Showing 77 items

matching heating iron

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Try pot, c. 20th century

This try-pot is one of a set of three. Whalers used large iron pots, called try-pots to liquefy large chunks of whale blubber down into oil. Early on in the history of whaling, small whaling boats had no means to process blubber at sea and had to bring it into whaling stations for processing at shore-based try-works. Later, when bay whaling evolved and large scale vessel were utilised for hunting whales, try pots were mounted onto the top deck. This advance had its benefits as the processing facilities were mobile, whalers could move operations to follow whales and discover new whaling grounds. The deceased whale would be tied up alongside the ship, the crewmen cut away the blubber, or outer fat layer, in long strips. They hauled the strips aboard, cut them into smaller pieces, and tossed them into boiling cauldrons on deck to render the fat into oil. The whale oil was stored in barrels in the cargo hold, and brought to put for sale. The oil was much sought after as a good quality fuel tor heating, light and lubrication. Try pots were used in the whaling industry, one of the very early industries in Colonial Australia, including here on the southwest coast of Victoria. The high grade oil was a much sought after product and used for essential services such as fuelling the lights of the lighthouses. Commercial whaling ceased in Australia in 1979.Try pot, one of a set of three. A large cast-iron cauldron of about 180 gallons in capacity. Round metal container with rounded base and flat extended lip. It was used to heat whale blubber to remove the oil.flagstaff hill, warrnambool, maritime museum, shipwreck coast, try pot, trypot, cauldron, whale oil, whaling, fuel -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron Hand Kerosene, circa 1948

This item was in use before electricity and was manufactured after the flat stove irons.The weight of the iron base, is heavy, helping in smoothing out crinkly material being ironed. This item permitted ironing of clothes to be separate and away from heating stoves. It permitted greater flexibility for ironing clothes and permitted more control (consistency) of the temperature of the iron.Historically and significantly this item enforces the relative isolation of the Kiewa Valley and period when and where this domestic item was in use(manufactured circa 1950). A rural setting with mining, beef , milk and tobacco production in the early 1900s. Even though the community was in a rural setting, the standards of dress was the same as in the bigger towns and cities. Social and religious mores and values demanded that the personal appearance be clean and crisp no matter where a person was living or working. Heavy laborious work was considered by some religions as virtuous, therefore the heavy and tiring work of ironing during this period had its rewards. Rural areas where the last to be connected to electricity and therefore this item was a domestic necessity far into the 1950's.This iron has a steel base and a metal body coated with green coloured enamel. The wooden hand grip is painted dark green. The kerosene (spirit) container is a chrome metal cylinder with a flat bottom and top. The top has a small filler/air plug is located on the top side. There are two control knobs located next to and under the metal cylinder. The close to the cylinder is a lock which locks the top lid of the iron and the other knob controls the airflow to the heater rodOn the base of the handle "PEERMAN" and below this P/46, C.I. Thomas & Son Pty Ltd household, ironing, domestic kerosene, dry cleaning -

Orbost & District Historical Society

Orbost & District Historical Societyiron

Iron was heated on top of stove. Often the person ironing had two irons - one to iron with and the other heating on stove ready to use when the other cooled down. They were heavy to use and were generally cleaned with bees' wax and a cloth before use. Wooden handles were patented in 1865.This item is an example of a domestic appliance in common usage before the advent of electricity.Small rusty flat iron.domestic iron flat-iron -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Fire fender, Late 19th to early 20th century

A fender is part of the hardware used in open fireplaces to prevent the fire from spilling out of the fireplace. Wood fires were the main source of domestic heating in the 19th century.This fender is significant for its association with domestic heating in the 19th and early 20th century.Fire fender, cast iron, painted black, sides bolted onto front as is base plateflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, great ocean road, fire fender, fire guard, domestic heating, fender -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Fire Iron

... ocean road fire poker fire iron domestic heating Fire poker ...Fire irons like this one were an essential piece of domestic equipment as hey were used for the open fires.This iron poke is a piece of equipment essential for the open fireplaces used for 19th and early 20th century domestic heating.Fire poker, iron, painted black, shaped from a cylindrical rodflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, fire poker, fire iron, domestic heating -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Fire Iron

... for domestic heating in the 19th and early 20th century. This fire iron ...Fire irons or pokers are essential equipment for people with open fireplaces such as those used for domestic heating in the 19th and early 20th century.This fire iron is significant for representing the type of equipment used in the 19th and early 20th century for used with open heating.Fire poker, iron, painted black, shaped from a steel barflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, fire iron, fire poker, domestic heating, open fireplace -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Stove, 1960 - 1983

The Mont Eltham Pot Belly Stove History The Mont Eltham Pot Belly Stoves were first manufactured in the 1960s at the Burrowes family business The Lyn Iron Foundry in Coburg Victoria by Barry and his father Charles Thomas Burrowes. The manufacture of The Mont Eltham Pot Belly continued in Victoria as The Mont Eltham Stove Co. by Barry and Glenda Burrowes in Montmorency and later in Thomastown. The castings were produced by leading Melbourne foundries, Cox & Rosetti , and Anderson & Ritchie. They were also made in Ballarat by The Harding Bros Foundry, and in Shepparton by The Furphy Foundry. The Mount Eltham pot belly stoves were manufactured until the late 1980s. Stove; cast iron pot belly stove. Very large cylinder shape with square base, grate shelf around centre, on 4 legs. Inscription on door. "Swagman" model. Made by Mont Eltham Stoves, Victoria. "Mont Eltham Stoves Vic Swagman Aust"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, domestic heating, domestic heating, stove, pot belly stove, wood fired stove, old world stove, the mont eltham stove co., the lyn iron foundry, barry and glenda burrowes -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Stove, 1850-1890

In the industrialized world, as stoves replaced open fires and braziers as a source of more efficient and reliable heating, models were developed that could also be used for cooking, and these came to be known as kitchen stoves. The first manufactured cast-iron stove was produced at Lynn, Mass., in 1642. This stove had no grates and was little more than a cast-iron box. About 1740 Benjamin Franklin invented the “Pennsylvania fireplace,” which incorporated the basic principles of the heating stove. The Franklin stove burned wood on a grate and had sliding doors that could be used to control the draft (flow of air) through it. Because the stove was relatively small, it could be installed in a large fireplace or used free-standing in the middle of a room by connecting it to a flue. The Franklin stove warmed farmhouses, city dwellings, and frontier cabins throughout North America. Its design influenced the development of the pot-bellied stove, which was a familiar feature in some homes well into the 20th century. The first round cast-iron stoves with grates for cooking food on them were manufactured by Isaac Orr at Philadelphia, Pa., in 1800. The base-burning stove for burning anthracite coal was invented in 1833 by Jordan A. Mott. The subject item is a mid to late 19th century settlers stove probably of Canadian manufacture imported into Australia around this time. The stove gives us a social snapshot into what life must have been like for our early colonialists using this device for heating and cooking in their meagre homes. Cast iron stove with four-legs, 2 plates on top and a hinged front door. The door has been cast with a maple leaf design and the sides have a pattern cast into them.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, stove, domestic heating, domestic cooking, heater, cooking unit, pot belly stove, wood fired stove, wood stove -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Clothes Iron, last quarter of the 19th century

Blacksmiths started forging simple flat irons in the late Middle Ages. Plain metal irons were heated by a fire or on a stove. Some were made of stone. Earthenware and terracotta were also used, from the Middle East to France and the Netherlands. Flat irons were also called sad irons or smoothing irons. Metal handles had to be gripped in a pad or thick rag. Some irons had cool wooden handles and in 1870 a detachable handle was patented in the US. This stayed cool while the metal bases were heated and the idea was widely imitated. Cool handles stayed even cooler in "asbestos sad irons". The sad in sad iron (or sadiron) is an old word for solid, and in some contexts this name suggests something bigger and heavier than a flat iron. Goose or tailor's goose was another iron name, and this came from the goose-neck curve in some handles. In Scotland people spoke of gusing (goosing) irons. At least two irons were needed on the go together for an effective system, one would be in use, and the other re-heating. Large households with servants had a special ironing-stove for this purpose. Some were fitted with slots for several irons, and a water-jug on top.An early domestic object that gives an insight into how the ironing of clothes was done before the electric type irons we use and take for granted today.Clothes Iron, wedge shaped, cast iron painted black with cylindrical handle small funnel through centre of handle.Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, iron, flat iron, laundry equipment, sad iron, domestic object -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Flat Iron, 1890-1935

Blacksmiths started forging simple flat irons in the late Middle Ages. Plain metal irons were heated by a fire or on a stove. Some were made of stone. Earthenware and terracotta were also used, from the Middle East to France and the Netherlands. Flat irons were also called sad irons or smoothing irons. Metal handles had to be gripped in a pad or thick rag. Some irons had cool wooden handles and in 1870 a detachable handle was patented in the US. This stayed cool while the metal bases were heated and the idea was widely imitated. Cool handles stayed even cooler in "asbestos sad irons". The sad in sad iron (or sadiron) is an old word for solid, and in some contexts this name suggests something bigger and heavier than a flat iron. Goose or tailor's goose was another iron name, and this came from the goose-neck curve in some handles. In Scotland people spoke of gusing (goosing) irons. At least two irons were needed on the go together for an effective system, one would be in use, and the other re-heating. Large households with servants had a special ironing-stove for this purpose. Some were fitted with slots for several irons, and a water-jug on top.An early domestic object that gives an insight into how the ironing of clothes was done before the electric type irons we use and take for granted today. Flat iron cast iron with traces of original black finish on handle. Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, iron, flat iron, laundry, clothes ironing, sad iron, tailors goose -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Fire iron stand

... coast flagstaff hill maritime village great ocean road fire iron ...Fire iron stand; black, all metal stand with a singular spine attached to rectangular base. below the handle on the spine is a horizontal 'U' shaped rack with a hook at each end and a hook at the centre back of the 'U' for hanging tools. Decorative metal handles on tools and rack. 4 parts; stand, brush, shovel, poker. Impressed into underside of stand "B1O2" and " ATWN"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, fire iron stand, fire iron, fire tools, fireplace set, fire iron set, domestic ware, heating -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Stove, Cox and Rizzetti Stove Works, ca. 1918-1930s

Cast iron stoves burn solid fuel such as wood or coal, and are used for cooking and warmth. The stoves have a firebox with a grate where the fuel is burned. The hot air flows through flues and baffles that heat the stove top and the oven. Before cast iron stoves were invented, cooking and heating were carried out in outdoor open fires, and later, in fireplaces inside the home. In 1642 the first cast iron stove was manufactured in Lynn, Massachusetts, where molten cast iron was poured into a sand mould to make rectangular plates that were then joined together to make a box. Benjamin Franklin invented the more efficient Pennsylvania stove in 1744, and this efficient design is still used today. After the mid-19th century cast iron stoves were produced with burners in different positions, giving varied temperatures, so a wide variety of foods could be cooked at the same time at the most suitable heat, from slow cooking to baking scones. In contemporary times people the new wood-burning stoves had to meet the anti-pollution standards now in place to protect our environment. By the 1920s gas cookers were being introduced for domestic use, and by the 1930s electric home cookers were being offered to householders. PLANET STOVES In August 1925 the firm Cox and Rizzetti, Stove Works, and also Sydney Road, South Melbourne, advertised in the Brunswick and Coburg Leader of November 11, 1925 as "formerly with Harnwell and Sons" and as "specialists in solid cast iron Planet stoves ... which merit an inspection from builders and householders". The firm continued in business and was mentioned as sponsors in the King Island News in 1971. Harnwell and Sons was listed in the Victorian Government Gazette of 1894. It is curious that the firm was mentioned in an article in the Sunrasia Daily of June 14, 1934 titled 'Planet Stoves' as a manufacturer of Planet Stoves. This Planet No 3 stove is an uncommon example of cooking equipment used in kitchens in the early 20th century, as the firebox is above the oven rather than beside it. The cast iron combustion stove is significant as part of the evolution of domestic cooking. Previously cooking was mostly carried out in outdoors in open fires, and later in fireplaces indoors. Cast iron stoves are still used today and have additional features such as thermostats to monitor and maintain temperature, water heating pipes connected, and environmentally approved anti-pollution fittings. Stove; a compact, blackened cast iron combustion cooker, installed within a fireplace and enclosed by bricks on both sides. The upright rectangular stove has a flat top with three round, removable cook plates and a flue connected at the back. The front has three doors with round knob handles; a swing-down firebox door above a sliding ashtray, and two side-hinged oven doors above a sliding opening. Inside on the side walls are two pairs of runners. Behind the pair of doors is an oven with two pairs of rails and two removable metal shelves. The stove has cast inscriptions on the chimney flue and on the front of the right hand side stove door. The model of the stove is The Planet No 3, made in Melbourne.Chimney flue, "[within rectangle] THE / PLANET" Stove door, "(within oval) PLANET / No 3"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, stove, cast iron stove, combustion stove, wood-burning stove, wood stove, wood oven, solid fuel stove, cooker, the planet, planet, planet no. 3, kitchen equipment, baking, domestic cooking, cooking equipment, food preparation, planet stove, planet cooker, cooking range, slow combustion stove, antique, range cooker, cox and rizzetti, harnwell and sons, melbourne manufacturer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Firedogs

Firedogs is the common name for andirons and Chenets and have been in use since ancient Greek times. Firedogs are the decorative metal supports or stands that hold logs in a fireplace, allowing air to circulate around the fire to keep it burning, and preventing logs from rolling out of the fireplace. They are usually made of metal, cast iron or steel, but are sometimes ceramic. They have two feet joined across the front and one at the back. Some firedogs, mainly for kitchen use, were plain with forked uprights so that a bar could rest between them on which a cooking pot or a roasting spit could hang. Some firedogs are made in the likeness of animals, shields, crosses, figures and keys. This pair of firedogs are representative of the firedogs that were common to domestic use in previous centuries when home heating and cooking were only possible with open fires. Firedogs or andirons, pair of two decorative cast iron log supports for use in a fireplace hearth. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, fire dogs, firedogs, fire grates, log stands, domestic furniture, open fireplace equipment, andirons, chenets, domestic heating -

Glen Eira Historical Society

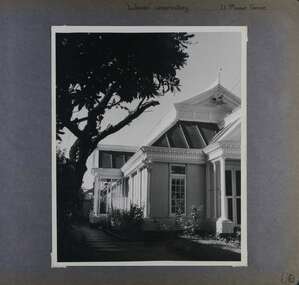

Glen Eira Historical SocietyAlbum - Album page, Labassa Conservatory, 21 Manor Grove, Circa 1972

... designs, enabled by technological developments in heating, glazing ...This photograph is part of the Caulfield Historical Album 1972. This album was created in approximately 1972 as part of a project by the Caulfield Historical Society to assist in identifying buildings worthy of preservation. The album is related to a Survey the Caulfield Historical Society developed in collaboration with the National Trust of Australia (Victoria) and Caulfield City Council to identify historic buildings within the City of Caulfield that warranted the protection of a National Trust Classification. Principal photographer thought to be Trevor Hart, member of Caulfield Historical Society. Most photographs were taken between 1966-1972 with a small number of photographs being older and from unknown sources. All photographs are black and white except where stated, with 386 photographs over 198 pages. WHAT IS SIGNIFICANT? [From Victorian Heritage Database citation for Former Labassa Conservatory - H2005 Victorian Heritage Register http://vhd.heritage.vic.gov.au/places/result_detail/12504 (25/01/2021)] The former Labassa Conservatory is believed to have been built as part of the extensive reworking of the Labassa estate in c1890 for the new owner Alexander Robertson, proprietor of the Cobb and Co line. Robertson commissioned the architect JAB Koch to remodel the house, and Koch may have been responsible for the conservatory as well. Alternatively, the conservatory may have been imported. The gates installed at Labassa in 1890 were manufactured by the MacFarlane foundry of Glasgow, Scotland, a firm known to have manufactured conservatories. Around 1917 the glass house from 'Labassa', Caulfield was offered for sale to Malvern Council for its own gardens but the offer was declined. Following subdivision of the Labassa estate in the 1920s the conservatory was converted into a residence. The structure has a simple rectangular plan, with a brick base and superstructure of cast iron columns and roof trusses. The hipped roof is surmounted by an elaborately decorated gable structure. Most of the original glass has been replaced by metal sheeting. The decoration comprises pressed metal fascias including an egg and dart style cornice moulding, mullion mouldings and gable end panels with a rising sun motif. Cast iron ridgework and finials add to the lively roof form. Internally the floor appears to have been raised as part of the conversion work to a residence, and stained timber panelling introduced to provide room spaces. Boilers probably heated the conservatory in the colder months, but these do not survive.From Victorian Heritage Database citation for Former Labassa Conservatory - H2005 http://vhd.heritage.vic.gov.au/places/result_detail/12504 (25/01/2021) HOW IS IT SIGNIFICANT? The former Labassa Conservatory is of historical and architectural significance to the State of Victoria. WHY IS IT SIGNIFICANT? The former Labassa Conservatory is historically significant for its associations with the Labassa estate. Subdivision of the estate separated a number of outbuildings from the mansion. The former conservatory is significant as part of the large scale improvements carried out to the estate in the 1890s. The nineteenth century was the great age of conservatory designs, enabled by technological developments in heating, glazing and iron. Whilst conservatories were common in botanical gardens and universities, where they were primarily used for cultivating, studying, and experimenting with plants, they had also become an accessory of the wealthy on private estates. The former Labassa conservatory is architecturally significant as a rare example of a building type. Many Victorian mansion houses had attached conservatories, but detached conservatories were much less common. The only other detached example associated with a residence known to survive on its original site in Victoria is an earlier example at Warrock homestead, near Casterton. Conservatories attached to nineteenth century mansions are far more numerous. The Labassa example is very ornate, and its decoration draws on the versatility of pressed metal and cast iron. This highlights the dual purpose of the conservatory, as both a functional structure and a picturesque building on the Labassa estate. This building is unusual as an example converted to residential use. Page 130 of Photograph Album with one portrait photograph of Labassa's conservatory.Handwritten: "Labassa" conservatory 21 Manor Grove [top right] /130 [bottom right]bracketed eaves, caulfield north, labassa, balaclava road, orrong road, sylliott hill, alexander william robertson, ontario, john a. b. koch, john boyd watson, mouldings, 1920's, la bassa, manor grove, st kilda east, architects, john koch, greenhouses, gardens, plants, land subdivisions, gates, macfarlane foundry, brick, cast iron work, hipped roofs, gables, 1890's -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Ironing board, 1910-1930

Ironing is the use of a machine, usually a heated tool (an iron), to remove wrinkles from fabric. The heating is around 180–220 °Celsius, depending on the fabric type. Ironing works by loosening the bonds between the long-chain polymer molecules in the fibres of the material. While the molecules are hot, the fibres are straightened by the weight of the iron, and they hold their new shape as they cool. Some fabrics, such as cotton, require the addition of water to loosen the intermolecular bonds. Many modern fabrics developed in or after the mid-twentieth century require little or no ironing. Permanent press clothing was developed to reduce the ironing necessary by combining Wrinkle resistant polymers with cotton. The first known use of the iron for removing wrinkles in clothes is known to have occurred in China, and the electric iron was invented in 1882, by Henry W. Seeley. Seeley patented his "electric flat iron" on June 6, 1882 (U.S. Patent no. 259,054). On 15 February 1858 W. Vandenburg and J. Harvey patented an ironing table that facilitated pressing sleeves and pants legs. A truly portable folding ironing board was first patented in Canada in 1875 by John B. Porter. The invention also included a removable press board used for sleeves. In 1892 Sarah Boone obtained a patent in the United States for improvements to the ironing board, allowing for better quality ironing of shirt sleeves.A domestic item with an interesting history of development, significant as it shows the progress and the evolution of a domestic item designed to make housework more efficient.Wooden Ironing board with press board for sleeves, board is folding.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, flagstaff-hill-maritime-village, domestic item, ironing board, ironing, clothes, wrinkles in clothes, henry w. seeley, w. vandenburg and j. harvey -

Federation University Historical Collection

Federation University Historical CollectionBook, A Survey of British Industrial Arts, 1935, 1935

The Ballarat Technical Art School was a division of the Ballarat School of Mines, and a predecessor of Federation University Australia. Red hard covered book including chapters on interior decoration, furniture, woodwork, carpets, textiles, metalwork, lighting, heating, pottery, and glass. Formerly Book R528 in the Ballarat Technical Art School Library.industrial arts, henry g. dowling, ballarat technical art school library, ballarat technical art school, j. ewins & son, bookplate, wrought iron, furniture -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, curved sad iron, c1880

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer.The Curtis family were early settlers in Moorabbin Shire c1880 and used sad ironsA small, curved, flat iron, with attached handle, used for cuffs, collars and frillsSILVESTER'S/ PATENT/ SALTERS / No 3 with the pretzel & a arrow going through the centresad iron, kitchen equipment, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen equipment, sad iron, c1880

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer.These sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire. The family of Miss M Curtis were early settlers in Moorabbin Shire. Sad-iron, domestic, flat, cast iron, Silvester's Patent, No 6, Salter, England, c. 1890-1900s A sad iron made from cast iron was heated over a fire or on a stove and used for pressing clothing and table wareSILVESTER'S/ PATENT/ SALTERS / No 6 with the pretzel & a arrow going through the centresad iron, kitchen equipment, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen equipment, gas-fuelled flat iron, c1900 - 30

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer. Thomas Fletcher (1840-1903). By 1880s he had a gas appliance manufactory in Thynne Street, Warrington. By 1895 the company had become Fletcher Russell and Co Gas Engineers, his firm having merged with Alexander and William Russell of Pendleton Iron Works. Circa 1950, the firm merged into Radiation Ltd which was later acquired by 'TI New World'; 1902: Fletcher, Russell & Co. Ltd., Palatine Works, Warrington In 1880 gas -fuelled irons were connected by rubber tubing to the gas light-fittings of the house or to gas canisters. However , not many houses had access to a gas supply until much later and this iron was popular in 1920’sThese sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire The family of Miss M Curtis were early settlers in Moorabbin Shire.A gas-fuelled flat iron, made in USA , It would have been attached to a gas hose fitting that was also used at night for light in the house. There is a small chimney to allow for air and to try to control the amount of heat in the iron. A 'shield' is under the leather covered handle to protect the user's hand from the heat, however it is made of copper metal - a heat conductor.FLETCHER RUSSELL CO. / LIM/ PATENT/ WARRINGTON on right side of handle 'Registered' on left side of handle ' Fletcher Russell Co L / Warrington, Manchester / & London.sad iron, kitchen equipment, fletcher russell co. ltd., england, warrington, manchester, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves, domestic gas supply, gas-light, gas cannisters -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen Equipment, flat iron with trivet stand, c1880

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer. These sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire The family of Miss M Curtis were early settlers in Moorabbin Shire. A) A heavy cast iron, flat iron with B) horseshoe shaped trivet stand c1880 The trivet can be attached to a table by an adjustable clamp.A) 5 on tip of ironsad iron, kitchen equipment, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen equipment, spirit-fuelled sad iron, c1920

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer. Late in the 19thC designers experimented with heat retaining fillings for these irons. William Coleman began selling Kerosene lanterns in 1900 in Kingfisher, Oklahoma, USA. He moved to Wichita, Kansas in 1902 and the company became world wide. The company also produced a range of cooking stoves and domestic irons. This spirit- fuelled flat iron was very popular in 1920s - 30s These sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire The family of Miss M Curtis were early settlers in Moorabbin ShireA) spirit- fuelled, sad iron with chrome plated sole c1920, and metal trivet The iron is blue enamel with a white speckled body, with a hemispherical tank for the Coleman 'Lighting Petrol' that provided the heat for smoothing the material B) Coleman Fuel measuring can and funnellMetal Trivet/stand " COLEMAN" ; Petrol can " COLEMAN" / MEASURING CAN / for INSTANT LIGHTING IRON/ with printed instructionssad iron, kitchen equipment, coleman william, kansas, oklahoma, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves, petrol fuelled irons, spirit flat irons, coleman lamp stove co. ltd. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen Equipment, sad iron with lifter, c1900

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and using the lifter the cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer.These sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire. The Curtis family were early settlers in Moorabbin ShireA) This heavy sad iron, made from cast iron, was heated over a fire or on a stove and used for pressing clothing and haberdashery. B) The separate tapered handle was used to lift the hot iron from the fire and when a "Potts" Handle was attached the ironing commenced. sad iron, kitchen equipment, fireplaces, stoves, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen Equipment, sad iron with Mrs Potts handle, c1900

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. Mrs Florence Potts invented in 1871 a detachable handle made from walnut wood with a metal latch to release the handle. These wooden handles prevented burned hands and were sold to grateful women all over the world. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer.Mrs Florence Potts invented this type of detachable walnut wood handle with a meta release latch for sad irons in 1871 and it sold widely throughout the world to grateful women including those in Moorabbin Shire. The family of Ms May Curtis were early settlers in Moorabbin ShireA) A sad iron, made of cast iron , has a special handle invented in 1871 by Mrs Florence Potts of Iowa, USA. B) The detachable handle made of walnut wood to prevent burned hands, was attached to the iron by a metal latch.A) UNITED/ N0 / 50 / AUSTRALIApotts florence, iowa usa, melbourne, moorabbin, sad irons, kitchen equipmentn fireplaces, walnut wood, sewing, laundry, table ware, linen, pioneers, early settlers, washing days, craftwork -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Flat Iron, 1890-1935

Blacksmiths started forging simple flat irons in the late Middle Ages. Plain metal irons were heated by a fire or on a stove. Some were made of stone. Earthenware and terracotta were also used, from the Middle East to France and the Netherlands. Flat irons were also called sad irons or smoothing irons. Metal handles had to be gripped in a pad or thick rag. Some irons had cool wooden handles and in 1870 a detachable handle was patented in the US. This stayed cool while the metal bases were heated and the idea was widely imitated. Cool handles stayed even cooler in "asbestos sad irons". The sad in sad iron (or sadiron) is an old word for solid, and in some contexts this name suggests something bigger and heavier than a flat iron. Goose or tailor's goose was another iron name, and this came from the goose-neck curve in some handles. In Scotland people spoke of gusing (goosing) irons. At least two irons were needed on the go together for an effective system, one would be in use, and the other re-heating. Large households with servants had a special ironing-stove for this purpose. Some were fitted with slots for several irons, and a water-jug on top.An early domestic object that gives an insight into how the ironing of clothes was done before the electric type irons we use and take for granted today. Flat iron cast iron with stand None item too badly corrodedflagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, iron, flat iron, laundry, clothes ironing, sad iron, tailors goose -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, brown glass, handmade. Tall slim Gallon style liquor bottle. Applied, double collar lip; square upper with flared lower. Neck has seams and shoulder seam from 3-piece mould. Body with horizontal ripples tapers inwards to base. Push-up base with pontil mark and embossed inscription. Tape over wire around mouth. Cork remnants inside mouth. Embossed on base "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, brown glass, handmade. Tall slim Gallon style liquor bottle. Applied double collar lip; square upper with flared lower. Push-up base with pontil mark and embossed inscription. Base is uneven, glass composition has imperfections.Embossed on base "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, brown glass, handmade. Tall slim Gallon style liquor bottle. Applied double collar lip; square upper and flared lower. Neck has seams and shoulder seam from 3-piece mould. Body tapers towards base. Push-up base with pontil mark and embossed inscription. Base is uneven. Mouth has remnants of the seal in it and tape remnants around its outside. Embossed on base "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, olive green glass, handmade. Tall slim, Gallon style liquor bottle. Applied double collar lip; square upper with flared lower. Neck is slightly bulged and there is a mould seam where shoulder joins base. Body tapers inward to base. Uneven base with deep push-up centre with small pontil mark. Scratches and imperfections in glass. Also encrustations on surface. flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, olive green glass, handmade. Tall slim Gallon style liquor bottle. Applied double collar lip; square upper and flared lower. Mouth has remnants of tape and wire seal. Mould seam around shoulder. Body tapers slightly inward to the base. Push-up base has pontil mark and is embossed in large letters. Base is uneven. Embossed on base "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. However, this bottle is rare, in that the base has been embossed then over-embossed with the same text, letters overlapping. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is a rare find, in that the base has been over-embossed with the same lettering, letters overlapping one another. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, over embossed, brown glass, handmade, rare. Tall slim Gallon style liquor bottle. Applied double collar lip; square upper and flared lower. Mouth has sealing tape remnants around top. Mould seam around shoulder. Body tapers inwards to push-up base. Top edge of lip has application faults. There is also a rectangular indent in the upper edge of lip. Base is embossed and over embossed, with the letters overlapping each other. Embossed on base "6 TO THE GALLON", then over-embossed with the same "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable, over embossed, rare