Showing 86 items

matching machine belts

-

Bendigo Military Museum

Bendigo Military MuseumPhotograph - PHOTOGRAPH WW1, FRAMED, c.1914 - 1918

Soldier at this time is not specifically known.Heavy timber frame, glass front, border surrounding a black & white photo of an Australian Soldier seated behind a water cooled machine gun. Soldier is holding controls & looking along the top of the gun. Alongside is an ammunition box with belt fed ammunition going to the chamber. Written on frame rear: "Bernie Hinton"photography-photographs, frame accessories, military history - army, portraits -

Bendigo Military Museum

Bendigo Military MuseumEquipment - CLINOMETER & CASE, Made in Australia D up arrow D, 1) 1943; .2) 1944

.1) Clinometer Mortar MKIII, brass,machined, with curved graduated markings. Centre is a bock with bubble in cross hairs. .2) Heavy leather case with ends sewn in. Rear has 2 leather keepers for a belt. Case shuts via strap & brass button..1) “TARGET - F TOUCH 1943 'A.3457'” .2) CASE. “MOR CLINO MKI (scratched on '3389') RB up arrow DCD 1944”instruments - measuring, containers - commercial, military history, clinometer -

Bendigo Military Museum

Bendigo Military MuseumWeapon - AMMUNITION - 7.62MM LINK

Part of the equipment carried by a section and its machine gunner. The G.P.M.G. uses a disintegrating link belt. Each section would carry between 400 and 600 rounds. The machine gunner's no2 would carry 300 rounds. Other items related to the machine gun would be shared out amongst the section.75 rounds of 7.62mm ammunition ( G.P.M.G. M60) joined with metal links to form a belt. Each round consists of a pointed metal projectile in a NATO rimless brass case.arms - ammunition, military history, vietnam war -

Bendigo Military Museum

Bendigo Military MuseumWeapon - AMMUNITION - 7.62MM LINK

Part of the equipment carried by a section and its machine gunner. The G.P.M.G. uses a disintegrating link belt. Each section would carry between 400 and 600 rounds. The machine gunner's no2 would carry 300 rounds. Other items related to the machine gun would be shared out amongst the section.63 rounds of 7.62mm ammunition ( G.P.M.G. M60) joined with metal links to form a belt. Each round consists of a pointed metal projectile in a NATO rimless brass case.weapons, vietnam war, arms - ammunition, machine gun -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageUniform - Tunic, 1899-1903

This original tunic or jacket is part of the full dress uniform of the pre-Federation Victorian Permanent Artillery regiment. Its owner had the rank of Sergeant, as indicated by the three inverted chevrons. The Artillery design of the badges and buttons indicate the date of the tunic to be from 1893 to 1903. However the maker of the tunic, W. Moncton, began manufacture in Melbourne in 1899, so this the tunic can be dated between 1899 and 1903. The donor's grandfather was given this tunic but not the name of the original owner. It has since been suggested to the family that the tunic was worn by a local Western District Light Horse member. This could very well have been the case because mounted troops were officially referred to as the Light Horse in the late 19th to early 20th century. Several local men were involved in the Light Horse during the First World War. The donor's grandfather wore this tunic in the local district when riding a penny farthing bicycle. The donor's father also wore the tunic when dressed as a 'Captain' hosting a local disco dance. BRIEF MILITARY HISTORY- The Crimean War began In 1854 and many people in colonial Australia were afraid of a Russian attack. Volunteer forces were established to strengthen the British Imperial troops posted here. A battery of artillery was raised in Victoria as well as in other Australian states. In 1870 Australia became responsible for its own naval and military defence. The Volunteer Corps and Victorian Navy shared the responsibility of defending the existing forts, assisted by volunteer coastal and mobile field batteries. The Permanent Victorian Artillery force was established. It was disbanded in 1880 then re-formed in 1882 as the Victorian Garrison Artillery Corps. In 1895 the Geelong, Warrnambool, Port Fairy and Portland Batteries became part of the Western District Garrison Artillery. Many of the volunteers who served in the Artillery were from rural areas. They belonged to rifle clubs and were experience horsemen as well. Australia's defence at this time relied on these mounted troops, or Light Horse men. In 1899 the Victorian Garrison Artillery Corps amalgamated with the New South Wales and Queensland Permanent Artillery to become the Victorian Regiment of the Royal Australian Artillery (RAA). Then prior to Federation, the RAA and the Permanent Artillery of South Australia, Western Australia and Tasmania all combined, becoming the Royal Australian Artillery Regiment with two Batteries of Field Artillery; Battery A from Sydney and Battery B from Melbourne.This original uniform tunic of the pre-Federation Victorian Permanent Artillery is significant for its association with Australia's military defence and the fortifications of our district, state and country. The tunic is also significant, representing part of the history and evolution of uniforms in the Australian military forces. The tunic is also significant in its representation of Australia's independence in forming its own defences. The tunic has local significance in its connection with local social events.Tunic or jacket, part of the full dress uniform of the pre-Federation Victorian Permanent Artillery operating from 1893 to 1903. Original, single-breasted tunic of dark blue wool, red piping trim, black cotton lining in body. Sleeves lined with blue striped, white cotton. Front closure has eight brass buttons. Red band-style collar with hook-and-eye closure has gold bullion braid trim and a brass badge pinned each side at the front. Upper right sleeve has three inverted chevrons on red fabric with gold bullion braid trim (rank of Sergeant). Both sleeves have gold bullion braid 'Austrian knot' emblems stitched onto lower arm, with ends finishing on the inner sleeve. Shoulder epaulettes have red piping and smaller brass buttons. Closed back vent has vertical scalloped design with six brass buttons, in two columns of three, and red piping trim. Brass belt hook is attached to the left back waist, close to the seam (right side has a mark indicating a previous similar clip). Inside left breast is a concealed pocket. Tunic has both machine and hand stitching. All brass shank-style buttons have matching Artillery emblems with inscriptions on the back. The two brass collar badges have additional artillery emblems of exploding grenade and star as well as an inscription. Buttons were made for W. Moncton, of Melbourne and marked with his name. He traded from 1899, dating the tunic to between 1899 and 1903.Button front: Artillery emblem on front (field cannon facing left, in front of a muzzle-loading ram rod). Button back: engraved "W. MONCTON . MELBOURNE ." Collar badges: Artillery emblem (field cannon facing right | stars | exploding grenade | "AUSTRALIA")flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, uniform jacket, uniform tunic, garrison volunteer uniform, fortifications in victoria, victorian permanent artillery, pre-federation military uniform, sergeant's uniform, jacket, militia, victoria, victorian volunteer forces, victorian regiment, royal australian artillery, raa, field gun, sergeant, w. moncton, garrison, dress uniform, tunic, scarlet collar, red collar, scarlet piping, red piping, gold bullion, artillery emblem, light horse, artillery, mounted troops, victorian garrison artillery corps -

Montmorency–Eltham RSL Sub Branch

Montmorency–Eltham RSL Sub BranchEquipment - Pouch, Leather, for Slide Rule Mk III, Vickers Machine Gun, 1940

To hold Slide rule MK III for Vickers Machine Gun. Leather pouch for Slide Rule Mk III for Vickers Machine Gun. Flap with stud closure and belt loop.slide rule, vickers mg -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPulley

Pulleys date back to Ancient Egypt circa 1800BC. it is a simple machine used to lift weights.Used by residents of the Kiewa Valley.Steel pulley. A pulley is a wheel on an axle or shaft enabling a taut cable or belt passing over the wheel to move and change direction, or transfer power between itself and a shaft.pulley, pulley machine -

Warrnambool RSL Sub Branch

Warrnambool RSL Sub BranchTrousers, Australian Defence Apparel, 2015

These trousers are part of a General Purpose Uniform issued by the Australian Airforce to Bernard Farley during service. This uniform type was developed in 2014 and replaced camouflage as the uniform worn during general base duties and in non-warlike environments. Although a camouflage pattern, this design is not intended for use as camouflage. This item has social significance, as an item of uniform worn by Warrnambool RSL community member and Secretary (2019), Bernard Farley during service with the Australian Airforce. The item is a representative example of current Airforce General Purpose Uniform and is in excellent condition. As a set, the uniform has aesthetic significance in it’s design, incorporating GPU uniform design from the Army alongside the colours and motifs of the Australian Airforce. General Purpose Uniform (GPU) trousers in Airforce colours of blue and grey in camouflage pattern. Long pants with elasticised drawstring fastener at ankle and velcro adjustment fasteners at the waist. Pants take a straight leg style and bears several pockets: two thigh level pockets with zippered horizontal opening, two open hip pockets on the front, one open pocket on the reverse right hand side with blue plastic button fastener. Five large belt loops encircle the waist and there is a zippered fly, secured at the top with a blue plastic button.Label on interior front right of trousers reads: “A193/ADA/MADE IN AUSTRALIA/JUL 2015/ PO: CC2X91/NSN: 8415 66 161 4017/SIZE: 95 R/(broad arrow)/NAME:............/PM KEYS NO:............./75% COTTON 25% POLYESTER/WARM MACHINE WASH 40*C/RINSE WELL, WARM IRON/DO NOT IRON OVER HOOK AND PILE/DO NOT BLEACH/DO NOT STARCH/MAY BE TUMBLE DRY 40*C/DRYCLEANABLE (P)”camouflage, general purpose uniform, airforce, uniform, australian defence force -

Orbost & District Historical Society

Orbost & District Historical Societydress

This dress is from the estate of James Cameron who was one of the first Snowy River councillors for the Tambo Shire. He selected land at Lochiel in 1892. From 1902-1920 he was the Assembly member for East Gippsland.Long black silk dress with long sleeves. It is hand-made - machine stitched. There is black beading around the neck and collar. The belt is also beaded. There are small black buttons on the belt and sleeves. It has a black underskirt.costum -female cameron -

Merbein RSL Sub Branch

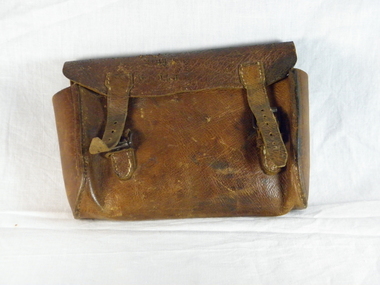

Merbein RSL Sub BranchSatchel Leather, (estimated); World-War-One

This Satchel has a wallet carried by Sgt Robert J Oscroft who served with the 12th lighthorse on Gallipoli,was wounded and returned to the 12th lighthorse about 12 months later.Brown leather satchel with 2 buckels metal, and 2 complimentry leather straps with 5 holes each. Attatched at back 2 leather straps for belt. On flap is some stamped inscription. Satchel is machine sewn.Inscription on satchel flap/made by metal punch/ illedgable/world war one, gallipoli, money, webbing, leather satchel, buckles, belt, army issue, robert james oscroft, 12th light horse -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeSewing machine

A domestic sewing machine used for dressmaking and handcrafts which was operated by hand.A hand sewing machine with a cast metal body and gold leaf decoration on the 'arm'. It stands on four 'legs/feet' with a kidney shaped base. The driving wheel is grooved for a belt. This has no handle. All cogs move.domestic, needlework, sewingmachine, stitching, dressmaking, needlecraft -

Federation University Historical Collection

Federation University Historical CollectionBook, New York Post, The School of Mine Quarterly: A Journal of Applied Science, 1889-1809

The School of Mines Quarterly was a jpournal of Applied Science from Columbia College, New York City.The Index to the School of Mines Quarterlu Volumes X1-XX (1900) and 32 green covered journals school of mines, new york, columbia college, schools of mines, columbia school of mines, witwatersrand goldfield, inter-continental railway, mine ropes, harbor improvememnts on the pacific coast, glycerine and artificial butter industry, transit factors for teh columbia college observatory, tables for the reducation of transit observations, ancienct methods for dividing and recoording time in japan, assay of tin, john strong newberry, standards of linnear measure, comparison of costs of electric lighting, huanchaca mine bolivia, el callao gold mine venezuela, john magnus adams, ores in saxony, hartz and rhenish prussia, hofmann apparatus, adjustment of trangulation, determination of carbonic acid in white lead, lower coals in western clearfield county pennsylvania, old telegraph mine ningham canon utah, mechanical preparation of ores, modern waterworks construction, curdling of milk, french regenerative gas furnace, irrication canals, peruvian salt mine, collection of metallurgic dust and fume, permeability of iron and steel, assay of silver, explosion in a zinc fume condenser, teaching archtectural history, liquid air, between the mine and the smelter, ballistic galvonometer, assay of telluride ores, analytical chemistry, theory and design of the masonry arch, silver pick mine wilson colorado, telegraphy and telephoney, mineralogy, morse code, michigan mining practices, titaniferous magnetites, paradox of the pantheon, rocks from wyoming, witwatersrand goldfields, gaseous sun, alternating current distribution, engineering tests on direct current electrical machinery, thomas egleston, ore dressing, frederick morgan watson, camp bird gold mine and mills, magnetic properties of iron and steel, morphology of organic compounds, antimony, structure of the starch molecule, cerrillos hills new mexico, geology, rossie lead veins, practical electrochemistry, lines of graphic statics, anistic acid by the ozidation of anniseed oil, bromate method for antimony, john krom rees, trust company of america building, helion lamp, frederick arthur goetze, mine surveying, pine wood oils, malleable cast iron, electrolytic treatment of galena, turpentine and pine oils, bluestone, ashokan dam bluestone, road resistances, oxy-gas blowtorch, mine dumps, segregation of steel ingots, masonry dam formulas, putnam county magnetic belts, gases, continuity of education, hydraulic diagrams, standardistion of potassium permanganate, sewerage discharge into sea water, modern waterworks, true column formula, slags from lead furnaces, missouri river, tempreture of gases, rocks, architectural history, modern dome, oil machine, undulations in railway tracks, irrigation engineering, cleps-tachymeters, electrical engineering, new york shales, fan pump, sucrose, isaac newton, french school of anstronomers, electrolytic polarization, benjamin bowden lawrence, diamond drilling, new york ciy water front, engineering profession ethics -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Early 20th century

Ward Brothers (George and Samuel) registered a company (Australian Sewing Machines Limited Pty Ltd) with the head office address in Errol St, North Melbourne, and Prahan. The earliest newspaper advertisement for this company was in 1897. Around this time the Ward Brothers first imported sewing machines from England and Wertheim placed their decal on them and mounted them in their own Australian made cabinets. David Ward later imported machines from Beisolt & Locke in Germany and registered name A.N.A. (All Native Australian), his shop was in Collingwood Melbourne. Some of these machines had Ward Brothers decals on them as well. The three brothers sold under the same name as Ward Brothers. The early Ward Brothers logo had a map of Australia with a picture of all three brothers on it. In 1911 all three of the Ward Brothers decided to share a stall in the yearly Melbourne exhibition. The A.N.A was the machine that got rave reviews. It was at this time that the Australian Sewing Machine Company Pty Ltd decided to add the A.N.A logo to their logo to cash in on the new found celebrity status that the A.N.A has gained. To cut a long story short. David Ward took his brothers to court to prevent this from happening. This was a long drawn out affair that took quite a few years. The settlement was decided out of court and nothing was disclosed of the deal that was made. David seemed to have left the scene, then the remaining Ward Brothers and A.N.A. combined and then became “Wardana”. There are many Ward Brothers sewing machines in displays, they originated from Japan, England, America, and Germany. It seems that where ever they got the best deal for sewing machines or parts is the direction they went. This is where the Bendigo sewing machine company came into the picture. All imported sewing machines into Australia drew a government tax. Bendigo Cording's Traction Company was given proposed two-pound tariff protection that gave the company a significant price advantage for its machines. As a result, the Ward Brothers purchased a huge number of Bendigo shares to get cheaper machines for their sewing machine cabinets. Ward Brothers then placed one of their company officials on the Board of “Bendigo Sewing Machines Limited” and the rest is history. Ward Brothers had shops Australian wide and in most of the major country towns. History for “Bendigo Sewing Machines Limited” Cordings Traction Company owners (H. Keck MLC, W. Wallace, and W. Ewing) operated their business out of the former W. Webb & Co. building in Queen St. Bendigo. Around 1923-1924 they decided to switch from traction engines to manufacturing sewing machines. The actual date is not known but that year's financial report made note of both Cordings and Bendigo Sewing Machines Limited. The switch was made with the government of the day agreeing to a tariff of two pounds per head for every machine head made completely in Australia. The change from traction engines to sewing machines went well. Government representatives visited the factory in Bendigo to inspect and ensure that the sewing machines were Australian made as a result they agreed on granting the two-pound tariff to the company. After the first 12 months, they built 30, the following 12 months the company had produced 1500 machines probably due to the involvement of the Ward brothers. However, the government proposed a new condition to the tariff agreement which was that the company must produce 20% of Australia's requirements for sewing machines. In 1924 after having had produced 1500 machines resulting in reaching their financial limit for tariff support. According to the government, the requirement was 15,000 machines for the next year had to be produced to qualify for the tariff. The company had already reached its production limit and unfortunately folded. There were several attempts to regain government assistance to save this new industry but it was to no avail. Even a promise to open another factory in Sydney was offered but unfortunately wasn't accepted. An item fabricated in Australia from a majority of imported parts from either Germany, America or England giving a snapshot into the early manufacturing industries that were operating at the time of Federation. Sewing machine, treadle, in timber cabinet. Branded Ward Bros, A.N.A., Australian Sewing Machine Coy. Decorative carved timber cabinet, hinged, fold-out laminated timber top and five drawers; two small on each side with handles and one long, shallow, between side drawers without handle. Thread is on bobbin in a rocket shuttle (both in good condition) plus spare empty shuttle (rusty). Brass ‘Half Yard’ ruler inlaid across front, measuring scale in inches and centimetres. Two metal shuttle cover plates (or throat plate / slide plate); front one is impressed with a gauge for needle and thread. Gold trim and decals on flatbed and machine front and back, serial number under shuttle cover, brand on decals and on round metal plate on back of machine. Front right of machine has a bobbin winder. Treadle belt shows signs of wear and laminate on timber machine cover is peeling slightly.Decal coat of arms on right front of machine: kangaroo on left, man with broad-brim hat, holding pick-axe on right, in centre, top “SEWING MACHINE / THE / A. N. A.” then below it, the rising sun, then below that is state of Victoria shield with the Southern Cross constellation. Wheat sheaves around edge on left and flowering plant on right. Gold ribbon banner at bottom with script “WARD BROS.“ Decal of map of Australia on flatbed of machine. States and capital cities are marked and named (no northern territory), portrait of two men. In centre of map are interwoven letters “A. N. A.” and written in script “WARD BROS.” Decal across front of machine body has large, decorated gold lettering “A. N. A.” Decal across the top of machine “THE AUSTRALIAN SEWING MACHINE COY. PTY. Ltd.” Steel shuttle cover at front has an impressed gage listing cotton and needle sizes and number of stitches. Brass disc on back of machine “A. N. A.” in centre. Brass ruler across front of machine has carved or pressed words in the timber. In centre “INCHES” above ruler and “CENTIMETRES” below ruler, and on right above ruler is “HALF YARD” Decal across back of machine’s body “A.N. A. / MADE IN U.S.A.” Stamped into metal under shuttle cover is “219415” (2 and 5 are partially there, first 1 could instead be a 7) flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ward bros., australian sewing machine co., a.n.a., treadle sewing machine, rocket shuttle sewing machine, home industry, clothing, wardana, australian sewing machine company, all native australian, dressmaking, clothing manufacturer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, Champion Blower & Forge Co

Bench drill belt driven with stand. Pat no 767.282.Aug.9.1804. Champion Blower & Forge Co USA. Painted red and green. Machine number No.201. large bench type. Circa 1900flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bench drill, champion blower & forge co -

Federation University Historical Collection

Federation University Historical CollectionCostume, Professional, Ballarat College of Advanced Education Nurses Uniform, 1980s

This uniform would have been worn by the students of the Ballarat College of Advanced Education, School of Nursing. The colour of the uniform was changed at the request of trained staff in white.This apricot princess style dress with a central front zipper and side pockets has a collar and short sleeves. The back has a yoke with side pleats and a half belt between the seams. There is machine embroidery on the collar and sleeves. There is a blue logo printed on the left breast. Original sales tag attaches to sleevePrinted in blue - Ballarat C.A.E. Nursingnursing, university of ballarat, ballarat college of advanced education nursing, nurse uniform, textiles, costume, apron -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - NEW MOON/STH: NEW MOON MINE

Sepia copy ( photocopy ) machinery, wheels, driving belts, iron hooped wooden barrels on bench. 6 adult males in background, 1 adult male in foreground. 'New Moon or Sth. New Moon' J. Lerk. On back 'cannot identify' stamp mark 'Bendigo Branch in circle. On the front ' View showing head of stamping machine 'organization, business, new moon mine -

Bendigo Historical Society Inc.

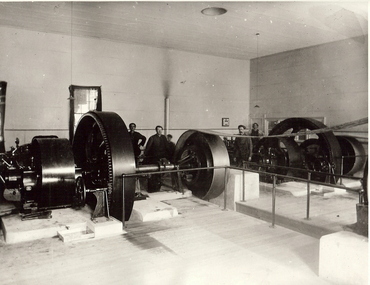

Bendigo Historical Society Inc.Photograph - MACHINERY INCLUDING LARGE GEARED WHEELS, c.1900

Black and white photograph. Machinery consisting of large gear wheels, driving wheels with belts in wooden board lined room. Five males included. Rails along and across part of floor at waist height (safety?) Two sets of similar gear. Electric motors. Rubber belts driving machinery out of picture. Building clean - new? Electric lights and switches.topic, objects, machine, machinery, workers, males -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - LADIES STRIPED''SHIRT MAKER'' LONG SLEEVED DRESS, 1950's

Clothing. A ''shirt-maker'' styled ladies long-sleeved dress, with 4 mm, red/navy striped fabric. The ''straight-through'' dress has a tie-belt, 2cm wide if desired. Long 3/4 set-in sleeves are gathered into a ''turn-back'' cuff 6.5 cms wide, and fastened by two x 1.5 cm covered buttons,and two false stitched button holes. Five covered buttons and machine-stitched burtton holes in the front, from below the revere collar to below the waist.costume, female, ladies shirtmaker dress -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - HARRY BIGGS COLLECTION: CHAFF CUTTER

... long flat belt. Behind the machine is a large pile of hay... cutter?, threshing machine? Via a very long flat belt. Behind ...Two photographs (proofs 64 and 65) No. 64, A traction Engine driving a chaff cutter?, threshing machine? Via a very long flat belt. Behind the machine is a large pile of hay with several men standing on the heap. To the right of the machine there is another group of men and bags of grain and several bag trucks are visible. Under this photo in very faded writing is: Threshing, Chaff Cutter, Chaff Factory Collingwood, Mrs. J. Collins. 65. A working Traction Engine, cutting or threshing, there are groups of men standing on a pile of hay and also near the machine. A sign on the roof of the machine reads 'Marshalls Gainsborough'topic, farming, threshing, chaff cutter, thresher, chaff factory collingwood, mrs. j collins, marshalls, gainsborough -

Bendigo Historical Society Inc.

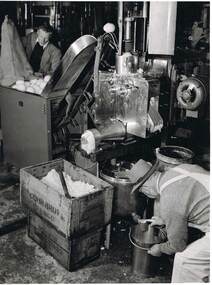

Bendigo Historical Society Inc.Photograph - COHN BROTHERS COLLECTION: JUICING MACHINE

... . The fruit travels up a conveyor belt and into the machine where... & aerated water manufacturers juicing machine Photograph. Cohn Bros ...Photograph. Cohn Bros. Collection. Black & white photo of a juicing machine. One man is tipping a bag of fruit into the hopper. Another man is emptying the juice into a bucket. The fruit travels up a conveyor belt and into the machine where it is juiced and the pulp comes out a side chute into a box. ML45/2organization, business, cohn bros, cohn bros. collection, brewers, cordial & aerated water manufacturers, juicing machine -

Puffing Billy Railway

Puffing Billy RailwayThe Quasi Arc Co Ltd Generator - Flat Belt Driven D.C, 1900s

QUASLARC Generator Built by the Quasi-Arc Co. Ltd. Victoria London SW.1, This generator is believed to have been used for welding purposes. The generator is driven by a belt from a nearby steam plant. The quasi-arc co ltd 6 kw. d.c generator 60/30 volts 0/200 amps 1200 rpm comp cont rating No 4696 Historic - Industrial Generator Large casting with a drive pulley on one end, cast aluminum covers, bronze makers plaque. The quasi-arc co ltd 15,grasyenor ????ens. Victoria,London,S.W.1 This machine is designed for use with ????? Arc electrodes 6 kw. d.c generator 60/30 volts 0/200 amps 1200 rpm comp cont rating No 4696puffing billy, generator, welding, quasi - arc -

Puffing Billy Railway

Puffing Billy RailwayNew Record Saw Bench, circa 1930's

Saw Bench - New Record Saw Bench Timber framed with steel wheels, belt driven saw blade powered by a Rosbery internal combustion engine. The Rosebery Engine No C28437 R.P.M 800 H.P. 6 Manufactured By Westinghouse Rosebery Pty.Ltd. Sydney Rosebery Engine Works Ltd began as the engine and pump manufacturing division of Buzacott & Company, and in 1923 became an incorporated company. In 1935, Westinghouse gave Rosebery Engine Works the right to manufacture and sell nearly all Westinghouse products. The name of the company then changed to Westinghouse Rosebery Ltd From the late nineteenth century, petrol engines gradually supplanted steam engines for running a wide range of machines, and in turn petrol engines were largely supplanted by electric motors. The Champion was a successful small petrol engine made by the large Sydney company, Westinghouse Rosebery, based on the American-designed Fuller and Johnson engine. With hopper cooling and a fuel tank between the skids, and weighing only 240 pounds (109 kg), it was easy to mount on wheeled transport, making the Champion a self-contained mobile source of power. Engines of this type were used in rural areas for driving chaff cutters, small saw benches, pumps and orchard sprayers. These engines were also commonly used in both rural and urban areas for powering concrete mixers. Both Westinghouse Rosebery in NSW and Toowoomba Foundry in Queensland made these engines in large quantities, beginning in the 1920s when tariff protection made local manufacturing viable. The production of small petrol engines continued in Australia until the 1970s, when reduced tariff protection led to increased competition from cheaper imported engines. Historic - Industrial Timber working - belt driven saw blade powered by a Rosbery internal combustion engine. Timber framed with steel wheels, belt driven saw blade powered by a Rosbery internal combustion engine. The Rosebery Engine No c28437 R.P.M 800 H.P. 6 Manufactured By Westinghouse Rosebery Pty.ltd. Sydneysaw bench, puffing billy, new record, internal combustioin, westinghouse rosebery pty.ltd., rosebery pty, internal combustion engine. -

Puffing Billy Railway

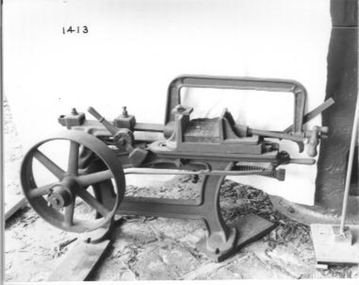

Puffing Billy RailwayKBW Belt Driven Slotting Machine

... KBW Belt Driven Slotting Machine... - Industrial - Slotting Machine belt driven puffing billy slotter kbw ...KBW Slotting MachineHistoric - Industrial - Slotting MachineLarge metal KBW Slotting Machine KBWbelt driven, puffing billy, slotter, kbw, slotting machine -

National Wool Museum

National Wool MuseumDrive Belt

... " Knitting Machine. Knitting Jepson Mr Keith Used as drive belt ...Used as drive belt for the Wertheim "Preciosa" Knitting Machine.Used as drive belt for the Wertheim "Preciosa" Knitting Machine.knitting, jepson, mr keith -

National Wool Museum

National Wool MuseumDrive Belt

... " Knitting Machine. Knitting Jepson Mr Keith Used as drive belt ...Used as drive belt for the Wertheim "Preciosa" Knitting Machine.Used as drive belt for the Wertheim "Preciosa" Knitting Machine.knitting, jepson, mr keith -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumGrain Grister, 1925

grinding grainWooden delivery /storage box on top of metal Grister with three cogs and flywheel [approx. 30 cm diameter] and metal grinding cylinders [rollers] with horizontal grooved lines all around .This is bolted to a wooden stand [painted green] which has a wooden box to receive the crushed grain Rollers are adjustable .Machine driven by flat leather belt on a pulley from a small stationary engine Metal plaque attached to top of delivery box. J Buncle Parkside Ironworks North Melbournegrain, grister, farming, machinery -

National Wool Museum

National Wool MuseumPicker

... . There are two large gear cogs on the rubber belt side of the machine.... There are two large gear cogs on the rubber belt side of the machine ...Wool picking machine designed to separate locks of wool before it is carded and spun. The picker opens the wool’s locks which makes it easier to send the fleece through a carding machine. It does this by teasing the fibres (which can also be done by hand just by pulling the lock structure apart), but a picker does this in bulk and much quicker than what can be done by hand. It is possible to spin fibres directly after the picking stage; however, it is usually more desirable to card and blend them with other fibres. Typically, at a textile mill, a picking machine can separate enough lengths of fibre for a full day’s work after just a single hour. It will also help to remove any vegetation matter or other any unwanted elements that may be present in the wool. The quality of the casting on this machine suggest that it was made locally, either in Australia or New Zealand. Mike Leggett, the donor of the machine, acquired it from New Zealand where the seller said it had been used by his father to pick wool to make hand stuffed horse saddles. Mike attempted to used it a couple of times to pick alpaca hair, but the speed of the attached motor caused damage to the fibres. The motor is thought to be an added attachment, sometime around the 1960s judging by its age, while the machine itself is thought to be dated around the 1920s. The machine works by inserting wool through the rollers. Initially there was a conveyor belt feeder system which was powered by the handle on the side. This conveyor belt has been removed however, most likely due to age and deterioration. Wool is now fed through the initial teeth and is met by a spiked rotating drum which works to separate the fibres. The separated fibres would then complete a loop of the drum before being dispatched somewhere below, around where the motor presently sits, at a rapid rate of speed. Typically this wool will be collected in a closet or large catchment area, as can be seen from the 8:47 minute marker in the linked video (link - https://www.youtube.com/watch?v=kMjx-t3tH3A). It is not apparent how the wool is collected with this machine. Red and green machine with four green legs currently attached to a wooden pallet with wheels for easy movement. The green legs lead up to a red central circular barrel from which many attachments are present. Also present on the wooden pallet is a small black motor which is attached by a rubber belt to the central drum inside the red barrel. The belt spins the wooden drum via a dark red circular plate attached to the side of the drum. On the other side of the red barrel, a green handle extends for turning the picker’s conveyor belt feeder system. Two green walls extend forward from the central red barrel, guarding either side of where the conveyor belt would have been. At the start of these walls is a wooden cylinder, which the conveyor belt would have wrapped around, followed by two interlocking gears which rotate and accept the fed wool. The red roof extends over the central cylinder from here, securing the wool inside and protecting hands from the heavily spiked internal wooden cylinder which rotates and separates (picks) the wool. Extending over the top of this red roof is a green handle which reaches to the back of the machine (not pictured). Here it accepts a weight to ensure pressure is always present for the initial feeder interlocked gear teeth. There are two large gear cogs on the rubber belt side of the machine and 3 small gear cogs on the handle side of the machine, all coloured green. A green handle is also present at the rear of the machine, below the location from which the weight is hanging. A power cable extends from the motor and there are two adjustable metal rods on the top of the machine, the purpose of these rods is presently unknown. Black texter. On top of drum. Wording: HG3707 Wording. Imprint: BRACEWIND BLYN On motor. Wording AEIwool picking, textile manufacturing, wool processing -

National Wool Museum

National Wool MuseumTool - Finishing machine

Variable speed cloth puller, used for tightening and smoothing blanket edges, prior to them being sewn or bound. Used at Collins Bros Mill.Textile finishing machine. Horizontal, made from grey steel with a small encased gear box and two attached rollers. Separate belt drive and nine other rollers. Enclosed in original brown cardboard box, used for shipping.SUISIE / VARIABLE SPEED / VERSATILE CLOTH PULLERtextile machinery, collins bros mill pty ltd, blankets -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Saw

... with overhead drive shaft and a section of canvas drive belt. Machine ...Used in an orchard workshop to cut metal.Belt driven power hacksaw or metal cutting saw with overhead drive shaft and a section of canvas drive belt.'Drawcut' make, on bow and 'adjust tension' etc on adjuster.trades, metalworking -

Dandenong/Cranbourne RSL Sub Branch

Dandenong/Cranbourne RSL Sub BranchWeapon - Belt of 7.62 ammunition

... ) for M60 Machine Gun Weapon Belt of 7.62 ammunition ...Link of 7.62mm link bullets (27) for M60 Machine GunMF,84,F4