Showing 37 items

matching gas tank

-

Lakes Entrance Historical Society

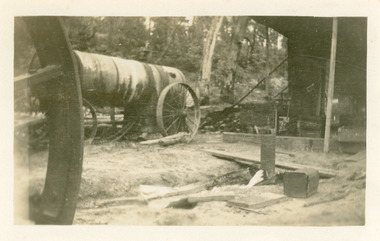

Lakes Entrance Historical SocietyPhotograph - Bunga Oil Bore, 1932 c

Photos taken prior to site being cleared of oil workings.Sepia photograph of the site of an early oil bore, identified as the Bunga Bore, has water tank on wagon with steel wheel. Lakes Entrance Victoriahistoric site, oil and gas industry -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - Various aircraft photos and drawings see description, CAC Misc documents and design drawings of various aircraft

xyz -

Eltham District Historical Society Inc

Eltham District Historical Society IncDocument - Property Binder, 1184 Main Road, Eltham

Newspaper article: A sustainable award, Diamond Valley Leader, 1 November2006, Architect and building Llewellyn Pritchard won resource Efficiency Housing Award, finalist in HIA Greensmart Building of the Year Award. House – Environmental Leader (Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p186) In 2006 environmental awareness was mushrooming in the community, which is reflected in the award-winning house at Main Road near Wattletree Road, Eltham. At first sight, the building appears a mix of a classic Eltham mud-brick house and an avant-garde building style. The crown of solar panels stretching along the width of the curved roof, indicates that this is no ordinary house. In fact it signals a new building trend of minimal impact on the environment. Yet it utilises the environment with high technical expertise to achieve comfort and cut running and maintenance costs. In recognition of this, its designer/builder, Conscious Homes, won the 2006 National HIA Greensmart Resource Efficiency Award. For Conscious Homes director, Llewellyn Pritchard, this house reflects a philosophy, strengthened by his connection with Aboriginal culture, through his foster siblings. Pritchard believes the sustainable way indigenous Australians lived and their spiritual connection with land, demonstrates how humanity is part of the ecology. His interest in environmental design stemmed from growing up in bushy Eltham Shire, with its mud-brick tradition. This was followed by studying Architecture at RMIT in the early 1980s, and learning about passive solar design. Pritchard says this house demonstrates that environmental sustainability is not about sacrifice, but about exceptional levels of occupant comfort, savings in running costs and modern fittings and appliances.1 The solar panels on the north roofs are intentionally obvious to make a statement about what the building is doing. But inside the systems are hidden and interactive with conventional services, such as the underground water tank. The house is water and energy self-sufficient and at 12 squares is much smaller than conventional houses, to minimise resources. Yet it accommodates his family of four with three bedrooms, a living/dining and kitchen area and a bathroom/laundry. Importantly the building is designed to last hundreds of years, by being able to be modified as the need arises, such as for commercial use. In this way the structure minimises its environmental impact. The solid double mud-brick walls (which are insulated) include steel beams and supporting frame, allowing the future removal or alteration of any section. The materials are local, recycled and of low toxicity where possible.2 Inside and out, the mud-brick is rendered and sealed with a combination of cement and sand and a mud-based coating in a soft golden hue increases its life. Inside, the golden-brown timber is plantation Mountain Ash and the concrete floors throughout – of local stone aggregate with a clear seal – have a natural looking random stone appearance. The house sustains a stable temperature of around 20 degrees, assisted by the concrete slab floor. The many large double-glazed windows and highlights (windows set high on walls) provide cross-flow ventilation. The north-facing living area maximises heating from the lower winter sun and is cooler in summer, because the sun is higher. Heating comes from a solar hydronic slab system. All appliances and fittings are high efficiency energy or water rated. Appliances in the timber kitchen include a gas stove and a dishwasher, using the building’s own power and water. French doors open from the living area to a deck, concealing the treatment system for all waste water. This is pumped through sub-soil drippers to the indigenous garden beds and no-dig vegetable patch. Below the carport is the 80,000-litre rainwater tank and at the back, the boiler room houses the solar boiler, water tank access, domestic water supply pump, filter gear and hydronic slab heating controls. The solar system is backed up with gas, which is needed to heat water only in winter. Gas used is less than one quarter of that for an average home with ducted heating. Excess power is fed back to the grid and the building uses about one quarter of the mains electricity of an average home. Other local builders have followed Pritchard’s lead in resource efficiency for minimal environmental impact.main road, eltham, businesses, llewellyn pritchard, hia greensmart building of the year award., efficiency housing award, conscious homes australia pty ltd -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionAerial Drip Torch (ADT) or "Dragon"

The Aerial Drip Torch (ADT) was an idea conceived in Canada in the 1970s by John Muraro It was developed in 1982 by the New Zealand Forest Service to become the Ashley Aphid Helitorch. Forestry Tasmania acquired one of the machines and modified it in February 1987. Also known as a dragon helitorch it consisted of a large 135-litre tank containing jellied petrol, a displacement pump, propane ignition system, burner nozzle and fire extinguisher system. It was first trialled in Victoria at Swifts Creek in 1991 and the Aerial Drip Torch (ADT) has now become standard practice.Two Aerial Drip Torches (ADTs) were built in the 1990s by the Fire Equipment Development Centre at North Altona, They were developed in conjunction with the Department of Conservation and Land Management in Western Australia. The first was trialled during the 1991/92 autumn burning season. The machine proved to be successful and a second machine was introduced in 1998 to assist with burning operations across the State. The ADTs were commonly used for regeneration burning (controlled burning of logging slash). The first ADT introduced in 1992 had a dry weight of 160kg and a capacity of 130 litres, providing about an hour of operation. Following initial use, systematic modifications were adapted including improved ignition of gel at the drop tube, installation of an air bleed valve at the pump to assist pump priming and improved mounting brackets for the CO2 bottles and propane canister attached to the machine. The second, and lightweight ADT, introduced in 1998 had a dry weight of 68kg and a capacity of 200 litres due to a smaller lightweight frame and plastic (Polyfin) tank. In operation the ADT is suspended below a helicopter via four strops attached to the vessel and a cable to the helicopter cargo hook. Gelled fuel is dispensed via a drop tube which is attached to the pump outlet of the machine, and ignited via a gas torch. Safety features built into the first ADT were: a brass melting plug designed to be activated at 200 C bursting disc designed to burst at170 Kpa should the vessel over pressurise. a pressure relief valve set to 35 Kpa ( vessel operated between 16 &34 Kpa) a low pressure sensor designed to shut down the machine should the vessel pressure drop below 15Kpa. the vessel is filled with CO2 above the gelled fuel to eliminate ignition with in the vessel. CO2 is used to expel any residue of ignited gel from the drop tube to prevent ignition when flying outside the boundaries of the burning area. See FIRE EQUIPMENT NOTE - 46 [ https://drive.google.com/file/d/1CKtcH-3rUlrtbE9dkNP27PYT2-raVVhF/view ]forests commission victoria (fcv), bushfire, bushfire aviation, planned burning -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph - Oil industry, 1945 c

05324.1 and .2Three black and white photographs of settling tanks at Lakes Oil Company facility Lakes Entrance Victoriaoil and gas industry -

Lakes Entrance Historical Society

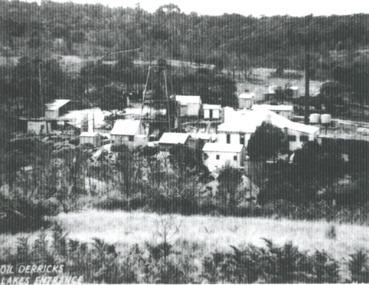

Lakes Entrance Historical SocietyPhotograph, Lakes Oil Limited Company's Deep Shaft, Lakes Entrance Victoria, 1944 c

Construction commenced 1942 concluded 1947 250,000 gallons of oil produced from shaftBlack and white photograph of Lakes Oil Limited Company's Deep Shaft production field, image shows derrick over pilot bore headframe over main shaft engineroom, storage tanks, offices and other necessary buildings, looking east from Myers Street Lakes Entrance Victoria'OIL DERRICKS LAKES ENTRANCE'oil and gas industry, engineering, social history -

Geoffrey Kaye Museum of Anaesthetic History

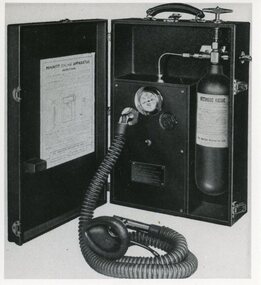

Geoffrey Kaye Museum of Anaesthetic HistoryPhotograph

Robert James Minnitt introduced the concept of self-administered analgesia, using an apparatus designed and built in conjunction with London scientific instrument-maker, Charles King. The Minnitt apparatus met with considerable success and led to further modifications, including the introduction of the Queen Charlotte gas-air analgesia apparatus in 1936, manufactured by the British Oxygen Company.Black and white photograph of a Minnitt gas/air analgesia apparatus, in a Queen Charlotte case. The case is standing open with the apparatus inside. A label with instructions is on the left side of the case, and the apparatus is on the right side of the case. A nitrous oxide cylinder tank and valve is connected to a small box with a regulator. A tube with a breathing mask is attached to the box. The Queen Charlotte case has hinges on the side and a handle on the top.minnitt gas air apparatus, minnitt, nitrous oxide, queen charlotte case, anaesthetic equipment