Showing 102 items matching "milk container"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Second half of 19th Century or first half of the 20th Century

Although glass containers for wine and beer are probably 1,600 years old, much of their use began only in the late 17th century. In the United States, large-scale production of bottles was pioneered by Caspar Wistar in 1739 at his New Jersey plant. In the 1770s the carbonation process for producing soft drinks was developed, and so began an entirely new bottling industry. At the Great Exhibition of 1851 in the Crystal Palace in London, one million “pop” bottles were consumed. The first beer pasteurised in glass was produced in Copenhagen in 1870. Pasteurisation of milk followed soon after. The moulding of a screw thread on a container was invented by John Mason in 1858. The principles of the “press-and-blow” process for making wide-mouth jars were shown in the United States by Philip Arbogast in 1882, and the “blow-and-blow” process for making narrow-neck containers was demonstrated by Howard Ashley in England in 1885. These processes employed manual delivery; fully automatic jar forming by a suction-and-blow process was perfected by Michael Owens over the period 1895–1917 at the Toledo (Ohio) Glass Company, which subsequently became the Owens Bottle Machine Company. The automatic single-gob feeder was developed in 1919–22 by Karl Peiler at the Hartford-Fairmont Company in Connecticut. Fully automatic machines followed, but the true rugged survivor, utilising fully automatic gob delivery to the maximum versatility, was the Individual Section, or IS, machine invented by Henry Ingle at the Hartford Empire Company in 1925. Source: https://www.britannica.com/topic/glass-properties-composition-and-industrial-production-234890/History-of-glassmakingUnlike item 4018, this is a much smaller ink bottle, and was probably used by an individual, as against the supply of ink to pupils from a much larger bottle.Cotton Reel Ink Bottle, green glass, small, chipped around the lip, bubbles in glass.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ink, bottle, glass -

Greensborough Historical Society

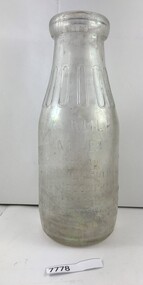

Greensborough Historical SocietyContainer - Bottle, Milk Bottles Recovery Ltd, Milk Bottles Recovery Ltd - one imperial pint, 1930-1950

... - one imperial pint Container Bottle Milk Bottles Recovery Ltd ...This bottle holds one imperial pint. The manufacturer Milk Bottles Recovery Ltd began production in Melbourne in 1930 and ended production in the 1970s. Clear glass bottle, embossed inscription.Inscription: "Milk. One Pint. This bottle is the property of Milk Bottles Recovery Ltd 18 Market St Melbourne. Can only be used by written permission and cannot be sold."milk bottles, milk, glass bottles, imperial pint -

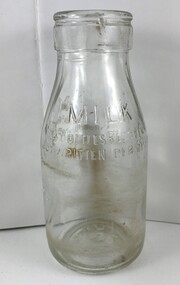

Greensborough Historical Society

Greensborough Historical SocietyContainer - Bottle, Milk Bottles Recovery Ltd, Recovery Ltd Milk Bottle - one third pint, 1951 to 1973

... Milk Bottle - one third pint Container Bottle Milk Bottles ...This bottle holds one third of an imperial pint. The manufacturer Milk Bottles Recovery Ltd began production in Melbourne in 1930. Possibly used for school milk which was a scheme in place from 1951 until 1973.Clear glass bottle, pressed inscription.Inscription: "Milk. Third Pint. This bottle belongs to Milk Bottles Recovery Ltd and cannot be used with out written permission."milk bottles, milk, glass bottles -

Montmorency–Eltham RSL Sub Branch

Montmorency–Eltham RSL Sub BranchEquipment - Ration Pack Emergency, WWII

WWII emergency ration pack used by Australian Armed Forces.WWII emergency ration pack used by Australian Armed ForcesWWII emergency ration pack used by Australian Armed Forces. Small rectangular shaped khaki green painted tin plate metal container with lid. Black ink printed usage instructions on the front and rear of the lid. Department of Defence logo printed on front cover.On front of the lid. MADE IN AUSTRALIA EMERGENCY RATION To be consumed only when no other rations of any kind are procurable. Consumption of this fation must be reported at first oppurtunity. Instructions for use are printed INSIDE the lid. KEEP PACK INTACT D(up arrow)D On rear of the lid INSTRUCTIONS FOR USE FRUIT RATION & MILK TABLETS: MEAT & VEG. RATION: ration pack, emergency, wwii, australian armed forces -

Greensborough Historical Society

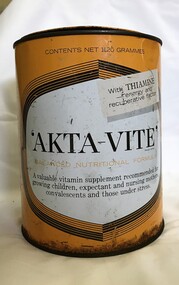

Greensborough Historical SocietyTin, Aktavite, 1950s

Containers used for a vitamin supplement "Aktavite" commonly used in the 1950s in milk drinks or sprinkled on foodTwo tins with lids, text painted brown on dull orangeaktavite, tins -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Churn, small domestic butter, c1880

A butter churn is a device used to convert cream into butter. This is done through a mechanical process, via a crank used to manually turn a rotating device inside the barrel shaped churn. The agitation of the cream, caused by the mechanical motion of the device, disrupts the milk fat. The membranes that surround the fats are broken down, subsequently forming clumps known as butter grains. These butter grains, during the process of churning, fuse with each other and form larger fat globules. Air bubbles are introduced into these fat globules via the continued mechanical action of the churn. The butter grains become more dense as fat globules attach to them while the air is forced out of the mixture. This process creates a liquid known as buttermilk. With constant churning, the fat globules eventually form solid butter and separate from the buttermilk. The buttermilk is then drained off and the butter is squeezed to eliminate excess liquid and to form it into a solid mass. Then rinsing could be done simply by washing in water, followed by draining, salting and working or "kneading" the butter with a pair of wooden butter pats, or with bare hands. This is a paddle churn, a barrel that contains a paddle, which is operated by a handle. The paddle churned the butter inside the container when the handle was turned. Early settlers had to be self sufficient, growing their own vegetables, making tools and clothing and usually had a house cow to produce their milk supplyThis domestic butter churn is an example of the skill of the pioneer craftsman, carpenters and tool makers c1900. As pioneers and early settlers had to be self sufficient they usually kept a dairy cow or 'house cow' to provide milk for drinking and for butter and cheese to made by the family.A small wooden, domestic butter churn with a lid and a crank that manually rotated the paddle inside. E. CHERRY / MAKER / GISBORNE / VICTORIA / Apioneers, early settlers, market gardeners, moorabbin, brighton, cheltenham, dairy products. dairy farmers, milk, butter, dairies -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Containers, cardboard box 'D.C.P. WAFERS', mid 20thC

‘D.C.P WAFERS’ made by Parke, Davis & Co Pty Ltd Sydney, that contained Calcium and Phosphorous. The wafers ‘could be chewed or allowed to dissolve in the mouth’ and ‘ were agreeably flavoured with Chocolate’An empty cardboard box, with a sliding inset, for ‘D.C.P WAFERS’ that contained Calcium and Phosphorous. The wafers ‘could be chewed or allowed to dissolve in the mouth’ and ‘ were agreeably flavoured with Chocolate’Top: 36 WAFERS / MEDICAMENTE VERA encircling PDCo. / D.C.P. WAFERS / (DICALCIUM PHOSPHATE) / AGREEABLY FLAVOURED / WITH CHOCOLATE / EACH WAFER CONTAINS DICALCIUM PHOSPHATE 15 GRAINS / FOR DIRECTIONS SEE REVERSE SIDE / PARKE, DAVIS & CO. / SYDNEY . Left and Right Sides: D.C.P. WAFERS. Base: D.C.P. WAFERS …… same ratio as … milk … soluble … Indicated during periods of growth …../ DIRECTIONS / ….. They may be chewed or allowed to disintegrate in the mouth….pharmacy, parke-davis pty.ltd, moorabbin, cheltenham, bentleigh, disease, bone disease, osteoporosis, calcium -

Kiewa Valley Historical Society

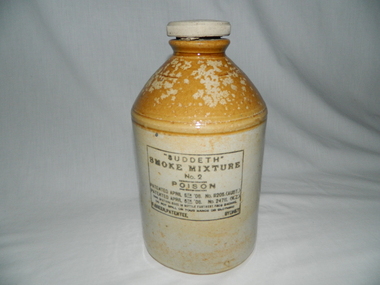

Kiewa Valley Historical SocietyJug Glazed, 1930s to 1950s

... by products contaminating their fresh milk containers and storage ...This item was used in conjunction with the Suddeth (Sudden Death) Carbon Bi-siilphide fumigator during many rabbit plagues that invaded Victoria and NSW before CSIRO introduced the myxomatosis virus in 1950.The contents of this jug was very important pre 1950 for all rural areas which suffered under the annual mice plagues, especially the wheat producing regions. Milk producers suffered from the mice by products contaminating their fresh milk containers and storage facilities. Rabbit warrens causing farm machinery instabilities and also horseback activities eg mustering herds.This glazed pottery jug has a screw on lid and a cream coloured body with a caramel brown neck. The remnance of a handle, which has been broken off is located at the top just below the the rim of the lid.On one side below the neck and within a black boundary mark "SUDDETH" and below "SMOKE MIXTURE No. 2" and sandwiched between two black lines "POISON". Below this and in five lines "PATENTED APRIL 6th '08 No. 11205(AUST.)" "PATENTED APRIL 6th '08 No. 24711 (N.Z.)" "THIS MIXTURE GOES IN BOTTLE FURTHEST FROM MACHINE" "DO NOT SPILL ON YOUR HANDS OR CLOTHING" "F, GREER, PATENTEE SYDNEY"ceramic bowls, contamination of farm produce, domestic farm hygiene, vermin extermination poisons -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMilkshake Containers

Milk Bars made flavoured milk shakes for customers. The drink included milk, flavouring and ice-cream.Mt Beauty had a cafe at the Mt Beauty shopping centre and there was a general store at Mt Beauty North.This milkshake set includes 2 metal mugs and 1 glass, mug size and 1 straw dispenser with lift up lid.milk shakes, milk bar, drink, cafe -

Ringwood and District Historical Society

Ringwood and District Historical SocietyContainer - Milk bottle, Milk Bottle - One Pint Imperial with heavy lip on top. (undated), c. 1930

... ) Container Milk bottle ...Milk bottle with printing around base. "One pint Imperial" 20.5"cms. tall with heavy lip on top designed to handle a circular cardboard seal. Diameter 4 cms. -

Orbost & District Historical Society

Orbost & District Historical SocietyFunctional object - pharmaceutical items, medication, 20th century

These items were used or were available for sale by chemists in Orbost. Chemists who worked in Orbost included Henry Cottman; James Alfred Dubois Williams; Harry Arthur Murray; Miss P.E .Mason (Phyllis Estelle?); Miss Sybil Monica Buzza; Thomas James Frayer; Australia Shaw; James David Torley; John William Zimmer; Dalkeith William Steele; William Thomas Hollingsworth; E.E. Cohen; R.S. Anderson; Frances John Perry Faith Everard Pardew and Charles Anthony Wurf.The practices of early pharmacists are revealed through these glass bottles. The items have a clear association with Orbost. A Nestle's Milk Chocolate Scorched Almonds box used as a container. 3219.2 is a brown cylindrical container with a red lid and a grey and white label, "ATROPINE SULPHATE". 3219.3 is a small clear glass container with cork stopper and paper labels, in red and black print, "SIGMA POISON HYOSCIN HYDROBORON BP" and stamped in purple "5 GRAINS". 3219.4 is a clear glass cylinder with a cork stopper and a white paper label with "SIGMA POISON 5 GRS PILOCARPIN. HCL " in red and black print. 3219.5 is a small stained plastic cylinder with a red lid. The brown contents have stained the inside. It has a paper label of red print on white, and white print on green, "PHYSOSTIGMINE SALICYCLATE BP".3210.6 is a clear gloss narrow plastic container containing powder. It is labelled, "POISON HOMATROPINE HYDROBROMIDE BP".There are six thin glass cylindrical phials with cork stoppers and paper labels, two clear glass stoppers and two glass cylindrical containers with cork stoppers.medicine, chemicals, pharmacy, orbost, phial -

Cheese World Museum

Cheese World MuseumRetailing equipment, Hamilton Beach Mfg Co, Milkshake mixer

The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. This milkshake maker is part of the collection of items given into the care of the Cheese World Museum. Uebergang catalogue No.N42 A single beater electric commercial milkshake maker with black lead, mounted on a white 'artificial marble' base with four rubber stops; and straight-sided aluminium mixing container. An extendable metal column (to H44cm) with a side clip attached is used to hold the container. The electric motor is housed in a slotted round metal casing.Hamilton Beach Mfg Co. Builders, Racine, Wisc. Made in USA. Pats Pending. Volts 220-50c. No.4N14412Aallansford, hamilton beach manufacturing company, usa, milkshake maker, milk, retailing equipment -

Cheese World Museum

Cheese World MuseumJug, Willow pattern milk jug

The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. This milk jug is part of the collection of items given into the care of the Cheese World Museum. Uebergang catalogue No.H557 Tall white round china jug with a 'Blue Willow' pattern. The handle has a 'twisted rope' design.H557allansford, uebergang, jugs, food and drink consumption, containers, willow pattern -

Cheese World Museum

Cheese World MuseumCentrifuge, electric

This Babcock tester was used in the laboratory at the Kraft cheese factory, Allansford. When it was superseded it was passed to one of the users of the machine, Les O'Callaghan, president of the Warrnambool & District Historical Society who placed it in the historical society collection. In 2009 when the historical society premises were upgraded there was insufficient room to store the tester so it was donated to Cheese World Museum. The machine was used to test the butterfat content of milk. Prior to dairy factories coming into existence farmers made butter individually on farms. There was no need for milk testing until farmers supplied factories for payment. Payment was based on a gallon of milk weighing 10lbs (pounds) and this led to richer milk, containing a high degree of butterfat for use in buttermaking, being paid at the same rate as lesser quality milk. In 1890 Stephen Moulton Babcock, an American professor at the University of Wisconsin-Madison, developed a method of determining the amount of butterfat in milk, thus providing a standardised and fairer system for payment. Babcock Test Process 1. 18 grams of milk (17.6ml) was put into a test tube 2. The same amount of sulphuric acid was added 3. A centrifuge at 50ºC was rotated at more than 900 revs per minute 4. The fat floating on top of the liquid in the test tube was measured The Babcock Test provided fairer compensation to farmers and also helped produce a consistent product for consumers. It also allowed for selective breeding when dairy herd testing evolved. ‘The Babcock Test is so simple that it can be used by any careful person, and it is inexpensive to operate. From the very beginning it was so complete in every detail that no change has had to be made in it.’ (Babcock Test http://www.en.wikipedia.org/wki/Babcock_test 31 March 2009) Round green metal container with opening lid. Inside houses a spinning rotor with 20 test tube holders around the outside in two circular rows.7173 BABCOCKTESTER 190allansford, dairy manufacturing, milk testing, babcock test, babcock, stephen moulton, butter, warrnambool cheese and butter factory company -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, Late 19th century or early 20th century

Glass manufacturing has evolved over thousands of years. Glass making has been traced back to 3500 BC in Mesopotamia. The earliest known glass objects were beads, perhaps made by accident while working with metal. In the late Bronze Age, several civilizations discovered how to make vessels and glass bottles by wrapping threads of melted glass around cores of sand or clay. Later, moulds were used to form dishes and table wares. Around the 1st century BC, glassblowing was discovered. This made glass containers less expensive than pottery. Mould-blown glass, the process of blowing a piece of molten glass into a wooden or metal mould, was invented during the 1st century AD. This technique was faster with more consistent results. It paved the way for mass production. It wasn’t until the late 1800s that the production process to become more efficient. In 1887, a company in England created a semi-automatic process that could produce up to 200 bottles an hour. This process has been refined to the point where modern machines can yield more than 600 containers per minute. Blown vs. Manufactured Glass Bottles Nowadays, glass bottles, jars, and cups are usually manufactured on a bigger scale than is found in individual glassblowing studios. If we still depended on hand-blown glass for all of our glass containers, we would see some major differences in the process of creating bottles and jars. First, there's the time. Hand blowing glass takes a significant amount of time, even for one simple container. In contrast, hundreds of jars per minute can be made using modern technology. This leads to the second advantage: price. Because of the automated and streamlined process, the price for manufactured containers is much lower than that of hand-blown glass. Third, manufactured bottles will be much more consistently uniform than bottles blown by hand. Automated glass manufacturing produces nearly identical batches of jars. Glass blowing is awesome for unique, beautiful pieces of art. But for lots of lower priced and uniformly shaped containers, automatic manufacturing is the preferred method to create glass bottles and jars. https://www.containerandpackaging.com/resources/glass-bottles-brief-history The invention and development of glass for domestic items including bottles, has been nothing short of revolutionary. The use of glass bottles, that could be easily washed, led to improved hygiene, and mass manufacturing of drinks of all types, including milk, cordial and alcoholic beverages.Green Glass Bottle Possibly a ginger beer bottle.Concave indentation at the base. Also on base are two raised lumps. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, glass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCentrifuge

Centrifuge, used to measure fat content in milk (see attachment), metal with metal cylindrical containers which adopt a horizontal position as you turn the handle. Cylinder hinged to four sets of twin spokes. Worm wheeled shaft attached to geared handle, pinned to base at 3 points. Thumbscrew at back to attach to a shelf or table. Embossed "OFFICIAL BABCOCK TESTER", "Made in USA" and "467x".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Dairy Equipment, enamel jug with lid, c1900

... containers milk A white enamel jug with a lid and wire loop carrying ...This white enamel jug was used to store milk, by early settlers families in Moorabbin Shire A typical enamel milk jug used by early settler families in Moorabbin Shire c1900A white enamel jug with a lid and wire loop carrying handledairy, dairy farmers, milk, early settlers, pioneers, moorabbin, brighton, bentleigh, cheltenham, containers milk -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Haberdashery, crochet doiley, c1900

Early settler women in Moorabbin Shire c1900, were skilled in crochet and made these doilies to cover milk jugs, and other food containers, to protect the contents from flies and other insects while on the kitchen table.The women of the early settler families in Moorabbin Shire c1900, were very skilled with craftwork, crochet, knitting, sewing, needlework.A crocheted cotton doily with raised decoration of a cup and saucer. Coloured beads anchor the points to add weight to keep the doily in place when protecting contents of a cup or jugpioneers, earley settlers, haberdashery, craftwork, crochet, doileys, kitchen equipment, moorabbin shire, bentleigh, moorabbin, ormond, cheltenham, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Butter churn domestic, circa 1800s

Circa late 1800s. Wooden domestic butter-churn. This is a paddle churn, a barrel that contains a paddle, which is operated by a handle. The paddle churned the butter inside the container when the handle was turned. Early settlers had to be self sufficient, growing their own vegetables, making tools and clothing and usually had a house cow to produce their milk supply. An unsigned note states it was used by a Chinese market-gardener’s family. From the mid 1800s into the1900s, there were numbers of Chinese market gardeners working in Bentleigh, Moorabbin, Mc Kinnon, and Cheltenham in the Shire of Moorabbin. After the sale of land following 'Dendy's Special Survey' 1841 many Chinese settlers rented allotments and established market gardens in the area and sold their produce to the increasing population of Melbourne at the markets in St Kilda and Melbourne.Circa late 1800s. Wooden domestic butter-churn consisting of a wooden barrel with a lid and a crank that manually turned a paddle inside to separate the butter fat from the butter milk 'BUTTER CHURN' written in chalk undated, unsignedchinese, melbourne, brighton, moorabbin, butter, cows, milk, pioneers, dairy, settlers, fruit, bentleigh, markets, mckinnon, cheltenham, vegetables, dendy henry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Glass Jar, Nestle, 1920s

This glass jar once contained Australian-made Nestle’s Malted Milk. The jar carries the company’s familiar logo. This jar would have originally had a screw-top metal lid. The large jar may have been used in a canteen, hospitality business or hospital due to its capacity. The jar was owned by Dr W.R. Angus, surgeon and oculist, who lived in Warrnambool with his wife and growing family for over thirty years. It may have been purchased from the Nestle factory in nearby Dennington. The jar was donated by his family and is part of the W.R Angus Collection. Nestles Malted Milk powder is usually added to either hot or cold milk as a nutritious drink supplement. The powder is a combination of evaporated whole milk powder, malted barley and wheat flour. Nestle began in 1867 and its products were available in Australia since the 1880s. Australia had become Nestle’s second-largest export market by 1906 and by 1908 Nestle had set up business in Australia. The Nestle factory in Dennington, Warrnambool, opened in 1911 and was the world’s largest condensed milk plant. For over 100 years the factory produced dried milk powder from the produce of local dairy farmers. It was a major employer for the district until an announcement was made on May 2019 by its recent owner Fonterra that it was closing its Dennington site for financial reasons. This Nestle Malted Milk jar is connected to the history of Warrnambool, as it was owned by the daughter of Dr W. R. Angus and his wife Gladys. It is part of the W.R. Angus Collection, which is notable for still being located at the site connected to Doctor Angus, Warrnambool’s last Port Medical Officer. It is also connected through its manufacturer Nestle. which had a branch in Warrnambool from 1911 to 2019, overlapping the time when the Angus family resided there, from 1939 to the 1970s. The jar is also significant as an example of the early-20th-century food found in local households and businesses, and could have been purchased from the local Nestle factory.Round tall clear glass jar with a wide mouth, short neck and straight sides on a cylindrical body. The jar has been blow-moulded in two pieces with a side seam running from the base to the top of the lip. There are air bubbles in the glass, and the base has been ground flat. The outside of the mouth is threaded. Inscriptions are moulded on one side and there is a round logo with text around an image of a mother bird with three young birds in a nest. The jar once contained Nestles Malted Milk and was made in Australia around the 1920s. The jar is part of the W.R. Angus Collection.Inscription: “PREPARED / IN AUSTRALIA” and “TRADE MARK / REGISTERED” Logo; “NESTLES MALTED MILK” around image [bird feeding young in next]flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, nestle, malted milk, glass jar, nestle jar, nestle malted milk, dennington, nestle australia, w.r. angus collection -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyContainer - Bottle, Lewis & Whitty milk of magnesium, excavated from cesspit at All England Eleven Hotel, 1850s - 1860s

... Container Bottle, Lewis & Whitty milk of magnesium, excavated from ...Dug from ground at demolished 282 Rouse Street in 1999 and donated by Peter LIBBISLewis & Whitty (Melbourne) milk of magnesium bottle from group of 1850/1860s bottles dug up at 282 Rouse Street in 1999Lewis & Whitty (Melbourne)domestic life - containers, business and traders - hotels, all england eleven hotel, w h dawbarn & son, health - general health, lewis & whitty (melbourne) -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyContainer - Milk bottle, Spain Bros Dairy, 1940s - 1950s

... . Dairy) with wad Container Milk bottle, Spain Bros Dairy ...Was purchased on behalf of the Society by Peter Libbis from the Ballarat Bottle Fair, Southern Indoor Tennis Centre, Sebastopol, Victoria, 15 April 2001Broad neck Imperial pint milk Bottle (Spain Bros. Dairy) with wadImprint: Spain Bros. Fernleigh Dairy' 'phone MX4080, MX 2909' 'One imperial pint'business and traders - dairies, spain brothers -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyContainer - Bottle, Lewis & White milk of magnesium, excavated from cesspit at All England Eleven Hotel, 1850s - 1860s

... by Peter LIBBIS Domestic Life - Containers Business and Traders ...Dug from ground at demolished 282 Rouse Street in 1999 and donated by Peter LIBBISLewis & White (Melbourne) milk of magnesium bottle from group of 1850/1860s bottles dug up at 282 Rouse Street in 1999Lewis & White (Melbourne)domestic life - containers, business and traders - hotels, all england eleven hotel, health - general health, lewis & white (melbourne) -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumBox, cardboard, c.1937-1960

Trove : Advertised from 1937-1949 in various publications search under "Wellcome"' Calcium Borogluconate (yes with 2 'l's) . Victorian Government Gazette , no.2 Jan 5, 1960, page 16. List of Registered Stock Medicine. Registered Wholesale Dealer : Burroughs Wellcome and Co. (Aust) Ltd. Cressy Street, Rosebery New South Wales. Manufacturer, if other than the Wholesale Dealer - , Distinguishing Name of Stock Medicine : "Wellcome" Calcium Borogluconate, Approved Use or for the Treatment of : Milk Fever, hypocalcaemia. Rectangular faded pink cardboard box opening at both ends with the remnants of a paper label on one side, containing a folded paper leaflet and a cellophane bag containing white granules.Outer label '.....ATE .s enclosed)..........ELLCOME & .............STRALIA..D., SYDNEY, N....in Australia'. Impressed on one flap of box '132'. Printed leaflet (side one) Illustration of a unicorn, a thick black line under which text 'WELLCOME' brand CALCIUM BOROGLUCONATE (Vetinary)' followed by another thick black line. 'Calcium Borogluconate ia a stable , non-irritant calcium preparation for subcutaneous or intravenous injection in the treatment of milk fever and other forms of acute hypocalcaemia. It is available in the dry state as 'Wellcome' Calcium Borogluconate, a granular product in single dose containers of 2 1/2 oz. Milk Fever In the treatment of milk fever in cows, 21/2 oz. to 31/2 oz. of the granules should be injected subcutaneously at two or three points in the neck, with the usual aseptic precautions. The granules should be dissolved in 10 fl. oz. of boiling water, the solution allowed to boil for five minutes, then cooled to body temperature before administration. Repetition of the dose is very rarely necessary. Should a more rapid response be desired, the whole of the solution hay be given by slow intravenous injection; alternatively , the greater part of the solution may be injected by this route and the remainder given subcutaneously in the manner described above. A convenient apparatus for the controlled administration of large volumes of fluid (leaflet side two) is the 'Wellcome' Flutter Valve Injection Apparatus. Prophylaxis Recurrent attacks at successive parturitions may be prevented by giving calcium borogluconate immediately after calving and again about 20 hours later. Each dose should be from one or two ounces of 'Wellcome' Calcium Borogluconate, dissolved as directed above. Other Indications Certain other conditions have been found to respond readily to calcium borogluconate therapy. These include parturient hypocalcaemia or milk fever in ewes, parturient eclampsia in sows and bitches, so-called "staggers" in lactating dairy cattle suspected to be due to hypocalcaemia, and transit tetany in horses. The dosage for various species is generally within the ranges indicated below : horses and cattle 11/2 to 31/2 oz. Sheep, goats and pigs 1/2 oz. to 1 oz. Dogs 11/2 dr. to 3 dr. 'WELLCOME' brand CALCIUM BOROGLUCONATE A readily-soluble granular product issued in cartons of 21/2 oz.' Illustration of a unicorn, 'BURROUGHS WELLCOME & CO. (AUSTRALIA) LTD. (Incorporated in England) SYDNEY, N.S.W.' A black line 'ref.A5007g 54.1. 25' milk fever, hypocalcaemia, subcutaneous -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyContainer - Milk bottle, M Woodruff Royal Dairy, Port Melbourne, c.1950

... . Container Milk bottle, M Woodruff Royal Dairy, Port Melbourne ...Michael Tomas WOODRUFF commenced his Woodruff's Royal Dairy in 1916. It was originally located at 22 Derham Street, Port Melbourne, and later expanded into Bridge Street. In 1956 the name was changed to the Superior Dairy.Glass milk bottle from Woodruff's Royal Dairy, Port Melbourne.MX2769 MX2000 Imperial Pint Woodruff's Royal Dairy Port Melbourne. On bottom 36.michael thomas woodruff, industry - manufacturing, business and traders - dairies, woodruff's royal dairy -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyContainer - Milk bottle, M Woodruff Royal Dairy, Port Melbourne, 1940s

... ) complete with wad (paper cap) Container Milk bottle, M Woodruff ...Broad neck imperial pint milk bottle (M Woodruff Royal Dairy) complete with wad (paper cap)'M. Woodruff - Royal Dairy Port Melb. To be washed and returned. This bottle contains milk bottled for sale by M Woodruff & always remains his property. It is loaned and cannot be legally used by others':Printed on wad: 'Pure Milk, please return bottles dailybusiness and traders - dairies, michael woodruff, royal dairy port melbourne -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyContainer - Milk bottle, M Woodruff Royal Dairy, Port Melbourne, 1940s

... with wad (cap) Container Milk bottle, M Woodruff Royal Dairy, Port ...Broad neck imperial 10 fl. oz. milk bottle (M Woodruff Royal Dairy) complete with wad (cap)'M. Woodruff - Royal Dairy Port Melb. MX2769 & MX2000.:Printed on wad: 'Pure Milk, please return bottles dailybusiness and traders - dairies, michael woodruff, royal dairy port melbourne -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumTin, food

... Korumburra gippsland Nestles Malted Milk Cylindrical metal container ...Cylindrical metal container with push on lid, label with yellow coloured background, white green and red text, red borders.Nestles Malted Milk