Showing 45 items

matching machinery shop

-

National Wool Museum

National Wool MuseumPhotograph - Product Photograph, Tape Condenser

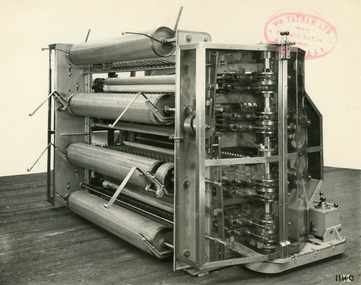

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A Tape Condenser is a device that receives the wide fibre web from a woollen card, divides it, and rubs each section into a sliver. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of a Tape Condenser in a landscape format. The first photo is of the front of the machine, the second is of the rear.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1138 Rear - Showing new model Tape Condenser with all-Perspex Guards, new gear box type of main drive to Condenser. New mounting of all Tape Rollers, cross shaft drive to Variable Speed Gear Box for drive to rubber shaft and many other improved features. 8038.2 - Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1140 Rear - New Model Four-teir Tape Condenser showing rubbing motion side Note greatly improved guarding completely enclosing rubbing motion and gearing, also Variable Speed Drive to Rubbing Motiom via heavy ‘V’ Belt. The drive is taken by cross-shaft from the main gearing of the Condenser. Rubbing Motion has all roller bearing eccentrics throughout.textile machinery, tatham, wool manufacture, tape condenser -

National Wool Museum

National Wool MuseumPhotograph - Product Photograph, Two-Part Scribbler

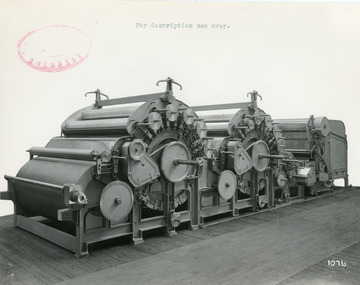

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The scribbler was the first part of a group of machines known collectively as the carding engine. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Two-Part Scribbler in a landscape format.Front - top margin: For description see over. Front bottom right corner - 1076 Rear - Two-Part Scribbler, Semi-Continental Type with Patent Automatic Feed having Extended Hopper. Cylinders in this case are 50” diam. Doffers 36” diam. Drive to strippers and other parts by ‘V’ Belts. Note improved guarding to Fancy Chain Drives, also feeder gearing.textile machinery, tatham, wool manufacture, scribbler, carding -

National Wool Museum

National Wool MuseumPhotograph - Product Photograph, Patent Parallel Fibre Feed

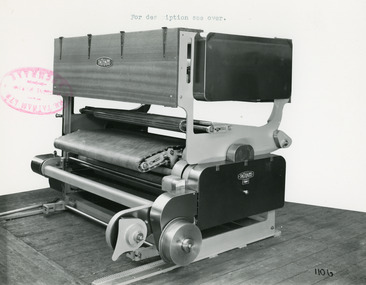

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Patent Parallel Fibre Feed machine is used for connecting Breaker and Finisher Card Sections. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Parallel Fibre Feed in a landscape format. Black wiritng on the rear, typed with a typewriter. Front - top margin: For description see over. Front mid left edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1106 On machine bottom right quadrant - TATHAMS Rear - New Patent Parallel Fibre Feed for connecting Breaker and Finisher Card Sections. This Machine incorporates a completely new type Plaiter Motion, the operation of which is quite unique.textile machinery, tatham, wool manufacture, carding, patent parallel fibre feed machine -

National Wool Museum

National Wool MuseumPhotograph - Product Photograph, Patent Automatic Feed Machine

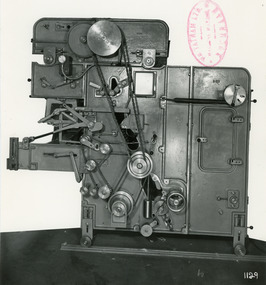

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. An Automatic Feeding Machine automatically and sequentially supplies uncarded wool to carding machines, The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Automatic Feed Machine in a portrait format. Black wiritng on the rear, typed with a typewriter.Front - mid left corner - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1129 Rear - Patent Automatic Feed with Extended Hopper fitted with balanced pressure plate which operates through Variable Speed Device to regulate speed of spiked lattice in accordance with material in Hopper. Electro-Magnetic Clutch Drive to spiked lattice controlled by Mercery Switch on scale arm. Diagonal Scale Pan with improved knife edge suspension. Dual Trap Doors over Pan actuated by Solenoid. Automatic device to slow spiked lattice just prior to weigh being obtained. Ball or roller bearings to main shaft, combs and other parts. Self-aligning bearing to timing shaft etc.textile machinery, tatham, wool manufacture, carding, automatic feeding machine, wool -

Vision Australia

Vision AustraliaPhotograph - Image, Queensland Institute for the Blind matting, cane and mattress workshop, August 1952

Fives images of the workshop machinery used by the Queensland Industrial Institute for the Blind in the manufacture of various products. 1 - Pitched brooms being made by Stewart Jewell (left) and Jack Dollier (right). 2 - Unknown worker at a basket station making a cane basket, surrounded by finished examples. 3 - Snowy Willis oversees the operation of the machine that bores holes into brush heads. 4 - Unknown worker operating a coir matting machine. There were apparently 10 such machines in use at the time this image was taken. 5 - Snowy Willis checking the bobbins being filled from a giant spool. In the background are empty bobbins stacked against walls and filled bobbins on spool holders. 6 - Roy Anderson checks the wadding on a recently filled mattress, whilst in the background Ellen McDevitt uses a portable sewing table to sew the ends of a filled mattress.6 x B/W photographs of the workshop machinery used by the Queensland Industrial Institute for the BlindC2-657: 2, Brush shop - pitch set brooms being made by blind workers C2-664: Basket shop - some of the various types of baskets made C2-654: Snowy Willis. Brush shop - a semi automatic brush stock boring machine in operation. C2-666: Matting shop - one of the ten coir matting looms in use. 1960. C2-659: Matting shop - bobbin winder and bobbin bank. C2-655: 15. 2 col wide. Bed shop wadding a fibre mattress. Also showing special sewing machine and movable table used in sewing the mouths of filled mattresses.queensland industrial institute for the blind, stuart jewell, jack dollier, snowy willis, roy anderson, ellen mcdevitt -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - ALBERT BUSH'S STORES INVOICE

Born in England in 1832, Albert Bush was attracted to Australia by the lectures of Dr Laing. In 1852 he travelled to Queensland and later to Sydney before coming to Bendigo. His initial mining efforts were not successful so he gained employment as a clerk in a grocery store. In 1857 he opened his own grocery shop in partnership with Mr Ferris. He bought out Ferris in 1859. In 1859 he married Jane Dalton (1836-1919). Following his death the business was continued by his son.Albert Bush's Stores Invoice. Cream paper with black print, hole in the centre. Bush's Moulamein & Wakool. Dated at Bendigo August 5th 1929. Mr S. A. Bush. Both of Albert Bush's Stores General Providers. Grocers, Bakers and Pastry cooks, Drapery, Hardware Timber, Woolpacks and Cornsacks. Insurances, Mitchell Farm Machinery, Mt Lyell Manures Sheep Dips, Building (under our own supervision). Invoice for 1 truck Box Blocks. Freight seven tons. Cartage Buckell & Jeffrey. Truck 1515. Receipt attached no. 172 dated August 19th 1929 with orange Stamp Duty Stamp for 2d. Mr S.A. Bush By Cash Cheque £11:6:1 Albert Bush's Stores. Box 625business, retail, general, albert bush's stores. s.a. bush -

Eltham District Historical Society Inc

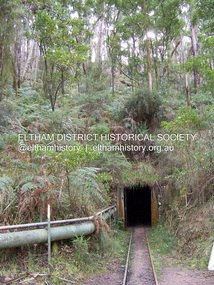

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, One Tree Hill Mine, Smiths Gully, 8 June 2006

Gold was discovered on One Tree Hill in 1854. The site has been worked intermittently until fairly recent times. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p53 Though still a working mine, One Tree Hill Mine at Smiths Gully, now stands in a tranquil reserve surrounded by bush and native animals - in contrast to its heyday. In the mid 19th century, when the mine was part of the Caledonia Goldfields, hundreds of men in search of their fortune worked the alluvial gold in the Yarra River, its tributaries and the reefs that made up the goldfields. Miner Stan Bone, assisted by Wilfred Haywood, is the last of the independent gold miners in the area and still uses the quartz crushing battery as miners did when gold was first discovered in the area in 1851.1 Stan, who is the last of six generations of miners in his family, was aged 17 when he began mining on his father Alex’ mine, The Golden Crown in Yarrambat. These days, after blasting the gold-bearing rock in Mystery Reef, one of the four reefs at One Tree Hill, Stan transports it around five kilometres by tip truck to the Black Cameron Mine for crushing. There he uses water from the waterlogged mine, (which still contains gold), as the Happy Valley Creek at One Tree Hill is usually dry.2 The One Tree Hill Mine has been worked for close to a century since it opened around the late 1850s.3 The Swedish Reef was its most productive reef and one of the largest in the area. Around 1859, extractions included 204 ounces (5.8kg) of gold, won from 57 pounds (26kg) of stone.4 Then during World War Two, Stan’s uncle, Bill Wallace, and Alex Bone, closed the mine. In 1973, Stan, with his Uncle Bill, reopened the Black Cameron Mine and worked there until 1988. Stan resumed mining One Tree Hill in 1998. As late as the 1920s gold was picked up by chance! When crossing a gully on his way to vote at the St Andrews Primary School, Bill Joyce picked up some quartz containing gold. This site was to become the Black Cameron Mine. The Caledonia Diggings, named after Scotland’s ancient name by local Scots, began around Market Square (now Smiths Gully) and included Queenstown (St Andrews), Kingstown (Panton Hill) and Diamond Creek. There were also poorer bearing fields in Kangaroo Ground and Swipers Gully (now Research). * None of these compared in riches to the Ballarat and Bendigo fields5, but the Caledonia Diggings continued intermittently for close to 100 years. Gold was discovered in Victoria following a bid to stem the disappearance of much needed workmen to the New South Wales diggings. Several businessmen offered a reward of £200, for the discovery of gold within 200 miles (322 km) of Melbourne. Late in June 1851, gold was first discovered at Andersons Creek, Warrandyte. Then in 1854, George Boston and two other men discovered gold at Smiths Gully. Gold transformed the quiet districts, with a constant flow of families and vehicles on the dirt tracks en route to the Caledonia Diggings. Three thousand people worked the gullies in Market Square, including about 1000 Chinese miners. The square established its own police, mining warden, gold battery, school, shops and cemetery and grog flowed. Market Square flourished until the middle 1860s. Bullocks transported quartz from the Caledonia Goldfields to the crushing machinery at the Queenstown/St Andrews Battery, near Smiths Gully Cemetery. It was destroyed by bushfire in 1962. By the late 1850s, most early alluvial fields were in decline, but minor rushes continued until around 1900 and some until the early 1940s. Some miners did well, although most earned little from their hard labour in the harsh and primitive conditions.6 But according to historian, Mick Woiwod, the gold fields helped to democratise society, as individuals from all walks of life were forced to share experiences, and the ability to succeed, depended less on inherited wealth or social rank.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, gold mining, one tree hill mine, smiths gully -

Bendigo Historical Society Inc.

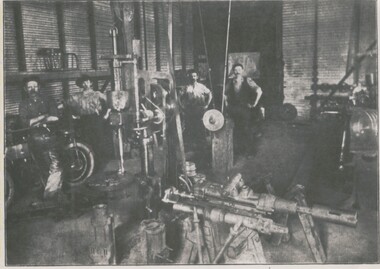

Bendigo Historical Society Inc.Photograph - New Moon Mine Battery

black and white photo - copy. Workshop in corrugated iron walls, 4 adult males standing amongst machinery. At bottom of image printed ' view showing fitting shop at crushing machine' New Moom Mine ? ( J. Lerk 26.11.1999 ).W.H. Robinson ?organization, business, new moon mine ? -

Federation University Historical Collection

Federation University Historical CollectionBooklet, Ballarat Illustrated for Enterprise, Education & Health

Green, red and black soft covered facsimile booklet. The book includes numerous illustrations including Ballarat City Municipal Chambers, Ballarat Banking Co. Ltd, Art Gallery of Ballarat, Ballarat Trustees, John McLeod, Pty Ltd, Ballaarat Gas Co., J. J. Goller, Star Office, Ballarat Courier Office, Morsheads, M.B. John, Rowlands, Huttons the Jewellers, Millers the Clothiers, James Smith Agricultural Machinery, Coles and Pullum, City Baths, Benoit's Sun Foundry, William Paterson Drapers, Eureka Terra Cotta and Tile Co., Ballarat Woollen & Worsted Co. Ltd, Sunnyside Woollen Mill, Red Shop tea Rooms, Allchine Bros., Brind's Dunnstown, Ballarat Breweing Co., R. Tunbridge & Sions, Ballarat Zoological Gardens, A. Cant Plumber, Hugh Jones, Eureka Reserve, W.F. Coltman, Loveland & Haslem, G. Warner, W. Cornell, Craig's Hotel, Electric Supply Company of Victoria (Ballarat), Longhurst's, P.C. Thornton, Cowley's Eureka Ironworks, W. Owen, Clarendon Ladies College, Lal Lal Falls, Corckers, Evening Echo Office, Campbell & Wilson and Broadbent brothers. A number of portraits associated with the above organisations are also reproduced in the booklet.non-fictionballarat, w miller, af alchin, a polson, wf longhurst, pj pringle, george crocker, r maddern, as rusden, w cornell, pc thorthon, w owen, cs benoit, h jones, d davies, j scullin, c walker, jh jones, j tyler, jj crifiths, n clark, s clark, cf taylor, tt hollway, morton, f davies, f herman, w knox, a cant, mb john, mwb john, wf coltman, w moir, j macleod, jj mcgowen, a hancock, j osborne, ao stubbs, rw baxter, g baxter, cg harvey, gh warner, cj coles, wj pullum, a mackenzie, jr petterson, ec chamberson, ba john, te miller, g miller, a bell, jh shelley, f sutton, re loveland, tr haslem, re loader, cuthbert, ballarat city municipal chambers, ballarat banking co. ltd, art gallery of ballarat, ballarat trustees, john mcleod, ballaarat gas co., j. j. goller, star office, ballarat courier office, morsheads, m.b. john, rowlands, huttons the jewellers, millers the clothiers, james smith agricultural machinery, coles and pullum, city baths, benoit's sun foundry, william paterson drapers, eureka terra cotta and tile co., ballarat woollen & worsted co. ltd, sunnyside woollen mill, red shop tea rooms, brind's dunnstown, ballarat breweing co., ballarat zoological gardens, a. cant plumber, hugh jones, eureka reserve, w.f. coltman, loveland & haslem, g. warner, w. cornell, craig's hotel, electric supply company of victoria (ballarat), longhurst's, p.c. thornton, cowley's eureka ironworks, w. owen, clarendon ladies college, lal lal falls, evening echo office, allchin brothers, r. tunbridge and sons, campbell and wilson, broadbent brothers, ballarat asylum, crockers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Foundry Patterns set, Briggs Brass Foundry, Early 20th century

The wooden crate contains a set of patterns or moulds that were once used at Briggs’ Brass Foundry for making sand moulds. The traditional method of sand casting is over 2000 years old. It is part of a crafted process used to make brass and copper alloy goods suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-corrosive and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry display was one of the early ‘working craft’ shops at Flagstaff Hill. It included a historic Cornish chimney that was set up as a working model, telling the story of heat from furnaces to smelt metal, which would then be poured into the sand moulds. This chimney is made from specially curved bricks and is about two-thirds of its full height when originally located at the Grassmere Cheese factory. HISTORY of BRIGGS BRASS FOUNDRY: - The family business was founded in 1912 by Herbert Harrison Briggs (1963-1931) with his son George Edward Briggs, trading as Briggs & Son Foundry at 70 Wellington Street, Collingwood. Younger son Cyril Falkiner McKinnon Briggs joined the foundry in 1922, and it was renamed H H Briggs & Sons Foundry. Both sons ran the firm after Herbert’s death in 1931, making products mainly for marine purposes. They became Bell Founders in 1936 and were known for their specialty of high-quality ship bells. They produced miniature varieties of these and other decorative items such as small propellers. The firm became known as Briggs Marine Foundry. The great-granddaughter of Herbert Briggs inherited the Briggs Brass Bell, similar to the one at Flagstaff Hill. Cyril became the sole family member of the firm in 1965. The Briggs Marine was an exhibitor at the 1965 Boat Show, where he advertised as “non-ferrous founders” and “Bell Specialists”. The foundry relocated to Chesterville Rd, Moorabbin. Cyril passed away in 1967. It is thought that either Cyril or his business partner Frank Lee donated the objects from the Briggs’ Foundry around the time when the business moved to Moorabbin. However, Flagstaff Hill hadn’t been thought about until 1972. The donated items were registered in the Collection in 1986 but they could have been in storage from an earlier date. In October of that same year, Briggs Marine restored Schomberg Bell, a shipwreck artefact from the collection at Flagstaff Hill. Peter Oram, who had worked for the previous owners of Briggs Marine as a fitter and turner, took over the firm in 2014, reviving some of the old casts for current use. The business is now located at Seaford in Victoria and is part of Alliance Casting & Engineering Solutions (Alliance Casting Pty Ltd). In 2016 the original Collingwood Foundry building was repurposed as a thriving business hub named The Foundry. The crate and its patterns are significant for their association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. The patterns are associated with the long-running firm, Briggs Brass Foundry, that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine is also associated with the Schomberg Bell in Flagstaff Hill, restoring the bell to is former state to show an example of the bell from a luxury mid-19th century vessel. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. Wooden rectangular crate with removable wooden lid. Inside is a set of wooden patterns of various shapes and sizes for making sand moulds in a metal foundry. The crate is made from thick wooden planks nailed together. The extended wooden struts on the long sides form a frame to hold the wooden lid. A pair of metal handles are at each short end of the crate, fixed with strong metal bolds. Between each pair of handles is an inscription stamped into the wood. The underside of the crate has red paint splashes. There are insect holes in the wood but no sign of current infestation. Stamped: "H.33 / II" (H may be N or a square B)flagstaff hill maritime museum and village, great ocean road, shipwreck coast, pattern, mould, foundry, brass foundry, metal foundry, crate, box, wooden container, briggs, traditional method, trade, sand cast, cast, brass alloy, copper alloy, marine equipment, marine tools, marine fittings, briggs' bronze, copper tin zinc lead, non-corrosive, briggs family, brassware, metalware, foundering, metalwork, maritime, casting, cornish chimney, curved bricks, grassmere cheese factory, 1912, herbert harrison briggs, h h briggs, george edward briggs, briggs & son foundry, collingwood, cyril falkiner mckinnon briggs, cyril briggs, h h briggs & sons foundry, bell founders, schomberg bell, alliance casting & engineering solutions, collingwood foundry, ship chandlers, marine products, flagstaff hill, warrnambool, maritime museum, maritime village, briggs & son brass foundry, briggs marine, moorabbin -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - VICTORIA HILL - THE BENDIGO DIGGINGS, PRELIMINARY DRAFT FOR BROCHURE

BHS CollectionNine typed pages of notes on a preliminary draft for a brochure on the Bendigo Diggings. First part is the objective which is to preserve the mining history and to have exhibits in the places they were used, e.g. quartz mining machinery exhibited in a quartz mining area, not on an alluvial field. Part B is historical notes on the area. Part C is the Site - Victoria Hill area. Part D is Stage One which consists of carpark area, technological museum, restaurant, mineral haulage line, picnic ground, earthworks and planting over the area. Part E is Stage Two which will consist of the open-air exhibits, in the area surrounded by the mineral haulage line, and the Central Nell Gwynne mine on the west side of the site. Part F is Stage Three which will consist of the winery, the steam tram track, the lake, the wildlife sanctuary and various buildings associated with gold mining. Part G is Costing with the prices to be filled in. Parts H and I are the Appeal and the Committee. Details to be filled in. Notes prepared by Albert Richardson.mining, marketing, victoria hill, victoria hill, the bendigo diggings - preliminary draft for brochure, aust national travel association, tullamarine jetport, emu bottom homestead, kyneton historical museum, chinese joss house, eaglehawk museum, whipstick scrub, cairn curran reservoir, castelmaine historical museum and market hall, national trust, ballarat hiatorical park, echuca's hopwood gardens, swan hill folk museum, gibson's mount alexander no 2 squatting run, captain brown, chief commissioner wright, hustler's reef, thomas hustler, mining board, drainage of reefs act 1862, first world war, bendigo amalgamated goldfields, second world war, sandhurst, w c vahland, battery trams, horse trams, steam trams, electric trams, central nell gwynne mine, theodore ballerstadt, george lansell, new chum hill, ballerstadt's open cut, 180 mine, new chum syncline battery, william rae, victoria quartz, wittscheibe's 'jeweller's shop', luffsman and sterry, gold mines hotel, adventure, bendigo and district tourist association, bendigo city council, bendigo branch of the royal historical society of victoria, professor brian lewis, school of architecture and building at the university of melbourne, taylor horsfield, lord robert cecil, south australian gold commissioner -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - NEW MOON MINE - COPIES OF NEGATIVES OF THE NEW MOON MINE

Four copies of negatives, three showing mining machinery and the fourth, a table. (a) shows machinery driven by a large flywheel. A man is operating the machine. (b) shows the crushing machine and tables. They are driven by long belts being driven by a long overhead shaft. Two men are at the machine. A tub is in the foreground. (c - shows a view of the fitting shop at crushing machine. Picture is not very clear. There are four men in the picture. (d) shows a reverse image table of gross total of tons, gold, dividends and calls to June 30th, 1906. photo, new moon mine, copies of negatives of the new moon mine, mine machinery, crushing works, a richardson -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING REPORTS - CATHERINE REEF UNITED MINE MANAGERS REPORTS

Handwritten notes, with typed transcript of same, on Catherine Reef United Mine Manager, J. M. Eyre Report 20/5/'72. Recommends the purchase of a new boiler. S. Jackson killed in a boiler explosion which the jury said was due to an error of judgement on his part. Recommendations, re New Winding Engine and Poppet Legs by Rbt. Coakes 18th May, 1905. Truck road from the shaft to the battery. Recommendation to call for tenders for a new changing house and a blacksmith shop. Reports about boilers, ropes, cleaning of machinery, testing of brakes, slack coal from the Powlett North Woolamai Collieries, crushings, number of batteries, low wood supply and a visit to the New Moon & South New Moon which are burning the Powlett slack coal. Albert Richardson Collectiondocument, gold, mining reports, mining reports, catherine reef united mine managers reports, j m eyre, myrtle creek coy, s jackman, rbt coakes, great northern co, virginia co, mr roberts, mr harkness, mr mcgrath, ernest mueller, roberts & sons, mr bennett, mr abrahams, mr sluyterman, j langdon, electrical supply coy, smiths, powlett north woolamai collieries, m j gwatkins, new moon, south new moon -

Bendigo Historical Society Inc.

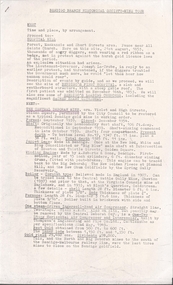

Bendigo Historical Society Inc.Document - VICTORIA HILL - BENDIGO BRANCH HISTORICAL SOCIETY - MINE TOUR

Typed notes for a tour of the area. Areas mentioned are: Hospital Hill, The Central Deborah Mine, New Chum Railway Mine, The Rocks, New Chum Hill, Victoria Hill, Central Nell Gwynne, Rae's Open Cut, Housing Commission Homes and Latham and Watson's. Description of machinery at the Central Deborah Mine, yields, dividends, depth of shafts and directions to get ot the various places is included.document, gold, victoria hill, bendigo branch historical society mine tour, all saints church, joseph la trobe, bendigo's first hospital, sacred heart cathedral, the central deborah mine, city council, londonderry west shaft, new red, white and blue consolidated (big blue), a roberts & sons, big deborah, the new golden fleece, new chum goldfields, central wattle gully mine chewton, virginia consols, black's quarries coldstream, thompson's engineering and pipe co ltd castlemaine, new chum railway mine, golden square methodist church, the rocks, e j dunn, gold monument, shamrock mine, mt alvernia hospital, j b lazarus, john brown knitwear factory, gold fmines hotel, david sterry, new chum hill, fortuna villa, geo lansell, theodore ballerstedt, a h q survey regiment headquarters, old chum mine, central nell gwynne, rae's open cut, theodore ballerstedt, new chum syncline, little 180 mine, victoria quartz, wittcheibe's 'jeweller's shop', adventure, advance, cinderella, j n macartney, bendigo goldfields registry 1870, wm rae, johnson's devonshire mine, snobs hill mine, ellenborough mullock heap, belmont mullock heap, sadowa, st mungo, united devonshire, mechanic's institute, log lock-up, court house, j b watson, housing commission homes, hustlers hill, latham and watsons', the great extended hustlers, a richardson -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - VICTORIA HILL - QUESTION 5 ON VICTORIA HILL

Handwritten notes and carbon copy titled Question 5. Notes refer to Victoria Hill being opened up by Theodore Ballerstedt and his son early in 1854. Theodore Ballerstedt left for Germany having sold his home, crushing battery and mine to Mr. Geo Lansell. He called the mine the '180'. Next mine north to the '180' was the Victoria Quartz. Also contains notes on machinery, geological formations and earning from the mines.document, gold, victoria hill, victoria hill, question 5 on victoria hill, theodore ballerstedt, mr geo lansell, fortuna villa, commonwealth survey regiment, the 180, ballerstedt's original open cut, bendigo south rotary club, john wybrandt, north old chum coy, victoria quartz, victoria reef quartz company, mr william rae, a roberts & sons united ironworks, australian mining standard special edition 1899, bendigo advertiser 10/2/1897, a harkness & coy, bendigo advertiser 30/6/1910 page 5, rae's open cut, e j dunn, bendigo saddle reefs, wittscheibe's 'jeweller's shop', roberts & frost, ashley noy & coy, grant & co, woodward & son, couth allen and co, taylor gould and co, crawshaw & co, roberts & co