Showing 74 items matching "machinery shed"

-

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCutter Green Feed, Hocking, estimated 1935; Early 20th Century

This iron chaff cutter was a vital piece of rural machinery especial for cattle in areas subjected to limited grass growing seasons. The Kiewa Valley and Alpine regions were up to the 21st century "snowed" in. The conditions requiring summer crops and fodder to be prolonged for the harsh winter climate are now becoming less and less and may confirm the precursor of "global warming". The Kiewa Valley is still a strong base for dairy cattle and other stock requiring all year access to hay/grass supplies. The use of, now defunct, Tobacco drying sheds for the storage of hay and other fodder is typical of the Australian farmer/grazier's adaptability to utilise anything available. To think outside the square.Black Iron Chaff Cutter. The wheel has a single piece inside with 4 curved spokes with adjustable blades attached by 4 screws & 3 rivets. The wheel has a wooden handle. Operated by cogs. HOCKING GREASE BALLARAT COGS FREELYagriculture, farm machinery, stock feeding, grazier, farm animals -

Ringwood and District Historical Society

Ringwood and District Historical SocietyDocument, Packet: Ringwood Coolstore Cuttings, Historical Notes, Equipment Sale, Rule Book. 1911-1959

Miscellaneous documents relating to the Ringwood Coolstore and Horticultural Society.Packet includes: . 3793(f): Hand written notes on the development of Ringwood Cool Stores in the early 1900's. . 3793(h): Typed document titled 'Fruit Cool Storage Symposium' dated 1963, produced by the Department of Agricultue and the Orchardists and Fruit Cool Stores Association. . 3793(g): Hand written minutes and general notes of the Ringwood Horticultural Society meetings and Shows, from 1899 to 1902. . 3793(e): Small booklet- 'Rules of The Ringwood Co-operative Cool Stores Society Limited, 1934.' . 3793(b),(c),(d): Typed documents: 1. How to lay out a packing shed. 2. Notice of the Forty-third Ordinary General Meeting of The Ringwood Co-operative Cool Stores Society Limited held in the Ringwood Town Hall on 31st March, 1959. 3. Notice of Important Auction Sale of 'Cool Stores Machinery and Plant Buildings for Removal' on December 2nd, 1959. . 3793(a): 2 Newspaper articles by J. K. McCaskill, J.P. on the Early History of Parish of Ringwood and Official Opening of the Ringwood Cool Stores in 1911. (Mail 3/12/1950 and 10/12/1959). -

Cheese World Museum

Cheese World MuseumPhotograph, Unknown photographer, The first mechanical milking machine public demonstration in Allansford district, 1905

The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. This photograph is part of the collection of items given into the care of the Cheese World Museum. Uebergang catalogue No. Photograph tells the story of a special celebration marking the occssion of the demonstration of the first mechanical milking machine on the Ernst Uebergang property Briarwood at Cudgee Victoria. Ernst Uebergang is inside the shed. Reported in Warrnambool Standard 5 June 1905.Photo on badly damaged brown mount board. Image depicts LKG milking machine demonstration. Dignitories, farmers and children present. Two men are inside the shed with two cows. Written on back of photo 'LKG Milking Machine Lawrence Kennedy 1902/ Mr Ernst Uebergang inside shed.'uebergang, dairy industry, rural industry, food manufacture, machinery, lkg, cudgee, briarwood, milking machine, children, cows, dignitories, farmers, bucket -

Federation University Historical Collection

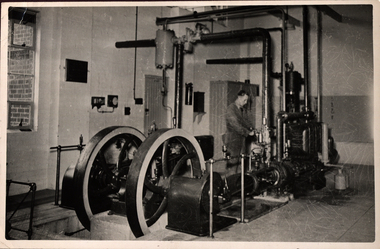

Federation University Historical CollectionPhotograph - Photograph - Black and white, Ballarat School of Mines Model Steam Engine

The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.Black and white photograph of the Davey Paxman Experimental Steam Engine installed at the Ballarat School of MInes. steam engine, model steam engine, davey paxman, thomas bath, experimental steam engine -

Federation University Historical Collection

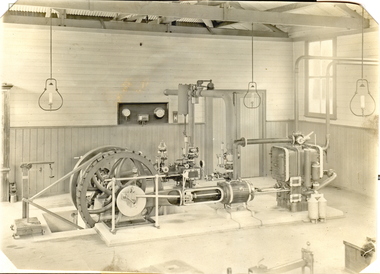

Federation University Historical CollectionPhotograph, Ballarat School of Mines Davey Paxman Experimental Steam Engine, c1902

The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only. Black and white photograph of an experimental steam engine which was produced for the Ballarat School of Mines. It was designed for experimental purposes, such as testing of efficiency, etc. The laboratory which housed the steam engine was lit with gas lighting. davey paxman experimental steam engine, model steam engine, davey paxman, steam, thomas bath, thermodynamics -

Federation University Historical Collection

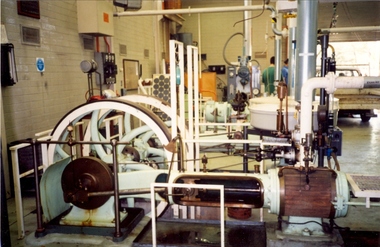

Federation University Historical CollectionPhotograph - Colour photograph, Davey Paxman Experimental Steam Engine in the Mount Helen Workshop, c1994

The Davey Paxman Experimental Steam Engine was purchased by the Ballarat School of Mines as the result of a bequest from Thomas Bath.The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.davey paxman experimental steam engine, model steam engine, steam, thermodynamics laboratory, thomas bath, bequest -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Machinery, n.d

Port of Portland Authority ArchivesBack: (2) - ink, top left -

Bendigo Historical Society Inc.

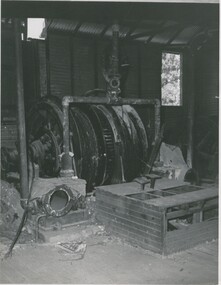

Bendigo Historical Society Inc.Photograph - DEBORAH EXTENDED MINE, 1960's ?

black and white photo : machinery in mine. Corrugated iron shed. Cable on large wheel. Winding engine. ' Horwood & Sons Winder, Deborah Extended Mine - now on display on Central Deborah ' .Alan Doney ( J. Lerk 17.3.2000 )organization, business, deborah extended mine -

Bendigo Historical Society Inc.

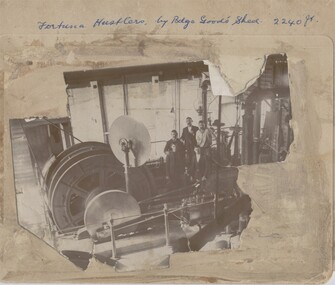

Bendigo Historical Society Inc.Photograph - FORTUNA COLLECTION: FORTUNA HUSTLERS WINDING MACHINE, 1910 ?

sepia photograph on cream board. Winding engine, written across of photo ' Fortuna Hustler's mine, near Bendigo Goods Sheds 2240 ft' 5 males standing near machine. Winding machine photographed from rear of machinery from an elevated position, a group of five men standing near the controls. (Photo belonged to Albert Richardson, whose father was an engine driver at the Fortuna Hustlers Mine. ( possibly ? ) ON BACK FORTUNA HUSTLERS B R S A RICHARDSONW.H. Robinsonorganization, business, fortuna hustlers winding machine -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - ROY J MITCHELL COLLECTION: FARM SHED NEAR GOORNONG

Colour photograph of farm shed, near Goornong. Shed is open shelter, has hand hewn uprights, corrugated iron roof. On back of photo:' 29.3.96 near Goornong, Vict, 14.30 hrs Shepparton Bendigo Road, by Roy J Mitchell, Bendigo.agriculture, farm, machinery -

National Wool Museum

National Wool MuseumPoster, Smoko at shearing time

... time" Shearing sheds Shearing Shearing machinery Galloway Mr ...The Herald and Weekly Times, "Smoko at shearing time"shearing sheds shearing shearing machinery, galloway, mr ken, bindi station tongio, victoria, shearing sheds, shearing, shearing machinery -

National Wool Museum

National Wool MuseumBook, Negative dobby shedding motions

... -and-the-bellarine-peninsula "Negative dobby shedding motions"- W Middlebrook ..."Negative dobby shedding motions"- W Middlebrook, "Textile Manufacturer" Monograph No 10"Negative dobby shedding motions"- W Middlebrook, "Textile Manufacturer" Monograph No 10.textile industry - education textile machinery, textile manufacturer, weaving machinery, weaving looms, textile industry - education, textile machinery -

National Wool Museum

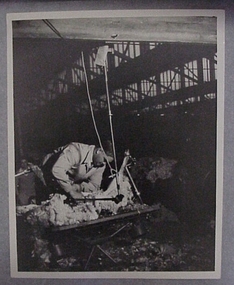

National Wool MuseumPhotograph, Shearing Table

Photograph of shearing table in use, designed by John Borthwick.Black and white photograph of shearer shearing sheep on shearing table, inside shed, with two men in suits adjacent.Shearing table marketed 1953 designed by Qld. grazier John Borthwick Illegible . 134654L 6965shearing machinery shearing, shearing machinery, shearing -

![Photograph, [Fred's loom]](/media/collectors/510b3f7f023fd725b4cd52cc/items/54065ff99821f50e3cc9fb11/item-media/54065ff99821f50e3cc9fb12/item-fit-380x285.jpg) National Wool Museum

National Wool MuseumPhotograph, [Fred's loom]

James Murgatroyd worked at Warrnambool Woollen Mills, Federal Mill, Tweedside, Collins Mills and set up looms for Alexander Spinning Mills Sydney, his son Fred Murgatroyd worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.Murgatroyd Photograph CollectionF Murgatroyd This is Fred's loom /You can't see much of it /though. He took this/ inside the shed. KODAK PRINTtextile machinery textile mills weaving mills textile mills, collins bros mill pty ltd tweedside woollen mills yarra falls mill, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills -

National Wool Museum

National Wool MuseumPhotograph, In the weaving shed

James Murgatroyd worked at Warrnambool Woollen Mills, Federal Mill, Tweedside, Collins Mills and set up looms for Alexander Spinning Mills Sydney, his son Fred Murgatroyd worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.Murgatroyd Photograph CollectionF Murgatroyd In the weaving shed KODAK PRINTtextile machinery textile mills weaving mills textile mills, collins bros mill pty ltd tweedside woollen mills yarra falls mill, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills -

National Wool Museum

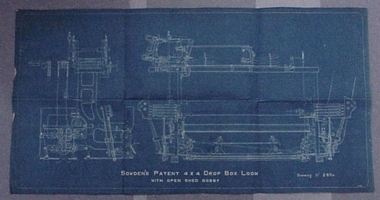

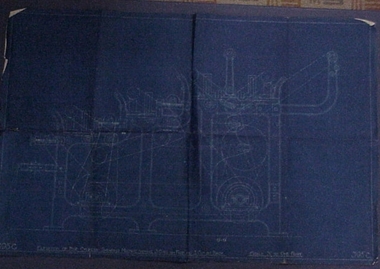

National Wool MuseumBlueprint, Sowden's Patent 4x4 Drop Box Loom with open shed dobby

Blueprint of part of a "David Sowden and Sons" 4x4 Drop Box Loom. It was among items from Yarra Falls Mill.Blueprint of part of a "David Sowden and Sons" 4x4 Drop Box Loom.SOWDEN'S PATENT 4X4 DROP BOX LOOM/WITH OPEN SHED DOLBY T & I H /Kent GWNtextile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving -

National Wool Museum

National Wool MuseumBlueprint, "Elevation of Four Cylinder Shearing Machine Shewing3 Cuts on Face and 1 Cut on Back"

... Shearing machinery Shearing sheds Shearing Shearing machinery ...Blueprint, printed white on blue paper, of the mechanical engineering drawings of "Elevation of Four Cylinder Shearing Machine Shewing3 Cuts on Face and 1 Cut on Back" -395C"Elevation of Four Cylinder Shearing Machine Shewing3 Cuts on Face and 1 Cut on Back" -395C.ELEVATIOB OF FOUR CYLINDER SHEARING MACHINE SHEWING 3 CUTS ON FACE AND 1 CUT ON BACK -395Cshearing machinery shearing sheds shearing, shearing machinery, shearing sheds, shearing -

National Wool Museum

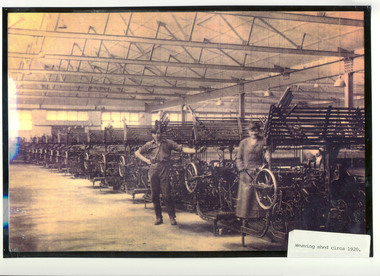

National Wool MuseumPhotograph, Weaving shed circa 1920

Acquired when "Classweave Industries" closed down.Weaving shed circa 1920 H L S POTTER/ PHOTO STORES/...textile mills woollen mills textile mills - staff, classweave industries pty ltd federal woollen mills ltd, weaving machinery, textile mills, woollen mills, textile mills - staff -

![Photograph, [Main weaving shed]](/media/collectors/510b3f7f023fd725b4cd52cc/items/54065f5e9821f50e3cc9f4fa/item-media/54065f5e9821f50e3cc9f4fb/item-fit-380x285.jpg) National Wool Museum

National Wool MuseumPhotograph, [Main weaving shed]

Acquired when "Classweave Industries" closed down17 Main weaving room 22/87 p?honetextile mills woollen mills, classweave industries pty ltd federal woollen mills ltd, weaving machinery, textile mills, woollen mills -

National Wool Museum

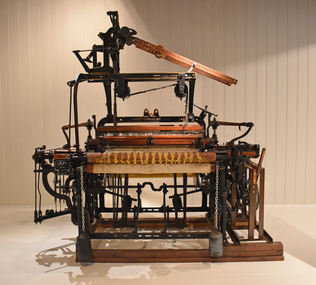

National Wool MuseumMachine - Loom, George Hattersley and Sons Ltd, 1920 - 1935

Weaving is the interlacing of two yarns, one at right angles to the other. Yarns that run the length of the fabric are called the warp. Yarns that run across the fabric are called the weft. Most woven fabrics are produced on a loom. The warp yarns are raised to form an opening - the shed. The weft carrier, usually the shuttle, shoots through the shed. Then the warp yarns change position up and down. Finally, the weft is pushed tight against the previous yarns, gradually building up the fabric. Hattersley dobby loom. In working order, black painted cast iron.weaving, george hattersley and sons ltd, weaving machinery, loom, wool processing, textile industry -

National Wool Museum

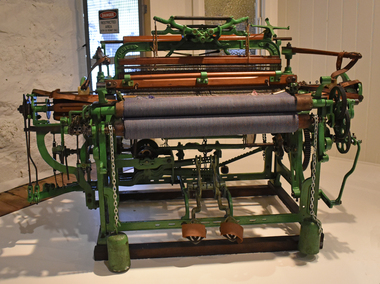

National Wool MuseumMachine - Loom, George Hattersley and Sons Ltd, 1920 - 1925

Weaving is the interlacing of two yarns, one at right angles to the other. Yarns that run the length of the fabric are called the warp. Yarns that run across the fabric are called the weft. Most woven fabrics are produced on a loom. The warp yarns are raised to form an opening - the shed. The weft carrier, usually the shuttle, shoots through the shed. Then the warp yarns change position up and down. Finally, the weft is pushed tight against the previous yarns, gradually building up the fabric. Hattersley treadle loom (revolving box hand loom). Beam of loom was removed and sent to Foster Valley Mill in 1989 to be returned via Tom Crocker. The National Wool Museum gratefully acknowledges the contribution of Mr Fred Murgatroyd & Mr Bernard Tolan in making this Hattersley Loom Operational. Green painted Hattersley treadle loom (revolving box hand loom).weaving, george hattersley and sons ltd, weaving machinery, wool processing, loom, restoration -

National Wool Museum

National Wool MuseumSlide Folder, Shearing Sheds

... machinery Wool Press - hydraulic Shearing sheds Shearing machinery ...Slide folder originally containing 11 slides depicting types of shearing sheds and the spaces within the sheds. Contains information about the slides.11 COLOUR SLIDES / SHEARING SHEDSshearing sheds shearing machinery, wool press - hydraulic, shearing sheds, shearing machinery -

Rutherglen Historical Society

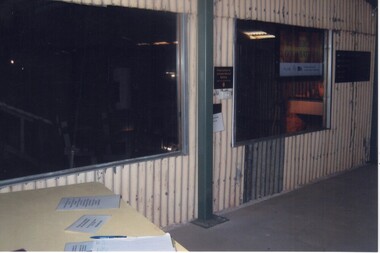

Rutherglen Historical SocietyImage, c1990

This photograph is of the viewing room inside the building, this side with windows overlooking the machinery and a video screen with a switchboard to run the video. One of a series of photographs of the Rutherglen Gold Battery. Its purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of the interior of a building showing two large windows and a video screen on a corrugated iron wall.gold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph is of Battery Box, showing the mouth where quartz is fed in. The five stamper rods can also be seen. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details. Colour photograph of a large piece of machinery inside a buildinggold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph is a view from the lower side of the stamper, showing amalgam table, box and stampers. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details. Colour photograph of a large piece of machinery inside a buildinggold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph is a view of the flywheel that drives the stampers. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details. Colour photograph of a large piece of machinery inside a buildinggold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph shows the workers' amenities at the Gold Battery. The building has a bedroom and kitchen. In front is a Baler Bucket and a cage. This particular cage was for raising and lowering the skips which brought the material to the surface. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of a corrugated iron cottage, with several pieces of machinery around it.gold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph is a general view of the machinery of the Gold Battery. The Bergin Pan is on the left, Stamper Box and in foreground concrete bed for Wilfrey table which has been removed. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of a number of large pieces of machinery inside a buildinggold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph is of machinery in the yard of the Gold Battery. The Baler Bucket is at the rear, the cage in the centre and the skip at the front. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of a pieces of machinery in the yard of the Gold Batterygold battery, gold processing -

Rutherglen Historical Society

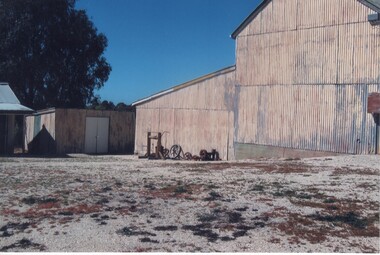

Rutherglen Historical SocietyImage, c1990

This photograph is of the side of the main building of the Gold Battery with workshop at rear (now demolished). Beside building is a hand windlass, along with some old pulleys and various parts. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of the side of a corrugated iron building with a smaller building at the left, and a number of pieces of machinery next to the buildinggold battery, gold processing