Showing 109 items

matching adding machines

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

... devices, between them several patents for adding machines and cash... for various devices, between them several patents for adding machines ...The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

... devices, between them several patents for adding machines and cash... for various devices, between them several patents for adding machines ...The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Bendigo Military Museum

Bendigo Military MuseumPhotograph - Capturing Topographic Features with a Wild B8 – Army Survey Regiment, Fortuna, Bendigo, c1980

... were upgraded, and additional machines added to expand the Army... were upgraded, and additional machines added to expand the Army ...These four photographs of SPR Santina (Argetto) Straube capturing topographic features – plotting with a Wild B8 stereo plotter were most likely taken in c1980. Introduced in 1966, the Wild B8 stereo plotter was used for plotting topographic detail and contours. These analogue machines were manually controlled by adjusting the control knobs for the orientation of the 3D image. The B8s used a nine-inch square photo image on a film or glass diapositive which allowed highly accurate extraction of map features. At first, plotting by B8 and B9 equipment was undertaken at the aerial photography scale of 1:80,000 in pencil onto a controlled plotting sheet. Sheets were then inked up and reduced photographically to the 1: 100,000 publication scale for scribe impression production. In these photos SPR Santina (Argetto) Straube was plotting with a pencil or ink pen mounted at the far end of the pantograph arm. The plotting procedure was upgraded to direct plotting in ink with photographic reduction to publication scale. In 1975 four B8s were upgraded with tri-axis locaters as part of the Input Sub-system to enable digital extraction to AUTOMAP 1’s topographic database. When AUTOMAP 2 was introduced in 1982 these B8s were upgraded, and additional machines added to expand the Army Survey Regiment’s digital capture capability. This is a set of four photographs of a technician capturing topographic Features with a Wild B8 stereo plotter in Air Survey Squadron – Army Survey Regiment, Fortuna, Bendigo. 1980. The photographs were on 35mm negative film and were scanned at 96 dpi. They are part of the Army Survey Regiment’s Collection. .1) to .4) Photo, black & white, c1980. SPR Santina (Argetto) Straube operating a Wild B8 stereo plotter..1P to .4P – no annotations.royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr, air survey, photogrammetry -

Bendigo Military Museum

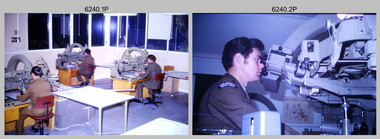

Bendigo Military MuseumPhotograph - Photogrammetric Equipment – Army Survey Regiment, Fortuna, Bendigo, c1960s to c1980s

... , and additional machines added to expand the Army Survey Regiment’s... were upgraded, and additional machines added to expand the Army ...This is a set of eight photographs of technicians operating photogrammetric equipment in Air Survey Squadron, Army Survey Regiment, Fortuna, Bendigo. c1960s to c1980s. The Wild A9 Stereocomparator and Wild B9 stereo plotter were introduced in 1962. The Wild B8 stereo plotter was introduced in 1966. Technicians used the Wild A9 Stereocomparator to accurately measure between pass, tie, and survey control points on aerial photographs. The Wild B9 and B8s were used for plotting topographic detail and contours. These analogue machines were manually controlled by adjusting the control knobs for the orientation of the 3D image. The B9s used a four and a half square, and the B8s used a nine-inch square photo image on a film or glass diapositive which allowed highly accurate extraction of map features. At first, plotting with B8 and B9 stereo plotters was undertaken at the aerial photography scale of 1:80,000 in pencil onto a controlled plotting sheet. Sheets were then inked up and reduced photographically to the 1: 100,000 publication scale for scribe impression production. In the early days topographic detail and contours were plotted with a pencil or ink pen mounted at the far end of the pantograph arm. The plotting procedure was upgraded to direct plotting in ink with photographic reduction to publication scale. In 1975 four B8s were upgraded with tri-axis locaters as part of the Input Sub-system to enable digital extraction to AUTOMAP 1’s topographic database. When AUTOMAP 2 was introduced in 1982 these B8s were upgraded, and additional machines added to expand the Army Survey Regiment’s digital capture capability. This is a set of eight photographs of technicians operating photogrammetric equipment in Air Survey Squadron, Army Survey Regiment, Fortuna, Bendigo. c1960s to c1980s. Black and white and colour photos are on photographic paper and scanned at 300 dpi. .1) - Photo, black & white, c1965. Unidentified technician operating a Wild A9 Stereocomparator. .2) - Photo, black & white, c1965. Unidentified technician operating a Wild B9 stereo plotter. .3) - Photo, black & white, c1967. L to R: Unidentified technician, SPR Ken Jeffery operating a Wild B9 stereo plotter. .4) - Photo, colour, c1974. Unidentified technician, operating a Wild B8 stereo plotter. .5) - Photo, black & white, c1974. Unidentified technician operating a Wild B8 stereo plotter. .6) to .7) - Photo, black & white, c1979. Unidentified technicians operating a Wild B8 stereo plotter. .8) - Photo, black & white, c1985. Unidentified technician in AUTOMAP 2 operating a Wild B8 stereo plotter..1P, .2P, .4P, .5P, .7P – no annotations. .3P – annotated ‘Standing - , Seated SPR Ken Jefferies (sic). .6P – annotated with date ‘1979’ .8P – annotated ‘AUTOMAP 2’royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr, air survey, photogrammetry -

Bendigo Military Museum

Bendigo Military MuseumPhotograph - Photogrammetric Equipment – Army Survey Regiment, Bendigo and School of Military Survey Bonegilla, c1960s to c1980s

... were upgraded, and additional machines added to expand the Army... were upgraded, and additional machines added to expand the Army ...This is a set of 14 photographs of RA Svy technicians operating photogrammetric equipment in Air Survey Squadron, Army Survey Regiment, Fortuna, Bendigo; and the School of Military Survey Bonegilla c1960s to c1980s. The Wild B9 stereo plotter were introduced in 1962 and the Wild B8 stereo plotter was introduced in 1966. The Wild B9 and B8 stereo plotters were used for plotting topographic detail and contours. These analogue machines were manually controlled by adjusting the control knobs for the orientation of the 3D image. The B9s used a four and a half square, and the B8s used a nine-inch square photo image on a film or glass diapositive which allowed highly accurate extraction of map features. At first, plotting with B8 and B9 stereo plotters was undertaken at the aerial photography scale of 1:80,000 in pencil onto a controlled plotting sheet. Sheets were then inked up and reduced photographically to the 1: 100,000 publication scale for scribe impression production. In the early days topographic detail and contours were plotted with a pencil or ink pen mounted at the far end of the pantograph arm. The plotting procedure was upgraded to direct plotting in ink with photographic reduction to publication scale. In 1975 four B8s were upgraded with tri-axis locaters as part of the Input Sub-system to enable digital extraction to AUTOMAP 1’s topographic database. When AUTOMAP 2 was introduced in 1982 these B8s were upgraded, and additional machines added to expand the Army Survey Regiment’s digital capture capability. There are several more photos catalogued in the Victorian Collections database of RA Svy personnel operating Wild B9 and B8 stereo plotters.Photogrammetric Equipment – Army Survey Regiment, Fortuna, Bendigo c.1981. . .7) – Unidentified technician operating Wild B8 stereo plotter in AUTOMAP 1 at ASR. .8) - Wild B8 stereo plotter in AUTOMAP 1 at ASR. Photogrammetric Equipment – Army Survey Regiment, Fortuna, Bendigo. c1981. .9) – ASR’s CPL Dave Cook in AUTOMAP 1 operating a Wild B8 stereo plotter. This is a set of 14 photographs of RA Svy technicians operating photogrammetric equipment at the Army Survey Regiment (ASR), Bendigo and the School of Military Survey (SMS) Bonegilla. c1960s to c1980s. The photographs are on 35mm colour slides and were scanned at 96 dpi. .1) - Photo, colour, c1964. Unidentified ASR technicians operating analogue Wild B9 stereo plotters. .2) - Photo, colour, c1974. ASR’s SPR Mick Minchin operating an analogue Wild B8 stereo plotter. .3) to .6) - Photo, colour, c1980. Photogrammetry Instructor SGT Neil ‘Ned’ Kelly at the SMS operating an analogue Wild B8 stereo plotter. .7) - Photo, colour, c1981. Unidentified technician operating Wild B8 stereo plotter in AUTOMAP 1 at ASR. .8) - Photo, colour, c1981. Wild B8 stereo plotter in AUTOMAP 1 at ASR. .9) to .14) - Photo, colour, c1981. ASR’s CPL Dave Cook in AUTOMAP 1 operating a Wild B8 stereo plotter..1P to .14P - Some of the equipment is annotated on the frame of the 35mm slides.royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr, photogrammetry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAudio - Phonograph Horn, Thomas A. Edison, Edison Laboratory, c.1909

... were bevelled so that the title's label could be added... that the title's label could be added. The last phonograph machine to use ...This external horn is part of an Edison Fireside Phonograph made in c.1909. The horn was attached to the machine when in use. The rings on the side of the horn allowed the horn to be suspended above the machine. The narrow opening on the horn was attached to the sound outlet on the machine and the conical shape of the horn amplified the sound. The horn was suspended to allow a clear sound. This was done by attaching the ring fitted to the outside of the horn to a chain or chord, which in turn was attached to a curved wire fitted to the phonograph machine. The phonograph machine was invented by Thomas Alva Edison in the late 19th century. Edison adapted the idea used when sending messages over a telegraph machine. He patented the phonograph in early 1878. The phonograph was able to record sound and play it back sound. This amazing invention opened up a whole new world of entertainments, where wax cylinders of pre-recorded sound could be purchased with a wide variety of music and played over and over. The first wax cylinders were white and used a combination of bees' wax and animal fax or tallow. By 1892 Edison was using 'brown wax' cylinders that ranged from cream through to dark brown. The Edison Phonograph Company was formed in 1887 to produce these machines. He sold the company in 1855 to the North American Phonograph Company but bought that company in 1890. He started the Edison Spring Motor factory in 1895 and then the National Phonograph Company in 1896. In 1910 the company became Thomas A. Edison Inc. In 1898 Edison produced the Edison Standard Phonograph, the first phonograph to carry his own trade mark. He began mass producing duplicate copies of his wax cylinders in 1901 using moulds instead of engraving the cylinders. The wax was black and harder than the brown wax. The ends of the cylinders were bevelled so that the title's label could be added. The last phonograph machine to use an external horn was produced in 1912 due to the much more robust records being invented. In 1913 Edison started producing the Edison Disc Phonograph. The company stopped trading in 1929. [NOTE: a phonograph machine plays cylinders, a gramophone plays records]This Edison external phonograph horn is significant for its connection to the c.1909 Edison Fireside phonograph model. The phonograph machine brought a new era of music into the homes of everyday people but was only popular for a few decades due to the growing popularity of records, which gave a much higher quality sound and were more robust.Phonograph horn; open horn, a conical shape with the lower part flaring out. The horn's shape on the opening half is octagonal, made from eight joined sheets of metal with a scalloped finish at the opening. The narrow end is hollow and ready to fit onto a phonograph outlet. There are two rings attached together on the side of the horn, perhaps for storing on a hook. The inner surface of the horn has remnants of deep red paint. This horn is from the Edison Fireside phonograph. (There is a mark on the outside of the horn where the Edison brand would be)flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, gramophone, phonograph, music player, entertainment, audio equipment, edison, thomas a edison, horn, phonograph horn, amplifier, audio, sound recording, sound playback, phonograph machine, external horn, edison phonograph company, wax cylinders, edison spring motor factory, national phonograph company, thomas a. edison inc, phonographic cylinder, sound reproduction -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAudio - Phonograph, Thomas A. Edison, Edison Laboratory, c.1909

... that the title's label could be added. The last phonograph machine to use... that the title's label could be added. The last phonograph machine to use ...The Edison Fireside Phonograph Combination Type A model phonograph was an open horn model. This machine was produced around 1909, just after the introduction of 4-minute record cylinders in 1908.; the selection lever on the front was either 4 or 2-minute choice. This Fireside model has a fluted octagonal horn that attaches to the reproducer on the machine and is suspended by on ring by a horn crane attachment. The phonograph machine is powered purely by mechanical means, winding the crank handle on the side of the machine to start the belt-driven, spring-loaded motor inside. The sound comes from a pre-recorded, vertical cut record cylinder, which slides over the Mandle, a smooth rotating drum. The reproducer, an all-in-one needle, amplifier and speaker, is lowered onto the cylinder, the needle picks up the sound and plays it on the speaker and the attached horn amplifies the sound. The phonograph machine was invented by Thomas Alva Edison in the late 19th century. Edison adopted the idea from the technology of the telegraph machine. He patented the phonograph in early 1878. It was able to record sound and play it back. This amazing invention opened up a whole new world of entertainment, where wax cylinders of pre-recorded sound could be purchased with a wide variety of music and played over and over. The first wax cylinders were white and used a combination of bees' wax and animal fax or tallow. By 1892 Edison was using 'brown wax' cylinders that ranged from cream through to dark brown. The Edison Phonograph Company was formed in 1887 to produce these machines. He sold the company in 1855 to the North American Phonograph Company but bought that company in 1890. He then started the Edison Spring Motor factory in 1895, and the National Phonograph Company in 1896. In 1910 the company became Thomas A. Edison Inc. In 1898 Edison produced the Edison Standard Phonograph, the first phonograph to carry his own trade mark. He began mass producing duplicate copies of his wax cylinders in 1901 using moulds instead of engraving the cylinders. The wax was black and harder than the brown wax. The ends of the cylinders were bevelled so that the title's label could be added. The last phonograph machine to use an external open horn was produced in 1912 due to the much more robust round records being invented. In 1913 Edison started producing the Edison Disc Phonograph. The company stopped trading in 1929.This Edison Fireside Phonograph model is significant for being one of the last models to have an external horn. It is also significant for its connection with the invention of the phonograph, which made music and sound available for domestic enjoyment. It was used for entertainment and education, even teaching languages. It signalled a new era of music that could be reproduced and played anywhere. It is also significant for its short time span of popularity, just a few decades, due to the growing use of records, which gave a much higher quality sound and were more robust.Phonograph; Edison Fireside Phonograph, Combination Type, Model A. It is in a wooden case with a domed lid, metal catches on each side and a folding wooden handle. It has a metal drum and a reproducer mechanism. The metal and wood crank handle starts the machine’s motor. A sliding lever at the front selects the speed for four- or two-minute cylinders. The inscribed plate has the maker, serial number, patents and other information. The reproducer also has an inscription. It has a curved metal open horn attachment. Made in Orange, New Jersey in c.1909. NOTE: the fluted octagonal horn is catalogued separately.Case front, in script, Edison’s early ‘banner’ decal “Edison” On the front of the machine “Thomas A Edison TRADE MARK” On the maker’s plate; "Edison Fireside Phonograph Combination Type" Serial number “14718” Around sound outlet; “C 4076” “REPRODUCER LICENCED FOR USE ONLY ON EDISON PHOTOGRAPHS SOLD BYT.A. EDISON INC.” At the front edge “4 MINUTES 2flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, gramophone, phonograph, music player, entertainment, audio equipment, edison, thomas a edison, horn, phonograph horn, amplifier, audio, sound recording, sound playback, phonograph machine, phonograph cylinder, external horn, edison phonograph company, wax cylinders, sound reproduction, edison spring motor factory, national phonograph company, thomas a. edison inc, crank-operated motor, open horn phonograph, 4 speed, 2 speed -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1900's

In August 1884, Alfred Hirst who had started his trade as a watch repairer and was described as a watchmaker extraordinaire established Hirst Brothers and Company, on Union Street in Oldham Manchester. He took his two stepbrothers into the business and the company was set up to produce timepieces and jewellery as well as importing “Limit company” Swiss watches and precision machine tools for the watch and clock trade. By 1902 Hirst Brothers. had become a limited company and was still growing, adding other businesses in Manchester in 1904 and at Birmingham in 1907. The quality of the clocks and watches was such that Alfred Hirst realised his greatest ambition in 1912 with a range of watches which carried the "Limit" trademark. These watch movements had originally been made in Switzerland and shipped to Hirst Bros. to be put into British made “Dennison” cases. This trade brought even more growth with additional sales offices opening in London and Glasgow. At the outbreak of the First World War in 1914 found them manufacturing aircraft parts including revolution counters and optical instruments. The firm had been tasked by the Ministry of Munitions to solve the problem of pilots dropping bombs by hand and as a result, they effectively created the first bomb rack. After the war, the company once again began to prosper and with the demand for their products increasing they looked to build a new purpose-built factory to manufacture their products. In 1917 they purchased a seven-acre field site at Tame Side Dobcross, the designing of the new factory was passed onto local architect AJ Howcroft. His brief for the design of the clockworks would have been prompted by Alfred Hirst who having visited modern factories in the United States was inspired by the latest factory designs providing as much daylight as possible during working hours. The factory was eventually completed in 1920, by the mid-1920s there were cheap clock imports from Germany and production turned to radio sets and other components as well as counter and gas meters for the "Parkinson and Cowan" company who was later to take over the business. In 1926 came the cotton crash and the District Bank who had loans with the company foreclosed on the Hirst loan. The company did survive and throughout the second World, War II were involved in munitions work at the factory as well as making instruments for various aircraft. In the 1950’s they were producing meters and high grade measuring equipment but by the 1970's the business had closed and the factory was demolished in the mid-1980 "s The item is a good example of the later use of an early mechanism “Fusee” that was originally invented around 1525 in Prague. This type of clock mechanism was replaced as watchmakers looked for mechanisms that could reduce the size of clocks and watches, it appears England was the only country to continue making clocks with a Fusee device until around 1900,s of which our clock is an example. The use of a Fusee movement eventually became obsolete in 1970,s. The item is significant for the collection as it is a clock with a movement that has long since been made obsolete. Fusee type gallery wall clock made by Tame Side with an 8-day mechanical fusee movement. The white enamel dial is a little crazed and some of the Roman Numeral numbers are fading due to over-cleaning. The movement has a hexagonal iron pendulum bob hooking onto a pendulum rod with a spring-wound anchor escapement.Only mark is stamped on the movement believed to be a production number "13490" and made in Tame Side. (If the clock had been made after 1912 it would have had a trade mark "Limit")flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, wall clock, fusee, gallery clock, alfred hirst, tame side -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, 1890s to 1911

... a swirling design on it. The machine has the added bonus of a ruler... a swirling design on it. The machine has the added bonus of a ruler ...This machine was made in Baden, Germany, for the Ward Brothers of Melbourne, who imported machines from various manufacturers and had them branded with their Ward Brothers decals. This machine is most likely dated before 1911, when the Ward Brothers became two separate businesses, as one of the decals appears to have been deliberately removed. The case is made in an attractive design and the machine itself has decorations that are pleasant to the eye. Even the metal cover of the folding handle has a swirling design on it. The machine has the added bonus of a ruler along the front base. Many sewing machine manufacturers in Germany produced their machines specifically for export. A company could mass-produce its machines and give the same product several different brand names, according to their overseas buyers. There was a huge market for domestic machines as it enabled tailored clothing to be made in households at a fraction of the retail prices. Ward Brothers began in Australia in the late 1890s and early sewing machines sold by them had the three brothers on their decals. In 1911 the brothers divided into two separate firms, one operating on his own, the other two remaining together, and all still operating in Melbourne and at first still using the name Ward Brothers.This sewing machine is one of two hand-operated Ward Brothers machines in our collection that were made in Baden, Germany, and the only one that has had the three Ward Brothers on its decal, and that has front and rear slide plates. This machine represents the early domestic market for sewing machines, making it possible for the everyday homemaker to produce fashionable garments and linen ware that was affordable. The owner of this machine could work at more than one location as it was portable and did not require a large space to set up. The machine is associated with the well-known Ward Brothers of Melbourne, who sold imported sewing machines that were branded with their own name. Sewing machine, hand operated, in wooden case. The machine is painted black with gold decals, and front and rear slide plates. The wooden base of the machine has an inlaid ruler. The case has curved sides and shaped ends, decorative woodwork on corners, an inlaid diamond pattern on top, and a folding metal handle. Accessories are included. The decals include doves, inscriptions and swirls, and there is a map of Australia with two portraits of men. The machine was made in Baden, Germany, for Ward Brothers, Melbourne. Images: Map of Australia with States marked, and with portraits of two men. [A portrait-sized area on the left of the men has had the image removed.] Text in printed script: "Specially / Made in Baden" "WARD BROTHERS / MELBOURNE" " with a Logo is a map of Australia,flagstaff hill, warrnambool, great ocean road, sewing machine, hand operated, pre-1911, domestic sewing, homemade clothing, fashion, ward brothers, made in germany, baden, front and rear slide plates, crank handle, hand crank sewing machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Blotting Paper Holder, Circa 1910

Blotting paper is made from different materials of varying thickness, softness, etc. depending on the application. It is often made of cotton and manufactured on special paper machines. Blotting paper is reputed to be first referred to in the English language in the 15th century but there is a tradition in Norfolk, England that it was invented by accident at Lyng Mill on the River Wensum. It is reported that a Berkshire (England) paper mill worker in East Hagbourne failed to add sizing to a batch of paper that was being produced. The batch was discarded. Subsequently, someone tried to write on a piece of this discarded "scrap" paper and found that it rapidly absorbed any ink applied, making it unusable for writing. Its marked absorbency having been noted, however, led to its subsequently being produced and used as blotting paper, replacing sand, which was the material that had been used for absorbing superficial wet ink. In a time when most paper was produced from "rags", red/pink rags, from which it was difficult to remove all colour and had generally been discarded, were now directed to the production of blotters, hence the historically characteristic pink colour of blotters. https://en.wikipedia.org/wiki/Blotting_paper This blotting paper holder and blotting sheets were donated to Flagstaff Hill Maritime Village by the family of Doctor William Roy Angus, Surgeon and Oculist. It is part of the “W.R. Angus Collection” that includes historical medical equipment, surgical instruments and material once belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) as well as Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. ABOUT THE “W.R.ANGUS COLLECTION” Doctor William Roy Angus M.B., B.S., Adel., 1923, F.R.C.S. Edin.,1928 (also known as Dr Roy Angus) was born in Murrumbeena, Victoria in 1901 and lived until 1970. He qualified as a doctor in 1923 at University of Adelaide, was Resident Medical Officer at the Royal Adelaide Hospital in 1924 and for a period was house surgeon to Sir (then Mr.) Henry Simpson Newland. Dr Angus was briefly an Assistant to Dr Riddell of Kapunda, then commenced private practice at Curramulka, Yorke Peninsula, SA, where he was physician, surgeon and chemist. In 1926, he was appointed as new Medical Assistant to Dr Thomas Francis Ryan (T.F. Ryan, or Tom), in Nhill, Victoria, where his experiences included radiology and pharmacy. In 1927 he was Acting House Surgeon in Dr Tom Ryan’s absence. Dr Angus had become engaged to Gladys Forsyth and they decided he further his studies overseas in the UK in 1927. He studied at London University College Hospital and at Edinburgh Royal Infirmary and in 1928, was awarded FRCS (Fellow from the Royal College of Surgeons), Edinburgh. He worked his passage back to Australia as a Ship’s Surgeon on the on the Australian Commonwealth Line’s T.S.S. Largs Bay. Dr Angus married Gladys in 1929, in Ballarat. (They went on to have one son (Graham 1932, born in SA) and two daughters (Helen (died 12/07/1996) and Berenice (Berry), both born at Mira, Nhill ) According to Berry, her mother Gladys made a lot of their clothes. She was very talented and did some lovely embroidery including lingerie for her trousseau and beautifully handmade baby clothes. Dr Angus was a ‘flying doctor’ for the A.I.M. (Australian Inland Ministry) Aerial Medical Service in 1928 . Its first station was in the remote town of Oodnadatta, where Dr Angus was stationed. He was locum tenens there on North-South Railway at 21 Mile Camp. He took up this ‘flying doctor’ position in response to a call from Dr John Flynn; the organisation was later known as the Flying Doctor Service, then the Royal Flying Doctor Service. A lot of his work during this time involved dental surgery also. Between 1928-1932 he was surgeon at the Curramulka Hospital, Yorke Peninsula, South Australia. In 1933 Dr Angus returned to Nhill and purchased a share of the Nelson Street practice and Mira hospital (a 2 bed ward at the Nelson Street Practice) from Dr Les Middleton one of the Middleton Brothers, the current owners of what previously once Dr Tom Ryan’s practice. Dr Tom and his brother had worked as surgeons included eye surgery. Dr Tom Ryan performed many of his operations in the Mira private hospital on his premises. He had been House Surgeon at the Nhill Hospital 1902-1926. Dr Tom Ryan had one of the only two pieces of radiology equipment in Victoria during his practicing years – The Royal Melbourne Hospital had the other one. Over the years Dr Tom Ryan had gradually set up what was effectively a training school for country general-practitioner-surgeons. Each patient was carefully examined, including using the X-ray machine, and any surgery was discussed and planned with Dr Ryan’s assistants several days in advance. Dr Angus gained experience in using the X-ray machine there during his time as assistant to Dr Ryan. When Dr Angus bought into the Nelson Street premises in Nhill he was also appointed as the Nhill Hospital’s Honorary House Surgeon 1933-1938. His practitioner’s plate from his Nhill surgery is now mounted on the doorway to the Port Medical Office at Flagstaff Hill Maritime Village, Warrnambool. When Dr Angus took up practice in the Dr Edward and Dr Tom Ryan’s old premises he obtained their extensive collection of historical medical equipment and materials spanning 1884-1926. A large part of this collection is now on display at the Port Medical Office at Flagstaff Hill Maritime Village in Warrnambool. In 1939 Dr Angus and his family moved to Warrnambool where he purchased “Birchwood,” the 1852 home and medical practice of Dr John Hunter Henderson, at 214 Koroit Street. (This property was sold in1965 to the State Government and is now the site of the Warrnambool Police Station. and an ALDI sore is on the land that was once their tennis court). The Angus family was able to afford gardeners, cooks and maids; their home was a popular place for visiting dignitaries to stay whilst visiting Warrnambool. Dr Angus had his own silk worm farm at home in a Mulberry tree. His young daughter used his centrifuge for spinning the silk. Dr Angus was appointed on a part-time basis as Port Medical Officer (Health Officer) in Warrnambool and held this position until the 1940’s when the government no longer required the service of a Port Medical Officer in Warrnambool; he was thus Warrnambool’s last serving Port Medical Officer. (Masters of immigrant ships arriving in port reported incidents of diseases, illness and death and the Port Medical Officer made a decision on whether the ship required Quarantine and for how long, in this way preventing contagious illness from spreading from new immigrants to the residents already in the colony.) Dr Angus was a member of the Australian Medical Association, for 35 years and surgeon at the Warrnambool Base Hospital 1939-1942, He served as a Surgeon Captain during WWII 1942-45, in Ballarat, Victoria, and in Bonegilla, N.S.W., completing his service just before the end of the war due to suffering from a heart attack. During his convalescence he carved an intricate and ‘most artistic’ chess set from the material that dentures were made from. He then studied ophthalmology at the Royal Melbourne Eye and Ear Hospital and created cosmetically superior artificial eyes by pioneering using the intrascleral cartilage. Angus received accolades from the Ophthalmological Society of Australasia for this work. He returned to Warrnambool to commence practice as an ophthalmologist, pioneering in artificial eye improvements. He was Honorary Consultant Ophthalmologist to Warrnambool Base Hospital for 31 years. He made monthly visits to Portland as a visiting surgeon, to perform eye surgery. He represented the Victorian South-West subdivision of the Australian Medical Association as its secretary between 1949 and 1956 and as chairman from 1956 to 1958. In 1968 Dr Angus was elected member of Spain’s Barraquer Institute of Barcelona after his research work in Intrasclearal cartilage grafting, becoming one of the few Australian ophthalmologists to receive this honour, and in the following year presented his final paper on Living Intrasclearal Cartilage Implants at the Inaugural Meeting of the Australian College of Ophthalmologists in Melbourne In his personal life Dr Angus was a Presbyterian and treated Sunday as a Sabbath, a day of rest. He would visit 3 or 4 country patients on a Sunday, taking his children along ‘for the ride’ and to visit with him. Sunday evenings he would play the pianola and sing Scottish songs to his family. One of Dr Angus’ patients was Margaret MacKenzie, author of a book on local shipwrecks that she’d seen as an eye witness from the late 1880’s in Peterborough, Victoria. In the early 1950’s Dr Angus, painted a picture of a shipwreck for the cover jacket of Margaret’s book, Shipwrecks and More Shipwrecks. She was blind in later life and her daughter wrote the actual book for her. Dr Angus and his wife Gladys were very involved in Warrnambool’s society with a strong interest in civic affairs. He had an interest in people and the community They were both involved in the creation of Flagstaff Hill, including the layout of the gardens. After his death (28th March 1970) his family requested his practitioner’s plate, medical instruments and some personal belongings be displayed in the Port Medical Office surgery at Flagstaff Hill Maritime Village, and be called the “W. R. Angus Collection”. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The collection of medical instruments and other equipment is culturally significant, being an historical example of medicine and administration from late 19th to mid-20th century. Dr Angus assisted Dr Tom Ryan, a pioneer in the use of X-rays and in ocular surgery. Blotting paper holder, part of the W.R. Angus Collection. Wooden rocking blotting paper holder, arc-shaped with handle and blotting paper inserted in slots (paper is used). Two books of blotting paper sheets, (1) advertising printed on cover. “ACIBAN ANTACID”, “G.P. PTY LTD / Sydney Australia” (2) Folder of blotting paper, with advertising “AMPHOTABS” and “WYETH”“ACIBAN ANTACID”, “G.P. PTY LTD / Sydney Australia” “AMPHOTABS” and “WYETH” flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dr w r angus, dr ryan, surgical instrument, t.s.s. largs bay, warrnambool base hospital, nhill base hospital, mira hospital, flying doctor, blotting paper holder, office stationery circa 1910, rocking blotting paper holder -

Montmorency–Eltham RSL Sub Branch

Montmorency–Eltham RSL Sub BranchUniform - Coat, US Cold Weather, M-65, US Cold Weather Coat

In 1951 - in the context of the Cold War - the Menzies government established the 'National Service Act 1951', which called-up men for compulsory military training for a period of 176 days. The 14th Battallion was located in Victoria. The coat has historic significance in the wider context of Australia’s involvement in the Cold War (particularly in Vietnam) and in the establishment of a National Service Scheme. Olive green army man coat with four outside pockets - two on the chest, two at the bottom; each pocket has one metallic button attached. Coat has a metallic zip as well as metallic buttons; two velcro scratches at the wrist level. Extra removable padding inside, which is attached with plastic buttons. Two identical inscriptions on right and left shoulder reading '14 National Service Battalion'. Two identical inscriptions on right and left shoulder - reading '14 National Service Battalion' Manufacturing details on the inside reading: Coat, Cold weather, Man's, Field M-65. Olive green colour. Style 8120/8542 DSA 102-81-C1204. 1. Wear as outer garment or as under-layer in cold-dry climate. 2. Wear button-in liner for added insulation. 3. Adjust closures and drawcords to ventilate; avoid over-heating of body. 4. When hood is used, lower extension shall be worn over neck opening, preventing water. 5. Brush snow or frost from garments before entering opening. 6. For fast drying, remove liner from coat. 7. Do not expose to high temperature of a stove. 8. Lubricate slide fasteners with wax. 9. For cleaning and restoring of water repellency return to laundry for machine washing in accordance with established procedures for quarpel garments. 10. Do not starch. Do not remove this label. Black ink pen inscription on manufacturing label reading '3/715875' and 'N.Wain'war, army, coat, man's coat, australian army, military uniform, national service scheme, cold war, vietnam war -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Functional Object - Adding Machine, n.d

... House Unknown Functional object Functional Object - Adding ...Displayed at History HouseUnknown -

Kiewa Valley Historical Society

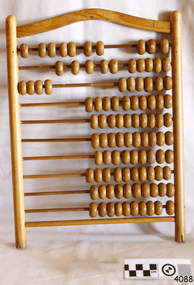

Kiewa Valley Historical SocietyContex Adding Machine, Office Equipment

... Scheme. Contex Adding Machine Office equipment 'Context' embossed ...1946 One of the first Contex calculators, the Half-Keyboard Adder used Leibniz step cylinders to perform simple addition. The predominant use of this Contex would have been adding sterling currency. Starting from the right, the levers were used for half and quarter pence, the next row would be pence, followed by shilling up to 19, and pounds. On the far left there is a zeroing lever for the entire mechanism; Ref: Online: 'physicsmuseum.uq.edu.au'Used by the office staff at the SECV construction of the Kiewa Hydro Electric Scheme.Bakelite small typing machine consisting of numbers with a screen above.'Context' embossed centre front 'Lubrication' with instructions and with Patents on bottom 'Chartres Business Service' at back 'Numbers 1 - 5' at front on knobscontex, adding machine, office equipment -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyChurn Butter - Wooden

This type of butter churn was used around the early to mid 20 century by household and small farms of the Kiewa Valley who kept cows for Milk. The buy product of the milk was cream and butter. Once the cows had been milked, often by hand, women would place the milk in shallow dish, and next morning the cream would be separated from the milk. Or a cream separator machine would be used. The cream would then be churned by the paddles in the butter churner until it formed in butter clumps. Butter Pats would be used to take the butter out and press into triangle butter blocksThis butter churner is significant due to its historical value which explains how butter was made by hand before this process became mechanistically made. Many houses or small farms in the Kiewa Valley had these butter churns to make their own butter for their household or to sell. This has very good interpretation significance as it adds to the history of dairy industry in the Kiewa Valley. Wooden box with a metal handle for turning the blades /paddles /slats inside the box.These blades churn the cream when the handle is turned. There is also a wooden handle and a wooden lid.butter, dairy, milk, manual, domestic, item, food, preparation, dairying, technology -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Spring Balance Scale, George Salter & Co, 1920s

Scales such as the subject item were used to measure commercial quantities, possibly grains and farm produce for quite large amounts of product. Bags of grain etc would have been hooked up and weighed. Salter has been a name long associated with weights and measures. The firm began life in the late 1760s in the village of Bilston, England when Richard Salter, a spring maker, began making the first spring scales in Britain. He called these scales "pocket steelyards", though they work on a different principle from steelyard balances. By 1825 his nephew George had taken over the company, which became known as George Salter & Co. George later established a manufacturing site in the town of West Bromwich, about 4 miles (7 km) from Bilston. West Bromwich Albion football club was formed from workers at this works site. From here the company produced a wide variety of scales including the UK's first bathroom scales. Other items were added to the range, including irons, mincers, potato chippers, coin-operated machines and the first typewriters made in the UK. The business thrived throughout the 1900s, and by 1950 it employed over 2000 people, still in the same area and owned by the same family.Salter is a British housewares brand developing products that span a wide range of core product categories, including scales, electrical, cookware. It is a market leader in kitchen and bathroom scales and one of the UK’s oldest consumer brands. Established in 1760, Salter has been developing precision products for over 260 years. It was acquired by Manchester-based consumer goods giant Ultimate Products in 2021 after they had previously licensed the brand for cookware and kitchen electrical since 2011.Balance scale Salters Spring Balance consisting of a circular, bronze face engraved with measurements in pounds, with an iron hand, weighing mechanism and hanging loop. Engraved on the face: "Class III Salter's Spring Balance Silvester's Patent To Weigh 300lbs".flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, salter balance scale, weight measuring scale, weighing dry goods -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wringer/Mangle, Melvin Newton Lovell, 1898 -1900

... for adding machines (cash registers). flagstaff hill warrnambool ...Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers).Wringer (or mangle); portable wooden washing wringer with rubber rollers, manually driven by iron set of gears and handle. Includes iron clamps and adjusting screws for attaching. Marked on frame "382", "12 x 1 3/4" Anchor Brand "Made in USA" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mangle, clothes wringer, washing equipment, laundry, wringer, domestic, washing mangle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClothing - Traveller's Apron, Eliza Towns, Circa 1915

This apron is one of several linen and clothing items that were made and belonged to Mrs. Eliza Towns and donated to Flagstaff Hill Maritime Museum and Village. Eliza was born Eliza Gould in 1857 in South Melbourne (Emerald Hill) and in 1879 married Charles Towns. In the early 1880's they moved to Nhill in western Victoria and remained there for the rest of their married life. Charles was a jeweller and later became an accountant and for many years was involved with the Shire Council, the local show committee (A & P Society), the Hospital Committee and the Board of the local newspaper (the Nhill Free Press). They had three children and lived a life that would be regarded as comfortably "middle class". Eliza probably had a treadle sewing machine and would have made many of her own clothes - adding her own handmade embroidered or crocheted decorative trim. In March 1915 Eliza travelled to San Francisco to visit her son, James. She went by train to Melbourne ("a pleasant journey on the up express') and the next day caught the express train to Sydney. She noted in her letters home that a " number of young men were going to Sydney to enlist but they had to stop in the corridors most of the way as there was no room for them to sit down". She spent the night on the train and arrived in Sydney the next morning and on the following day she boarded the R.M.S. "Moana" (a steamer which took about twenty-four days to reach San Francisco). She returned from Vancouver about five months later on board the "Manuka". It is very likely Eliza took this "Travelling Apron" with her on her travels. Eliza was travelling by herself and had no one to help her with her dress or her hair. "Travelling Aprons" (also known as Toilet Aprons or Tourist Aprons) were designed with different sized pockets for holding a lady's toiletries - hairbrush, hair pins, comb and sometimes even soap and a powder puff. This allowed the owner, when travelling and getting dressed in small places such as an overnight train compartment or a ship's cabin, to have all her requirements at hand without needing to search for them or have them roll onto the floor. Some of the pockets are finished with buttoned flaps to keep the items in place and when not in use, the apron could be hung up or rolled up and put away. Articles about the "Traveller's Apron" appeared in numerous Women's columns in Australian newspapers in the early 20th century - often with instructions and sometimes a pattern. In the "Age" on Sat 5th October 1907 in a column titled "Feminine Facts and Fancies" the author wrote "No man can appreciate the difficulties of dressing in a "wobbly" train or trying to do one's hair while a ship is weathering a storm". A year earlier (Saturday 24th March 1906) in the same column, the author wrote "... you have to spend nights in a train... forever struggling to dress yourself in a wretched little lavatory. You know how your hairpins and combs jump all over the place ... a train is always at its liveliest when you're trying to do your hair. My travelling apron saved me many a rage."This item is an example of the needlework skills of women in the early 20th century - combining machine stitching with hand embroidery to personalise and embellish a practical domestic object. It is also an excellent (and rare) example of an early 20th century innovation that helped solve the difficulties of privacy and convenience that many women experienced at a time when travel was becoming more accessible to them. A half apron, made of ivory linen with two waist ties and seven pockets. Along the top are two smaller pockets with triangular, buttoned flaps labelled "Hairpins" and "Nailbrush" and one larger unlabelled pocket. Underneath are two larger pockets labelled "Brush & Comb" and "Work" and two unlabelled narrow pockets. The seams are machine stitched and the pockets are outlined with hand embroidered feather stitch. The labels on the pockets are embroidered in stem stitch."Hairpins" / "Nailbrush" / "Brush and Comb" / "Work"flagstaff hill maritime museum and village, nhill, eliza towns, apron, travelling apron, tourist apron, textiles, toilet apron, sewing, embroidery, travel, warrnambool, great ocean road, trains, ships, moana, manuka, feather stitch, stem stitch, fashion, handmade, clothing, charles towns, needlework -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTextile - Bolster Sham, Eliza Towns, Late 19th century to early 20th century

This bolster sham is one of several linen and clothing items that were made and belonged to Mrs. Eliza Towns and donated to Flagstaff Hill Maritime Museum and Village. Eliza was born Eliza Gould in 1857 in South Melbourne (Emerald Hill) and in 1879 married Charles Towns. In the early 1880's they moved to Nhill in western Victoria and remained there for the rest of their married life. Charles was a jeweller and later became an accountant and for many years was involved with the Shire Council, the local show committee (A & P Society), the Hospital Committee and the Board of the local newspaper (the Nhill Free Press). They had three children and lived a life that would be regarded as comfortably "middle class". Eliza probably had a treadle sewing machine and would have made many of her own clothes and household linens - adding her own handmade embroidered or crocheted decorative trim. Most beds during the late 19th and early 20th century had a feather, hair or spring mattress covered by a blanket and topped with an under sheet, an upper sheet, several blankets and a bedspread. A flat bolster could be placed either under the pillows or on top of the pillows with a decorative sham. Washing pillows and quilts by hand would have been a very onerous task (involving heating water and handwashing in a tub or using a copper) and so it became the practise of many housewives to cover the pillows and bolsters with an outer slip (or sham) of washable material which could be easily removed and washed when needed. If the bolster was kept under the pillows it wouldn't need to be very decorative but many shams or slips that were "on show" were often highly decorated with embroidery, pintucks, ribbons or lace. This bolster sham is machine made and quite plain with the exception of some pintucking and eyelet lace on each end which suggests that it would mostly be hidden under the top pillows with just the decorative edges on display.This item is an example of the needlework skills of women in the early 20th century - combining machine stitching with hand embroidery to personalise and embellish a practical domestic object. It is also significant as an example of an early 20th century innovation that helped make the working lives of housewives a little bit easier.A long white cotton rectangular bolster sham, machine sewn, with seven ties and two buttons (plus one missing button) to enable it to be folded over lengthwise and closed. It has two pull string ties near each end to enclose a bolster and is finished with a decorative edge of pintucks and handmade eyelet lace and embroidery.flagstaff hill maritime museum and village, eliza towns, sham, bedding, great ocean road, shipwreck coast, warrnambool, household textiles, sewing, bolster sham, housework, pillow sham, charles towns, nhill, haberdashery, needlework, manchester, handmade, household linen -

Federation University Historical Collection

Federation University Historical CollectionInstrument - equipment, Mechanical Pinwheel Calculator, c1940, 1935-1945

... of the machine, and are added to the register visible in the carriage... are dialed into the sliding levers on the top part of the machine ...Willgodt T. Odhner invented his very successful “pinwheel” four-function calculator mechanism in Russia in 1874, and his invention was cloned by numerous companies, resulting in dozens of similar models that remained in wide use for almost a century. Numbers are dialed into the sliding levers on the top part of the machine, and are added to the register visible in the carriage at the bottom when the large crank is turned. Shifting the carriage sideways allows multiplication through a sequence of addition operations; the two small cranks zero the registers. The design includes ingenious error-preventing interlocks between all the controls: should the operator fail to return a crank to its resting position, the other controls are frozen until this is corrected. A bell indicates calculations in the negative. Used in Ballarat Institute of Advanced Education (B.I.A.E) Physics department.Black, mechanical calculating machine. Metal. Hand-operated, with three hand-cranks. 10x10 rotor with 13 digit result. Ser. No. 29-286781.5 Black symotape on base front: "PHYSICS". Maker's identification on top surface. Supplier's label (metal, silver & blue) on back: "STOTT & HOARE Pty. Ltd. 171 William St. Melbourne C1 M1991". Stamped on rear panel: "MADE IN SWEDEN". Cast lettering on underside: "M-602 07".calculating machine, pinwheel, calculator, scientific instruments, stott & hoare pty ltd, physics, odhner, ballarat institute of advanced education -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClothing - Child's dress, Eliza Towns, Late 19th century

This child's dress is one of several linen and clothing items that were made and belonged to Mrs. Eliza Towns and donated to Flagstaff Hill Maritime Museum and Village. Eliza was born Eliza Gould in 1857 in South Melbourne (Emerald Hill) and in 1879 married Charles Towns. In the early 1880's they moved to Nhill in western Victoria and remained there for the rest of their married life. Charles was a jeweller and later became an accountant and for many years was involved with the Shire Council, the local show committee (A & P Society), the Hospital Committee and the Board of the local newspaper (the Nhill Free Press). They had three children and lived a life that would be regarded as comfortably "middle class". Eliza probably had a treadle sewing machine and would have made many of her own clothes as well as clothes for her children - adding her own handmade embroidered or crocheted decorative trim. A photograph of their youngest child, Alice, taken in circa 1903 depicts her wearing the dress. The dress would have been only worn on special occasions (such as a formal family photographic portrait) as most young girls in that era would have smocks or pinafores for everyday wear. The age of the dress is in question as it may have been made by Eliza for her eldest daughter, Dorcus, who was born in 1884. This dress has some machine sewing at the neck, waistband and pintucks but much of the dress is handsewn and richly embroidered with Broderie anglaise. Broderie anglaise (also known as eyelet lace) is a form of cutwork embroidery. The foundation fabric is cut to make decorative holes which are sewn with overcast or buttonhole stitches to create a lace like effect. Designs often involve floral motives that are enhanced with simple embroidery stitches such as stem stitch and satin stitch and scalloped edges finished with buttonhole stitches. It was commonly used to trim baby clothes, dresses, nightclothes, underclothes and household linens - particularly in the Victorian and Edwardian eras. This item is an example of the needlework skills of women in the late 19th century - combining machine stitching with hand embroidery to personalise and embellish a child's special dress.Child's white dress made of cotton and lawn, with a skirt of hand embroidered circular cutwork (broderie anglaise), a scalloped hem edged in buttonhole stitch and a gathered waist. The lined bodice has three panels of hand embroidered broderie anglaise (eyelet lace) inserted in a V shape with pintucks and bordered with a broderie anglaise lace frill. The short sleeves also have an inserted broderie anglaise lace strip, three pintucks and a broderie anglaise lace frill. The skirt is semi lined with fine lawn. The dress has a back opening with one button and two ties. The neckline is decorated with two rows of hand embroidered broderie anglaise lace.flagstaff hill, flagstaff hill maritime museum & village, warrnambool, shipwreck coast, great ocean road, nhill, wimmera, eliza towns, dorcus towns, child's dress, machine sewing, hand sewing, broderie anglaise, cutwork, embroidery, eyelet lace, clothing, handmade, charles towns, alice towns -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClothing - Petticoat, late 19th century to early 20th century

This petticoat was one of several items donated from the estate of Susan Henry OAM nee Vedmore (1944 - 2021). It is in very good condition and appears to be from the Edwardian era - early 20th century. A petticoat is a lady's undergarment - worn under a skirt or dress. They provided warmth, modesty and shape to the dress. In the middle of the 19th century, petticoats were worn over hoops, bustles or in layers. Petticoats varied according to the style of the outside skirt or dress. Plain petticoats tended to be worn with everyday wear whilst better dresses (party dresses or silk gowns) were worn with petticoats that often had more trim and embellishments. Edwardian petticoats had less volume than Victorian era petticoats and they had a "dust ruffle" or lining under a lace flounce. The "dust ruffle" protected the lace flounce and gave the petticoat more flare at the bottom, greater freedom when walking as well as saving the flounce (which was often made of finer material) from everyday wear and tear. Tucks are another feature of Edwardian petticoats - when the lace at the bottom became worn, it could be cut off and the tucks released. This extended the life of the petticoat. This petticoat features an intricate trim of broderie anglaise. Although broderie anglaise was a lace that could be made by hand, it was very time consuming to make. St Gallen was a city in Switzerland that had become known for producing quality textiles. At the beginning of the 19th century, the first embroidery machines were developed in St Gallen. Factories used embroidery machines but people also had them in their homes. They were able to produce broderie anglaise for export. By the early 20th century, machine made lace, fabric, ribbons etc. were being sold in drapers shops all over England and Wales to women who were making clothes and furnishings for their families. It is highly likely that the lady who made this petticoat brought the lengths of broderie anglaise already made to embellish and personalise her petticoat. Susan's family (Harold and Gladys Vedmore) immigrated to Australia from Wales in 1955 and settled in Warrnambool. Susan was well known in the Warrnambool community for her work supporting children and families across the district - particular those with disabilities, or those who were homeless, unemployed or isolated. Susan was the founding trustee of the "Vedmore Foundation" - a Warrnambool philanthropic trust set up in 2010 to support a range of charitable and not-for-profit causes by providing grant assistance. In 2021, she was awarded a Medal of the Order of Australia for services to the community.This item is an example of the needlework skills of women in the late 19th century - creating pintucks and adding lace to personalise and embellish a practical item of clothing. It is also significant as an example of a practical solution to the difficulties that women of this era faced with regard to the washing of clothes and household linens.A white lawn petticoat with a 22.5 cm opening that fastens with 2 small buttons and a drawstring tie. It is decorated with two wide pintucks followed by two gathered frills (or flounces) - one decorated with three rows of narrow pintucks and a single row of broderie anglaise and the bottom frilled hem finished with 3 rows of broderie anglaise in a flower design. The two bottom frills are lined with plain white cotton fabric.flagstaff hill maritime museum and village, great ocean road, petticoat, lady's petticoat, undergarment, lady's undergarment, lingerie, edwardian petticoat, broderie anglaise, lace, machine made lace, hand sewn, machine sewn, draper's shop, susan henry oam, vedmore foundation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle with pens, Early 20th century

This handmade, aqua glass ink bottle's design is sometimes called a ‘boat’ shape. The base was mouth-blown into a rectangular mould, evidenced by the lack of seams, the pontil, crease lies and the uneven thickness of the glass. The shoulder section was mouth-blown into a two-piece mould and then cut off from the blowpipe. The lip is sometimes referred to as a 'burst-lip, which was often filed to be smooth. This method of making bottles was often used in the mid-to-late 19th century. The bottle would then be filled with ink and sealed with a cork. More expensive bottles would have a lip added, which was more time-consuming and costly. The capacity for a bottle such as this was about 3 ½ oz (ounces) equal to about 100 ml. Pens are a common item for that period. Pen and ink have been used for handwriting since about the seventh century. A quill pen made from a bird’s feather was used until the mid-19th century. In the 1850s a steel point nib for the dip pen was invented and could be manufactured on machines in large quantities. The nis only held a small amount of ink so users had to frequently dip the nib into an ink well for more ink. Handwriting left wet ink on the paper, so the blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased as a ready-to-use liquid or in powdered form, which needed to be mixed with water. In the 1880s a successful, portable fountain pen gave smooth-flowing ink and was easy to use. In the mid-20th century, the modern ballpoint pen was readily available and inexpensive, so the fountain pen lost its popularity. However, artisans continue to use nib pens to create beautiful calligraphy.The ink bottle is of interest, being made of aqua glass rather than the more common clear glass. This set of ink bottles and pens is significant because of the bottle's method of manufacture, which is representative of a 19th-century handcraft industry that has now been largely replaced by mass production. The bottle and pens are historically significant as tools used for handwritten communication until the mid-20th century when fountain pens and modern ballpoint pens became popular and convenient and mechanical typewriters became part of standard office equipment.Victorian 'Boat' ink bottle, small rectangular, aqua glass ink bottle with grooves along the long sides for pen rests. The base has a pontil, no seams, and the glass is uneven in thickness. The shoulder has two side seams and there is a ridge where it is joined onto the base; there are round indents on each of the shoulder, on the short sides, four in all. The mouth has rough edges. The neck leans to one side. The glass has impurities, crease lines and bubbles. There is dried ink in the bottle. Two pens with metal nibs are included with the ink bottle. flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, ink, nib pen, writing ink, writing, copying, banks, lawyers, commerce, student, permanent ink, stationery, record keeping, handwriting, writing equipment, writing accessory, office supply, cottage bottle, boat bottle, mouth-blown bottle, two-part mould, sheer-lip bottle, burst-lip, cork seal, copy ink, aqua glass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle and Pen, Caldwell’s Ink Factory, Early 20th century