Showing 37 items matching "motor accessories"

-

Trafalgar Holden Museum

Trafalgar Holden MuseumAccessory - Webbing belt

general purpose military beltmanufactured and sold by General Motors HoldenArmy green webbing belt with brass clip on front two brass buckles on the back from which pieces can be attached military, canvas, belt -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - Holden FE special sedan, July 1956

BY THE time the FJ Holden was replaced with the FE in July 1956, Australia’s own had taken many steps forward. The six-volt electrics were replaced with a 12-volt set-up, the two-piece windscreen was replaced with a single curved item and the skinny 15in rims were replaced with 13x4.5 steelies. Unlike the FX-FJ, the FE was designed locally by an Australian team. The resulting car was much sleeker than the earlier models, being two inches longer in the wheelbase, four inches longer overall and slightly heavier than its predecessor. To compensate, the 132ci grey motor was blessed with another small dose of horsepower thanks to larger valves and improved cylinder heads. Other mechanical improvements included pendulum-style brake and clutch pedals, hydraulic clutch actuation, larger brake drums and recirculating ball (rather than worm and sector) steering. Other great leaps forward included optional heater, indicators, reversing lights, windscreen washers and demister. In knocked down form was the first model to be exported to New ZealandBlack painted special sedan. Added accessories include exterior sun visor, headlight protectors, and on the interior grab handle mounted across the back of the front seatDiecast special sedan badge on rear quarters. Number plate club permit 63450 Hfe special, holden, sedan, car -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Singer Electric Sewing Machine, The Singer Manufacturing Company, 1950

Singer was first established as I. M. Singer & Co. in 1851 by Isaac Merritt Singer with New York lawyer Edward C. Clark. Best known for its sewing machines, it was renamed Singer Manufacturing Company in 1865, then the Singer Company in 1963. The Singer company began to market its machines internationally in 1855 and won first prize at the Paris world's fair that year. They had offices established in both Sydney and Melbourne by the mid-1960s. The company demonstrated the first workable electric sewing machine in 1910. Singer was also a marketing innovator and a pioneer in promoting the use of instalment payment plans, making their machines more affordable for many people. According to its serial number, this machine was manufactured in 1950 and was one of the new models designed to be more portable as it only weighed about 10 KG.This sewing machine is of local, national and international significance as it represents developments in technology and the impact this had upon the work of women.The Singer 99 was a sturdy and reliable machine that was easy to use. Lighter than other machines of its time, this machine weighed only 10 Kgs. It is mounted on a wooden base with a small compartment under the balance wheel to store accessories and bobbins. It has a 'Bentwood' (polished plywood) cover which also provided some room for storage. The machine is driven by a small electric motor and a light to illuminate the work area. It is decorated with gold decals and a filigree pattern. It includes a knee control which is inserted in a hole at the front of the machine. The serial number EG045782 indicates it was manufactured in 1950.Across the top in gold script: "The Singer Manufacturing Co. / Made in Great Britain" On light cover: "SINGER" Plate with specifications also attached. On front of machine in oval badge: A CENTURY OF SEWING SERVICE/ THE SINGER MANFG. CO. 1851 - 1951singer sewing macnine, domestic appliances, women's work, technology -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Australian Army Issue Clasp Knife

Australian manufactured clasp knives were a standard issue to Australian Military Forces during World War 2. The most commonly encountered knife was an all metal model with a canoe shaped body. This knife was a Whittingslowe first pattern clasp knife which included a blade, a tin opener and a marline spike as well as screw driver and shackle to attach the knife to a lanyard or belt clip. These knives were given a dull Nickel plating to protect them. William Thomas Whittingslowe was born in Wales in 1888, he was educated in England and at 18 migrated to Canada and then to Australia, arriving in about 1912. After working in various states, he settled in South Australia and in the 1920s set up his own business, Whittingslowe Engineers Limited. He specialised in ironworking and knife manufacturing. His firm produced a large amount of blade ware during World War 2. He also designed and built manufacturing equipment for General Motors Holden. He died at Murray Bridge (SA) in 1956.This item is significance because it was donated by a member of the community of Wodonga which has a strong connection to Australian military history.A clasp knife made completely from metal with nickel plating. The accessories all fold into a canoe-shaped body. It included a knife, can opener and marlin spike.On knife blade: WE over a broad arrow/I\australian army equipment ww2, thomas whittingslowe, australian army -

Greensborough Historical Society

Greensborough Historical SocietyFunctional object - Tow Ball, Tow Ball - 2 1/4 inch

... motor vehicle accessory... by the Petts family of Greenhills. tow ball motor vehicle accessory ...Old Style Tow Ball used to attach to car for towing. Used by the Petts family of Greenhills.Cast Iron tow ball with nuttow ball, motor vehicle accessory, petts family -

Ringwood and District Historical Society

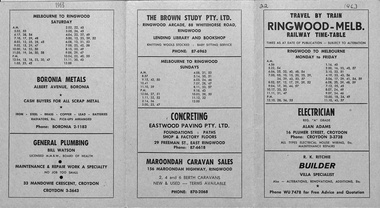

Ringwood and District Historical SocietyDocument, "Mail" Print. Phone Ringwood 65, Railway Time Table. Ringwood to Melbourne and Melbourne to Ringwood from 1963

Light green coloured tri-fold card with black printing. Ringwood to Melbourne and Melbourne to Ringwood timetables, includes Monday to Friday, a separate Saturday and separate Sunday listings. Most of the front and back of folding card contains advertisements, including Electrician (Alan Adams of Croydon), Builder (R.K. Ritchie - villa specialist), Fuel Merchant (H. Tortice of Ringwood), Grass Cutting (C.G. Pattenden of Adelaide St, Ringwood), Motor Mowers Sales and Service (John Salisbury of Ringwood), TV Radio Service (D.G. Hill of Heathmont), Real Estate Agent (A.T. Miles & Son of Ringwood), Women's, Men's & Children's Wear - (Louis Economy Shop of Ringwood), Painting, Decorating & Paperhanging (D.G Jeffs of Heathmont), Fruiterer and Greengrocer (Vincenzo Condello of Ringwood), Pygmalion Ladies' Accessories (Ringwood Arcade), Boronia Metals (Albert Ave, Boronia), General Plumbing (Bill Watson of Croydon), The Brown Study - Lending Library and Bookshop (Ringwood), Concreting - Eastwood Paving Pty Ltd (East Ringwood), Maroondah Caravan Sales (Ringwood), -

Bendigo Historical Society Inc.

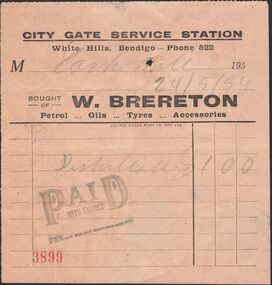

Bendigo Historical Society Inc.Financial record - INVOICE COLLECTION: Motor industry invoices

10934.23a Square Receipt no. 3899 for City Gate Service Station - White Hills, Bendigo. Phone 522 Cash sale 24 May 1954 Bought of W. Brereton Petrol... Oils... Tyres... Accessories... paid £100 Paid with thanks made from thin paper, written in pencil. Printed in black ink 10934.23b Large rectangular receipt on pale cream, blue lined paper. Logos and information printed in black ink. Portrait image printed in black ink showing a tire. Market Square Telephone 345 Bendigo, February 1st 1925 Mr. RMS Abbott Bendigo to Bendigo Motor Tyre Hospital (James H. Tubb, proprietor) Receipt was written in black ink. There is also a black ink stamp with the signature of WJ Coaey in the lower third of the receipt. There is a small postage stamp stuck to the page with the signature of WJ Coaey 10934.23c Mitchell Street N. 11130 Phone 786 Bendigo 15/2/1934 Bendigo Motor Co. Vauxhall & Buick Cars. Bedford Trucks sold to Gills George Receipt is printed in blue ink on a rectangular shaped receipt of thin paper 10934.23d 27/6/50 Cash Sale Bought of City Gate Service Station White Hills Bendigo Phone 522 Receipt came from an Eclipse Check book Receipt written in pencilcity gate service station, bendigo motor tyre hospital, bendigo motor co.