell (Fred) (1880 to 15-6-1967). It would be been joined to the stafe or frame of a jinker and used to step up from the ground and onto the seat. He was a wheelwright by trade. He made and repaired vehicles such gigs, buggies, jinkers, sulkeys, spring carts and farm wagons. His workshop was on the corner of Cramer Street and Raglan Parade in Warrnambool., previously the site of Fotheringhams, and after McDowell's, and still in 2023, occupied by Reece Plumbing Fred's workplace prior to retiring was at Bryant & Waterson's in Kepler Street, opposite the Criterian Hotel, making rubber tyred horse-driven farm wagons.This jinker's foot grip id part of a jinker or two-wheeled carriage. It is a rare item, made by a local wheelwright Frank McDowell who operated his buggy making and repair business in Warrnambool's CBD in the early twentieth century. It is an example of the equipment used on horse-drawn vehicles for safety and convenience.Foot grip, iron with silver plate finish. Rectangular metal plate with textured crossed over diagonal lines on the top surface and inset rectangles with impressed text. the curved and shaped ends have a drilled round hole. the length of the plate is an inverted 'v' shape towards the base. Made by F. McDowell, Warrnambool."F McDOWELL" "WARRNAMBOOL"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, fred mcdowell, frederick mcdowell, wheelwright, gig, buggy, jinker, sulkey, spring cart, farm wagon, 2-wheeled cart, horse cart, horse cart parts, jinker buggy, transport, vehicle, horse drawn, horse jinker, bryant & waterson, jinker part, jinker foot grip, step, foot plate, horse cart part, stafe, 2-wheeled carriage -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Cherry and Sons, 1890-1920

The subject item is a good example of a large, hand-operated Bentwood box butter churn used to make up to 14 pounds of butter. It was made in Gisborne, Victoria, by the famous manufacturer, E. Cherry, and is known as an Improved Patent No.2 model probably dating from the late 1800s. The Cherry works specialised in making all types of butter churns and equipment for both domestic use on farms and small butter factories during the late nineteenth and early to mid. twentieth centuries. Milk was "separated" to retrieve the cream which was then beaten to make butter. E Cherry began making various models of Cherry butter churns in 1858, Edward Cherry migrated from Herefordshire England to Australia in 1855 with his wife Ann Appleby, nee Davis, and established a joinery workshop at Gisborne, Victoria. He began by making butter churns in his spare time and his product soon became popular allowing him to establish a viable business. A factory was established in 1875 and he started to make churns of all sizes including up to industrial scale. He exported his products to many countries around the world, Edward Cherry died in 1909 and the business was then run by his son George until he died in 1917. E Cherry's other son Thomas (1861-1945) was also involved in the firm maintaining an interest for several years. He had been born in Gisborne and became a senior house medical surgeon at the Melbourne Hospital in 1890. He continued his studies at Kings College London, eventually becoming a renowned bacteriologist and agricultural scientist. A significant giving an snapshot into how early industrial manufacturing became established in Australia.Rectangular manual butter churn, footed wooden box containing an X-shaped wooden interior rack, which is joined to an exterior metal hand crank with turned wood handle, through a hole in the box. Beneath the hand crank is a hole from the interior lined with metal. The lid has a carry handle affixed to the lid on two cross pieces attached to the lid by brass screws.Label in block transfer Manufactured by Cherry & Sons Pty Ltd Gisborne, Victoria Size "00"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, butter churn, cherry and sons, wooden butter churn -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Rigging

The shrouds or fore-rigging are a part of the standing rigging on a sailing ship. They are used in pairs on each side of a ship to help hold the masts in place and to aid the sailors who climb the rigging. They are part of the basic framework for the sails. Larger vessels may have two or three pairs, and some ships may have upper and lower shrouds. The upper shrouds would be fixed to a protruding structure on the top of the masts so that they hung from the right angle. The ropework skills of the sailmaker would be used to create the shrouds, choosing fibres with properties suitable for the job at hand and creating the triangular shape carefully. Deadeyes and ropes were then used to attach the shrouds to the ship's structure.This shroud is an example of a part of the standing rigging of a sailing ship. Shrouds were used in pairs on larger sailing vessels to help hold the masts in place and give access to adjustable rigging such as sails.Fore Rigging or Shrouds, made from rope fibres. This shroud includes the upper and lower wooden deadeyes. They are part of a ship's rigging. flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, shroud, fore-rigging, ropework, sailing ship rigging, standing rigging, natural fibres, sailmakers, handmade, deadeye, knot making -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Rigging

The shrouds or fore-rigging are a part of the standing rigging on a sailing ship. They are used in pairs on each side of a ship to help hold the masts in place and to aid the sailors who climb the rigging. They are part of the basic framework for the sails. Larger vessels may have two or three pairs, and some ships may have upper and lower shrouds. The upper shrouds would be fixed to a protruding structure on the top of the masts so that they hung from the right angle. The ropework skills of the sailmaker would be used to create the shrouds, choosing fibres with properties suitable for the job at hand and creating the triangular shape carefully. Deadeyes and ropes were then used to attach the shrouds to the ship's structure.This shroud is an example of a part of the standing rigging of a sailing ship. Shrouds were used in pairs on larger sailing vessels to help hold the masts in place and give access to adjustable rigging such as sails.Fore Rigging or Shrouds, made from rope fibres. This shroud includes the upper and lower wooden deadeyes. They are part of a ship's rigging.flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, shroud, fore-rigging, ropework, knot making, sailing ship rigging, standing rigging, natural fibres, sailmakers, handmade, deadeye -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Medicine Glass, ca. 1887 to early 20th century

This small medicine glass has ho manufacturer's or owner's marks. It has no side seams, the base is slightly concave, the embossed inscriptions are inside the glass, the clear glass has slight imperfections and ripples, and the glass is slightly opaque below the lip; these features point to the glass being blown into a mould, partially set, and spun between that mould and an internal mould that had the embossing on it, called a turn-mould process. The lip was then ground to be smooth. The process was patented in 1887 with the title of "Mold for blowing turned bottles".This medicine glass is significant as an example of medical equipment that has a design still used today. It is significant also for having the embossing inside the glass, which was likely produced by the turn-mould method of bottle (and container) making.Medicine glass or dose cup; clear glass with small imperfections and ripples in the glass, no side seams and a slightly concave base. All embossed marks are inside the glass. The imperial measurements are in graduated scales for tablespoons, teaspoons, and ounces and drachmas. "OUNCES DRACHMS" "TABLE TEA"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, medicine glass, measuring glass, dose cup, medicine dispensing, medicine measurement, sambell pharmacy warrnambool, sambell chemist and dentist, internal embossing, glass embossed inside, 20th century chemist, blown glass, two-piece mould, turn-moulded glass, turned bottles -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Lee Breakwater, Portland, n.d

Port of Portland Authority Archivesport of portland archives, lee breakwater, construction, concrete -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - PHT Harman Dragline, n.d

... on road making. Some Harbour Trust homes in the background... photo of earth moving equipment working on road making. Some ...Port of Portland Authority ArchiveBack: ? Monthly 2/12/57 - biro -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

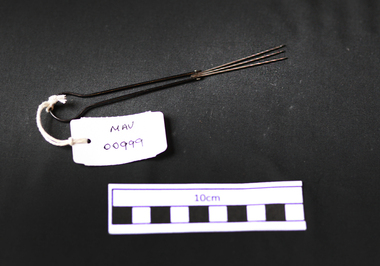

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Craftwork, lacemaking hooks tiny, c1890

The women of the pioneer families were very skilled at dressmaking , needlework and lace making. The early settlers had to be self reliant and made and repaired their own clothes, haberdashery , furnishings, tools and equipment. Lacework was a common pastime for 19thC women. , A set of tiny lace making crochet hooks.craftwork, crochetwork, needlework, moorabbin, cheltenham, pioneers, early settlers, clothing, brighton, pioneers, dressmaking, market gardeners, early settlers, craftwork, tools, lacework, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Dairy Equipment, thermometer, 20thC

Dairy Thermometers are used for testing the temperature of milk while making yogurts and cheese. Early settler families owned a 'House cow' to provide milk ,cream, cheese for their familiesA typical milk thermometer used by early settlers in Moorabbin Shire c1900A graduated Dairy thermometerDAIRY THERMOMETER / MADE IN GERMANY early settlers, market gardeners, dairy farmers, milk products, cheese making, thermometers, cooking utensils, kitchenware, castiron cooking pots, blacksmiths, slow cooking, moorabbin shire, bentleigh, mckinnon, highett, cheltenham,mcewan james pty ltd, melbourne, bunnings pty ltd,