Showing 174 items

matching furnaces

-

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumPhotograph, Optical Munitions, with E.J. Hartung

Part of a series entitled “Optical Munitions - School of Natural Philosophy, 1942-1945”. Black and white photo of Professor Hartung trmoving experimental pot of optical glass from furnace.In ink on lower left hand corner : “36”. -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumPhotograph, Optical Munitions, with E.H.S.Burhop

Part of a series entitled “Optical Munitions - School of Natural Philosophy, 1942-1945”. Black and white photo shows Eric Burhop operating an optical pyrometer ....with possibly a vacuum furnace?In ink on lower left hand corner : “22”. -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Black & White Photograph/s, 1905

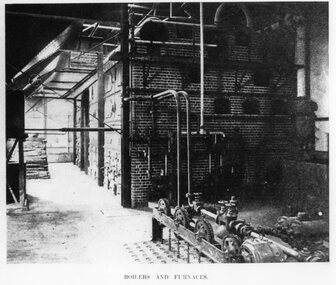

B&W photograph of the interior of the Wendouree Parade power station boiler house of ESCo, at the time of its opening. Photo shows boilers and furnaces, pipe work, coal hoppers and some control equipment. The print for this photograph made from a copy negative of page 454 of the Australasian, August 19, 1905 in 1993. Print includes caption "BOILERS AND FURNACES". See Reg, Item No. 763. See Alan Bradley, draft Chapter 3 of the history of Ballarat Tramwaystramways, trams, esco, power station, boilers, ballarat -

Federation University Historical Collection

Federation University Historical CollectionMagazine, Ballarat School of Mines Students' Magazine, Vol. 8, No. 2., Second Term, 1905, 1905

Grey soft covered magazine on 18 pages. Contents include: Wet Lead Assay, Swedish Iron, Cambridge Life, Arizona Mining Camp (photograph) , Adelaide School of Mines, Blast Furnace, Cupellation and Parting.ballarat school of mines, ballarat school of mines students' magazine, david ham, swedish iron, blast furnace, refining, commercial wet lead-assay, daniel walker, woolfram ores, mounty lyell ore deposits, cambrisge university, arizona copper mining camp, g.j. dawbarn, arizona, new mexico, clifton, adelaide school of mines, j.a. haslam, biggest blast furnace in the world, o.e. jager, anaconda copper mining co., cupellation, j.m. baldwin, kerr grant, w.j. lakeland, e.m. weston, r. lamb, h.b. cooke, p. mathews, g.s. hart, john rahilly, martin h. bade, hugo eklund, cupulation -

Federation University Historical Collection

Federation University Historical CollectionBooklet - Document, Robert Ashley et al, 'The Lal Lal Iron Tramway', 1970

High on a series of terraces overlooking the Moorabool River stands the remains of the Lal Lal Blast Furnace, classified 'A' by the National trust (to be preserved at all costs). This was the location of Victoria's only pig iron industry. A series of tramways served the works, as a well surveyed narrow-gauge tramway connected the blast furnace with the Victorian Roailways' main line about 3.5 miles away. Light Railways, no 24, Summer 1970-71, 36 pages. This booklet considers the Lal Lal Iron Tramwaylal lal iron, lal lal blast furnace, tramways, railways, pig iron, ironstone quarry, industrial heritage -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - ROSELLA FACTORY

Land, bordered by Brougham, Havlin and Mundy Street was purchased in 1911 and the distillery onsite was modified to suit the needs of the Rosella Company. Renovations and additions, including a 21 metre high steel chimney, were completed in time for the 1911/12 tomato season. First manager was Owen WIlliams (1883-1948), a Welshman. He was married to Amy Price (1882-1949). Full history available "Bendigo's once flourishing tomato industry" by James A Lerk. Item 5985sepia photograph. Interior at workshop - anvil at back left., centre, drum standing on bench, used as small furnace ? Portion of man wearing work apron at back right. On back in ball point pen 'Rosella Preserving Factory, Brougham St. 'organization, business, rosella factory -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Traction Engine, Melbourne Electric Supply Co. (MESCo), c 1919-20

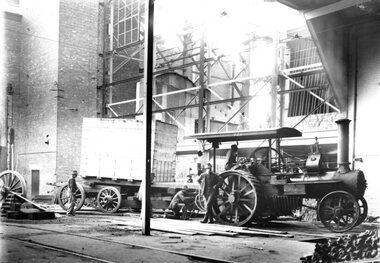

Contractor's steam tractor bringing heavy equipment to be installed in the furnace room being built behind the tractor. 1919-1920.Yields information on the early development of the furnace room at Geelong Power StationBlack and white glass plate photograph.Plate 2-4 written in ink on the back of the photographsteam tractor, steam tractor and trailer, geelong power station, boiler room -

Federation University Historical Collection

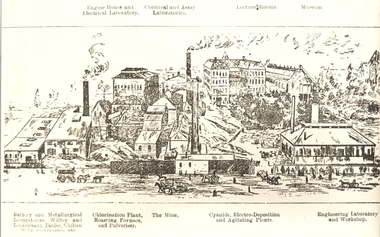

Federation University Historical CollectionImage, Ballarat School of Mines from Albert Street, Ballarat, c1904

This image was reproduced in the Ballarat School of Mines Handbook and Prospectus, 1905.Copy of a line drawing of the Ballarat School of Mines from Albert Street, Ballarat, including the battery and metallurgical laboratories, chlorination plant and roasting furnace, cyanide plant, engineering laboratory and the Ballarat School of Mines Botanical Gardens. The original of this image is Cat. No. 4774.ballarat, school of mines, battery, metallurgy, chlorination plant, roasting furnace, cyanide plant, engineering, laboratory, museum, assay, mine, m3334, ballarat school of mines botanical gardens -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Val D'Angri, Former Clunes School of Mines, c2000, c2000

On 29 February 1892 'The Argus' reported on the first Annual Meeting of the Clunes School of Mines. "The annual meeting of the council of the Clunes School of Mines was held last evening at the town-hall. In place of members of the council retiring by effluxion of time the following were elected: — Rev. Elder Gray, Messrs. John Beveridge, R. Nichol, J. Bryant, W. T. Pitcher, J. H. Daley, and T. Gilbert. The first annual report, showing remarkable progress, was received and adopted. The following officers were elected for the ensuing year: — Rev. E. Grey, president; Rev. Father John Barrett and Dr. Gordon, vice- presidents; Mr. Joseph Bryant, hon. director; Mr. W. Y. Witherden, hon. treasurer, Mr. H. E. Sando retained the office of secretary, and the officers for the time being were appointed trustees." Great satisfaction was expressed with the success of the school, and the progress and extent of the classes. It was referred to a sub committee to make arrangements for allowing the free inclusion, in certain classes, of a limited number of boys and girls of 14 and upward, who on examination qualified themselves for the privilege. An offer by an anonymous resident to pay the fees for four miners for admission to any class in the school was announced by the president, and received with thanks.Two photographs showing the exterior of a weatherboard building known as the former Ballarat School of Mines Clunes campus. The Timber hall was erected as a School of Mines and later used by the Australian Natives Association. The retort furnace (indicated by the large chimney) is still located in the rear rooms.ballarat school of mines, assaying, clunes school of mines, john beveridge, r. nichol, j. bryant, w. t. pitcher, j. h. daley, t. gilbert, e. grey, john barret, joseph bryant, w. y. witherden, h. e. sando, schools of mines -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Brown coal

This particular specimen was recovered from the Lal Lal Coal and Iron Mine in Victoria, 19km from Ballarat. Brown Coal was discovered here in 1857, just alongside the Geelong to Ballarat Railway line. This discovery of lignite (brown coal) was the first in Victoria, which would bring important benefits to the region and state, both of which had previously been reliant on coal imports. In the 1860s, iron ore was found just 5km from Lal Lal, and the area was converted into an Iron Ore Mine. The Lal Lal Iron Mining Company took over operations in 1874, who then peaked iron production in 1884. This mine continued operations until June 1884, when the blast furnace was extinguished and never recommenced. The blast furnace at Lal Lal is considered one of the most important and highly significant sites ion early industrial history in Australia, as it is the only remaining best furnace from the nineteenth century in the Southern Hemisphere. The furnace ruins are 17 metres high, and are clearly visible today on Iron Mine Road, Lal Lal, near the Bungal Dam. This specimen of Lignite (brown coal) is significant, as it was mined from the area where brown coal was first discovered in Victoria, leading to an important and controversial future of the mining and use of brown coal in this State. The Victorian Heritage Database has listed the Lal Lal Coal Mine with local significance, with their Statement of Significance stating: "The Lal Lal coal mine is historically significant as the site of the first discovery of lignite (brown coal) in Victoria, and one that promised important benefits to regional and state industries that were reliant on coal imports at the time. The significance of the stie is reduced by the poor state of preservation of the coal mining and processing fabric". This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.A hand-sized light-weight, soft and combustable sedimentary rock specimen, that is dark brown in colour. The specimen has jagged edges, as though parts of the rock have crumbled away. Brown coal, or Lignite, is formed naturally from compressed peat, and is typically found in natural basins. The stages to the formation of coal ('coalification') begin with plant material and wood, which will decay if it is not subjected to deep burial or heating, and turn into Peat. Peat, when sufficiently compressed naturally, will turn into Brown Coal (Lignite), and finally into Black Coal (sub-bituminous, bituminous and anthracite). Each successive stage has a higher energy content and lower water content. It is brownish-black in colour. Brown Coal has a high moisture content, between 50 and 75 percent, and a low carbon content. Some Brown Coals may be stratified, with layers of plant matter, which means little coalification has occurred beyond the peat natural processing stage. When Brown Coal is submerged in dilute nitric acid or boiling potassium hydroxide solution, it reacts to produce a reddish solution, of which higher-ranked coals do not. When brown coal is pulverised and burned in boilers, the steam is used to drive turbines, which generates electricity. It is the lowest rank of coal, as when burned, it creates a relatively low heat content, which in turn does not create a great output of steam. burke museum, beechworth, indigo shire, beechworth museum, geological, geological specimen, mineralogy, brown coal, brown coal specimen, lignite, lal lal, lal lal coal mine, lal lal iron mine, ballarat, blast furnace -

Clunes Museum

Clunes MuseumMap, 1890

Features location of Club Hotel, Union Bank, Engine rooms, Port Phillip Hotel, Pyrites furnace, Battery, Office, Smith Shop,Surface Tramway to BatteryPhotocopy of map/plan of Dixon's New North Clunes, Central Clunes Co. and South Clunes utd showing various shafts and pre-emptive rights. Scale 1 inch = 100 feetOn front in red ink; "drawn in 1890"mine shafts, hotels, plans -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Crucible, The Patent Plumbago Crucible Company, circa 1878

This crucible was raised from the wreck of the LOCH ARD. It is one of six similar relics, in a range of sizes, now in the Flagstaff Hill collection. All bear markings to indicate their manufacture by the Morgan brothers of Battersea, trading as the Patent Plumbago Crucible Co. A crucible is a container used for purifying and melting metals so that they can be cast in a mould to a predetermined shape and use. They must withstand extremely high temperatures, abrupt cooling, and shed their contents with minimal adherence. The addition of graphite to the traditional firing clays greatly enhanced the durability of industrial crucibles in mid-Victorian Britain, a significant technological advance at a time of great activity in foundries and expansion of demand for refined metals. The Morgans first noticed the advantages of graphite crucibles at the Great Exhibition held in London in 1851. Initially they contracted to be sole selling agents for the American-made products of Joseph Dixon and Co. from New Jersey, but in 1856 they obtained that firm’s manufacturing rights and began producing their own graphite crucibles from the South London site. The Morgans imported crystalline graphite in 4-5 cwt casks from the British colony of Ceylon (now Sri Lanka) and mixed it with conventional English (Stourbridge) clays to be fired in kilns. Their products were purchased by the Royal Mints in London and India, and exported to official mints in France and Germany. They were successful exhibitors of their crucibles and furnaces at the London Exhibition held in 1861 (Class 1, Mining, quarrying, metallurgy and mineral products, Exhibit 265, Patent Plumbago Crucible Co). The range of sizes represented by the six crucibles retrieved from the LOCH ARD, suggest they may have been part of a sample shipment intended for similar promotion in the Australian colonies ― at Melbourne’s International Exhibition to be held in 1880. The summary of cargo manifest, by Don Charlwood in ‘Wrecks and Reputations’ does not mention any crucibles, implying that they were not a large consignment of uniform items. A newspaper account of an 1864 tour of the Morgan brothers’ ‘Black Potteries’ at Battersea indicates: “All the pots were numbered according to their contents, each number standing for one kilogram, or a little over two pounds; a No. 2 crucible contains two kilogrammes; a No. 3, three kilogrammes, and so on.” These numbers are obscured by marine sediment on three of the crucibles in the Flagstaff Hill collection, but those legible on the remaining three are 5, 6, and 8. None of the six are of the same size from a visual appraisal.The shipwreck of the LOCH ARD is of State significance ― Victorian Heritage Register S417A large crucible, or fluxing pot, for heating and pouring molten metal. It was recovered from the wreck of the LOCH ARD. The clay fired vessel rises from circular flat base to a larger rim with pouring lip. It is stained a rust colour and bears some sedimentary accretion. Half of its loose fitting lid with central knob has also survived. Markings on the artefact indicate it is a Morgan’s crucible, made with graphite to prevent cracking in the furnace and provide a smooth (non-adhesive) inner surface. On base: “…RGAN’S PATENT CRUCIBLE”. On rim: “MORGAN’S PATENT P…” Below top edge "BAK"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, graphite crucible, plumbago crucible, morgans crucible company, loch ard, fluxing pot, crucible -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, T & F Johnson, boilermakers, late 19th century

A steam boiler like this late 18th century boiler, is often called a colonial boiler. Steam boilers were used in factories throughout Australia, mounted over similar designs of brick furnaces. This heat from the fire travels through the tubes in this fire tube boiler and the water heats as it circulates around them. Another kind of boiler is a water tube boiler, in which the water is inside the tubes and the heat of the combustion surrounds the tubes. The boiler in our collection burned wood as fuel but others of this design could also burn coal, coke, gas and liquid fuels. The boiler was made by T & F Johnson, boilermakers. In 1922 their factory was located at Coventry Street, South Melbourne. They were still advertising their 'Colonial, multi, vertical boilers, all sizes' at the same address in 1934. The connected pressure gauge, made in London by Dewrance, measures 0 to 400 pounds per square inch. John Dewrance is renowned as a pioneer of the steam locomotive in the early 19th century. He founded John Dewrance & Co. in South London in 1844. His son Sir John Dewrance took over in 1879. In 1939 the company became a subsidiary of Babcock & Wilcox, and was eventually owned by Emerson. How the boiler works: - A boiler is about two-thirds filled with water and heat is applied, in this case in the form of burning wood. The heat is transferred through the metal of the boiler to the water. When the water boils the steam rises to the top, and as it escapes from the boiler the steam pressure builds up in the steam space to later be released to do work; drive machinery such as ship and train engines, turbines, presses, wheels, and driving belts to operate looms and saws. The heat associated with the boiler can be used for preserving food, sterilising, factory manufacturing processes, and steaming wood for shipbuilding. Every boiler has several components fitted for safe operation: - - Safety valves - Gauge glass - Pressure gauge - Main steam stop valve - Water check valve - Blowdown valve - Manhole doorThe boiler is a significant item that gives us a snapshot of early Melbourne's industrial history. It is an example of the technological advancement during the Industrial Revolution where steam-driven machinery and motors could perform tasks more efficiently than manual labour. The makers were one of many boilermaker businesses in Melbourne during the early late-19th andearly 20th centuries. The maritime trade and skills of boilermaking are still learned and applied today. The Dewrance steam pressure gauge connected to the boiler was made by the London firms foundered by John Dewrance. He was renowned for developing the steam locomotive in the early 19th century.Boiler; a horizontal cylindrical underfired steam boiler. It is a multi-tubular design and is timber plank-clad, with brass fittings and pressure gauges. The boiler has an iron door at one end with a metal chimney above it. It is installed over a brick-enclosed solid fuel furnace. Two large, wood-mounted pressure gauges are connected to the boiler and have inscriptions. An inscription is on a red, cast iron plaque above the boiler door. The boiler's maker is T & F Johnson, South Melbourne. One of the pressure gauges was made by Dewrance, London..Maker's plate: "T & F JOHNSON / BOILERMAKERS / SOUTH MELBOURNE" Pressure gauge: "POUNDS PRESSURE / PER [square] INCH / DEWRANCE LONDON"flagstaff hill, warrnambool, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, boiler, multi tube boiler, steam boiler, steam technology, underfired boiler, horizontal boiler, timber clad boiler, steam power, industrialisation, boilermakers, south melbourne, dewrance, john dewrance, pressure gauge, dewrance pressure gauge, t & f johnson, london, steam engine, steam locomotive, pounds per square inch, 19th century, steam machine, johnson tyne foundry, colonial boiler, fire tube boiler -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumPhotograph, Optical Munitions with E.H.S. Burhop

Part of a series of optical munition snapshons 1940-1947. Refer to Cat No 142 for full details. Black and white photo shows Eric Burhop operating a radiation pyrometer ....with possibly a vacuum furnace? Duplicate copy of Cat no 142; in OMP Album Vol 2 #22 .Melbourne University”In ink on lower left hand corner : “22”. Inscribed on back in pencil: “No. 22 E.H.S. BURHOP” -

Federation University Historical Collection

Federation University Historical CollectionBook - Catalogue, F.W. Braun Modern Labor Saving Laboratory Appliances. 1903, c1905

... furnaces ...100 page catalogue from F.W. Barun. Includes numerous line illustrations.non-fictionj.w. glover, john w. glover, crushers, furnaces, blowpipe outfits, cupel machines, blowpipe -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSign - Hudson's Soap Enamel Advertising Sign, Patent Enamel Co Ltd, c. late 19th century- early 20th century

Hudson's Soap Powder, was the first satisfactory and commercially successful soap powder and was made in Liverpool by Robert Spear Hudson. He was also an innovator in using advertising, commissioning striking images from professional artists and paid for publicity , something which few other businesses did, and as such Hudson's soap became a household name. Horse, steam and electric tramcars, print periodicals and chemist shops carried his advertisements. This sign was manufactured by Patent Enamel Co Ltd was a company built in 1889 at Selly Oak, Borough of Birmingham, West Midlands, England, United Kingdom. The business was the first factory specifically devoted to enameled iron sign making. It had twelve furnaces for fusing the enamel, two scaling furnaces, and a large printing room, plus a huge area for steampipe drying. The company also smelted its own enamels and colour oxides. It is believed that the factory was decommissioned and demolished in the 1960's.the first factory specifically devoted to enameled iron sign making. It had twelve furnaces for fusing the enamel, two scaling furnaces, and a large printing room, plus a huge area for steampipe drying. The company also smelted its own enamels and colour oxides.The factory was decommissioned and demolished in the 1960s.The signage demonstrates the increasing demand for domestic soap products and new forms of advertising. The soap business was apart of the flourishing export trade between Australia and Britain during the height of the British Empire.Enamel advertising sign for Hudson's soapflagstaff hill, warrnambool, maritime museum, hudson's soap, advertising signage, patent enamel co ltd, selly oak, borough of birmingham, robert spear hudson -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumModel - copper, 1940's

Made by Internee Roland Frank at Camp 3, Tatura. (Company B)Black painted model of wood burning copper (or stove) with copper coloured dish, small metal mug hung on lid. Has tall chimney and wood stack attached. Lid and furnace doors hinged to body of copper. Red crepe paper inside to represent fire, plus a few pieces of woodcooker, model, metal, streker l, camp 3, tatura, ww2 camp 3, handcrafts -

Phillip Island and District Historical Society Inc.

Phillip Island and District Historical Society Inc.Tool, Chicory Scoop, 19th Century

One of Phillip Islands earliest industries was chicory farming. The first kiln was constructed in 1870. The chicory scoop was used for turning the chicory over on a mesh floor above the furnace. This scoop was imported from Europe in the late 1880's.Chicory scoop with wooden handle, wooden scoop and steel joins and reinforcments.phillip island, wood, steel, tool, chicory, kiln, chicory scoop -

Federation University Historical Collection

Federation University Historical CollectionDocument, Henry Richards Caselli, Annual Report Presented to the Governors and Subscribers of the School of Mines Ballarat, December 22rd 1875, 22/12/1875

Six handwritten foolscap pages of the Ballarat School of Mines Annual Report by President Henry Richards Caselli. The following attendances were recorded in 1875:- First Term - 70 Second Term - 69 Third Term - 75 Fourth Term 54 200 pounds was expended on the erecton of a large chimney stack and poison (arsenic) chambers , and in building the foundations of the furnace. henry richards caselli, ballarat school of mines, ballarat school of mines annual report -

Melbourne Tram Museum

Melbourne Tram MuseumEphemera - Ticket/s, Melbourne & Metropolitan Tramways Board (MMTB), "Scholars' Concession Ticket - Junior 2nd Term 1975", 1975

Part of a "Scholars' Concession Ticket - Junior 2nd Term 1975", probably printed on a cream coloured light card with a red colour "2" overprinted on one side and white on the other side. Ticket No. 04646 - has been singed around the edges. Has not been used, possibly recovered from a furnace destroying the ticket. Gives the conditions of travel on the rear.trams, tramways, mmtb, tickets, schools, schools tickets, scholar's tickets -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - Forest next Wesley Church

Cast iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore, was melted in a blast furnace, mixed with alloys and poured into molds made of sand. The alloys needed a minimum of 2% carbon.Black and White Photo by A Doney Bendigo of balustrade in Forest Street next to Wesley ChurchA. Doney Bendigoa doney, forest street -

Bendigo Historical Society Inc.

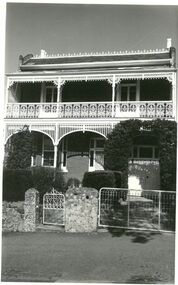

Bendigo Historical Society Inc.Photograph - 247 View St, Bendigo

Cast Iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore was melted in a blast furnace, mixed with alloys and then poured into molds usually made of sand. The alloys needed a minimum of 2% carbon.A black and white photograph by Alan Doney of the building at 247 View St in Bendigo. The photo shows detail of the wrought iron on the verandah. alan doney, bendigo, wrought iron -

Bendigo Historical Society Inc.

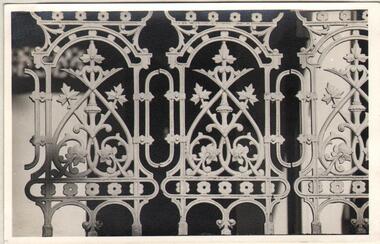

Bendigo Historical Society Inc.Photograph - 257 View St, Bendigo

Cast Iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore, was melted in a blast furnace, mixed with alloys and then poured into moulds usually made of sand. The alloys needed a minimum of 2% carbon.A black and white photograph by Alan Doney of the building at 257 View St in Bendigo. The photo shows detail of the wrought iron on the verandah. alan doney, bendigo, wrought iron -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - 22 Valentine St, Bendigo

Cast Iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore, was melted in a blast furnace, mixed with alloys and then poured into molds usually made of sand. The alloys needed a minimum of 2% carbon.A black and white photograph by Alan Doney of the building at 22 Valentine St in Bendigo. The photo shows detail of the wrought iron on the verandah. alan doney, bendigo, wrought iron -

Bendigo Historical Society Inc.

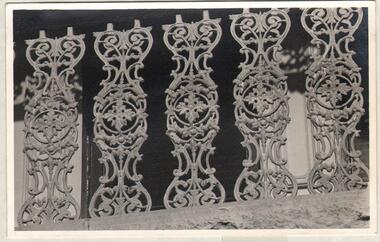

Bendigo Historical Society Inc.Photograph - 288 View St, Bendigo

Cast iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron",iron ore, was melted in a blast furnace, mixed with alloys and then poured into moulds usually made of sand. The alloys needed a minimum of 2% carbon. A black and white photograph by Alan Doney of 288 View St in Bendigo. The photo shows detail of the wrought iron on the fence. alan doney, bendigo, wrought iron -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - 159 Forest St, Bendigo

Cast Iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore, was melted in a blast furnace, mixed with alloys and then poured into moulds usually made of sand. The alloys needed a minimum of 2% carbon.A black and white photograph by Alan Doney of 159 Forest St in Bendigo. The photo shows detail of the wrought iron on the verandah. alan doney, bendigo, wrought iron -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - Corner McKenzie Short

Cast iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore, was melted in a blast furnace, mixed with alloys and then poured into moulds usually made of sand. The alloys needed a minimum of 2% carbon.Black and White photos by A Doney of House on corner of Mc Kenzie and Short Street Bendigo showing lace ironwork on the balustrade.Photo A Doneyiron lace work, a doney, historical home bendigo -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - Cathedral Short Street Bendigo

Cast iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore, was melted in a blast furnace, mixed with alloys and then poured into moulds usually made of sand. The alloys needed a minimum of 2% carbon.A black and white photograph by Alan Doney of Caretakers Residence Cathedral Short Street Bendigo showing detail of the wrought iron on the verandah. A Doney Bendigoalan doney, bendigo, wrought iron, balustrade -

Bendigo Historical Society Inc.

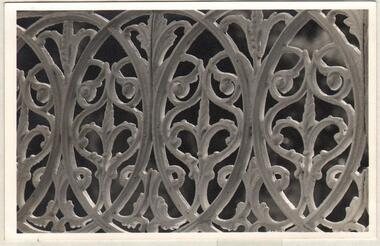

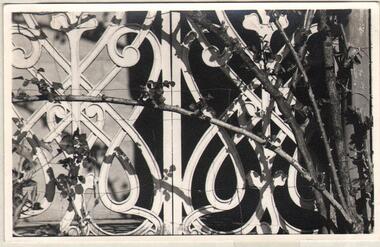

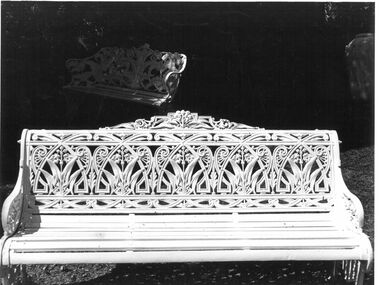

Bendigo Historical Society Inc.Photograph - Bench Seat Iron Lacework

Cast iron lace was made in foundries in most cities. There were 42 such factories in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore was melted in a blast furnace, mixed with alloys and then poured into moulds usually made of sand. The alloys needed a minimum of 2% carbon.Black and White photos by A Doney of bench seats one showing fern detail and the other leaves and flowers.Photo A Doneyiron lace work, a doney, bench seats -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - Cnr Forest Barnard Streets Bendigo

CAst iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron"' iron ore, was melted in a blast furnace, mixed with alloys and poured into moulds usually made with sand. The alloys needed a minimum of 2% carbon.Black and White photo by A Doney of Balustrade on property on the corner of Forest and Barnard Streets Bendigo.A Doney Bendigoalan doney, bendigo, wrought iron, forest street bendigo, barnard street bendigo