Showing 163 items

matching aircraft manufacturing

-

Nhill Aviation Heritage Centre

Nhill Aviation Heritage CentreBooklet - R.A.F Signal Manual Part V, Ground Signal Codes (Provisional)

... to discuss the manufacture of aircraft in those countries... the manufacture of aircraft in those countries such as Wirraways ...Signal codes used by Royal Air Force. This booklet was authorised by Sir Donald Banks, Secretary of the British Air Ministry . He was responsible for setting up the Empire Air Training Scheme . He travelled to Australia and New Zealand to discuss the manufacture of aircraft in those countries such as Wirraways and Beaufighters.Orange cardboard cover with 40 buff coloured pages.For official use only. Air Publication 1632, March 1938. Issued for the information and guidance of all concerned. By command of the Air Council (signed) Donald Banks. Air Ministry -

Frankston RSL Sub Branch

Frankston RSL Sub BranchCigarette Case, (estimated); possibly WW2 trench art

... is possibly trench art manufactured from aircraft parts.... from oval shaped Aluminium tube (or similar aircraft ...Cigarette case probably made from oval shaped Aluminium tube (or similar aircraft construction material). The case has a removable lid which slides over an inner tube (see 'photos). The oval shaped ends of the case are made from a perspex (?) material or similar. The perspex piece fitted into the lid has four Japanese (?) characters marked in red. This item is possibly trench art manufactured from aircraft parts.There are four Japanese (?) characters written on lid however not yet translated.aluminium, case, container, trench art, cigarette case, tubing, tube -

Moorabbin Air Museum

Moorabbin Air MuseumMachine - CAC CA-1 Wirraway A20-10, 1939

... Corporation (CAC) was formed in 1936 to manufacture aircraft... Corporation (CAC) was formed in 1936 to manufacture aircraft ...Historical Details: The AARG aircraft was delivered in September 1939 as the 8th production Wirraway and numbered A20-10 ( A20-1 and A20-2 being the imported NA-16 aircraft), and was initially allocated to No. 22 General Purpose Squadron at Richmond in NSW, however 12 months. Description: The Commonwealth Aircraft Corporation (CAC) was formed in 1936 to manufacture aircraft in Australia. The first General Manager of CAC was Lawrence Wackett whose innovative aircraft design was to be seen throughout his time at CAC. The Wirraway was the. Level of Importance: National -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - Roland Jahne Collection - See Description for details

... Various British Aircraft Manufacturing Co -Swallow, Eagle, Double... Various British Aircraft Manufacturing Co -Swallow, Eagle, Double ... -

Moorabbin Air Museum

Moorabbin Air MuseumMixed media (item) - Brian Ridgeway Collection Miscellaneous aircraft photos, newspaper items etc. See under "Description" Section

... , 1939 Manufacture of aircraft in Australia defence sub-committee... 2 March, 1939 Manufacture of aircraft in Australia defence ... -

Puffing Billy Railway

Puffing Billy RailwaySteam Driven Weir Pump, 1900s

... in the First World War. As well as shells, they manufactured aircraft..., they manufactured aircraft including the Royal Aircraft Factory F.E.2 ...G. and J. Weir of Holm Foundry, Cathcart, Glasgow and now known as the Weir Group. The company was established in 1871 as an engineering firm by two brothers, George and James Weir, founding G. & J. Weir Ltd. The Weir brothers produced numerous groundbreaking inventions in pumping equipment, primarily for the Clyde shipyards and the steam ships built there. These pumps became extremely well known for their use as boiler feedwater pumps, and for ship's auxiliary equipment such as evaporators. Under W D Weir, the company turned to producing munitions and war material in the First World War. As well as shells, they manufactured aircraft including the Royal Aircraft Factory F.E.2 fighter and bomber. James George Weir (aviator, son of James Galloway Weir) a director of the company formed the Cierva Autogiro Company. G & J Weir would be a financial supporter of the company during its existence. In 1943, they provided the finances for the construction of the W.9, an experimental helicopter, to Air Ministry requirements. It was first listed on the London Stock Exchange in 1946. Double-acting Weir steam pumps were virtually standard fitment on British-built steamships, being used for pumping water, fuel, air and much else well into the 1950s, as well as being used on other ships worldwide. Historic - Double-acting Weir steam pumpSteam Driven Pump made of iron & steel puffing billy, weir pump, weir, steam driven pump -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

... of vehicle and aircraft manufacture were catered for by new types... specific needs of vehicle and aircraft manufacture were catered ...The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Moorabbin Air Museum

Moorabbin Air MuseumEquipment (item) - Graviscope for Lincoln (Australian) RAAF Ident No G6C/3972, Graviscope for Lincoln

... in the British designed but Australian manufactured, Government Aircraft... in the British designed but Australian manufactured, Government Aircraft ...Description White plastic doubled sided Graviscope stored in protective leather carry case. Case is fitted with pair of press studs, pocket in front for holding instructions and is stamped "Graviscope / for / Lincoln / (Australian) / Manufactured by / Melb > W & G < Aust / R.A.A.F / Ident. No G6C/3972". Plastic graviscope consists of a 277mm white disc, printed on both sides, overlaid on one side by a 224mm disc and the other side by a 175mm disc. All discs located by central screw, to which is attached a 160mm long x 25mm wide clear celluloid strip. History / Summary The graviscope is a computing device, which in aircraft was used for measuring the centre of gravity in an aircraft. This would vary depending on crew, bomb load, fuel and stores carried. It was used in the British designed but Australian manufactured, Government Aircraft Factory (GAF) Lincoln heavy bomber, which was operated by the Royal Australian Air Force (RAAF) in the years following the Second World War. This aircraft was originally a derivative of the famous Avro Lancaster bomber. The Lincoln was used by both the RAAF and the Royal Air Force in operations against Malayan Communist terrorists during the Malayan Emergency, 1948-1960. This graviscope is of the type designed for and used by RAAF and RAF aircrew who operated this aircraft.Many by W and G Australia -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (Item) - (SP) CAC History Correspondence between CAC and the British Aviation Group 1935 to 1937

... aircraft from Britain prior to WW2. CAC had decided to build... aircraft CAC may manufacture Letter to B Lewis 14/1/1937 from ...This correspondence relates to Australia possibly buying aircraft from Britain prior to WW2. CAC had decided to build the NA 16 and there was correspondence from Hawker Siddeley expressing their wish to negotiate on future aircraft CAC may manufacture Letter to B Lewis 14/1/1937 from Secretary re Hawker Siddeley Letter from Brian Lewis to Secretary CAC 11/1/1937 enclosing letter from Hawker Siddeley Letter from Brian Lewis to Essington Lewis, CAC 27/2/1937 Letter from Essington Lewis to Secretary CAC 1/3/1937 Letter from Secretary CAC to Brian Lewis 30/11/1937 Letter from Brian Lewis to Essington Lewis CAC 24/11/1937 Letter from Essington Lewis to Brian Lewis 1/3/1937 Letter from Hawker Siddeley Aircraft Company Limited to Secretary CAC 16/12/1936 Letter from Secretary CAC to Brian Lewis Memorandum for CAC Board re Hawker Siddeley proposals advising not to accept any of the proposals made - instead mentioning Bristol and de Havilland 17/11/1936 Letter from Brian Lewis to Essington Lewis 6/11/1936 Letter from Brian Lewis representing Hawker Siddeley to Essington Lewis 21/10/1936 Letter from Brian Lewis to Essington Lewis 27/6/1936 representing Hawker Siddeley anticipating the return of Wackett from his overseas trip and the setting up of the aircraft industry in Australia Letter from Brian lewis to Essington Lewis 28/3/1936 re passing over of Hawker Siddeley proposals to Mr Parkhill in Canberra Memorandum of interview with Brian Lewis and Essington Lewis and FM Mitchel of the syndicate. 19/3/1936 Proposals for co-operation in Australia by Hawker Siddeley (group consists of Hawker, glister, Armstrong whit worth, Armstrong Siddeley, Burlington carriage and A V Roe Letter from Brian Lewis to Essington Lewis providing his background and relationship with Hawker Siddeley 3/2 1936 and 17/12/1935 and 26/12/1935 Very relevant to how the aircraft industry was set up in Australia -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1900's

... . At the outbreak of the First World War in 1914 found them manufacturing... in 1914 found them manufacturing aircraft parts including ...In August 1884, Alfred Hirst who had started his trade as a watch repairer and was described as a watchmaker extraordinaire established Hirst Brothers and Company, on Union Street in Oldham Manchester. He took his two stepbrothers into the business and the company was set up to produce timepieces and jewellery as well as importing “Limit company” Swiss watches and precision machine tools for the watch and clock trade. By 1902 Hirst Brothers. had become a limited company and was still growing, adding other businesses in Manchester in 1904 and at Birmingham in 1907. The quality of the clocks and watches was such that Alfred Hirst realised his greatest ambition in 1912 with a range of watches which carried the "Limit" trademark. These watch movements had originally been made in Switzerland and shipped to Hirst Bros. to be put into British made “Dennison” cases. This trade brought even more growth with additional sales offices opening in London and Glasgow. At the outbreak of the First World War in 1914 found them manufacturing aircraft parts including revolution counters and optical instruments. The firm had been tasked by the Ministry of Munitions to solve the problem of pilots dropping bombs by hand and as a result, they effectively created the first bomb rack. After the war, the company once again began to prosper and with the demand for their products increasing they looked to build a new purpose-built factory to manufacture their products. In 1917 they purchased a seven-acre field site at Tame Side Dobcross, the designing of the new factory was passed onto local architect AJ Howcroft. His brief for the design of the clockworks would have been prompted by Alfred Hirst who having visited modern factories in the United States was inspired by the latest factory designs providing as much daylight as possible during working hours. The factory was eventually completed in 1920, by the mid-1920s there were cheap clock imports from Germany and production turned to radio sets and other components as well as counter and gas meters for the "Parkinson and Cowan" company who was later to take over the business. In 1926 came the cotton crash and the District Bank who had loans with the company foreclosed on the Hirst loan. The company did survive and throughout the second World, War II were involved in munitions work at the factory as well as making instruments for various aircraft. In the 1950’s they were producing meters and high grade measuring equipment but by the 1970's the business had closed and the factory was demolished in the mid-1980 "s The item is a good example of the later use of an early mechanism “Fusee” that was originally invented around 1525 in Prague. This type of clock mechanism was replaced as watchmakers looked for mechanisms that could reduce the size of clocks and watches, it appears England was the only country to continue making clocks with a Fusee device until around 1900,s of which our clock is an example. The use of a Fusee movement eventually became obsolete in 1970,s. The item is significant for the collection as it is a clock with a movement that has long since been made obsolete. Fusee type gallery wall clock made by Tame Side with an 8-day mechanical fusee movement. The white enamel dial is a little crazed and some of the Roman Numeral numbers are fading due to over-cleaning. The movement has a hexagonal iron pendulum bob hooking onto a pendulum rod with a spring-wound anchor escapement.Only mark is stamped on the movement believed to be a production number "13490" and made in Tame Side. (If the clock had been made after 1912 it would have had a trade mark "Limit")flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, wall clock, fusee, gallery clock, alfred hirst, tame side -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Diving Compressor, Siebe Gorman & Co. Ltd, 1880-1890

This compressor was part of the E.G. Ward Collection. It is connected to the diving suit and boots also in our collection. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water-pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12 bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunneling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr. E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The compressor is a very significant item as it gives a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. Siebe & Gorman the company that made the equipment was a leading inventor, developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job during the early days of marine exploration.A single cylinder divers' pump by Siebe Gorman & Co Ltd, London, eccentric hand cranked in brass mounted mahogany case with instructions to the underside of the lid, brass covered pressure gauge and air outlet, brass makers plaque to the front, water inlet and outlet to the rear, green painted lifting rings. Machinery has some blue painted areas on the metal.Plate on the back 'WATER SUPPLY" "WATER OVERFLOW" "WATER DRAIN-IN" Pressure gauge dial "BOURDON'S PRESSURE GAUGE" STEBE GORMAN & CO. LONDON", "LBS PRESSURE" "FEET OF SALT WATER" Plate on the front " PATENT, Siebe Gorman & Co Ltd Submarine Engineers" below emblem (Lion, Crown, Horse)flagstaff hill, warrnambool, flagstaff-hill, maritime-museum, diving compressor, london, siebe gorman & co ltd, marine technology, life saving, deep sea diving, maritime museum, maritime village, manine history -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Diving Suit, boots and weight, 1900

This diving suit with helmet, boots and weight is part of the E.G.Ward collection, along with the diving compressor and a photograph of a diver in this equipment. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12-bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunnelling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A.Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire-fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The items are very significant as a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. The company that made the equipment was a leading inventor,developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job.Diving suit including helmet, boots and a weight. Diving suit is made of canvas with knitted cuffs. The helmet is metal. The boots have a thick sole and thick leather upper that is held on with leather straps and buckles. The toe of the boot is heavy metal. The weight is worn next to the trunk of the diver and it has an inscription to mark the front. It is worn with straps and buckles holding it in place. Royal Navy Admiralty Pattern 6 bolt No 3 light Siebe Gorman light diving helmet circa 1960 used by the Royal Navy before and after World War 2"Siebe Gorman & Co Ltd Marine Engineers London. Patent" with "E G Ward" on front and back plate. On weight "FRONT"flagstaff hill, warrnambool, diving suit, siebe gorman and co ltd., siebe gorman and co ltd marine engineers london, marine engineers, diving helmet, diving boots, diving weight, marine diving, maritimemuseum, maritime village, maritime history, marine technology, life saving, deep sea diving -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageParallel Rule, 1947-1955

History/Context: In 1947, the scientific instrument manufacturing firms of Henry Hughes & Son Ltd, London, England, and Kelvin Bottomley & Baird Ltd, Glasgow, Scotland, came together to form Kelvin & Hughes Ltd. Hughes Company History: Henry Hughes & Sons were founded in 1838 in London as a maker of chronographic and scientific instruments. The firm was incorporated as “Henry Hughes & Sons Ltd” in 1903. In 1923, the company produced its first recording echo sounder and in 1935 a controlling interest in the company was acquired by S Smith & Son Ltd resulting in the development and production of marine and aircraft instruments. Following the London office's destruction in the Blitz of 1941, a collaboration was entered into with Kelvin, Bottomley & Baird Ltd resulting in the establishing “Marine Instruments Ltd”. Following the formal amalgamation of Kelvin, Bottomley & Baird Ltd and Henry Hughes & Sons Ltd in 1947 to form Kelvin & Hughes Ltd. Marine Instruments Ltd then acted as regional agents in the UK for Kelvin & Hughes Ltd who were essentially now a part of Smith's Industries Ltd founded in 1944 and the successors of S. Smith & Son Ltd. Kelvin & Hughes Ltd went on to develop various marine radar and echo sounders supplying the Ministry of Transport, and later the Ministry of Defence. The firm was liquidated in 1966 but the name was continued as Kelvin Hughes, a division of the Smiths Group. In 2002, Kelvin Hughes continues to produce and develop marine instruments for commercial and military use. (See Note section this document for further information on the company's origins)This model parallel map ruler is a good example of the commercial diversity of navigational instruments made by Kelvin & Hughes after world war 2. It was made in numbers for use by shipping after the second world war and is not particularly rare or significant for its type. Also, it was made no earlier than 1947 as the firms of Kelvin, Bottomley & Baird Ltd and Henry Hughes & Sons Ltd who took over from Smith & Sons were not amalgamated until 1947. It can there for be assumed that this ruler was made during the company's transitional period to Kelvin & Hughes from Smith Industries Ltd.Metal parallel rule with Kelvin & Hughes Ltd, Made in Great Britain imprinted, numerous measurements, two handles and 3 hinges.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, parallel rule, kelbin & hughes ltd, metal parallel rule -

Bendigo Military Museum

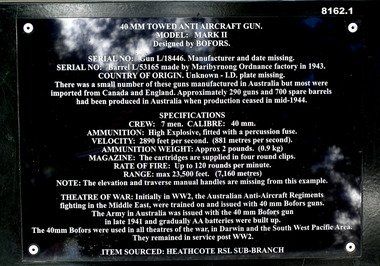

Bendigo Military MuseumWeapon - ANTI AIRCRAFT GUN, TOWED, Unknown

This item is on display in the gardens of the Bendigo District RSL Havilah Road. Refer photo .1) for details re manufacture, history and use..1) Plaque metal black on a stand with white text re details of the item. .2) Bofor 40 mm Anti Aircraft Gun M11 painted light green, mounted on a four wheeled base towed item.brsl, smirsl, bdrslinc, bofor, 40 mm, anti aircraft -

Waverley RSL Sub Branch

Waverley RSL Sub BranchShell 40 Cal

The Bofors 40 mm gun, often referred to simply as the Bofors gun, is an anti-aircraft/multi-purpose autocannon designed in the 1930s by the Swedish arms manufacturer AB Bofors. It was one of the most popular medium-weight anti-aircraft systems during World War II, used by most of the western Allies as well as by the Axis powers. The shells were manufactured according to a British design after it was discovered that the Swedish shells had much too sensitive a contact fuse, "which functioned on impact with rain drops". Although the shells could nominally reach out to 11,000 yards (10,000 meters), almost all the shells manufactured had self-destroying tracers that detonated the rounds at a range of 4000-5000 yards (3700-4600 meters.) This helped prevent friendly fire incidents or other collateral damage. In addition to the TNT bursting charge, the shell contained a pellet of powdered magnesium and aluminum as an incendiary. Production of ammunition peaked at 12 million rounds per month in the winter of 1944. Ammunition type Contact fused HE/incendiary fixed shell. AP shells were also available. Projectile weight 1.985 lb 0.80 kg Velocity 2890 feet/s 881 m/s Maximum elevation 90 degrees Range 11,000 yards 10,000 meters Altitude 22,800 feet 6950 meters Rate of fire 120 rounds per minuteCollected by Norman Hall D.J Hall 17455 RAN2 shells (complete) for a Bofors 40mm Anti Aircraft Gun used by the R.A.N.See Imagesbofors 40 mm, anti aircraft gun, shell, r.a.n. bofors gun, world war ii, wwii, norman hall -

Waverley RSL Sub Branch

Waverley RSL Sub BranchDesk Set H.M.A.S. Sydney

HMAS Sydney was a Chatham class light cruiser of the Royal Australian Navy (RAN). Laid down in 1911 and launched in 1912, the cruiser was commissioned into the RAN in 1913. During the early stages of World War I, Sydney was involved in supporting the Australian Naval and Military Expeditionary Force, and escorting the first ANZAC convoy. On 9 November 1914, the cruiser defeated the German cruiser SMS Emden at the Battle of Cocos. During 1915 and 1916, Sydney operated on the North America and West Indies Station, before joining the 2nd Light Cruiser Squadron at Greenock, Scotland in November 1916. On 4 May 1917, the cruiser was involved in an inconclusive action against the German zeppelin L43; neither was damaged. During late 1917, Sydney became the first Australian warship to launch an aircraft, and the first warship to do so from a rotatable platform. After the war's end, Sydney spent a year in reserve before being reactivated to serve as Flagship of the RAN. The cruiser was decommissioned in 1928 and broken up for scrap. Several sections of the ship, including her bow and foremast, have been preserved as monuments, and three of the ship's main guns saw later use in shore fortifications.A number of these desk sets were manufactured and given to the Headmasters of selected schools throughout Australia in recognition of the efforts of school children in assisting the War effort during World War IMade from timber extracted from a companionway or staircase in the battle cruiser H.M.A.S. Sydney 2 x 5 cm.square glass containers are fitted. Blue attachment advising,wood from H.M.A.S. Sydney h.m.a.s. sydney, desk set, r.a.n -

Lara RSL Sub Branch

Lara RSL Sub BranchPicture Print, Hurricane, Unknown

... fighter aircraft manufactured by Hawker Aircraft, Ltd ...The Hawker Hurricane is a British single-seat fighter aircraft of the 1930s–40s that was designed and predominantly built by Hawker Aircraft Ltd. for service with the Royal Air Force (RAF). It was overshadowed in the public consciousness by the Supermarine Spitfire's role during Battle of Britain in 1940, but the Hurricane actually inflicted 60 percent of the losses sustained by the Luftwaffe in the engagement, and it went on to fight in all the major theatres of the Second World War. Url Hurricane.html. The Hawker Hurricane Mk.IIc - LF363, first flew on the 1st January 1944 and is believed to be the last Hurricane to enter service in the RAF. It was in service with 63 squadron and 26 squadron. After hostilities, LF363 was spared the scrap yard and used on various station flights and also appeared in films 'Angels one five', 'Reach for the Sky' and 'The Battle of Britain'. Whilst flying to Jersey in September 1991, LF363 suffered engine problems and had to be diverted to RAF Wittering but on the final approach the aircraft suffered complete engine failure and had to make an emergency landing. The pilot was saved with relative minor injuries (a broken ankle and minor burns) but the aircraft suffered severe damage. Historic Flying Limited completely rebuilt LF363 and by 1998 it was flying again as part of the B.B.M.F. LF363 currently wears the colour scheme of a Mk.I Hurricane of 17 squadron, P3878 'YB-W' which was flown by Flying Office Harold Bird-Wilson at Debden and Tangmere. Harold 'Birdy' Bird-Wilson had previously been badly burned in a pre-war flying accident. Upon his recovery he joined 17 squadron and fought through the 'Battle of France' and the 'Battle of Britain' achieving 6 confirmed kills. On 24th September 1940, 'Birdy' was shot down by Adolf Galland, his 40th 'kill', and had to bale out. 'Birdy' survived the war and when he retired from the RAF he had reached the rank of Vice Marshall and had been awarded the CBE, DSO, DFC & Bar and the AFC & Bar. British single-seat fighter aircraft manufactured by Hawker Aircraft, Ltd., in the 1930s and ’40s. The Hurricane was numerically the most important British fighter during the critical early stages of World War II, sharing victory laurels with the Supermarine Spitfire in the Battle of Britain (1940–41) and the defense of Malta (1941–42). Hurricanes served in all theatres of war where British forces were engaged. https://www.britannica.com/technology/Hurricane-airplane Framed coloured picture print on plastic sheetOn the aircraft are the markings LF 363 -

Bendigo Military Museum

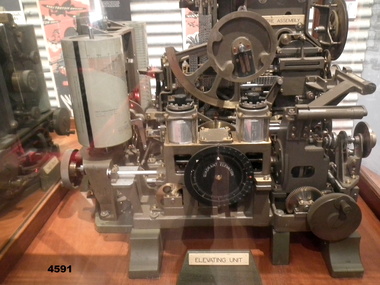

Bendigo Military MuseumEquipment - VICKERS No1 MK III A.A. PREDICTOR, Commonwealth Government Ordnance Factory, c. 1942

This piece of equipment was used to predict the flight path of an aircraft in order for anti-aircraft artillery to fire accurately at an approaching enemy airborne target. A crew of six operated the machine with information ready to be relayed to a gun within 50 seconds. The predictor was manufactured at the Commonwealth Government Ordnance Factory, Maribyrnong.The item is made primarily from metal, is square shaped and bolted to a wooden base. Numerous hand operated wheel dials attached to gauges which input information related to wind speed, bearings and elevation are visible. Each of the four sides has a specific task with three sides being labelled - Elevation Unit, Wind Calculator, Bearing Unit. The item is housed in a glass and wood display case. Attached to the front of the display case: 'VICKERS A.A. PREDICTOR No1 MK III MANUFACTURED BY ORDNANCE FACTORY MARIBYRNONG'pedictor, military equipment, ordnance, anti-aircraft guns -

Bendigo Military Museum

Bendigo Military MuseumEquipment - VENTURI, AIRCRAFT, c. 1939 - 45

... aircraft Manufactures plaque states "Type B-4 plus misc numbers ...Item belonged to Maxwell Lennox Matheson No 418447 RAAF. Refer Cat No1959 for his service record.This device was mounted outside of aircraft, in air stream, generating a vacuum. L = 27 cm. Air tube and coupling at base. Manufactures plaque states "Type B-4 plus misc numbers."venturi, equipment aircraft -

Frankston RSL Sub Branch

Frankston RSL Sub BranchCalculator, Course & Speed, E.R Watts & Son London Pty Ltd

Course and Speed calculator used as a navigational aid by Air Force pilots to calculate aircraft relative groundspeed whilst allowing for wind speed and direction. A similar example (MKIIA version) can be seen at the following Imperial War Museum web page: Inscribed "COURSE & SPEED CALCULATOR MKII", "E.R.WATTS & Son No 757/35", "A.M. REF No 6B/119".raaf, navigation, calculator, ww2, raf, aircraft, course, speed, wind drift -

Frankston RSL Sub Branch

Frankston RSL Sub BranchCompass, Astro

A World War 2 era W. W. Boes and Co. MKll astro compass typically used as an aviation navigation aid. It is manufactured from aluminum with black enamel finish. An astro compass is a navigational tool used to determine true north from the position of the sun or astronomical bodies. These are used in circumstances where magnetic compasses and gyrocompasses are unreliable, for example in the presence of magnetic field anomalies (such as polar regions, ships hulls, aircraft hulls, etc.). Nameplate on the base reads "ASTRO-COMPASS MK II / The W.W. BOES CO. / DAYTON, OHIO, USA"compass, astro compass, navigation, aeronautical, raaf, raf, ww2, -

Frankston RSL Sub Branch

Frankston RSL Sub BranchHelmet, Flying

Vietnam era issue flying helmet type HGU-2A/P. The helmet is manufactured from fibreglass in a jungle green finish and has a thick high density plastic foam lining for head protection. Complete with an adjustable chin strap and a dual visor kit of clear and tinted visors to protect the eyes. This helmet is fitted with two loudspeaker/earphones and a microphone positioned in front of the mouth of the wearer. The microphone has a flying lead with an audio connector for connection to the aircraft communications equipment. -

Montmorency–Eltham RSL Sub Branch

Montmorency–Eltham RSL Sub BranchInstrument - Instrument, Aircraft, Artificial Horizon

Cylinder shape a few scratches and showing wear and tear, Glass window with cream and green numbers. With black matt baked on paint.Behind glass reads - GYRO HORIZON AMALGAMATED WIRELESS (A/SIA), MANUFACTURED UNDER LICENSE FROM THE SPERRY GYROSCOPE CO. LTD Label reads - Serial No A.W.A /2739-, Part no 643720R, Patented Aust. 110675, 18.8.39, R.A.A.F. Ref no G6A/3330gyroscope, r.a.a.f, artificial horizon, aircraft, sperry -

Geelong RSL Sub Branch

Geelong RSL Sub BranchPhotograph - Winjeel Trainer Aircraft, 1955

... designed and manufactured, three seat training aircraft... are an Australian designed and manufactured, three seat training aircraft ...This is a photograph of Winjeel Training Aircraft at Laverton in September 1955. The Aircraft are an Australian designed and manufactured, three seat training aircraft. The aircraft were used by the RAAF as an advanced trained from 1955 to 1975, it was later used by Forward Air Control for target marking until 1994.This is an original photograph of the aircraft at Laverton in September 1955.An oblong black and white photograph of Winjeel Trainer Aircraft.A typed inscription attached across the bottom of the photiograph, 'Laverton September 1955. Handing over of Winjeel Trainer Aircraft'.photograph, winjeel training aircraft, laverton, -

Federation University Historical Collection

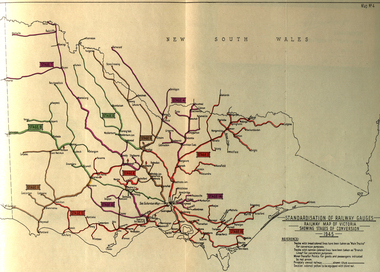

Federation University Historical CollectionBook, Standardization of Australia's Railway Gauges, 1945, 1945

... in the manufacture of fighter aircraft in the defence of Australia... in the manufacture of fighter aircraft in the defence of Australia ...Sir Harold Winthrop Clapp KBE (7 May 1875 – 21 October 1952) was a transport administrator who over the course of thirty years had a profound effect on Australia's railway network. In two decades as its Chairman of Commissioners, he revolutionised Victorian Railways, with unprecedented attention to customer service and innovations such as more powerful locomotives, air-conditioned carriages, and faster services culminating in the introduction of the flagship Spirit of Progress express train. Seconded to the Federal Government in World War II, he played a pivotal role in the manufacture of fighter aircraft in the defence of Australia. As Director-General of Australia's Land Transport Board, he presented a report on railway gauge standardisation that ultimately led to the eventual linking of all Australian mainland capital cities by a uniform rail gauge. (http://en.wikipedia.org/wiki/Harold_Winthrop_Clapp, accessed 02/10/2013)Grey, soft covered, stapled report of 89 pages. "Standardization of Australia's Railway Gauges" by Harold Clapp is a report and recommendation regarding the standarization of Australia's railway gauges. The contents include: * Lines suggested for conversion or new lines to be constructed * scheme of conversion of tracks and structures * scheme of conversion of locomotives and rolling stock * Estimated costs * Associated works * Estimated manpower which the project will absorb in its various phases *Standardization of rolling stock * Other considerations associated with the project * Estimated time involved in the various phases of the work. The report includes 8 maps: * Map of Australia showing the various proposals referred to *Map of Australian railways showing extent of standard gauge if proposals are carried out * Map of Australian railways as of 30 June 1944 *Map of Australia showing principal mileages referred to in the report * Railway Map of Western Australia, 1945 * Railway Map of South Australia, 1945 * Railway Map of Victoria, 1945 * Railway Map of Melbourne Suburbs, 1945 railway, guage, standardization, standardisation, fremantle, perth, kalgoorlie, peterborough, silverton, tramway, tram, train, townsville, dajarra, bourke, cunnamulla, charleville, blackall, longreach, winton, hughenden, townsville, gajarra, birdum, darwin, narrow gauge -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1940's

Smiths began with a craftsman named Samuel Smith who in 1851 opened a shop in Newington Causeway, London, where he made and sold watches, clocks and precision instruments. Samuel had a son, Samuel Jnr who was apprenticed in his fathers business. Samuel Jnr eventually opened his own business at 85 Strand and later opened other premises at 9 Strand, Trafalgar Square and 68 Piccadilly. In 1899 he turned his business into a private limited company, S. Smith & Son Ltd. Samuel Jnr son, Sir Allan Gordon-Smith, joined him as Manager at 9 Strand in 1903 and laid the foundation of the vast Smiths organisation of the future, leading the company towards the supply of accessories for the then developing motor industry making car clocks and the first speedometers patented in 1904. In July 1914 a new company was formed under the name S. Smith & Sons (Motor Accessories) Ltd., to take over the motor accessory business of S. Smith and Son Ltd. and this became the main company of the group which eventually grew to become Smiths Industries Ltd. The original company S Smith and Sons Ltd., continued as jewelers and clock and watchmakers until 1930 when the company was taken over by Bravingtons retail jeweller chain. In 1931 Smiths decided to enter the domestic clock market and formed a new company, Smiths English Clocks Ltd., as the Clock and Watch division of S Smith & Sons (Motor Accessories) Ltd. This is the start of "Smiths Clocks" because this is when they began to manufacture domestic clocks in quantity. Moreover, they set out to produce these clocks at a price that the average householder could afford. S Smith & Sons (Motor Accessories) was at this time was the main company in the Smiths group of companies and their business developed both in the motor vehicle field and outside it. Smiths began to make automatic pilots for aircraft and, through the acquisition of a majority interest in Henry Hughes & Sons Ltd., entered the field of marine instruments. During the war from 1939 to 1945, Smiths' production expanded. There was a demand for motor, aircraft and marine instruments for the Services and the production of industrial instruments and it is at this time that our item was made. In 1944 many changes were made to the Smiths' organisation. The name of the principal company was changed from S Smith & Sons (Motor Accessories) to S. Smith & Sons (England) Ltd. and four new subsidiary selling companies were set up. These were Smiths Motor Accessories Ltd., Smiths Aircraft Instruments Ltd., Smiths Industrial Instruments Ltd., and Smiths English clocks Ltd. The manufacture of clocks and watches ceased in 1979 and 1983 saw Smiths withdraw from producing items for the motor industry.An item that is now regarded as a vintage, sought by horology collectors worldwide and is in excellent condition. The item is unique in that it was made specifically for ships by the Smith company a well known British clock manufacture. Its provenance is well established and it was made during the world war II era specifically for merchant and naval vessels of the time. Naval brass ships bulkhead clock. The clock face is of white enamel with black Roman numerals, an outer minutes ring and black steel hands. There is a subsidiary seconds dial with sweeping hand just above the centre and a fast/slow adjustment lever above that. There is no manufactures name on the dial. There are a beveled glass and brass hinged lid to the front of the clock. The clock is housed in a heavy brass case with screw holes around the circumference for mounting. There are no markings on the clock or mechanism flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, s smith and sons, clock, maritime clocks, clock makers, bulkhead clock -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Binnacle and Magnetic Compass

In 1947, the scientific instrument manufacturing firms of Henry Hughes & Son Ltd, London, England, and Kelvin Bottomley & Baird Ltd, Glasgow, Scotland, came together to form Kelvin & Hughes Ltd. Hughes Company History: Henry Hughes & Sons were founded in 1838 in London as a maker of chronographic and scientific instruments. The firm was incorporated as “Henry Hughes & Sons Ltd” in 1903. In 1923, the company produced its first recording echo sounder and in 1935 a controlling interest in the company was acquired by S Smith & Son Ltd resulting in the development and production of marine and aircraft instruments. Following the London office's destruction in the Blitz of 1941, a collaboration was entered into with Kelvin, Bottomley & Baird Ltd resulting in the establishing “Marine Instruments Ltd”. Following the formal amalgamation of Kelvin, Bottomley & Baird Ltd and Henry Hughes & Sons Ltd in 1947 to form Kelvin & Hughes Ltd. Marine Instruments Ltd then acted as regional agents in the UK for Kelvin & Hughes Ltd who were essentially now a part of Smith's Industries Ltd founded in 1944 and the successors of S. Smith & Son Ltd. Kelvin & Hughes Ltd went on to develop various marine radar and echo sounders supplying the Ministry of Transport, and later the Ministry of Defence. The firm was liquidated in 1966 but the name was continued as Kelvin Hughes, a division of the Smiths Group. In 2002, Kelvin Hughes continues to produce and develop marine instruments for commercial and military use. (See Note section this document for further information on the company's origins) This model binnacle and compass is a good example of the commercial diversity of navigational instruments made by Kelvin & Hughes after world war 2. It was made in numbers for use by shipping after the second world war and is not particularly rare or significant for its type. Also, it was made no earlier than 1947 as the firms of Kelvin, Bottomley & Baird Ltd and Henry Hughes & Sons Ltd who took over from Smith & Sons were not amalgamated until 1947. It can there for be assumed that this item was made during the company's transitional period to Kelvin & Hughes from Smith Industries Ltd.Mid 20th century ship's binnacle with Kelvin Hughes/ F. Fuselli Genova 8 inch diameter (glass) compass on gimballed ring. Round, teak wood pedestal with mounted brass compensating sphere brackets and painted iron balls one green the other red. Heavy brass helmet style compass cover with hinged front door and removable top for compass viewing and natural lighting. A single handle is located on the side and single burner on the opposite side. Retains an old finish and some wear to the pedestal base. Binnacle marked Serial No 163 "Veritas" Made by Kelvin Hughes Compass marked "Kelvin Hughes & Made in Great Britain Serial No 760 C J"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Diving compressor and helmet, 1944

Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water pumps, refrigeration equipment, and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards, and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12 bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering, and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air, and under the sea (including mine rescue, tunneling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A.Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman's fortunes began to decline as an aging Sir Robert Davis failed to invest, or change the company's business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire-fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998). (For information regards the diving helmet & Frank King see Notes Section at the end of this document)The items are very significant as a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. The company that made the equipment was a leading inventor,developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job. Frank Kings' diving helmet and compressor (communication pipe stored separately). Compressor is hand cranked. US Navy diving helmet, Mark V. Two maker's plates attached. Made in 1944.On rear "WATER SUPPLY" On front 'PATENT" " Logo: Images (Lion, Crown, Horse, Shield within an oval) "SIEBE, GORMAN & Co. Ltd. SUBMARINE ENGINEERS, LONDON.flagstaff hill, warrnambool, maritime museum, great ocean road, us navy diving helmet, commonwealth government salvage, diving helmet, marine salvage, frank king, diver, siebe. gorman & co ltd, submarine equipment, diving equipment, communication under water, hand cranked, diving compressor -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyBooklet, John Kepert and the Aviation Historical Society of Australia, Fishermen's Bend - A Centre of Australian Aviation, 1989

Fishermen's Bend - A Centre of Australian Aviation - publication prepared on the 50th anniversary of Aeronautical Research Laboratory in association with the Aviation Historical Society of Australia. Included are a map and aerodromes, companies and aircraft which used Fishermen's Bend A second copy is held in the Transport - Air filetransport - aviation and aerodrome, fishermans bend, built environment - industrial, industry - manufacturing, engineering, john kepert, aeronautical research laboratory -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyDocument - Newsletter, Pursuit, Commonwealth Aircraft Corporation, 1980s

Reports, newsletters etc from Commonwealth Aircraft Corporation 1980's. "Pursuit" newsletter June 1982transport - aviation and aerodrome, industry - manufacturing, ian grundy