Showing 183 items

matching machine tool

-

Bendigo Historical Society Inc.

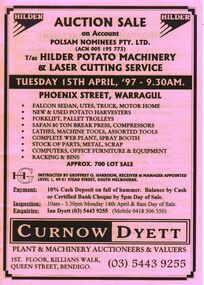

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - POLSAM NOMINEES PTY LTD

... ton press, compressors, lathes, machine tools, assorted tools..., pallet trolleys,80 ton press, compressors, lathes, machine tools ...Pink paper catalogue with black printing for a sale on account of Polsam Nominees Pty. Ltd. T/as Hilder Potato Machinery & Laser Cutting Service on 15th April '97 at Warragul. For sale were vehicles, potato harvesters, forklift, pallet trolleys,80 ton press, compressors, lathes, machine tools, assorted tools, complete web plant, spray booth, parts, metal, scrap, computers, office furniture & equipment, racking and bins. Announcement printed in the front of catalogue mentions that J. H. Curnow & Son Pty. Ltd. Are combining their name with the Dyett family and trading as Curnow Dyett, Real Estate Agents, Auctioneers and Qualified Valuers.business, auctioneers, curnow dyett, ian dyett collection - auction catalogue - polsam nominees pty ltd, hilder potato machinery & laser cutting service, geoffrey o harrison, ian dyett, curnow dyett, j h curnow & son pty ltd, occupational health and safety act 1985, noel dyett, ian dyett, fred dyett -

Bendigo Historical Society Inc.

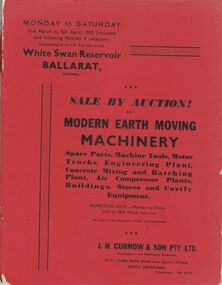

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - WHITE SWAN RESERVOIR

... , Machine Tools, Motor Trucks, Engineering Plant, Concrete Mixing..., Machine Tools, Motor Trucks, Engineering Plant, Concrete Mixing ...Three auction catalogues, two with red covers and the third is missing the cover. Sale of Earth Moving Machinery. Spare Parts, Machine Tools, Motor Trucks, Engineering Plant, Concrete Mixing and Batching Plant, Air Compressor Plants, Buildings, Stores and Costly Equipment on 31st March to 5th April 1952 (inclusive) at the White Swan Reservoir, Ballarat, Victoria. J. H. Curnow & Son Pty. Ltd. Were the auctioneers. Included in the catalogue is a Locality Plan showing location of lot areas - access roads, etc. Page 4 has a black and white photo showing Super c Tournapull, Lot 63 and Tractor hauling 12-15 cub. Yd. capacity scoop. Page 9 photo is Lot 209, a Sheep's Foot Roller, Page 12 photo is Lots 258, 259 & 260 - Class 1 tractor hauling two 12-15 c yd Te Tourneau Scrapers, and page 68 has a black & white photo of Lot 2377, the Concrete Batching Plant.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - white swan reservoir, the ballarat water commissioners, j h curnow & son pty ltd, prahran telegraph printing co -

Bendigo Historical Society Inc.

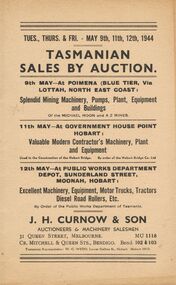

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - TASMANIAN MINING AND CONTRACTOR'S AUCTION

... of Machine Tools and Gauges under Regulation 59 of the National... Department Hobart J H Curnow & Son W C Wedd Director of Machine Tools ...Beige covered catalogue of Tasmanian Sales by Auction held over three days. On Tuesday 9th May 1944 was an auction of Mining machinery,pumps, plant, equipment and buildings at the Michael Moon Mine, Poimena (Blue Tier) and at the AZ Mine, Poimena (Blue Tier). Thursday 11th May 1944 was the sale of Contractor's Machinery, plant and equipment used in the Construction of the Hobart Bridge by order of the Hobart Bridge Co. Ltd. And Friday 12th May 1944 was the auction of machinery, equipment, motor vehicles etc. at the Public Works Depot at Moonah, Hobart. J. H. Curnow & Son were the Auctioneers. Booklet contains description of some of the machinery, Special Notice regarding travelling and freight, Conditions of Sale and an Auctioneer's Notice mentioning the sale is being conducted by permission of the Director of Machine Tools and Gauges under Regulation 59 of the National Security (General) Regulations. Principals only are allowed to bid and buy unless special permission is granted by DMT & G for some person to act on their behalf, and that person must be an employee of the Firm.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - tasmanian mining and contractor's auction, michael moon mine, a z mines, hobart bridge co ltd, public works department hobart, j h curnow & son, w c wedd, director of machine tools and gauges, national security (general) regulations, the prahran telegraph printing co, c j curnow, h j lowe, f c dyett, j l jamieson & co -

Bendigo Historical Society Inc.

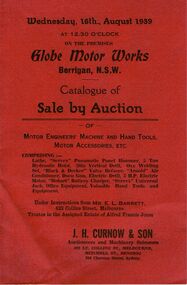

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - GLOBE MOTOR WORKS

... ' Machine and Hand Tools, Motor Accessories. J. H. Curnow & Son... included Motor Engineers' Machine and Hand Tools, Motor Accessories ...Two red covered auction catalogues for a sale on 16th August 1939 at Globe Motor Works, Berrigan, N.S.W. Under Instructions from Mr. E.L. Barrett, Trustee in the Assigned Estate of Alfred Francis Jones. Lots sold included Motor Engineers' Machine and Hand Tools, Motor Accessories. J. H. Curnow & Son were the auctioneers.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - globe motor works, mr e l barrett, alfred francis jones, j h curnow & son, the cambridge press -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumSewing Machine and Case, Pfaff sewing machine

... containing various tools. Sewing machine is a Pfaff attached... tools. Sewing machine is a Pfaff attached to a wooden board ...Wooden case or cover for hand operated sewing machine. Has silver metal carrying handle, metal locking key with plastic tie attached and removable accessories drawer incorporated in case containing various tools. Sewing machine is a Pfaff attached to a wooden board.Martha Weller (in case) Weller (on accessories box)pfaff sewing machine, portable sewing machines -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Tilting Saw Bench, W F & John Barnes, 1874 to 1880

... machinery, and custom-built machinery, machine tools, electrical... machinery, and custom-built machinery, machine tools, electrical ...he subject item is a pedal-powered rip saw with a tilting table made in the USA by W.F. & John Barnes Co. of Rockford, Illinois, between 1874 and 1890. The saw's blade moves rapidly in a circular motion and is driven by a pedal that spins a heavy flywheel with a leather belt attached to a gear drive that in turn drives the circular saw blade. The operator holds a wood workpiece on the table and moves it forward so the blade cuts it to the desired width and length. Company History: WF & John Barnes Co. was established in 1869, by making a formal partnership between William F. Barnes and John Barnes in 1872, and then incorporating in 1884. This company was an early manufacturer of pedal-powered equipment. By 1881 they were also making powered machinery such as lathes and pedestal drills. Many companies were making lightweight foot-powered equipment, but Barnes and the Seneca Falls Co. were the only ones to also make professional-grade workshop machines. From the beginning of their existence, they focused on pedal-powered machinery and specialised in making scroll saws. By 1937 the company focus had completely shifted to automotive assembly machinery, and custom-built machinery, machine tools, electrical, hydraulic, and mechanical controls and systems, including nuclear hardware. their production of foot-powered machinery had ceased. In the intervening years, they have got out of manufacturing completely. After a series of ownership changes, their equipment parts and stock were purchased in 1998 by LeBlond Ltd. of Amelia, Ohio. An item that although incomplete gives a snapshot into the manufacture and use of early woodworking machinery before the introduction of electricity or electric motors to power machines.A Treadle powered tilting table saw benchWF & J Barnes, Rockford Ill USA flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Booklet - Catalogue of Tools and Machines, Hand Tool Preservations Association of Australia Inc

... Catalogue of Tools and Machines for Engineers...Tools & machines J. Buck Engineers & woodworkers J. Buck 56 ...Catalogue of Tools and Machines for Engineers and Woodworkers. Book describes tools, with components and measurements for various parts. This catalogue is a reprint by HTPAA (Hand Tool Preservation Association of Australia Inc) from the original catalogue produced by J. Buck 56 Holborn Viaduct E. C. which was established 1750.J. Buck 56 Holborn Viaduct E. C. tools & machines, j. buck, engineers & woodworkers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pump, circa 1930's - 1940's

... , manufacturing Macson lathes and made machine tools that previously had... Macson lathes and made machine tools that previously had ...This pump is an Ajax Type L2 Series A model, made and sold by McPherson’s Pty Ltd of Melbourne circa 1930’s to 1940’s, is a mechanical, hand operated, constant flow pressure pump. It would have been used to pump fluids from one area to another, for example from a dam to a tank or used as a bilge pump on a small vessel, mounted on the vessel’s bulkhead, floor or deck. This type of hand pump is sometimes called a ‘Reciprocating Suction Pump’. It has a mechanical pumping action of the lever moves the piston inside the pump up and down. The water is lifted from below the pump through the inlet pipe and into the pump’s cylinder. This action causes the lower valve to close and the piston’s valve opens and the pressure within the pump forces the water out of the pump through the exit pipe. The limitation of this type of pump is that it can only raise the water a maximum of about 7 metres from beneath the ground and yields 24-26 Litres per minute. This type of pump could be used for many purposes such as pumping water or fuel. McPherson’s 1940’s advertisement proclaims “For all jobs on the land – irrigation, spraying, tank, plumbing, fire-fighting – there’s a suitable “Ajax” pump. Send us the details of you pumping problem. Our Expert’s advice will help you choose the right pump – the one that will give you most years of PROFITABLE PUMPING.” (The Australasian (Melbourne) Sat. 26th October 1940.) McPherson’s Pty Ltd, the manufacturer, advertised a similar pump to this one in The Australasian (Melbourne) in 1936, calling it the Ajax Double Acting Hand Pump. In 1942 another advertisement advised that a representative for a fire-fighting equipment supplier was visiting the western district of Victoria. The company could now supply double-action two-spray Ajax pumps at lower prices than similar pumps the district had recently purchased from Adelaide. McPHERSON’S FOUNDER and COMPANY TIMELINE 1860 – Thomas McPherson, a Scottish immigrant (c. 1853 ), founded McPherson’s in Melbourne, supplying pig iron (lead ingots imported as ballast in ships) to local manufacturers. 1882 – Thomas McPherson established a warehouse in Collins St Melbourne and included tools, steam fittings and machinery in his wares. The business expanded to include steam saw mills and became known as Thomas McPherson and Sons (William Murray and Edward). 1888 – Thomas passed away and his sons inherited the business. In 1896 William Murray became the sole proprietor after his brother Edward’s death. 1900 – The firm expanded, establishing Acme Bolt Company to manufacture nuts and bolts. 1912 – McPhersons Pty Ltd established a machinery warehouse and showroom in 554-556 Collins St Melbourne. McPherson’s went on to establish branches in Sydney (1911), Adelaide (1921) and Perth (1930) 1917 - McPherson’s supplied ‘dog spikes’ for the transcontinental railway, running from Eastern to Western Australia. 1918 – A tool works set up in Kensington, Melbourne, manufacturing Macson lathes and made machine tools that previously had to be imported. 1924 – The Bolt Works was transferred to a new building in Melbourne. McPhersons began making pumps. 1929 – McPherson retired. His son (Sir) William Edward McPherson (known as ‘WE’), was born in Hawthorne, Melbourne, in 1898. After his education he began work in his father’s Melbourne hardware and machinery business He took over as governing director when his father retired. 1929-1932 – McPherson’s supplied thousands of tons of rivets from its Richmond (Melbourne) Bolt Works for the construction of the Sydney Harbour Bridge. 1936 – McPherson’s Pty Ltd is advertising Ajax Pumps in newspapers 1934 – McPhersons purchased the property adjoining the warehouse in Collins Street, and during 1935-1936 built a new office and showrooms on the site of 546-445 Collins St. 1939 - McPherson’s acquired the Tool Equipment Co. Pty. Ltd and Associated Machine Tools Australia Pty Ltd was formed to separate McPherson’s machine-tool manufacturing and merchandising interests. 1939 – Ajax Pump Works, a foundry and pump manufacturing plant, was established in Tottenham, Melbourne, and the Ajax Bolt and Rivet Co Pty Ltd began manufacturing in New Zealand. 1944 - McPherson’s became a public company, McPherson’s Ltd. 1948 - The Ajax Pump Foundry opened at Kyneton, Victoria and in the post war years it grew to became a large manufacturer. 1980’s – Ajax Pumps brochure lists the address as 6 Buckhurst St, South Melbourne, Vic 3205 with the Telephone number 03 669 3588 1988 - Ajax Pumps acquired the Forrers Company, which was established in 1921. Manufacturing in Ipswich, Queensland, specialising in submersible sewage pumps. 1991 – KSB Ajax was formed, bringing together the companies KSB and Ajax Pumps 1993 – Manufacturing was moved to state-of-the-art premises in Tottenham, Victoria 2001 - The Forrers facility was moved to Tottenham. 2007 - Company name KSB Ajax Pumps was changed to KSB Australia Pty Ltd. 2009 - KSB Australia opened a branch in Townsville, Queensland. 2011 - KSB Australia moved to its dedicated Water and Waste Water Competence Centre in Bundamba, Queensland. DISPLAY OF THIS AJAX PUMP This pump was installed at Flagstaff Hill Maritime Village as part of a working display in the village by the Friends of Flagstaff Hill, in acknowledgement of the dedicated involvement of one of its long serving members, Bob Crossman. The display was officially opened 31st March 2018 and incorporates a restored Furphy Tank and Water Pipe Stand. The pump is used to draw water from the lake, through the water stand pipe and into the reconditioned Furphy Tank. This Ajax pump made by McPherson’s Pty Ltd is significant for its association with McPherson’s, a prominent manufacturer of hardware in Victoria. McPherson’s is famous for supplying ‘dog-spikes’ for the transcontinental railway (eastern to western Australia, 1917) and rivets for the Sydney Harbour Bridge (1929-1932). The Ajax pump is also of significance because of its association with McPherson’s Governing Director (Sir) William McPherson, former premier and treasurer in Victoria 1928-1929. The former McPherson’s Pty Ltd building in Collins Street Melbourne is now on the Victorian Heritage Register VHR H0942 This pump is representative of mechanical pumps popular in the early to mid-1900’s and still used today. Hand operated pressure pump, double acting. Cast metal case, painted red, with steel hose attachments and long metal lever. Pump is bolted to wooden plank. Model of pump is AJAX, Type L2, Series A pump. Embossed on lower section of pump "L2 - 10", "L2 - -1", "AJAX" “(?) –2-1” Embossed on lower handle “3-7” “L – 4” Embossed on attached plate “FOR SPARE PARTS / TYPE L2 / SERIES A / PUMP ASSEMBLED BY T R” Manufactured by McPherson’s Pty Ltd of Melbourne circa 1930’s - 1940’s.flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ajax pump works tottenham melbourne, ajax pump factory kyneton, william edward mcpherson, thomas mcpherson of melbourne, mcpherson’s pty ltd melbourne, acme bolt company, tool equipment co. pty. ltd, associated machine tools australia pty ltd, ajax bolt and rivet co. pty ltd new zealand, forrers company ipswich queensland, ksb ajax pumps, ksb australia pty ltd, macson lathes, tool manufacturer early to mid- 20th century, ajax double acting hand pump, ajax type l2 series a pump, qisjax pumps, water pump 1940’s, fuel pump 1940’s, hand operated constant flow pressure pump, reciprocating suction pump, agricultural hand pump, plumber’s hand pump, portable hand pump -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Treadle Scroll Saw, Hobbies Ltd, Manufactured by Hobbies in England from 1928- 1965

... , Treadle Machines, Model Maker's Tool Kits. The company also... Outfits, Tools, Treadle Machines, Model Maker's Tool Kits ...Since 1895, Hobbies Ltd have been supplying model makers and enthusiasts throughout the world with a wide range of quality model kits, accessories, tools, components and handbooks. The Hobbies Company began life in Dereham, Norfolk in 1881 with a London Office opened later (1922) at 65 New Oxford Street, WC1. In 1895 Hobbies began supplying model makers with their products and in 1897 were incorporated into a Public company. In 1922 at a British Industries Fair the company had a stand advertising their products as "The All-British Firm with a World reputation". Fretwork Outfits. Fretwork Machines. Carpentry Outfits. Strip work Outfits. Also manufactures of Fretwork Tools and Benches, Wood, Circular Saws, Lathes, Picture Framing Outfits, Tools, etc. In 1947 the company had expanded and was still making tools and materials for the amateur craftsman in wood. They had acquired a reputation as manufacturers of quality Fretwork Outfits, Tools, Treadle Machines, Model Maker's Tool Kits. The company also publishers of ‘Hobbies Weekly magazine’ and also sold plans for fretwork, model making and wooden toys. In 1961 they were still manufacturers and retailers of craft tools and materials, timber merchants, light engineers and Government contractors with around 500 employees. A vintage tool made for hobbyists and distributed throughout the world by a British company that is still in existence today. The item is significant as it catalogues the manufactures history at a specific time in the company's development.Foot operated treadle Fret saw called "GEM" subject item is a short saw , the stand in the background is the base for a Delta Q3 model scroll saw. Gem inscription cast into the cast iron frameworkflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, saw, treadle saw, fret saw, pedal saw, the gem, tool, hobbies ltd, treadle, foot operated -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

... an agreement was signed with Hindustan Machine Tools... with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers ...The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1900's

... as importing “Limit company” Swiss watches and precision machine tools... and precision machine tools for the watch and clock trade. By 1902 Hirst ...In August 1884, Alfred Hirst who had started his trade as a watch repairer and was described as a watchmaker extraordinaire established Hirst Brothers and Company, on Union Street in Oldham Manchester. He took his two stepbrothers into the business and the company was set up to produce timepieces and jewellery as well as importing “Limit company” Swiss watches and precision machine tools for the watch and clock trade. By 1902 Hirst Brothers. had become a limited company and was still growing, adding other businesses in Manchester in 1904 and at Birmingham in 1907. The quality of the clocks and watches was such that Alfred Hirst realised his greatest ambition in 1912 with a range of watches which carried the "Limit" trademark. These watch movements had originally been made in Switzerland and shipped to Hirst Bros. to be put into British made “Dennison” cases. This trade brought even more growth with additional sales offices opening in London and Glasgow. At the outbreak of the First World War in 1914 found them manufacturing aircraft parts including revolution counters and optical instruments. The firm had been tasked by the Ministry of Munitions to solve the problem of pilots dropping bombs by hand and as a result, they effectively created the first bomb rack. After the war, the company once again began to prosper and with the demand for their products increasing they looked to build a new purpose-built factory to manufacture their products. In 1917 they purchased a seven-acre field site at Tame Side Dobcross, the designing of the new factory was passed onto local architect AJ Howcroft. His brief for the design of the clockworks would have been prompted by Alfred Hirst who having visited modern factories in the United States was inspired by the latest factory designs providing as much daylight as possible during working hours. The factory was eventually completed in 1920, by the mid-1920s there were cheap clock imports from Germany and production turned to radio sets and other components as well as counter and gas meters for the "Parkinson and Cowan" company who was later to take over the business. In 1926 came the cotton crash and the District Bank who had loans with the company foreclosed on the Hirst loan. The company did survive and throughout the second World, War II were involved in munitions work at the factory as well as making instruments for various aircraft. In the 1950’s they were producing meters and high grade measuring equipment but by the 1970's the business had closed and the factory was demolished in the mid-1980 "s The item is a good example of the later use of an early mechanism “Fusee” that was originally invented around 1525 in Prague. This type of clock mechanism was replaced as watchmakers looked for mechanisms that could reduce the size of clocks and watches, it appears England was the only country to continue making clocks with a Fusee device until around 1900,s of which our clock is an example. The use of a Fusee movement eventually became obsolete in 1970,s. The item is significant for the collection as it is a clock with a movement that has long since been made obsolete. Fusee type gallery wall clock made by Tame Side with an 8-day mechanical fusee movement. The white enamel dial is a little crazed and some of the Roman Numeral numbers are fading due to over-cleaning. The movement has a hexagonal iron pendulum bob hooking onto a pendulum rod with a spring-wound anchor escapement.Only mark is stamped on the movement believed to be a production number "13490" and made in Tame Side. (If the clock had been made after 1912 it would have had a trade mark "Limit")flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, wall clock, fusee, gallery clock, alfred hirst, tame side -

Puffing Billy Railway

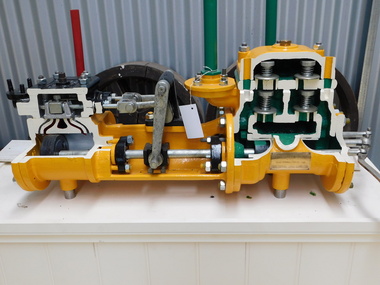

Puffing Billy RailwaySectioned Tangye Steam Operated Water Pump, 1900s

... , gas producers and machine tools in the late 19th and early..., gas producers and machine tools in the late 19th and early ...Sectioned steam pump so that the pump workings can be seen. Inscriptions & Markings: Tangye Birmingham, This steam pump was presented by the colonial gas Assn Ltd (brass plaque) The Colonial Gas Association was originally formed in London on 2 February 1888, as The Australasian Gas Association Limited. The primary objective of the company was to provide investment capital to help finance the construction and management of gasworks being established by the London engineering firm John Coates & Co in metropolitan cities and regional towns throughout Australia and New Zealand. By 1890, the Australasian Gas Association had acquired gasworks at Benalla, Shepparton, Wangaratta, Warragul, Maldon and Seymour, and had constructed a large gasworks at Box Hill to supply the eastern suburbs of Melbourne. In 1893, the company's name was changed to the Colonial Gas Association Limited. During the 1890s, the company acquired regional gasworks in Queensland, Western Australia and South Australia, followed by its first gasworks in New South Wales, in 1911. In 1914, the company consolidated its metropolitan supply area by purchasing the Oakleigh and Footscray gasworks. Further expansion occurred in the 1920s with the purchase of established gasworks at Williamstown, Frankston and Dandenong and the acquisition of ten further gas undertakings in Queensland and New South Wales, making the firm the fifth largest gas producer in Australia. info from The Colonial Gas Association Limited, circa 1893 https://collections.museumvictoria.com.au/items/1553322 Originally formed by the five Tangye brothers from Cornwall as James Tangye & Brothers in 1857, this Birmingham engineering firm grew to become one of the largest suppliers of jacks, pumps, steam and oil engines, hydraulic presses, gas producers and machine tools in the late 19th and early 20th centuries. The successful sideways launching of I.K. Brunel's 'Great Eastern' from the mud of the Thames in 1857 using Tangyes hydraulic jacks gave the firm much needed publicity and new orders flowed in. To finance expansion, George Price provided additional capital and the company name became Tangye Brothers & Price in 1859. A new factory known as the 'Cornwall Works' was built in Clement Street, Birmingham. In 1872, the firm became Tangye Brothers and in about 1879- 1880 began production of internal combustion stationary engines based on Horace Robinson's patents, later using the Otto four-stroke design for its Soho range of gas engines. Examples of the Soho engine were exhibited by the firm at the 1880 Melbourne International Exhibition. Petrol and oil engines were made from the 1890s onward, and by 1910 had developed into the Model B, BR and AA series engines. Tangyes supplied custom-built pumps and presses for particular applications, becoming a major exporter of engineering equipment. In 1884, Tangye Brothers opened a custom-built branch office, showroom and warehouse in Melbourne at Cornwall House in Collins Street West, advertising the full range of engineering products. These lantern slides images are taken from Tangyes product catalogues from the 1910-1925 period and are believed to have been used as sales promotional aids in Australia by the Tangye Brothers. info from https://collections.museumvictoria.com.au/articles/4670 Historic - Industrial Steam Operated Water Pump built by Tangye Bros and used by the Colonial Gas Company - Melbourne, Victoria, AustraliaSectioned steam pump so that the pump workings can be seen. Tangye Birmingham, This steam pump was presented by the colonial gas Assn Ltd (brass plaque)puffing billy, steam pump, sectioned, tangye bros -

Orbost & District Historical Society

Orbost & District Historical Societyhand drill

... of new drilling machines. These human-powered tools were a vast... of new drilling machines. These human-powered tools were a vast ...The invention of a hand drill is credited to Arthur James Arnot and William Blanch Brain of Melbourne, Australia who patented the electric drill in 1889. In 1895, the first portable handheld drill was created by brothers Wilhem & Carl Fein of Stuttgart, Germany. Hand-powered devices have been used for millennia. However, during the last quarter of the 19th century a radically improved generation of tools appeared. These tools took advantage of modern mass production machinery and processes (like interchangeable parts) and an increased availability in superior material (metal instead of wood). One of the outcomes included an array of new drilling machines. These human-powered tools were a vast improvement over earlier tools.This item is an example of a commonly used domestic tool - pre power tools.A Stanley hand drill with two wooden handles. The red wheel is painted metal. On red wheel - STANLEY ENGLANDwoodwork tool hand-drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Barometer, 1867

... . Their sole machine tool, when they commenced as a business.... Their sole machine tool, when they commenced as a business ...Langlands Company History: Langlands foundry was Melbourne's first foundry and iron shipbuilder established in 1842, only 8 years after the founding of the Victorian colony by two Scottish immigrants, Robert Langlands and Thomas Fulton, who had formed a partnership before emigrating (1813–1859). The business was known as the 'Langlands Foundry Co'. Henry Langlands (1794-1863), left Scotland in 1846 with his wife Christian, née Thoms, and five surviving children to join his brother Robert. By the time he arrived in early January of 1847 the partnership of Robert Langlands and Fulton had dissolved as Fulton had gone off to establish his own works. It was at this time that the two brothers took over ownership of Langlands foundry. Several years later Robert retired and Henry became sole the proprietor. The foundry was originally located on Flinders Lane between King and Spencer streets. Their sole machine tool, when they commenced as a business, was a small slide rest lathe turned by foot. In about 1865 they moved to the south side of the Yarra River, to the Yarra bank near the Spencer Street Bridge and then in about 1886 they moved to Grant Street, South Melbourne. The works employed as many as 350 workers manufacturing a wide range of marine, mining, civil engineering, railway and general manufacturing components including engines and boilers. The foundry prospered despite high wages and the lack of raw materials. It became known for high-quality products that competed successfully with any imported articles. By the time Henry retired, the foundry was one of the largest employers in Victoria and was responsible for casting the first bell and lamp-posts in the colony. The business was carried on by his sons after Henry's death. The company was responsible for fabricating the boiler for the first railway locomotive to operate in Australia, built-in 1854 by Robertson, Martin & Smith for the Melbourne and Hobson's Bay Railway Company. Also in the 1860s, they commenced manufacture of cast iron pipes for the Board of Works, which was then laying the first reticulated water supply system in Melbourne. Langlands was well known for its gold mining equipment, being the first company in Victoria to take up the manufacture of mining machinery, and it played an important role in equipping Victoria's and Australia's first mineral boom in the 1850s and 1860s. Langlands Foundry was an incubator for several engineers including Herbert Austin (1866–1941) who worked as a fitter at Langlands and went on to work on the Wolesely Shearing machine. He also founded the Austin Motor Company in 1905. Around the 1890s Langlands Foundry Co. declined and was bought up by the Austral Otis Co. in about 1893. History for Grimoldi: John Baptist Grimoldi was born in London UK. His Father was Domeneck Grimoldi, who was born in Amsterdam with an Italian Father and Dutch mother. Domeneck was also a scientific instrument maker. John B Grimoldi had served his apprenticeship to his older brother Henry Grimoldi in Brooke Street, Holburn, London and had emigrated from England to Australia to start his own meteorological and scientific instrument makers business at 81 Queens St Melbourne. He operated his business in 1862 until 1883 when it was brought by William Samuel and Charles Frederick, also well known scientific instrument makers who had emigrated to Melbourne in 1875. John Grimoldi became successful and made a number of high quality measuring instruments for the Meteorological Observatory in Melbourne. The barometer was installed at Warrnambool's old jetty and then the Breakwater as part of the Victorian Government's insistence that barometers be placed at all major Victorian ports. This coastal barometer is representative of barometers that were installed through this government scheme that began in 1866. The collecting of meteorological data was an important aspect of the Melbourne Observatory's work from its inception. Just as astronomy had an important practical role to play in navigation, timekeeping and surveying, so the meteorological service provided up to date weather information and forecasts that were essential for shipping and agriculture. As a result, instruments made by the early instrument makers of Australia was of significant importance to the development and safe trading of companies operating during the Victorian colonies early days. The provenance of this artefact is well documented and demonstrates, in particular, the importance of the barometer to the local fishermen and mariners of Warrnambool. This barometer is historically significant for its association with Langlands’ Foundry which pioneered technology in the developing colony by establishing the first ironworks in Melbourne founded in 1842. Also, it is significant for its connection to John B Grimoldi who made the barometer and thermometer housed in the cast iron case. Grimoldi, a successful meteorological and scientific instrument maker, arrived in the colony from England and established his business in 1862 becoming an instrument maker to the Melbourne Observatory. Additional significance is its completeness and for its rarity, as it is believed to be one of only two extant barometers of this type and in 1986 it was moved to Flagstaff Hill Maritime Village as part of its museum collection. Coast Barometer No. 8 is a tall, red painted cast iron pillar containing a vertical combined barometer and thermometer. Half way down in the cast iron framed glass door is a keyhole. Inside is a wooden case containing a mercury barometer at the top with a thermometer attached underneath, each with a separate glass window and a silver coloured metal backing plate. Just below the barometer, on the right-hand side, is a brass disc with a hole for a gauge key in the centre. The barometer has a silvered tin backing plate with a scale, in inches, of "27 to 31" on the right side and includes a Vernier with finer markings, which is set by turning the gauge key. The thermometer has a silvered tin backing plate with a scale on the left side of "30 to 140". Each of the scales has markings showing the units between the numbers.Inscription at the top front of the pillar reads "COAST BAROMETER" Inscribed on the bottom of the pillar is "No 8". and "LANGLANDS BROS & CO ENGINEERS MELBOURNE " The barometer backing plate is inscribed "COAST BAROMETER NO. 8, VICTORIA" and printed on the left of the scale, has "J GRIMOLDI" on the top and left of the scale, inscribed "Maker, MELBOURNE". There is an inscription on the bottom right-hand side of the thermometer scale, just above the 30 mark "FREEZING" Etched into the timber inside the case are the Roman numerals "VIII" (the number 8)flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, warrnambool breakwater, coast barometer, coastal barometer, barometer, weather warning, ports and harbours, fishery barometer, sea coast barometer, austral otis co, coast barometer no. 8, henry grimoldi, henry langlands, john baptist grimoldi, langlands foundry co, meteorological instrument maker, robert langlands, scientific instrument maker, thermometer, thomas fulton -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

... advanced machine tools. And beyond the oil derived from whales... to lubricate increasing advanced machine tools. And beyond the oil ...Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone in two pieces. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

... advanced machine tools. And beyond the oil derived from whales... to lubricate increasing advanced machine tools. And beyond the oil ...Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

... advanced machine tools. And beyond the oil derived from whales... to lubricate increasing advanced machine tools. And beyond the oil ...Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070. Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone vertebrae. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

... advanced machine tools. And beyond the oil derived from whales... to lubricate increasing advanced machine tools. And beyond the oil ...Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined