Showing 126 items

matching steam boiler

-

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Book - Molassine Blotter, 1910

... steel tanks for molasses bought from Danks, Steam Boiler... steel tanks for molasses bought from Danks, Steam Boiler ...Molassine was created in 1900 to exploit a secret formula for animal fed. The formula had been brought to Britain by Arthur Stein ‘a mid European probably hailing from one of the Balkan States’. At first the feed was made up by Henry Tate but in 1908 they began work in Greenwich. The molasses was bought locally from Silvertown and Plaistow refineries and the company built the first steel tanks for molasses bought from Danks, Steam Boiler Manufacturers, between 1910-1914. Their main product was a molasses based feed for horses - this consisted of sphagnum moss mixed with both beet and cane molasses and a ‘soupcon of maganesium calcum carbonate’. In the First World War this feed was considered antiseptic and soldiers used it as a plaster for wounds.Molassine Blotter Book published by the Molassine Company Limited, Tunnel Avenue, East greenwich, London, S.E. Red covered, it contains information Calendar for three years and information on domestic animals - how to keep them when ill, also an English Dictionary, Atlas, ready reckoner, address book, at home days diary etc.history, james lerk collection, molassine blotter -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BADHAM COLLECTION: ENGINEMAN’S MASTER'S KEY - BOOK BY L.F.R. SCHNABEL

... and specifications executed for Steam engines. Boilers and Power Plants, hard.... Plans and specifications executed for Steam engines Boilers ...Engineman’s Master's Key by L.F.R. Schnabel Licensed Inspector Melbourne, Victoria. Printed at the L.F.R Schnabel Engineering Institute, 443 Bourke St, Melbourne C 1903. Pans and specifications executed for Steam engines. Boilers and Power Plants, hard covered book worn.document, memo, railway, engineman’s master's key - book by l.f.r. schnabel - licensed inspector melbourne victoria, printed at the l.f.r schnabel engineering institute , 443 bourke st melbourne. plans and specifications executed for steam engines, boilers and power plants. -

National Wool Museum

National Wool MuseumInstrument - Pressure Gauge, Dane Taylor & Co. Pty. Ltd

... in the departments requiring steam such as the boiler and dyeing rooms. ... the pressure in the departments requiring steam such as the boiler ...Used in the Albion Mill to determine the pressure in the departments requiring steam such as the boiler and dyeing rooms. Circular brass object with black hand painted text and numbers, and a central dial. Printed: PRESSURE / GAUGE / LBS. PER INCH. DANE TAYLOR & Co. Pty. Ltd. / MELBOURNE [on base]: 277828instruments, pressure gauge, albion mill, dane taylor & co pty ltd, south melbourne, geelong, wool industry -

Stawell RSL Sub Branch War Museum

Stawell RSL Sub Branch War MuseumProtograph of WW1 soldier Christopher Clark, Portrait WW2 Soldier Christopher Clark, Approx 1916

... licence and drove the sugar trains then worked on the steam boiler... the sugar trains then worked on the steam boiler engines ...Soldier in WW1 Australian Imperial Expeditionary Force No 5998 Christopher Clark 59th Battalion Born in StawellChristopher was a WW1 Serviceman from Stawell who returned to Australia Framed Studio Portrait of Soldier No 5998 Christopher Clark Australian Imperial Expeditionary Force WW1,59th Battalion Christopher Clark was born in Stawell on 25th December 1892 and was brought up on the family farm in Callawdda and worked in the district and then in Queensland where he obtained an engine drivers licence and drove the sugar trains then worked on the steam boiler engines in the sugar mills. When the First World War started he came back to Stawell and enlisted in the army on 11/4/1916. He was sent to France in the 59th Battalion. He was in the army 1175 days, serving 1029 days abroad. During his service he was promoted to Lance Corporal. Details from his daughter Ruth Clark of Ararat December 2017.ww1, serviceman, soldiers, military, stawell -

Stawell RSL Sub Branch War Museum

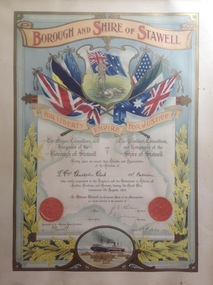

Stawell RSL Sub Branch War MuseumCertificate of Appreciation from Stawell Borough and Shire for WW1 soldier Christopher Clark, Certificate of Appreciation, Approx 1916

... on the steam boiler engines in the sugar mills. When the First World... then worked on the steam boiler engines in the sugar mills. When ...Soldier in WW1 Australian Imperial Expeditionary Force No 5998 Christopher Clark 59th Battalion Born in StawellChristopher was a WW1 Serviceman from Stawell Framed Certificate of Appreciation for Soldier No 5998 Christopher Clark Australian Imperial Expeditionary Force WW1, 59th Battalion Christopher Clark was born in Stawell on 25th December 1892 and was brought up on the family farm in Callawdda and worked in the district and then in Queensland where he obtained an engine drivers licence and drove the sugar trains then worked on the steam boiler engines in the sugar mills. When the First World War started he came back to Stawell and enlisted in the army on 11/4/1916. He was sent to France in the 59th Battalion. He was in the army 1175 days, serving 1029 days abroad. During his service he was promoted to Lance Corporal. Details from his daughter Ruth Clark of Ararat December 2017. Soldier No 5998 Christopher Clark Australian Imperial Expeditionary Force WW1 59th Battalion Born in Stawellww1, serviceman, soldiers, military, stawell -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBrush

... the tubes and flues of a steam engine or other boiler. L 6' 2"... of a steam engine or other boiler. L 6' 2" Brush ...Tube Brush also called a Flue Brush. Used for cleaning the tubes and flues of a steam engine or other boiler. L 6' 2"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Stawell RSL Sub Branch War Museum

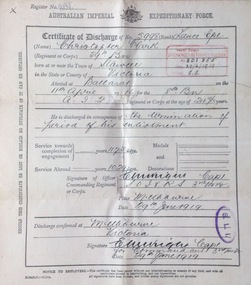

Stawell RSL Sub Branch War MuseumCertificate of Discharge, Australian Military Forces, Document, June 1919

... the sugar trains then worked on the steam boiler engines... on the steam boiler engines in the sugar mills. When the First World ...Each soldier had one of these forms filled out on Discharge from the army. WW1 Australian Imperial Expeditionary Force Certificate of Discharge No 5998 Christopher Clark 59th Battalion Born in StawellChristopher was a WW1 Serviceman from Stawell WW1 Australian Imperial Expeditionary Force Certificate of Discharge of Soldier No 5998 Christopher Clark Australian Imperial Expeditionary Force WW1,59th Battalion Christopher Clark was born in Stawell on 25th December 1892 and was brought up on the family farm in Callawdda and worked in the district and then in Queensland where he obtained an engine drivers licence and drove the sugar trains then worked on the steam boiler engines in the sugar mills. When the First World War started he came back to Stawell and enlisted in the army on 11/4/1916. He was sent to France in the 59th Battalion. He was in the army 1175 days, serving 1029 days abroad. During his service he was promoted to Lance Corporal. Details from his daughter Ruth Clark of Ararat December 2017.Form is filled out for soldier Christopher Clarkww1, serviceman, soldiers, military, stawell -

Bendigo Historical Society Inc.

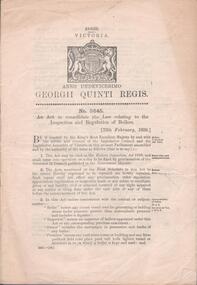

Bendigo Historical Society Inc.Document - MINING REPORTS - BOILERS INSPECTION ACT 1928

... causing damage or injury to a Steam Boiler. Document is part... causing damage or injury to a Steam Boiler. Document is part ...Printed document Inspection and Regulation of Boilers, dated 12th February 1929, No 3645 which sets out rules and regulations for the ownership and use of boilers. Items mentioned are: Inspectors, Registration of Boilers, Inspection of Boilers, Certificate of Inspection, Powers and Duties of Inspectors, Necessity for Certificate, Notice f Alterations, Duties and Liabilities of Owners of Boilers and Others, Explosions and Accidents and Miscellaneous. Also Schedules. First Schedule is the Number and Title of Act, Second Schedule is Notice of Registration, Third Schedule is Certificate of Inspection, Fourth Schedule is certificate stating the number of lbs. per square inch the safety valve blows off, Fifth Schedule is Notice to Owner that Boiler is Dangerous and Sixth Schedule is a Report with regard to Explosion of or Accident causing damage or injury to a Steam Boiler. Document is part of the Albert Richardson Collection. document, mining reports, boilers inspection act 1928, t rider -

Puffing Billy Railway

Puffing Billy Railwaysingle cylinder Blackham stationary engine, circa 1900

... steam from a separate boiler to operate. Maker : W.H Blackham... steam from a separate boiler to operate. Maker : W.H Blackham ...Engine (power producing equipment) A single cylinder Blackham stationary engine. This engine required steam from a separate boiler to operate. Maker : W.H Blackham King Street, Melbourne, Victoria c. 1900 Historic - Industrial - Single cylinder Stationary engine - W. H. Blackham - Kings St. Melbourne, Victoria, Australia A single cylinder Blackham stationary engine. - Made from Iron, wrought Iron & brassW.H Blackham King st. Melbournepuffing billy, blackham, single cylinder stationary engine -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING REPORTS - REGULATION OF MINES STATUTE 1873

... , no person under 18 to be in charge of any steam engine, boiler... to be in charge of any steam engine, boiler or mechanical power ...Handwritten extract from the Bendigo Advertiser 3/1/1874. Regulation in force from 1st january 1874. Regulation states the minimum age of boys working at the mines, no female of any age can be employed underground, the maximum hours under 18's worked, no person under 18 to be in charge of any steam engine, boiler or mechanical power and no person in charge of steam machinery to be employed more than eight hours in any one day as an ordinary day's work.document, gold, mining reports, mining reports, regulation of mines statute 1873, bendigo advertiser 3/1/1874 -

Bendigo Historical Society Inc.

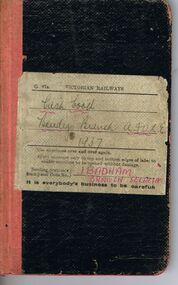

Bendigo Historical Society Inc.Document - BADHAM COLLECTION: CASH BOOK BENDIGO BRANCH AFLE

... of steam engines: boiler efficiency, boiler power, calorific value... contains notes re running of steam engines: boiler efficiency ...Black covered notebook, red spine. On front ' Cash book, Bendigo Branch AFULE 1937' J. Badham, Branch Secretary. Inside front cover, written in blue ink ' J. Badham, 16 Abbott Street, Bendigo' (front pages are cut out of book, presumably cash records ). Remainder of book contains notes re running of steam engines: boiler efficiency, boiler power, calorific value, boiler power rating, engine power, superheating, boiler abuses, superheater metallic packing,supervision, examination 1000 miles. Outstations 1938.person, receipts, badham, railways, cash book -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MARKS COLLECTION: SPECIFICATION AND GENERAL CONDITIONS OF CONTRACT HERCULES AND ENERGETIC MINE, 2nd March, 1870

... to bricklayers and stonemasons work required for the erection of Steam... and stonemasons work required for the erection of Steam Engine, Boiler ...Handwritten document, outlining 'specifications to bricklayers and stonemasons work required for the erection of Steam Engine, Boiler and Winding Gear for the Hercules and Energetic Goldmining Company, Sandhurst' Sections consist of details for excavation for engine and foundations, masonry, brickwork chimney, excavations for boiler seating, firing floor, firing boiler brickwork engine bed, winding gear, mortar and cement, seating of boiler. Document is dated Mar 12, 1870. Attached to the document is a blue printed 'General Conditions of Contract' document, handwritten on top 'Bricklayers' Drawings by Wm. Middleton, engineer. See 8300.14.Drawings by, Wm Middleton, Engineer Sandhursts.bendigo, buildings, fortuna villa, william middleton, hercules and energetic gold mine -

Bendigo Historical Society Inc.

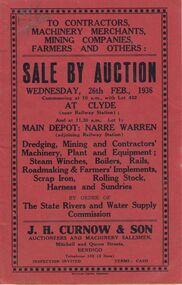

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - THE STATE RIVERS AND WATER SUPPLY COMMISSION

... , Steam Winches, Boilers, Rails, Roadmaking & Farmers' Implements... and Contractors' Machinery, Plant and Equipment, Steam Winches, Boilers ...Red covered auction catalogue for a sale held on the 26th February, 1936 by Order of The State Rivers and Water Supply Commission at Clyde and the Main Depot at Narre Warren. For sale was Dredging,Mining and Contractors' Machinery, Plant and Equipment, Steam Winches, Boilers, Rails, Roadmaking & Farmers' Implements, Scrap Iron, Rolling Stock, Harness and Sundries. Columns to write prices on the right side edge of the pages. Hand written Supplementary List for Narre Warren Depot machine sewn inside the back cover. J. H. Curnow & Son were the auctioneers and the catalogue was printed by Boltons Print, Bendigo.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - the state rivers and water supply commission, j h curnow & son, boltons print bendigo -

Federation University Historical Collection

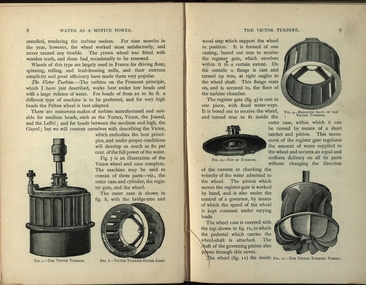

Federation University Historical CollectionBook, Machinery for Metalliferous Mines, 1894, 1894

... engines and ventilating machinery, Steam boilers/engines and oil... ventilation oil engine california america water steam boilers steam ...The 1st edition of this famous work, giving an excellent account of the machinery used in late 19th century metal mining in the UK and overseas is very rare. It covers a wide range of equipment - pumps, steam engines, drills, winding engines, stamps & concentration mills, aerial ropeways, tramways and early uses of electricity etc. Brown hard cloth covered book. xvi 564 pages with additional advertisements, with over 300 illustrations and drawings, some fold out. Chapters include Water as a motive power, Wind engines and ventilating machinery, Steam boilers/engines and oil engines, hoisting machinery, draining of Mines, pumping engines, rock drilling machinery, boring machinery, concentration machinery, sizing and classifications trommels, joggers and jigging, fine concentration, milling of gold ores, milling of silver ores, amalgamation plates and machinery, dry and roasting machinery, chlorination and cyandide processes for the extraction of gold, electricity as a motive power for mining, electric lighting and blasting, aerial wire ropeways, transport by rail and road. There a a number of lovely line illustrations in the book including: Poncelot's undershot waterwheel; Fromont furnace;Victor turbine; Pelton waterwheel; Root's positive blower;Cross section and front elevation of Lancashire boiler; Robey's Compound Mill Engine; Portable Winding Plant; Iron Pit Head Gear ; Loading Arrangement in an Incline Shaft; kibble; Worthington Pump; California Pump; Scram's Air Compressor; Rock drill Bits; Special Sharpening tools; Boring tools;Rotating Picking table; Ore Feeder; roller crusher; stamp battery; round buddle; slime table; vanner; amalgamating plant; belt elevator;roasting furnace;splicing wire rope; capel; tipping waggon;mining, cornish pump, linkenbach table, water wheel, ventilation, oil engine, california, america, water, steam boilers, steam engines, oil engines, pumpimg, rock drilling, boring, jiggers, milling, silver, gold, drying and roasting, chlorination, cyaniding, lead, zinc, copper, electricity, electric lighting, wire ropes, transport, wind engine, poppet head -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph, "Melbourne & Hobson's Bay United Railway Co'ys Pier, Sandridge (Port Melbourne) 1865", 1865

... and in the foreground, workmen, carriages loaded with ballast and a boiler... and in the foreground, workmen, carriages loaded with ballast and a boiler ...City of Port Phillip Collection - pm 0988 "Melbourne & Hobson's Bay United Railway Co'ys Pier, Sandridge (Port Melbourne) 1865" . View looking South showing tall masted ships and in the foreground, workmen, carriages loaded with ballast and a boiler for steam powered cranes. Image attributed to Charles Nettleton transport - shipping, piers and wharves - railway pier, maritime, railway pier, charles nettleton, hobson's bay united railway -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncSteam Engine, Estimated late 19th century

... designed to be towed. Fire box painted black, boiler and steam... and steam cylinder green, wheels red. Boiler is not sound so engine ...Large 4 wheeled single cylinder (horizontal) steam engine designed to be towed. Fire box painted black, boiler and steam cylinder green, wheels red. Boiler is not sound so engine is connected to an independent steam/air source to be operated for display purposes. 150 cm flywheel on LHS looking forward toward the front. Brass water drain tap on firebox. Also other brass fittings on firebox. Cast brass disc with red background fixed high on firebox :- "Marshal Sons & Co. / Made expressly / to the order / Shut, No. 45781, Open / of / Robison Bros / South Melbourne." "10017" raised in relief on firebox door. machinery; engines; steam power source -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Letter - MCCOLL, RANKIN AND STANISTREET COLLECTION:CAMERON SUTHERLAND SEWARD TO STANISTREET ESQ

... pounds. Steam mining winches, Cornish boiler, Lancashire Jackass... Mines. Deborah Mine: horizontal steam driven air compressor ...Letter Cameron Sutherland Seward Pty Ltd., 26 May 1931 to J.J.Stanistreet Esq, Commonwealth Bank Buildings, Charing Cross, Bendigo re quotes from Mr. Bloomfield 'in connection with the Deborah, Monument Hill and Central Nell Gwynne Mines. Deborah Mine: horizontal steam driven air compressor, air receiver - price 45 pounds. Steam mining winches, Cornish boiler, Lancashire Jackass boiler, Cornish Flue Boiler (Roberts) funnels for boilers, exhaust tanks, quartz hoppers, poppet heads.bendigo, gold mining, mccoll rankin and stanistreet, bendigo, monument hill gold mine, deborah gold mine, central nell gwynne gold mine, g. seward, j.j. stanistreet, cameron, sutherland and seward pty ltd. -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncSteam Engine, 1877

... painted black, boiler and steam cylinder green, wheels grey.... Known as "Aunty Jack" Machinery - Engines - Steam On brass ring ...Restored by Maldon Flywheelers Association. Originally owned and used by Zemster Brothers of "Brook Mount" Shellbourne.Known as "Aunty Jack"Large 4 wheeled 9 HP single cylinder (horizontal) steam engine, designed to be towed. Front wheels smaller than rear. Folding smoke stack with spark arrestor. Fire box and smoke stack painted black, boiler and steam cylinder green, wheels grey. In working order but engine is connected to an independent steam/air source to be operated for display purposes. 150 cm flywheel on LHS looking forward toward the front. Timber front turntable and back brake pad assembly. Brass water drain tap on firebox. Also other brass fittings on firebox.On brass ring near top of firebox:- "Serial No. 5672, Marshal Sons & Co. / Limited / Engineers / Gainsborough England". Metal plate on front turntable:- "Restoration of the Front Undercarriage / and retubing of the boiler by / Castlemaine Technical School / 1979". Cast in relief on wheel hubs:- "Marshal Sons & Co. Gainsborough".machinery - engines - steam -

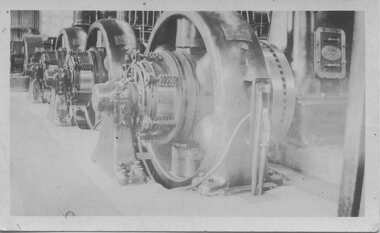

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Set of 6 Black & White Photograph/s, mid 1910's?

... with engines in the background .2 - Steam power engines. .3 - Boilers... with engines in the background .2 - Steam power engines. .3 - Boilers ...Set of six small black and white prints of the interior of the Ascot Vale or Essendon NMETL power house and associated control and generation equipment, mid 1910's? .1 - DC power generators with engines in the background .2 - Steam power engines. .3 - Boilers - and fire boxes with two man standing in the photograph. .4 - Switchboard with three men standing alongside. .5 - Repairing generator equipment - partly dismantled. .6 - ditto with three men in the photograph. .7 - Photo of rotary converters, possibly Carlton, but no notation on rear of photograph. From name plates on machines - Westinghouse Manchester.On rear in ink .1 - "Generators Ascot Vale" .2 - "Engines Ascot Vale" .3 - "Switchboard Ascot Vale" .4 - ditto .5 - "Ascot Vale breakdown" and in pencil " .6 - "Ascot Vale breakdown" and in pencil "trams, tramways, mmtb, substation, nmetl, essendon, ascot vale, rotary converters, switchboards, boilers, generators, carlton, westinghouse -

Tarnagulla History Archive

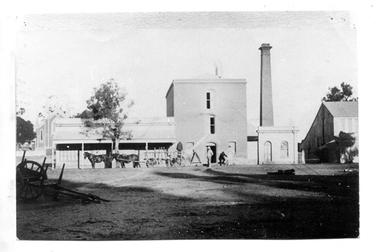

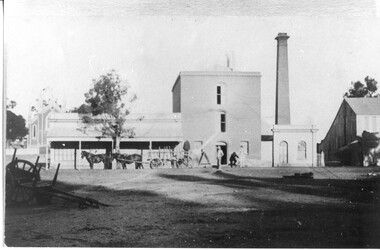

Tarnagulla History ArchivePhotograph - Photograph: Workers at Tarnagulla Flour Mill, c. 1873-1920, probably around 1900

... to Company's Dam to obtain water for the Mill's boilers. Steam was got... to Company's Dam to obtain water for the Mill's boilers. Steam was got ...Williams Family Collection. A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. Thomas Comrie was the proprietor and was responsible for the Mill being built. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years.Monochrome photograph depicting workers at Tarnagulla Flour Mill, some loading or unloading a horse-drawn cart. An original photograph, mounted on card. Handwritten on back: 'L.Williams Tarnagulla' and 'Leo Fitzgerald' and full recipe for a red currant dessert.tarnagulla -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

... this would have been driven by steam from a boiler, the main power... press like this would have been driven by steam from a boiler ...This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Tarnagulla History Archive

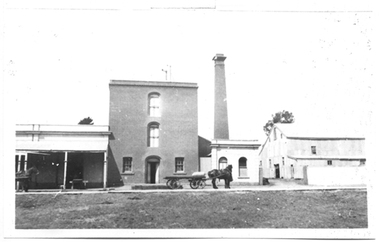

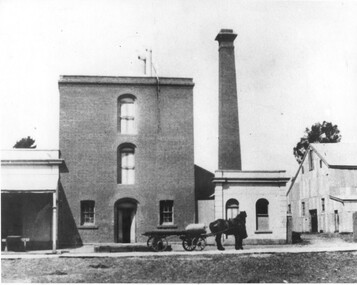

Tarnagulla History ArchivePhotograph of Flour Mill, Tarnagulla, Flour Mill, Tarnagulla, circa 1920

... for the Mill's boilers. Steam was got up for the first time on 30th March... to Company's Dam to obtain water for the Mill's boilers. Steam was got ...Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. Thomas Comrie was the proprietor and was responsible for the Mill being built. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. This is a poor copy of an older original. Copy probably made by Murray Comrie in the late 1960s. Monochrome photograph of the Flour Mill in Tarnagulla, around 1920.tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph of Flour Mill, Tarnagulla, Flour Mill, Tarnagulla, circa 1920 (original image)

... for the Mill's boilers. Steam was got up for the first time on 30th March... to Company's Dam to obtain water for the Mill's boilers. Steam was got ...Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. Thomas Comrie was the proprietor and was responsible for the Mill being built. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. This is a poor copy of an older original. Copy probably made by Murray Comrie in the late 1960s. Monochrome photograph of the Flour Mill in Tarnagulla, around 1920. Cropped version of 2019.0047.tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Letter - MCCOLL, RANKIN AND STANISTREET COLLECTION: QUOTE FROM MILLER AND CO. MACHINERY, 25th May 1931

... steam drive air compressor, air receiver, Cornish flue boiler... flue boiler, Worthington duplex steam pump. Price for foregoing ...Five-page letter and quote, 25th May 1931, from Miller & Co Machinery, 27 Queen Street, South Melbourne. Bendigo office phone 50. Quote for Central Nell Gwynne shaft: steam winch, straight line steam drive air compressor, air receiver, Cornish flue boiler, Worthington duplex steam pump. Price for foregoing 740 pounds. Delivery of boiler at Redan shaft, poppet legs standing at Buttrey's Reward Mine and the whole of the balance of the plant F.O.R. Melbourne Monument Hill Shaft: steam winch double cylinder, straight line single stage steam driven air compressor, air receiver crown flanged ends, Cornish flue boiler, steam pipes, air pipes, iron chimney stack 26'0' x 3'.6' diameter, black steel wire ropes 1000' length Price for foregoing 610 pounds. If preferred, self-contained boiler in lieu of Cornish type offered, the following is offered: return tube boiler, by Roberts and Sons Bendigo. This boiler is self-contained Deborah shaft: straight line steam driven air compressor, air receiver. Price 200 pounds.bendigo, gold mining, mccoll rankin and stanistreet, miller and co., machinery., central nell gwynne gold mine, monument hill gold mine -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph of Flour Mill complex, Tarnagulla, Flour Mill complex, Tarnagulla, circa 1882-1920

... for the Mill's boilers. Steam was got up for the first time on 30th March... to Company's Dam to obtain water for the Mill's boilers. Steam was got ...Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Thomas Comrie was the proprietor and was responsible for the Mill being built. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. The far left section of the complex was originally John Pierce's Southern Cross General Store, a wholesale grocer and spirit merchant. It was put up for sale after Pierce's death in 1871, and later incorporated into the Mill complex. This is a poor copy of an older original. Copy probably made by Murray Comrie in the 1960s. Monochrome photograph of men, horses and a wagon outside the Flour Mill complex formerly situated on the south east corner of King Street and Commercial Road in Tarnagulla. At far left the Methodist church is partially visible in the background. At far right is part of the Mill's storage shed. Same image as THA-2019.0211Written on reverse: 'M. Comrie'tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph of Flour Mill complex, Tarnagulla, Flour Mill complex, Tarnagulla, circa 1882-1920

... for the Mill's boilers. Steam was got up for the first time on 30th March... to Company's Dam to obtain water for the Mill's boilers. Steam was got ...Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Thomas Comrie was the proprietor and was responsible for the Mill being built. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. The far left section of the complex was originally John Pierce's Southern Cross General Store, a wholesale grocer and spirit merchant. It was put up for sale after Pierce's death in 1871, and later incorporated into the Mill complex. This is a reasonable copy of an older original. Copy probably made by Murray Comrie in the 1960s. Monochrome photograph of men, horses and a wagon outside the Flour Mill complex formerly situated on the south east corner of King Street and Commercial Road in Tarnagulla. At far left the Methodist church is partially visible in the background. At far right is part of the Mill's storage shed. Same image as THA-2019.0048Written on reverse: 'M. Comrie'tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Brown coal

... coal is pulverised and burned in boilers, the steam is used... in boilers, the steam is used to drive turbines, which generates ...This particular specimen was recovered from the Lal Lal Coal and Iron Mine in Victoria, 19km from Ballarat. Brown Coal was discovered here in 1857, just alongside the Geelong to Ballarat Railway line. This discovery of lignite (brown coal) was the first in Victoria, which would bring important benefits to the region and state, both of which had previously been reliant on coal imports. In the 1860s, iron ore was found just 5km from Lal Lal, and the area was converted into an Iron Ore Mine. The Lal Lal Iron Mining Company took over operations in 1874, who then peaked iron production in 1884. This mine continued operations until June 1884, when the blast furnace was extinguished and never recommenced. The blast furnace at Lal Lal is considered one of the most important and highly significant sites ion early industrial history in Australia, as it is the only remaining best furnace from the nineteenth century in the Southern Hemisphere. The furnace ruins are 17 metres high, and are clearly visible today on Iron Mine Road, Lal Lal, near the Bungal Dam. This specimen of Lignite (brown coal) is significant, as it was mined from the area where brown coal was first discovered in Victoria, leading to an important and controversial future of the mining and use of brown coal in this State. The Victorian Heritage Database has listed the Lal Lal Coal Mine with local significance, with their Statement of Significance stating: "The Lal Lal coal mine is historically significant as the site of the first discovery of lignite (brown coal) in Victoria, and one that promised important benefits to regional and state industries that were reliant on coal imports at the time. The significance of the stie is reduced by the poor state of preservation of the coal mining and processing fabric". This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.A hand-sized light-weight, soft and combustable sedimentary rock specimen, that is dark brown in colour. The specimen has jagged edges, as though parts of the rock have crumbled away. Brown coal, or Lignite, is formed naturally from compressed peat, and is typically found in natural basins. The stages to the formation of coal ('coalification') begin with plant material and wood, which will decay if it is not subjected to deep burial or heating, and turn into Peat. Peat, when sufficiently compressed naturally, will turn into Brown Coal (Lignite), and finally into Black Coal (sub-bituminous, bituminous and anthracite). Each successive stage has a higher energy content and lower water content. It is brownish-black in colour. Brown Coal has a high moisture content, between 50 and 75 percent, and a low carbon content. Some Brown Coals may be stratified, with layers of plant matter, which means little coalification has occurred beyond the peat natural processing stage. When Brown Coal is submerged in dilute nitric acid or boiling potassium hydroxide solution, it reacts to produce a reddish solution, of which higher-ranked coals do not. When brown coal is pulverised and burned in boilers, the steam is used to drive turbines, which generates electricity. It is the lowest rank of coal, as when burned, it creates a relatively low heat content, which in turn does not create a great output of steam. burke museum, beechworth, indigo shire, beechworth museum, geological, geological specimen, mineralogy, brown coal, brown coal specimen, lignite, lal lal, lal lal coal mine, lal lal iron mine, ballarat, blast furnace -

Federation University Historical Collection

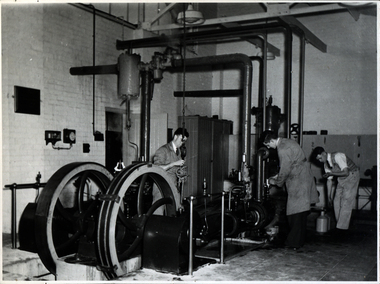

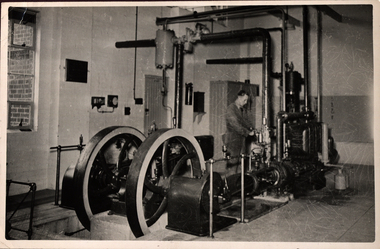

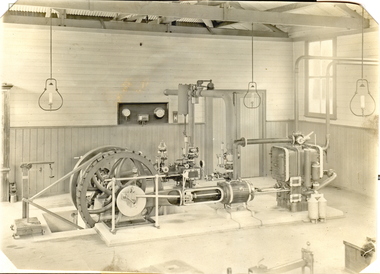

Federation University Historical CollectionPhotograph - Black and white photograph, Ballarat School of Mines Model Steam Engine

... , including the experimental steam engine and boiler. The experimental..., including the experimental steam engine and boiler. The experimental ...The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.Black and white photograph of the Davey Paxman Experimental Steam Engine. On the brake is returned serviceman Norman WIlliam Ludbrook (Diploma Electrical Engineering, 1952). Far right is Roy E. Mawby (Diploma Electrical Engineering, 1950)steam engine, model steam engine, davey paxman, electrical engineering, laboratory, scientific instrument, norman ludbrook, norman william ludbrook, roay mawby, roy e. mawby -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photograph - Black and white, Ballarat School of Mines Model Steam Engine

... , including the experimental steam engine and boiler. The experimental..., including the experimental steam engine and boiler. The experimental ...The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.Black and white photograph of the Davey Paxman Experimental Steam Engine installed at the Ballarat School of MInes. steam engine, model steam engine, davey paxman, thomas bath, experimental steam engine -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Ballarat School of Mines Davey Paxman Experimental Steam Engine, c1902

... , including the experimental steam engine and boiler. The experimental..., including the experimental steam engine and boiler. The experimental ...The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only. Black and white photograph of an experimental steam engine which was produced for the Ballarat School of Mines. It was designed for experimental purposes, such as testing of efficiency, etc. The laboratory which housed the steam engine was lit with gas lighting. davey paxman experimental steam engine, model steam engine, davey paxman, steam, thomas bath, thermodynamics