Showing 38 items

matching electric pumps

-

El Dorado Museum Association Inc.

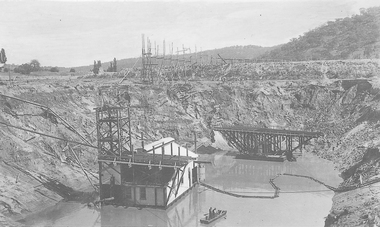

El Dorado Museum Association Inc.Photograph (item) - Digital Image

Cocks Pioneer Gold & Tin Mines NL sluicing works, open cut hydraulic mine. Cocks Pioneer Electric Gold & Tin Mine Company was formed in 1899. The company's first power station, located at the eastern end of the valley began operating with its 340 Kilowatt steam-powered generator. By 1909, from 2,500,000 cubic yards worked, reported recovery was 17,284 ounces of gold and 224 tons of tin ore. By 1909, Cocks Pioneer’s power plant had become inadequate and uneconomical. The barge was floated downstream about a mile, but lost time caused the operations to cease. Following testing, a new mine was established by diverting Reid's Creek at a cost of £25,000. Settling dams were built, one of which held 1,935,900 cubic feet. Sold earth banks, built against a wall of stringy bark saplings constructed and laced with vertical props, were built. In 1914, the company was reformed as Cock’s Pioneer Gold and Tin Mines NL, another power station was constructed at the western end of the township, near the junction of Clear and Reid's Creeks. From 6,800,000 cubic yards of material processed, the returns were 64,397 ounces of gold and 855 ton of tin. Cocks Pioneer mine then moved the barge downs stream and continued sluicing. In 1929 Cocks Pioneer Electric Gold and Tin Mining Company ceased operations due to a drop in values. Cock’s Pioneer Gold and Tin Mines NL carried on large-scale hydraulic sluicing operations until 1941. mines, mining, gold, tin, gold mining, tin mining, sluicing, men, cocks pioneer, el dorado, eldorado -

El Dorado Museum Association Inc.

El Dorado Museum Association Inc.Photograph (item) - Digital Image

Cocks Pioneer new engines. Cocks Pioneer Electric Gold & Tin Mine Company was formed in 1899. The company's first power station, located at the eastern end of the valley began operating with its 340 Kilowatt steam-powered generator. By 1909, from 2,500,000 cubic yards worked, reported recovery was 17,284 ounces of gold and 224 tons of tin ore. By 1909, Cocks Pioneer’s power plant had become inadequate and uneconomical. The barge was floated downstream about a mile, but lost time caused the operations to cease. Following testing, a new mine was established by diverting Reid's Creek at a cost of £25 000. Settling dams were built, one of which held 1,935,900 cubic feet. Sold earth banks, built against a wall of stringy bark saplings constructed and laced with vertical props, were built. In 1914, the company was reformed as Cock’s Pioneer Gold and Tin Mines NL, another power station was constructed at the western end of the township, near the junction of Clear and Reid's Creeks. From 6,800,000 cubic yards of material processed, the returns were 64,397 ounces of gold and 855 ton of tin. Cocks Pioneer mine then moved the barge downs stream and continued sluicing. In 1929 Cocks Pioneer Electric Gold and Tin Mining Company ceased operations due to a drop in values. Cock’s Pioneer Gold and Tin Mines NL carried on large-scale hydraulic sluicing operations until 1941. mines, mining, tin, gold, tin mining, gold mining, hydraulic mining, cocks pioneer, el dorado, eldorado -

El Dorado Museum Association Inc.

El Dorado Museum Association Inc.Photograph (item) - Digital Image

Cocks Pioneer Barge with new pump and punt. Cocks Pioneer Electric Gold & Tin Mine Company was formed in 1899. The company's first power station, located at the eastern end of the valley began operating with its 340 Kilowatt steam-powered generator. By 1909, from 2,500,000 cubic yards worked, reported recovery was 17,284 ounces of gold and 224 tons of tin ore. By 1909, Cocks Pioneer’s power plant had become inadequate and uneconomical. The barge was floated downstream about a mile, but lost time caused the operations to cease. Following testing, a new mine was established by diverting Reid's Creek at a cost of £25,000. Settling dams were built, one of which held 1,935,900 cubic feet. Sold earth banks, built against a wall of stringy bark saplings constructed and laced with vertical props, were built. In 1914, the company was reformed as Cock’s Pioneer Gold and Tin Mines NL, another power station was constructed at the western end of the township, near the junction of Clear and Reid's Creeks. From 6,800,000 cubic yards of material processed, the returns were 64,397 ounces of gold and 855 ton of tin. Cocks Pioneer mine then moved the barge downs stream and continued sluicing. In 1929 Cocks Pioneer Electric Gold and Tin Mining Company ceased operations due to a drop in values. Cock’s Pioneer Gold and Tin Mines NL carried on large-scale hydraulic sluicing operations until 1941. mines, mining, gold, tin, gold mining, tin mining, watercraft, punt, boats, men, cocks pioneer, el dorado, eldorado -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Anglican Vicarage in Main Street Stawell

Brick Anglican Vicarage in Main Street purchased 1923 surrounded by trees and with picket fence and gate. In 1923 the house on the west side of the Church was purchased to be the Vicarage, the former Vicarage in Stawell West being sold. In this same year electricity was connected to the Church, the Hall and the Vicarage. The organ which had been hand pumped till then was fitted with and electric blower. This photo is a copy off a loaned postcard. The dwelling was purchased by the Anglican Church 1923, the former vicarage in Seaby Street being sold. The Spire in the background is St. Matthews Presbyterian Church. The vicarage is now demolished and replaced by a new building.Black & White photograph of a scene depicting a brick dwelling with veranda right hand side and a church spire in the background. Trees surrounding the building. A picket fence with gate and footpath in foreground.stawell religion church -

Ballarat Tramway Museum

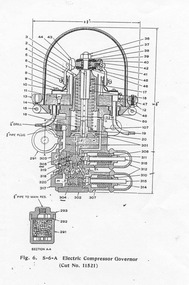

Ballarat Tramway MuseumDocument - Instruction, Ballarat Tramway Museum (BTM), "S-6-A Electric Compressor Governor", 2009

Yields information about a compressor governor that is fitted to some Ballarat Trams, Westinghouse.Two A4 photocopied sheets, giving a side elevation of the Westinghouse "S-6-A Electric Compressor Governor" and the setting or the regulation and adjustment, installation and maintenance of the Governor. Commonly known as a "Bettleback" Governor. Dates from 1916. See Reg Item 703 for a MMTB drawing. WAD’s thoughts on setting Beetle back compressor Governors – 19/12/2009. Refer to instructions as well. Set both valves to approximately the same tension or thread length If when pumping up, both valves start to chatter, screw down the back valve further. When working satisfactorily, but pressures not right, that is, the governor is cutting out without valves chattering or with excessive range or pressure too high. Adjust the front valve until the desired cut out pressure arrived at. The cap must be on this valve for it to work. Adjust the back valve to adjust the cutting in setting, screw down for high cut in pressure. Adjust both as necessary to obtain your desires! And best of luck, it can be done, but is frustrating!!!!!trams, tramways, governors, westinghouse, air compressors, instructions -

Department of Energy, Environment and Climate Action

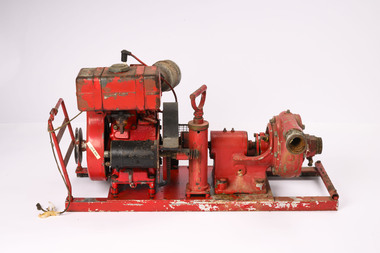

Department of Energy, Environment and Climate ActionGaam 30B pump

The Gaam 30B pump delivers 80 Gallons per minute @ 80 PSI The original Howard engine, equipped with a rope start, could be temperamental and difficult to start on occasions, and were replaced with an electric start 7 HP Wisconsin motor. This modification was designed and installed by the FCV Fire Protection Workshop at North Altona in the early 1960s.Wisconsin 7HP motor coupled to a Gaam 30B pump With hand primerforests commission victoria (fcv), fire pump, bushfire -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - COLEMAN Fuel Iron

Coleman, originally known for making lanterns, made over 30 different models of irons from 1929 to 1948. They generally came in an enamel coloured finish. The best known and most commonly found today is the “Cool Blue” enamel Coleman’s 4A gasoline iron. The Coleman 4A gasoline iron was much lighter than the previous ‘sad irons’ and no longer required to be heated on the stove or by charcoal. Instead, the pump was used to build up pressure in the fuel tank and a match was lit underneath the iron, making a flame inside the iron that would distribute the heat on the surface. Despite these benefits, fuels irons made ironing a potentially dangerous job. They had a very real possibility of causing a fire or exploding. Gas-pressure irons, that had been manufactured as early as 1900, were eventually replaced by electric-powered steam irons, in the 1970s as an affordable and safer alternative.This item is significant because it is an example of domestic appliances used widely throughout the Wodonga District.A self-heating iron which made from metal and enamel plate which included a small tank for fuel which powered the unit. A small wooden pump was used to build up pressure in the iron’s fuel tank. It has a wooden handle.domestic appliances, coleman fuel irons -

Alfred Hospital Nurses League - Nursing Archive

Alfred Hospital Nurses League - Nursing ArchiveEquipment - Portable electric suction machine, Clements Suction and Pressure Pump

... . Suction Clements portable suction respiratory pressure pump ...This equipment was located in the outpatients department (Philip Block) until September 2021 when it was deemed obsolete by Infection Prevention. Hubert Ingham Clements (1886-1969) was an Australian engineer who established his own engineering business in NSW in 1908 manufacturing combustion engines. He became interested in anaesthesia equipment and from the 1920s Clements worked on improving ether apparatus and manufacturing portable suction machines for use in hospital operating theatres. The latter machines were to earn an unrivalled reputation for reliability; many remained in service over thirty years after their date of production. The business became H. I. Clements & Son when his son William joined the company. (https://adb.anu.edu.au/biography/clements-hubert-ingham-12846)Item is an example of equipment from its time period and is of historic significance.Portable Clements Suction & Pressure Pump built by H I Clements & Son Ltd Consists of motor with attached carry handle, attached pressure regulator, attached disposable drainage cannister with tubing and power cable mounted on a trolley with castors.H I Clements & Son Pty. Ltd. Metal Manufacturing label with: Serial Number 1725FS and SAA Certificate Number BCG/4S/60194 on motor (front side) Ward 11 engraved on motor handle AH Biomedical Engineering orange test due sticker and AH Biomedical blue test sticker (reverse side)suction, clements, portable suction, respiratory, pressure pump, surgical drainage