Showing 52 items matching "electrical technology"

-

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTransformer Lamp System, late 1950's

This transformer lamp system, which has a dial to transform 240 volts to a minimum of 32 volts was used by electrical technicians to inspect internal parts of the large generators (even in small confined spaces). The reason for the reduction of the 240 volts to the 32 volts was for the safety of the inspector. The SEC Victoria Hydro Scheme's electrical generators are powered by the hydro force of "stored" water at a higher altitude. The establishment of both the NSW and Victorian Hydro schemes was achieved from the mid 1900's to the 1960's. At this the point in time the need for additional power sources to quench both an industrial and domestic demand for electricity was purely an economic and not and environmental (carbon reduction) factor. This hydro scheme was instigated by "the Government of the day" as a bold move and was the major force of the World War II refugee and "technical" workforce inclusion of skilled and unskilled migration into the Australian environment. Although this mass "invasion" of workers with families was thought of in some circles as intrusive, the expansion of population post war years and its integration into the Australian rural sector, produced the multi- lingual multi-cultural diversity of later years.This transformer lamp is very significant to the Kiewa Valley as it was introduced as a very small part of the explosion of human resources into the valley. This influx of population transformed the region from that of a basically quiet rural region to one which evolved into both industrial and larger residential community. This evolution in the valley created a change, not only in the "physical" landscape but also the socio-economic expansion which permitted other "tourist" based industries into the valley. This is also a specific electronic item which was manufactured in Melbourne and not sourced from Europe or Asia. This demonstrates the fast evolution of Australian technology to a high standard compatible to that of the rest of the world.This heavy hand held electrical transformer (transforms 240 volts to 32 Volts) an has one leather handle on the top with three small (gauze filtered) air holes. It also has two 2 pin directional cable distribution (clipsal) in/out points 10amps / 240 volts. There is one glassed in volts/ac meter and one variable switch (180 to 150 voltage in settings of 10 volt increments.There are two vents (one on each of the smaller sides). There is also one three pin electrical lead coming out from the top.On one side is a manufacturer's plaque with "ELECTRONIC A & R EQUIPMENT MELBOURNE" and underneath "TYPE 1719, PRI V. 180 250" underneath "V.A. 1250" underneath "CYC 50" underneath "SEC V. 115" underneath "SEC A. 10 . 8". The label on topside "CAUTION SET SWITCH TO 250 v BEFORE CONNECTING TO MAINS THEN, WITH EQUIPMENT OPERATING, SET METER TO RED LINE.kiewa hydro electricity scheme, victorian state electricity commission, transformers -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMeter AVO, circa 1930 to 1951

When this AVOMETER was being utilised in the early 1950's it was at the "leading" edge of electrical measuring instrumentation.The first meter was produced by Automatic Coil Winder and Electrical Equipment Co. in 1923. This model was produced in the time from 1933 to 1951 when it was superseded by the most popular model, Model 8 (1951 to 2008).This AVO meter brought the measuring of three electrical power indicators i.e., amps, volts and ohms into one measuring unit. By using a "one fits all" unit, the carrying of separate measuring devices was reduced considerably. The need for a mountainous and a large area of operational requirements, such as the SEC Vic Kiewa Hydro Electricity Scheme, to minimise the weight of equipment carried by electricians and technicians was of the utmost relevance. The significance of this meter to the Kiewa Valley region relates to the impact of modern technology (at that time) upon a mainly rural environment. This equipment shows how the boost of "modern" equipment into the area because of the "Hydro Scheme" was facilitated a lot faster than would have taken under "normal" evolutionary time. The speed of information on all "new technology" had a relatively slow assimilation rate to those living in rural communities. This AVOMETER is a Model 7 MKII, production pre 1951. This meter measures electrical Amps, Volts and Ohms and has two internal batteries for its power. The main casing is made from aluminium with a bake-lite front. The front has a "window" detailing, with a needle pointer, the amount of electrical power being tested. There are two big dial switches, detailing Direct Current(DC) and Alternating Current(AC) when reading measurements of Ampere, Voltage and Ohms for power. This meter took the place of three or four meters used earlier. Modern meters (2000 onwards) have become digilised and are considerably lighter in weight and smaller. There are two electrical connection leads (one black and one red) each has a removable clasp and is 125cm long.Molded on the front centre panel " UNIVERSAL AVOMETER". Below this and above the left hand dial "D.C. SWITCH" .Above the right hand switch the right "A.C. SWITCH". On the left of each switch is an arrow pointing to it.The left switch is marked with a "+" and the right one with a "-". There is a "divisional 2" mark. Between and below the dials is "CUT OUT" plunger.electrical meters, electrical equipment, sec vic., state electricity commission of victoria, mt beauty, bogong village -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCase Leather, circa mid to late 1900's

When this AVOMETER leather case was being utilised in the early 1950's it contained the "leading" edge of electrical measuring instrumentation.The first meter was produced by Automatic Coil Winder and Electrical Equipment Co. in 1923. This model was produced in the time from 1933 to 1951 when it was superseded by the most popular model, Model 8 (1951 to 2008).This leather case which holds its AVO Meter brought the measuring of three electrical power indicators i.e., amps, volts and ohms into one measuring unit. By using a "one fits all" unit, the carrying of separate measuring devices was reduced considerably. The need for a mountainous and a large area of operational requirements, such as the SEC Vic Kiewa Hydro Electricity Scheme, to minimise the weight of equipment carried by electricians and technicians was of the utmost relevance. The significance of this meter to the Kiewa Valley region relates to the impact of modern technology (at that time) upon a mainly rural environment. This equipment shows how the boost of "modern" equipment into the area because of the "Hydro Scheme" was facilitated a lot faster than would have taken under "normal" evolutionary time. The speed of information on all "new technology" had a relatively slow assimilation rate to those living in rural communities. The use of solid leather carrying bags for transporting equipment up and down the mountains provided some form of protection against bumps and dust.This carry case for its AVO meter has an outer leather covering with an inner thick cardboard liner. The case has two mild steel buckles but stitched onto one side but no lid to fasten down. The sides are stitched together with strong tick twine. On either side there are small strap holds. On the bottom are four large chromed metal lugs acting as feet to keep the bottom from lying flat on any floor. The outside bottom has been branded "SOLID COWHIDE"Between the front two buckles is a identification plate riveted onto the cowhide "STATE ELECTRICITY COMMISSION OF VICTORIA ELECTRICAL ENGINEERING SECTION"electrical meters, electrical equipment, sec vic., state electricity commission of victoria, mount beauty, bogong village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeWireless/ Radio, 1950 (estimated)

This unit was designed and manufactured in a factory where many local people of Bacchus Marsh worked. Ref. Historical Notes-Significance Assessment Study ( October 2008)Bakelite tabletop radio,small box,camel-coloured leatherette covered,glass front,three dials,electrical cord,4 vlave reflex super heterodyne, cord attached, incription on set reads "MARSHMAN MUSIC MASTER".Maker's mark in blue print "MARSHMAN MUSIC MASTER" (Inscription on the central area of the glass front of the unit) "BROADCAST" is printed in cream twice in the area of the radio Frequency Band listings.electrical, , bacchus marsh, bakelite, radiogram, bob butler, post war invention, leatherette, technology, 1950 s, small scale radio, heterodyne, cabinet radio, arbee supply c0, civilian radio, manufacturer s drawings, wiring layout, console model -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Foghorn, Late 19th century

A foghorn is a device that uses sound to warn of navigational hazards like rocky coastlines, or boats of the presence of other vessels, in foggy conditions. The term is most often used with marine transport. When visual navigation aids such as lighthouses are obscured, foghorns provide an audible warning of rocky outcrops, shoals, headlands, or other dangers to shipping. An early form of fog signal was to use a bell, gong, explosive signal or firing a cannon to alert shipping. From the early 20th century an improved device called the diaphone was used in place of these other devices, The diaphone horn was based directly on the organ stop of the same name invented by Robert Hope-Jones, creator of the Wurlitzer organ. Hope-Jones' design was based on a piston that was closed only at its bottom end and had slots, perpendicular to its axis, cut through its sides, the slotted piston moved within a similarly slotted cylinder. Outside of the cylinder was a reservoir of high-pressure air. Initially, this air would be admitted behind the piston, pushing it forward. When the slots of the piston aligned with those of the cylinder, air passed into the piston, making a sound and pushing the piston back to its starting position, whence the cycle would be repeated. This method of producing a low audible sound was further developed as a fog signal by John Northey of Toronto and these diaphones were powered by compressed air produced by an electric motor or other mechanical means that admitted extremely powerful low-frequency notes. The example in the Flagstaff collection is an early cased and portable diaphone used on pleasure or sailing craft. By manually turning the crank handle air is produced and fed into valves that direct air across vibrating metal reeds to produce the required sound. in foggy weather, fog horns are used to pinpoint a vessels position and to indicate how the vessel is sailing in foggy conditions. One blast, when sailing on starboard tack and two blasts, when sailing on a port tack and three dots, when with wind is behind the vessel. Since the automation of lighthouses became common in the 1960s and 1970s, most older foghorn marine installations have been removed to avoid the need to run the complex machinery associated with them, and have been replaced with an electrically powered diaphragm or compressed air horns. The example in the collection is significant as it was used in the early 19th century for sailing vessels was important but these portable crank fog horns have also been superseded by modern electric varieties. Therefore the item has a historical connection with sailing and maritime pursuits from our past.English Rotary Norwegian Pattern nautical foghorn within a boxed pine varnished case with exposed corner dovetailing, original leather carrying strap, brass side crank, and original copper trumped horn. Card accessory with Directions for Use in both English and French.Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, foghorn, maritime technology, maritime communication, marine warning signal, portable foghorn, bellows foghorn, crank handle, robert hope-jones, john northey -

Federation University Historical Collection

Federation University Historical CollectionBooklet, The 140th Anniversary of the School of Mines and Industries, Ballarat: University of Ballarat SMB Campus, 2010, 2010

Twenty two page Ballarat Courier supplement celebrating the 140th year since the establishment of the Ballarat School of Mines. Contents include a timeline; Ballarat School of Mines HIstory; Graeme Hood and Electrical Engineering; Australian War Artist Geoff Mainwaring, Prospects Training Restaurant; Ballarat Gaol, Gaol cells underneath the E.J. Tippett Library; Ghost tours; School of Business; Brewery Complex.ballarat school of mines, anniversary, 140th anniversary, smb campus, david battersby, timeline, trades, manufactuyring services, cindy brundell, graeme hood, electrical engineering, celtlink, geoff mainwaring, julia mainwaring, australian war artist, prospects training restaurant, li ji yuane, caitlyn murrell, joshua martin, ballarat gaol, ballarat gaol cells, eerie tours, ghost tours, nathanie buchanan, peter dyer, ben swanson, nikki green, dylan reece, matthew lewis, business services, betty collier, feduni college, ub tec, manutacturing technology training centre, mttc, brewery complex -

NMIT (Northern Melbourne Institute of TAFE)

NMIT (Northern Melbourne Institute of TAFE)DVDs: Promotional DVDs NMIT 1990-2010

Instructional and promotional DVDs ranging in date from 1990-2010 promoting courses and services of NMIT. 1990s An Introduction to NMIT 1996 X 2 Building & Construction Heidelberg 1992 Building & Construction Heidelberg 1992 1, 2, 3 (Umatic) Concrete pour - Heidelberg 1992 Greensborough Music Promotional 1994 Making the move 1996 (also booklet) NMCOT College Promotion 1990 NMCOT College promotion 1992 NMCOT Corporate Video 1992 NMCOT Corporate video 1994 NMCOT Enrolment form 1991 (Umatic) NMCOT Enrolment Form 1992 NMCOT To Market to Market Promotional video 1993 NMCOT To Market to Market Promotional video 1994 NMIT School of Arts & Social Sciences 1996 NMIT School of Building & Construction 1996 NMIT School of Business 1996 NMIT School of Electrical, Electronics & Sciences 1996 NMIT School of Horticulture & Rural Studies 1995 NMIT School of Horticulture & Rural Studies 1996 NMIT School of Manufacturing Engineering 1996 NMIT School of Mechanical Manufacturing 1996 NMIT School of Tourism & Hospitality 1996 NMIT Faculty of Earch Sciences 1998 NMIT The Electrical Connection 1995 Open Day 1992 Student Information 2003-2008 Advanced Diploma of Music Performance (undated) Challenges accepted, NMIT Roadshow 2005 Mechanical manufacturing 2003 Promotional video (master) 2006 Songwriting competition NMIT 2008 The Electrical connection 2003 2009 Animal Studies 2009 Bachelor of Viticulture & winemaking 2009 Certificate III in Aged Care 2009 Children’s Services 2009 Courses through Design Drafting & Interior Fittings 2009 X2 Equine Studies 2009 (also accompanying book) Erection and Dismantling procedure for an Oldfields Mobile Scaffold 2009 Facilitate Individual Learning Activity The REV shop Case Study 2009 Formwork to Columns and Beams 2009 Green skills Centre of Excellence : Contributing to sustainability directly through the design, our actions and by educating future generations on sustainable technology, [DVD], NMIT Epping Campus, [2009] Interior design 2009 Locksmith Apprenticeships 2009 Secondary to Tertiary: the Journey begins 2009 X 2 Visual Arts at NMIT 2009 2010 Advanced Diploma of Building design 2010 Bachelor of Accounting 2010 Bachelor of Equine Studies 2010 Certificate III in Farriery (Trade) 2010 Civil Engineering 2010 Cloisonne Enamel 2010 Conservation and Land Management 2010 Health & Community studies 2010 Horticulture 2010 How to check and adjust a single stage Liquid Petroleum Gas Regulator 2010 Locksmithing more than a trade 2010 Music, Sound & Television 2010 Pragmatic Failures in Intercultural Communication 2010 Technical Education Centre, Youth Unit, NMIT 2010 Viticulture & Winemaking 2010 Why study Community Services at NMIT 2010 courses, handbooks, nmit -

NMIT (Northern Melbourne Institute of TAFE)

NMIT (Northern Melbourne Institute of TAFE)Photograph: Mr. George Thomas Teacher and Councillor CTS 1937-1972

Mr. George Thomas' connection with Collingwood Technical School began as a junior technical student at Collingwood in 1913. He then became an apprentice in the electrical trades during which time he also undertook a Diploma course in Electrical Engineering. Mr Thomas was appointed as a teacher (part-time) of Electrical Wiring at Collingwood in 1922 having had previous experience teaching in Geelong at the Gordon Institute of Technology. In 1930 Mr Thomas became a full-time teacher in Electrical Trades, the year of the commencement of the Apprenticeship Commission in Victoria. In 1937 he was instrumental in introducing electroplating as a trade whereas it had previously only been taught as a section of the Electrical Trades. This was a period of severe economic constraints following the Great Depression and spending on education was limited. Needing the latest knowledge of industrial practices, Mr Thomas canvassed electroplating industries around Melbourne seeking employment opportunities and met with favourable responses. He approached Quinton’s electroplating firm in North Melbourne with the proposal to work for them on Saturday mornings without payment. In return for his labour, he asked to be taught the basics of the trade. During the week he was able to impart his knowledge to his students. Initially, he wanted to develop electroplating as an outlet for the Youth Employment Training Scheme. Once the class was firmly established, he submitted a proposal to the Education Department to establish an Electroplating Department, and this became the first of its kind in the southern hemisphere. He gave up teaching in 1939 to become the Northcote City Electrical Engineer where he served for 26 years. During this time he was also a Consulting Electrical Engineer to Box Hill and Port Melbourne Councils. His association with Collingwood Technical School (and later, College) continued, first as an examiner on the State Electricity Commission (SEC) panel and from 1947 as a member of the School Council. He was president of the Council in 1961 and 1962. He also represented the College on the Northern Regional Council and participated in the selection of Electrical Trades teachers. For four years, 1967-1971, he represented the metropolitan Technical Schools and Colleges on the Council of the Monash University, in which capacity he gave outstanding service to technical education. George H. Thomas attended his first Council meeting on June 12, 1947 and remained on the Council until the secondary and post-secondary sections were separated in 1981 – a period in excess of 34 years. (See Scott p36).Black and white photographs of Mr. George Thomas who had a long association with Collingwood Technical School and Collingwood Technical College, spanning the years 1937-1972. He began his connection with the school as a teacher and went on to become a member of the School Council. He introduced Electroplating as a trade to be taught at Collingwood Technical School in 1937. (Scott p36) The photographs include one of Mr. George Thomas in Monash University regalia 1971. Another of Collingwood Technical School Council 1972 with Mr. Thomas. Images also include an excerpt from Mr. Scott's history.collingwood technical school, george h. thomas, electroplating course, nmit -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Article, Rowe Corp excels again, 1992

Nunawading electrical contractor, Rowe Corporation, were runners-up in the annual electrical industry's excellence award.Nunawading electrical contractor, Rowe Corporation, were runners-up in the annual electrical industry's excellence award. They were nominated for the award improving infrastructure facilities at Melbourne International Airport.Nunawading electrical contractor, Rowe Corporation, were runners-up in the annual electrical industry's excellence award. technology, rowe corporation ltd, rowe, max, thompson, peter -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Audio - Clock Radio

Purchased in 1973 with a group of fellow office workers. Used by Ted Arrowsmith for 33 years as a bedside alarm and later as a clock in our back room.1973 Clock Radio FM - AM. Cream attached casing - black face - electrical - Peak DC 12|It worked through a ratchet arrangement which enabled the time disc to drop after each minute and then hourly. It was a 24 hour clock.'Peak DC 12'audio-visual technology, audio appliances -

Moorabbin Air Museum

Moorabbin Air MuseumManual (Item) - RAAF Basic Electronic Technology & Testing Practices, Royal Australian Air Force Basic Electronic Technology & Testing Practices Magnetic and Electrical Fundamentals

-

Bendigo Historical Society Inc.

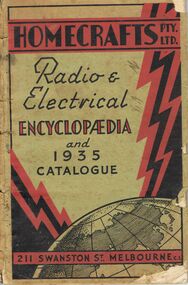

Bendigo Historical Society Inc.Book - LYDIA CHANCELLOR COLLECTION: RADIO & ELECTRICAL ENCYCLOPAEDIA AND 1935 CATALOGUE, 1935

A damaged soft covered book titled 'Radio & Electrical Encyclopaedia and 1935 Catalogue. Homecrafts Pty. Ltd. 211 Swanston St. Melbourne C.1. Verona Press, Melbourne, 1935.electronic, multimedia, radio, lydia chancellor, collection, electrical, electrics, electronics, sciences, radio, technology, radio, encyclopaedia, catalogue -

National Communication Museum

National Communication MuseumEquipment - Ericofon, Ericsson, 1950s

The Ericofon was the first commercially successful telephone which incorporated both handle and dial within a single unit. Manufactured by the Swedish company Ericsson, and available for lease from the Postmaster-General’s Department, the streamlined design has been praised for anticipating the cordless phone, and later mobile phone, by several decades. The ‘cobra’ design was formulated in the 1940s and manufactured in the 1950s; Australian cases were likely made in the L M Ericsson Broadmeadows factory. Although new thermoplastic technology allowed for a bolder aesthetic than traditional black Bakelite telephones, Ericofon sales accounted for only 4% of the market and it never enjoyed popularity with Australian subscribers. The design did, however, spark a conceptual shift whereby the telephone “was seen more as a consumer product than merely an extension of telephony” (Ericsson).Clear plastic telephone casing inside which are coloured electrical wires. Telephone has a broad base that contains the dial, mouthpiece and cord with cream plastic coated wall plug attached at rear. Handle tapers in a curve to a stylised squared earpiece. Dial underneath is a rotary dial with red disconnection button in the centre. telephone, design, domestic, ericsson, industrial design -

National Communication Museum

National Communication MuseumPhotograph (item), The Telegraph, James Melrose with aeroplane My Hildegarde, 16 October 1934

This was the first press photograph transmitted by radio from England to Australia. On 16 October 1934, South Australian aviator, C J Melrose, was pictured beside his plane at the Mildenhall aerodrome, England, preparing for the start of the Centenary Air Race. Within hours of capture, the image was transmitted from London to Melbourne and then sent via picturegram to Sydney’s press, the greatest distance a photograph had been transmitted over radio. Wirephotos, as they are commonly called, are produced through electrical pulses which travel along telephone or telegraph wires, or radio waves. Like the transmission of Morse dots and dashes, the technology communicates the light and dark portions of an image, to be recorded on a negative or photographic paper at the receiver’s end. Previously, photographs of an event appeared several days after the fact; wirephoto technology enabled visual communication with relative speed. Our consumption and expectation of the immediacy of news and communication continued to grow, an expectation that forms the basis of time-based social media activities such as Snapchat or Facebook and Instagram stories.london to melbourne air race, wirephoto, picturegram, uiver, james melrose -

Parks Victoria - Cape Nelson Lightstation

Parks Victoria - Cape Nelson LightstationInstrument - Morse Code Key Set

The battery powered set, which dates from the second half of the twentieth century, comprises two main components, the electronic keyer with a single lever for tapping, and a transmitter (?), both connected by a keying cable. Morse code was invented in the 1830s by American, Samuel Finely Breese by using electrical signals to quickly transmit information over a long range. In the early 1890s Italian inventor, Guglielmo Marconi improved the technology to the point where it became an essential device used for commercial and government purposes. The first practical applications were demonstrated with maritime messaging, where this simple mode of communication was seen as a timely replacement for the historic practice of signaling by flags, lights and foghorns. Cape Schanck has an earlier Morse code key, which is original to the lightstation (CSLS 0035), and Cape Otway has another early example although its provenance to the lightstation has not been formally verified (COLS 0074). The Morse code set has first level contributory significance for its historical value as an earlier communications device that has since been made redundant by more sophisticated technologies.Morse code key set. Comprised of the tapping component and a metal box part with a white electrical cord.Yes -

Wodonga & District Historical Society Inc

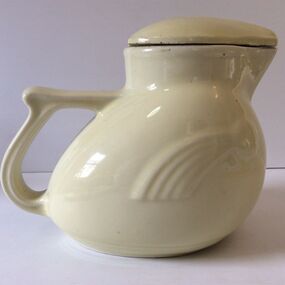

Wodonga & District Historical Society IncDomestic object - Ceramic KOOKABURRA Electric Jug, Nilsen Porcelain Australia, 1930s

Electric kettles were invented by the English to speed up tea preparation. In Australia fancy ceramic electric jugs quickly became a status symbol. During the Great Depression era anyone who could offer you a cuppa from a beautiful Electric Kookaburra Jug was considered to be doing well. Made by Nilsen Porcelain Australia in the 193Os, these kettles were unique for their charming art deco bird shape. Nilsen Electric Kookaburra Jugs are now regarded as a classic Australian icon prized by collectors. Oliver John Nilsen was born in Collingwood, Victoria in 1894. In 1916 he began his own electrical business, Oliver J. Nilsen & Co. (later Oliver J. Nilsen (Australia) Ltd). Nilsen's manufactured goods included such diverse products as transformers, bearings, battery chargers, bells, buzzers and gongs, porcelain ware, fuses, insulators and neon signs. Nilsen Porcelain Australia was a smaller company within the Nilsen group. Nilsen still operates as an electro-technology company operating throughout AustraliaThis jug is an excellent example of art deco ceramic appliances of the 1930s to 1950s on both a local and national level. It is also representative of products developed by a major Australian manufacturer. Earthernware ceramic jug, moulded in art deco style to represent an Australian kookaburra.vintage electric kettles, kitchen appliances, nilsen australia -

Bacchus Marsh & District Historical Society

Bacchus Marsh & District Historical SocietyRadio, Marshman Music Master, Ca 1946-1950

This radio set was designed and manufactured in Bacchus Marsh from 1946 and into the 1950s. In 1946 a local company Arbee Supply Co Pty Ltd acquired from Mr. R. C. Butler the business of wholesale and retail distributors of electrical goods carried on by him for some years at Bacchus Marsh. The company manufactured at Bacchus Marsh Marshman radio and electrical equipment for a number of years.A relatively rare example of a locally designed and produced new consumer technology product. Bakelite tabletop radio, small box, camel-coloured leatherette covered, glass front, three dialsIn blue print "MARSHMAN MUSIC MASTER" radios, manufacturing industries -

Melbourne Tram Museum

Melbourne Tram MuseumNewspaper, The Age, “App to curb crowding on public transport”, 6/10/2020 12:00:00 AM

Newspaper clippings titled: “App to curb crowding on public transport” by Timna Jacks Newspaper clipping from the Age 6/10/2020 Trial of new technology designed to encourage social distancing on public transport for buses and trains. Article also refers to government announcement on proposed spending on tram rolling stock. $26M to be spent on life extension works for A and Z-class trams. Works will maintain electrical, braking and traction systems on trams running on 17 routes across Melbourne, about 1/3 of the city's fleet. Government has ordered 50 E-class trams since 2015, with 89 of total order of 100 trams now in use. 111 Z-class 3 trams and 69 A-class trams are still in use. PTUA spokesman Daniel Bowen comments on need for maintenance of older trams and calls for newer, air conditioned trams.trams, tramways, a class, e class, z3 class, myki, ptua, covid-19 -

Melbourne Tram Museum

Melbourne Tram MuseumBooklet, Victorian Government, "Moving Victoria - a world of experience in Light Rail", c1998

Booklet - "Moving Victoria - A World of experience in Light Rail" - produced by the Victorian Government to advertise and market its expertise in Light Rail manufacturing and operation. Notes Melbourne trams, track infrastructure, Electrical systems and Asset Management. Includes images of Sydney Light Rail and Hong Kong vehicles. Has a forward by Mark Birrell, Minister for Industry Science and Technology (Minister from 1996 to 1999). Includes an extensive list of contacts, companies and their products. See item 7206 for a similar document c2003.Yields information about Victorian Light Rail manufacturing capacity.Booklet - 24 pages, centre stapled titled "Moving Victoria - a world of experience in Light Rail"victoria, tramcar manufacture, sydney, hong kong, melbourne, light rail, tramways, marketing -

Whitehorse Historical Society Inc.

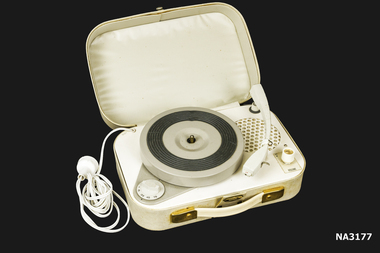

Whitehorse Historical Society Inc.Functional object - Portable Record Player, c1970

Bought at a church fete by donor and used at her beach house at Philip island.A small vinyl covered case containing a turntable and tone arm, volume control and speed controls, with an electrical cord and plug. Case is cream with a beige contrast.audio-visual technology, audio appliances, musical instruments, accessories