Showing 119 items matching " textile factories"

-

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Textile - FLOUR BAG COLLECTION: MCALPIN'S FLOUR, 1900-1950

Textiles. Calico bag printed on one side in red and green. ''McAlpin's Self Raising Flour''. Alpine Brand. There's no other 25 lbs net when packed. Malto Pepsin Process. Prepaired with phosphate Aerator Aerophos. J.McAlpin & Sons, Abbotsford, Melbourne, Phone JA 3126. Centre picture of three mountain peaks in oval frame. Border edge of wheat stalks on either side. Remnants remain of stitching used to seal the top of the bag. The collection has other uncatalogued samples of McAlpin wheat bags as listed. Eight 25 lb bags. Three bags with slogans ''Enriched Self Raising Flour, Sure success every pack''. Four bags with slogans,''Pre-sifted Self Raising Flour. Sifted through silk seven times''. One bag with slogan ''Malto Calcium Enriched''. These eight bags are packed by McAlpine Flour Pty., Ltd., Abbotsford, Victoria. Three 7 lb bags. All bags include the slogans''Specially Milled, No Substitutes used''. "There's no other''. These bags packed at ''Factory Abbotsford, Melbourne, Phone JA 3126''. McAlpin's was a major Victorian flour company in the nineteenth and early twentieth centuries. Owned and operated by J. McAlpin and Sons, the company sold its flour products across Australia and overseas.textiles, domestic, mcalpin flour calico bag -

Bendigo Historical Society Inc.

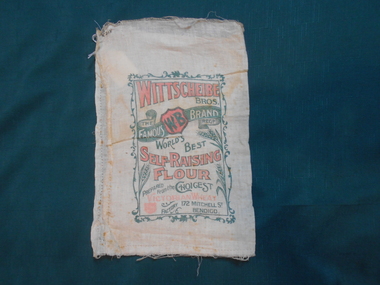

Bendigo Historical Society Inc.Textile - FLOUR BAG COLLECTION: WITTSCHEIBE BROS, BENDIGO, 1900-1950

Textiles. Linen flour bag printed on both sides in red and green.1. ''WITTSCHEIBE BROS. The famous WB Brand Regd. World's Best Self Raising Flour prepared from the choicest Victorian wheat. Factory 172 MITCHELL ST>< BENDIGO< 5 lbs''. Side 1 printed in black ink KA No 712. Side 2 printed in pen ink 1149. 5lbs net. Self raising Flour W.B. Brand Self Raising Flour is mixed and prepared from the choicest Victorian grown wheat, and possessing highly nutritious qualities is unequalled for Scones, Cakes, Puddings, ETC 172 Mitchell St., Bendigo, Telephone 339''.textiles, domestic, wittscheibe bros, bendigo. flour bag -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Textile - FLOUR BAG COLLECTION: JONES, MILLER & CO BENDIGO, 1900-1950

Textiles. Calico flour bag printed on both sides in black ink. 1. ''Jones, Miller & Co's Royal Self Raising Flour, 5 lbs Net. Factory Bendigo, Victoria. Coat of Arms printed in centre JM&C. Illegible signature in brown ink in one corner. 2. JONES, MILLER & CO.Self Raising Flour Factory Manufactures of Jams, Jellies, Canned Fruits, Pickles, Tomato Sauce, Chutneys, Custard Powders, Essences, Etc. Williamson & Myers Streets, Bendigo, Victoria. Telephone 73 and 19 Box 50. Collection has another in linen fabric which has been unstitched on side and bottom seams. Uncatalogued. The Bendigonian reported in 1933 that Jones, Miller and Company had an up-to-date factory that had already gained a standard of excellence for Bendigo pure food products.textiles, domestic, jones, miller & co flour bags -

National Wool Museum

National Wool MuseumFilm - Hirst Family Films, Cedric L Hirst, 1950s

Copy of Godfrey Hirst family videos/photograph on CD. Including 1951 floods at Mill. All video content filmed at Godfrey Hirst Woollen Mill, Swanston Street, South Geelong. Godfrey Hirst's children. Family home in Newtown and holiday home in Eastern View.Compact disc (CD) containing colour video footage. Film has no audio content. Visual content outlined below: 00:00 – 00:05 – External view of brick building – Godfrey Hirst & Co. Pty. Ltd. 00:05 – 00:10 – Exterior garden setting, three men in suits with fabrics and object 00:10 – 00:28 – Exterior garden setting showing eight women, most likely on a break from working at the Godfrey Hirst factory. The footage shows them all getting up and walking back towards the building at the end. 00:28 – 00:38 – Exterior garden setting, showing seven men in white shirts and ties seated and standing around a table, turning pages on a folder on the table. 00:38 – 00:52 – Interior factory setting, showing four men in coats handling green and red wool. 00:52 – 1:08 – Three men in suits in an exterior garden setting looking at paperwork. 1:08 – 1:23 – Four men in coats in a garden handling coloured wool samples. 1:23 – 1:42 – Four men in suits in a garden setting handling woven fabric. Two of the men are holding pipes. 1:42 – 1:57 – Interior factory setting showing men operating machinery. 1:57 – 2:05 – Exterior factory setting showing a man driving machinery carting wool bales. 2:05 – 3:14 - Flood scenes, showing the exterior of the Godfrey Hirst building with a man rowing a boat down the street, and a horse and cart in flood waters. There are scenes of flooded streets, exterior of flooded buildings and people standing in flood waters. 3:14 – 3:40 - Interior building views of flood waters in factory with people, machinery, equipment and textiles in flood waters. 3:40 – 4:03 - Exterior views showing a tractor, boat, horse and people in flood waters. 4:03 – 7:02 Exterior setting showing crowds of people watching a fashion parade. The fashion parade is of women in various clothing, including suits jackets, skirts, coats and hats. 7.02 - END"Hirst family films 1936-1964 Incl. Godfrey Hirst and co P/L Woollen mills"geelong, godfrey hirst & co. pty. ltd., family films, factory, flooding, 1950s, wool processing, fashion, textiles, horse and cart, wool bales, transport, machinery, fashion parade, working life -

National Wool Museum

National Wool MuseumRug

... on closure of factory. Textile Art Brintons Australia Pty Ltd ...The rug hung in the boardroom at the Brintons Carpet premises/factory at Fellmongers Road, Breakwater. Acquired on closure of factory.W7199 Page 1 of a history of Brintons Carpets. Page 2 of a history of Brintons Carpets. A list of catalogues/items in the Brintons Collection donated after closure of Fellmongers Road factory in July 2008.Labore Vinces Brintons Carpets/Special Enquiry Prepared for/Ref. No 15/2878 for Aurora/Quality colours in trial/standard/non standard/Design and colour sample does not represent qualitytextile art, brintons australia pty ltd brintons pty ltd (geelong) brintons ltd (uk), carpet -

National Wool Museum

National Wool MuseumBobbin

A bobbin used at the Brintons Carpets factory at Fellmongers Road, Breakwater.W7203 Page 1 of a history of Brintons Carpets. Page 2 of a history of Brintons Carpets. A list of catalogues/items in the Brintons Collection donated after closure of Fellmongers Road factory in July 2008.textile machinery weaving, brintons australia pty ltd brintons pty ltd (geelong), carpet, geelong, victoria, textile machinery, weaving -

National Wool Museum

National Wool MuseumBobbin

A bobbin used at the Brintons Carpets factory at Fellmongers Road, Breakwater.W7205 Page 1 of a history of Brintons Carpets. Page 2 of a history of Brintons Carpets. A list of catalogues/items in the Brintons Collection donated after closure of Fellmongers Road factory in July 2008.textile machinery weaving, brintons australia pty ltd brintons pty ltd (geelong), carpet, geelong, victoria, textile machinery, weaving -

National Wool Museum

National Wool MuseumBobbin

A bobbin used at the Brintons Carpets factory at Fellmongers Road, Breakwater.W7206 Page 1 of a history of Brintons Carpets. Page 2 of a history of Brintons Carpets. A list of catalogues/items in the Brintons Collection donated after closure of Fellmongers Road factory in July 2008.weaving textile machinery, brintons australia pty ltd brintons pty ltd (geelong), carpet, geelong, victoria, weaving, textile machinery -

National Wool Museum

National Wool MuseumBobbin

A bobbin used at the Brintons Carpets factory at Fellmongers Road, Breakwater.W7207 Page 1 of a history of Brintons Carpets. Page 2 of a history of Brintons Carpets. A list of catalogues/items in the Brintons Collection donated after closure of Fellmongers Road factory in July 2008.textile machinery weaving, brintons australia pty ltd brintons pty ltd (geelong), carpet, geelong, victoria, textile machinery, weaving -

National Wool Museum

National Wool MuseumBobbin

A bobbin used at the Brintons Carpets factory at Fellmongers Road, Breakwater.W7208 Page 1 of a history of Brintons Carpets. Page 2 of a history of Brintons Carpets. A list of catalogues/items in the Brintons Collection donated after closure of Fellmongers Road factory in July 2008.textile machinery weaving, brintons australia pty ltd brintons pty ltd (geelong), carpet, geelong, victoria, textile machinery, weaving -

National Wool Museum

National Wool MuseumBobbin

A bobbin used at the Brintons Carpets factory at Fellmongers Road, Breakwater.W7209 Page 1 of a history of Brintons Carpets. Page 2 of a history of Brintons Carpets. A list of catalogues/items in the Brintons Collection donated after closure of Fellmongers Road factory in July 2008.textile machinery weaving, brintons australia pty ltd brintons pty ltd (geelong), carpet, geelong, victoria, textile machinery, weaving -

National Wool Museum

National Wool MuseumShuttle

Used at Brintons Carpets Fellmongers Road factory. Acquired on closure of factory. (Used for Brintons Wilton Loom?)W7210 Page 1 of a history of Brintons Carpets. Page 2 of a history of Brintons Carpets. A list of catalogues/items in the Brintons Collection donated after closure of Fellmongers Road factory in July 2008.Made in England Ramsey McDonald Pty.Ltd. Melbourne 6/83 28textile machinery textile industry textile mills weaving weaving mills, brintons australia pty ltd brintons pty ltd (geelong), geelong, victoria, textile machinery, textile industry, textile mills, weaving, weaving mills -

National Wool Museum

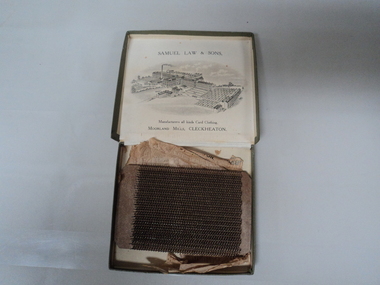

National Wool MuseumSample, Card Clothing

Card clothing sample manufactured by Samuel Law and Sons, Cleckheaton and probably sent to the Collins Bros Mill at the same time as W621. Card clothing is defined as 'the leather or other stiff material which holds the wire staples, the points of which project outwardly and form the carding teeth which operated on the fibres.' This fits into a carding machine ("The Textile Industries" vol. 8 - William S. Murphy, 1911).Card clothing sample, comprising rows of bent wires mounted on a thick rectangular leather base. Wrapped in tissue printed with an engraving of the factory where it was made and housed in an olive green lidded cardboard box, the interior of which is printed with an image of the manufacturer's factory.SAMUEL LAW & SONS, / Manufacturers all kinds Card Clothing. / Moorland Mills. / CLECKHEATON, England. SAMPLE OF CARD CLOTHING / FROM / SAMUEL LAW & SONS, / (branch of the English Card Clothing Company, Limited). / CLECKEATON. / MOORLAND MILLSsamuel law and sons collins bros mill pty ltd, carding, card clothing -

National Wool Museum

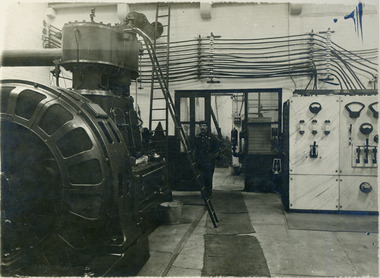

National Wool MuseumPhotograph, Unknown

... processing factory. textile machinery wool manufacture wool Black ...Man standing in what looks to be a wool processing factory.Black and white photo of a man surrounded by machinery in a landscape format. The photo is attached to a olive coloured board.textile machinery, wool manufacture, wool -

National Wool Museum

National Wool MuseumBook, The Textile Tools of Colonial Homes

"The Textile Tools of Colonial Homes: from raw materials to finished garments before mass production in the factories" - Marion L. Channing, Massachusetts, USA, (first published in 1969) this edition 1971. Donated as part of the Zakrzewski Collection of spinning wheels which were given to the National Wool Museum by Mr Wlodzimierz Zakrzewski. For many years, Mr Zakrzewski collected, researched and repaired spinning wheels from all over the world. This book was owned by him.handicrafts - history wool processing flax, spinning, zakrzewski, mr wlodzimierz, handicrafts - history, wool processing, flax -

National Wool Museum

National Wool MuseumPlan - Machinery Layouts, J Dyson & Sons Pty Ltd

... & Textiles Pty Ltd in Hobson's Road, Kensington. factory machinery ...Two machinery plan layouts for Mimosa Wool & Textiles Pty Ltd in Hobson's Road, Kensington.1617.1 Rectangular blue paper with white lined plan drawing and white text 1617.2 Rectangular blue paper with white lined plan drawing1617.1 Front: Final Plan / PLAN OF MACHINERY LAYOUT / MIMOSA WOOL & TEXTILES PTY LTD / HOBSON'S ROAD KENSINGTON / BY MESSRS J DYSON & SONS / SOUTH GEELONG / Scale 3/32" - 1.0"factory, machinery, wool, textiles, mill, kensington, south geelong, plans, drawings, blueprint, layout, mimosa, j. dyson and sons pty ltd -

National Wool Museum

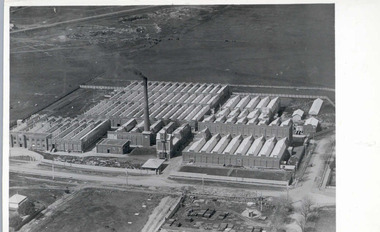

National Wool MuseumPhotograph - Valley Worsted Mill, 1923

Photographic postcard depicting the newly constructed Valley Worsted Mill, c.1923.Photographic postcard, black and white. Depicts an aerial view of the newly constructed textile mill. A chimney stack and many saw toothed roofs can be seen.POST CARD / CORRESPONDENCE ADDRESS ONLY / KODAK / AUSTRALtextile mills, valley worsted mill foster valley mill pty ltd, aerial photography, factory, wool, industrial building -

National Wool Museum

National Wool MuseumFunctional object - Time Card Rack

A time clock, sometimes known as a clock card machine, punch clock, or time recorder, is a device that recorded the time an employee entered and left the factory. In mechanical time clocks, this was accomplished by inserting a heavy paper card, called a time card, into a slot on the time clock. When the time card hit a contact at the rear of the slot, the machine would print day and time information (a timestamp) on the card. One or more time cards could serve as a time sheet or provide the data to fill one. This allowed a timekeeper to have an official record of the hours an employee worked to calculate the pay owed an employee.Metal time card rack.time sheet, time card, factory, employee, work life, punch clock, textile industry -

National Wool Museum

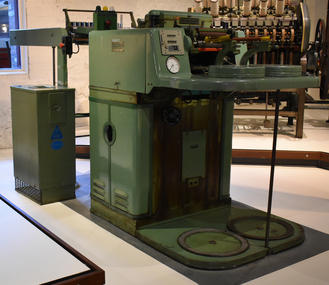

National Wool MuseumMachine - French Comb, Schlumberger & Cie, 1964

... processing Textile Industry Factory Machine comb restoration fibres ...Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. Machine has been completely rebuilt and set up by Nick Sokolov of Comb Research and Development with the help of Bruce Hill and others. NSC Schlumberger Comb PB25L machine No 3953, year of manufacture 1964. A rectilinear version of the Noble Comb, this machine separated long and short fibres. Donated to the National Wool Museum by Port Phillip Wool Processing Pty Ltd in 1993.French comb machine. 1962 Shlumberger and Co, France Model PB 251 NO. 3953.french comb, wool processing, textile industry, factory, machine, comb, restoration, fibres -

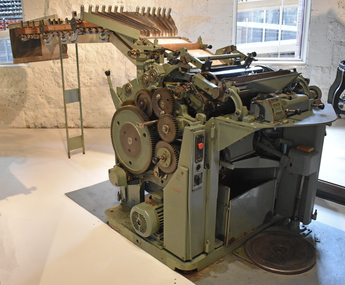

National Wool Museum

National Wool MuseumMachine - Cap Spinner, 1925

... and knitting. weaving knitting cap spinning cap spinner machine textile ...This cap spinner squeezes the thread under the stationary cap and winds them onto the bobbin. Spinning transforms tops into yarns. The tops are pulled out into fine strands known as rovings. They are then twisted to bind the thread together to give the yarn greater strength. The yarns are wound into differently shaped tools. They are then sent off for weaving and knitting.Cap spinning machine.weaving, knitting, cap spinning, cap spinner, machine, textile industry, factory -

National Wool Museum

National Wool MuseumMachine - Gill Box, Deutscher Spinnereimaschinenbau Ingolstadt, 1963

... . deutscher spinnereimaschinenbau ingolstadt gilling Gill Box Textile ...This machine uses a series of combs attached to bars that move with increasing speed away from a starting point. This draws-out and aligns the wool fibres to produce a gilled top. The gilling process is also used in other positions along the worsted production line. A gill box draws and combs the fibres prior to spinning. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Gill box. Green painted steel.Deutscher / Spinnereimaschinenbau / Ingolstadt / 1963deutscher spinnereimaschinenbau ingolstadt, gilling, gill box, textile industry, wool processing, factory, machine, mills, spinning, fibre, comb -

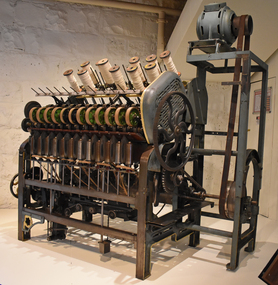

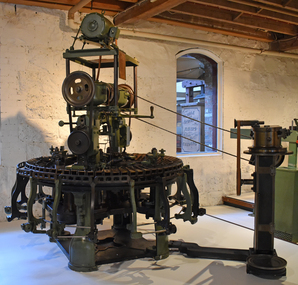

National Wool Museum

National Wool MuseumMachine - Noble Comb, Prince Smith & Sons, Burlington Shed, Keighley, 1915

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. A Nobel Comb separates short (Noils) fibres while also blending long (Tops) fibres together. The long fibres are used for worsted materials while the short fibres are used for woollen fabrics. Woollen materials are soft, bulky and fuzzy, such as a picnic blanket; whereas worsted materials are fine, smooth and crisp, such as a suit jacket. The Valley Worsted Mills in Geelong, now the Little Creatures Brewery, ran 12 noble combs up until 1981. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Noble Comb with plates - 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box). 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box).wool manufacturing, noble comb, textile industry, geelong, little creatures brewery, valley worsted mills, fibres, wool, factory -

National Wool Museum

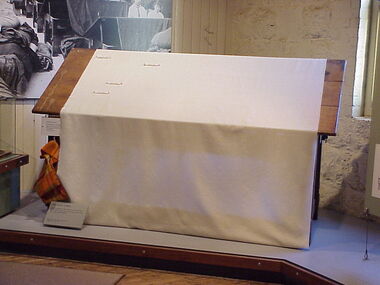

National Wool MuseumFunctional object - Mending Table, c1930

Any faults in the final product can be repaired by mending. Prior to more advanced machinery, fabric was draped over a mending table and carefully inspected for faults. Quick eyes and nimble fingers were needed. Repairing faults was a highly skilled manual operation. Any knot or thickness had to be removed without affecting the quality of the fabric and mending had to be invisible. In the 1930s to make the day pass faster, popular records were played to the factory workers in the mending room. The top of the table is propped up to make it a well-lit surface over which bolts of fabric were unrolled to check for faults. Menders repaired them with invisible hand stitching. Each weaver stitched a coloured thread in the selvage to show the start of their shift, therefore if mistakes were found the company could easily find who was responsible. This table was used by Gail Morris in teh 1960s. Large wooden table with tilted top. mending table, wool processing, fabric, textile industry -

National Wool Museum

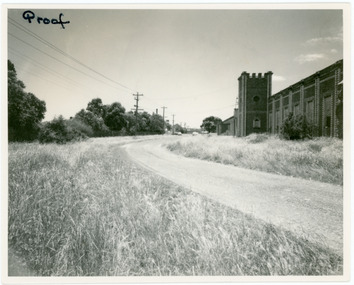

National Wool MuseumPhotograph

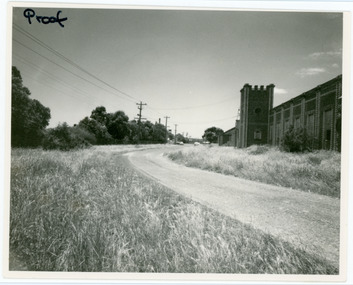

Depicts the west wall of the Barwon Mill, looking north in Factory Road. The Barwon Mill was built in 1874 and taken over by Godfrey Hirst and renamed Excelsior One in 1890. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile mills, godfrey hirst and co. pty ltd, barwon woollen mill, excelsior one mill -

National Wool Museum

National Wool MuseumPhotograph

Depicts the west wall of the Barwon Mill, looking north in Factory Road. The Barwon Mill was built in 1874 and taken over by Godfrey Hirst and renamed Excelsior One in 1890. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile mills, godfrey hirst and co. pty ltd, barwon woollen mill, excelsior one mill -

National Wool Museum

National Wool MuseumBook, Textile Machines

... of English textile machinery, machinery makers and factories. Textile ...This book provides a brief history and overview of English textile machinery, machinery makers and factories.SHIRE / ALBUM / 103 / Textile Machines / ANNA P. BENSONtextile machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Article - Newspaper Clipppings, Worker's paradise factory at Blackburn, 1951 & 1988

... de stoop textile factory... textile factory de stoop roger 'The Belgians in Australia' gives ...'The Belgians in Australia' gives a brief history of Roger, 1950 - 1975.Belgian, Roger de Stoop, plans a spinning and weaving factory at Blackburn. He plans many innovative amenities to keep his staff happy. Also another article - 'The Belgians in Australia' gives a brief history of Roger, 1950 - 1975. 'The Belgians in Australia' gives a brief history of Roger, 1950 - 1975.textiles, de stoop textile factory, de stoop, roger -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Pamphlet, Heroes of Holeproof, 2010

Booklet and DVD produced by the Textile Clothing and Footwear Union of Australia.Booklet and DVD produced by the Textile Clothing and Footwear Union of Australia on the closure of the Holeproof factory Nunawading. The booklet mainly consists of recollection of the workers. See NP3674 for DVD.Booklet and DVD produced by the Textile Clothing and Footwear Union of Australia. trade unions, holeproof -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Colour, Textile Factory at Prato, Italy, 2017

... Textile Factory at Prato, Italy...textile factory... Office goldfields textiles textile factory loom tapestry prato ...textiles, textile factory, loom, tapestry, prato, tagliabue -

National Wool Museum

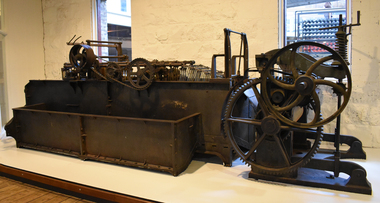

National Wool MuseumMachine - Scouring Bowl, J Dyson & Sons Pty Ltd, c.1890

... processing E. P. Robinson Textile Industry Factory Mill J. Dyson ...Scouring is the process that removes wool wax and other unwanted products from wool. Wool is washed in a hot detergent solution. It moves through a series of scouring bowls and is then rinsed and dried. Careful handling and washing preserves the strength and softness of wool. If the wool contains lots of seeds and other vegetable matter, it must be cabonized. This means it is treated with a solution of sulpheric acid and then baked at high temperature to remove impurities. The disused scouring water left-over from this process was often let drain into rivers and watercourses causing pollution. Many of Geelong's wool scours along the Barwon River were closed due to environmental damage. The race system on this bowl is not the original it has been modified with a variation of the harrow system. Used at E.P. Robinson South Geelong from c.1890-1970.Scouring bowl.J. Dyson & Sons Pty Ltd, Geelongsouring bowl, j dyson & sons, geelong, wool processing, e. p. robinson, textile industry, factory, mill