Showing 176 items

matching steel industry

-

Phillip Island and District Historical Society Inc.

Phillip Island and District Historical Society Inc.Tool, Chicory Scoop, 19th Century

One of Phillip Islands earliest industries was chicory farming. The first kiln was constructed in 1870. The chicory scoop was used for turning the chicory over on a mesh floor above the furnace. This scoop was imported from Europe in the late 1880's.Chicory scoop with wooden handle, wooden scoop and steel joins and reinforcments.phillip island, wood, steel, tool, chicory, kiln, chicory scoop -

Greensborough Historical Society

Greensborough Historical SocietyTin, Imperial Chemical Industries of Australia & New Zealand Ltd, Mexane powder, 1960c

This powder was used to sanitize lavatories and kill garden pests, flies and ants, particularly in the days before the sewer was connected.Cardboard container with steel top and bottom. Printed in blue and yellow on white, with cautionary label in red."Mexane" sanitary powder... contains "Gammexane", Contains 8 ozs. nett and directions for use.sanitation, disinfectant -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Blacksmith's Tongs, n.d

PORT OF PORTLAND COLLECTIONBlacksmith's tongs, hand forged, steelport of portland, blacksmith, trade, industry -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Blacksmith's Tongs, n.d

PORT OF PORTLAND COLLECTIONBlacksmith's tongs, forged steelport of portland, blacksmith, tongs, tool, industry, trade -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Screwdriver large, c1900

A screwdriver is a tool, manual or powered, for turning (driving or removing) screws. A typical simple screwdriver has a handle and a shaft, and a tip that the user inserts into the screw head to turn it. The shaft is usually made of tough steel to resist bending or twisting. The tip may be hardened to resist wear, treated with a dark tip coating for improved visual contrast between tip and screw—or ridged or treated for additional 'grip'. Handle are typically wood, metal, or plastic and usually hexagonal, square, or oval in cross-section to improve grip and prevent the tool from rolling when set down. The handle and shaft of screwdrivers have changed considerably over time. The "Perfect Pattern Handle’ screwdriver was first manufactured by HD Smith & Company, which operated from 1850 to 1900. Screwdrivers were probably invented in the late 15th century, either in Germany or France when Screws were used to construct screw-cutting lathes, for securing breastplates, backplates, and helmets on medieval jousting armor—and eventually for multiple parts of the emerging firearms, particularly the matchlock. The jaws that hold the pyrites inside medieval guns were secured with screws, and the need to constantly replace the pyrites resulted in considerable refinement of the screwdriver. The screwdriver depended entirely on the screw, and it took several advances to make the screw easy enough to produce to become popular and widespread Canadian P.L. Robertson, though he was not the first person to patent the idea of socket-head screws, was the first to successfully commercialize them, starting in 1908. In Portland, Oregon, Henry F. Phillips patented his own invention, an improved version of a deep socket with a cruciform slot, today known as the Phillips Screw. Phillips offered his screw to the American Screw Company, and after a successful trial on the 1936 Cadillac, it quickly swept through the American auto industry. A main attraction for the screw was that conventional slotted screwdrivers could also be used on them, which was not possible with the Robertson Screw. A large steel screwdriver with worn wooden handlepioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, screws, philllips head screwdrivers, h.d.smith & co usa, p.l. robertson, henry f.phillips , oregon, canada, american screw company, -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyRod Fishing, circa early 1900's

This bamboo fishing rod was used in the mid to late 1900's and demonstrates that local production of recreational fishing poles was at a high level and their demand was high. Imported recreational sporting goods from either the United Kingdom, the United States of America or Asia countries was due to the larger lead up times from these suppliers and the greater import costs from slower ocean supply ships. It was only after World War II that the trade influx from other countries has supplied cheaper goods. This recreational fishing pole is highly significant to the Kiewa Valley as it demonstrates that recreational fishing has been evolved from the need to supply a balanced diet by the early pioneer families of fish from the major Kiewa rivers. The ability of the Kiewa Valley rivers to provide a good fishing environment (high protein diet) for both early indigenous families and early pioneers was the important food source that provided for a balanced diet and the higher level of nutritious development of both body and mind. This two piece wooden fishing Rod is made from bamboo shafts or poles, one length thicker than the other. The smaller diameter shaft is the top end and fits into the longer thicker shaft at a stainless steel tube end.The smaller shaft has a stainless steel reinforcement ring where both shafts fit together. At the bottom end of the thick shaft is a black rubber "stopper" or "foot". There are two stainless steel rings, each with a reel holding "bulge" which allows for the the reel's "prongs" to be secured. The top ring has a greater diameter allowing it to move up and down the shaft/pole to secure the top "prong" firmly onto the shaft/pole.recreation, river, rod, fishing, industry, fish -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPipe Tobacco Smoking, Circa 1889

Pipe smoking has been in vogue for centuries, and in Australia it was a symbol of the "discerning smoker" such as the landed gentry or men of professional status. This pipe, of the Standard Canadian style, would have emigrated to Australia with its owner, a reasonable young professional or executive of the Hudson Bay Tobacco Company in the late 1800s or early 1900s. It is the type of pipe well suited to a harsh rural backdrop and with its owner found the Kiewa Valley a more relaxed environment than the Canadian Indian locations. The value of this pipe to the original owner, who would have sealed many trade contracts during the Canadian Indian smoke rituals In the late 1800s, is indicated by the long voyage to Australia and the Kiewa Valley. However with the health related restrictions placed on public smoking in the early 2000s, these tobacco pipes were not immune from the legislation, and even though the pipe smoke was not as offensive as cigarette smoke it still came under the umbrella of smoking. Pipes were also used in the process of inhaling illicit drugs i.e. marijuana, but this use was limited to a very few and not with this pipe. Smoking in the second millennium is being phased out as a social habit in Australia but may affect the few "private" smoker and has, as the United States prohibition era (alcoholic drinks) did, spawn an illicit trade in cheap contraband tobacco. Pipes such as this item show that smoking was not only part of the lifestyle of the era but also that it was part of a ritual (especially to the Indians of the Canada Hudson Bay region) that sealed a brotherhood not only socially but also politically and economically.This type of pipe lends itself well to the rural setting of the Kiewa Valley and although it is a very exclusive pipe it blended into the tobacco industrial environment of the Kiewa Valley and its surrounding districts. The Kiewa Valley region was up until the late 1900s part of the Australian Tobacco industry and the levels of men smoking pipes was enhanced by the readily supply, "off the fields", of tobacco leaves and the attitude to city based smoking restrictions was one of resentment.This pipe has a straight shank and stem and its style is 'standard Canadian'. The pipe has a permanent filter and a stainless steel band with the initials of the Hudson Bay Tobacco Company and its seals stamped on it.. The bowl and shank are one piece of appropriate shaped wood. The bit and bore are made from bakelite (dark brown in colour). The pipe is fashioned in the form of the clay pipes used by trappers, in the late 1800s early 1900s. It has a "rest" lug at the bottom of the bowl similar to clay pipes. This pipe has its own pipe case with wood reinforcement running the entire pipe shaped contour.On the stainless steel at the mortise and tenon junction is stamped "HP" and below that are stamped symbols of a ship's anchor, a lion and a tobacco leaf.tobacco, pipe smoking, smoking accessories -

Warrnambool and District Historical Society Inc.

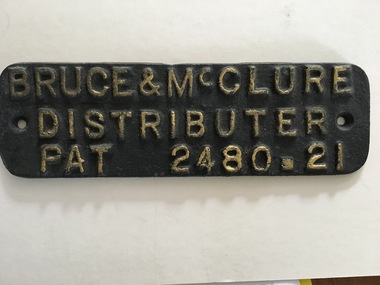

Warrnambool and District Historical Society Inc.Brass Plate, Bruce & McClure Distributer, C early 20th century

Bruce & McClure were manufacturers of windmills and agricultural machinery including motor engines , pumps, tanks,and appliances for supplying and conserving water.Also included was brass,iron and steel foundry works. They won 11 first prizes at the Grand national Show of 1907 and in 1914 designed and manufactured a new water boring machine which could also be used for oil and gold exploration They operated from Lava Street well into the 1940's as well as from the geelong area. This plaque is possibly from one of their machines.A tangible link to one of Warrnambool's manufacturing businesses which was innovative and an essential part of the beginnings of machine use in farms and industry in the district. Cast iron plaque with moulded text which is coloured in gold. rectangular with rounded corners. Back is painted grey.Bruce & McClure Distributer Pat 2480.21warrnambool, bruce & mcclure, bruce & mcclure machinery -

Orbost & District Historical Society

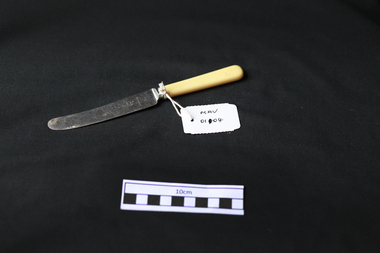

Orbost & District Historical Societybread knife

This knife was used by Lottie Rem who ran the cookhouse at Astergren;s Timber Mill at Cabbage Tree in East Gippsland from 1954 until 1966.. It was bought in Orbost around 1957 - 1958. Sited on the banks of the Cabbage Tree Creek, the township was built by the timber mills to house their workers. Although the timber mills have disappeared, some of the buildings still remain. The "Cook House" and "Manager's House" are two buildings. The Cook House was built to supply meals to the workers of the Alstergren Mill. Some of the original interior walls were made from hessian and wallpaper. The few houses to survive to today are now used as private dwellings.The Cabbage Tree Creek township was established to support the booming timber industry of the mid 20th century. Five timber mills worked full time supporting the families that were drawn to the area's wealth of natural resources. this item is associated with the history of Cabbage Tree.A stainless steel serrated edged knife with a cream coloured handle (bone?)on blade -""Made in Sheffield expressly for Orbost Hardware and Timber Co, Orbost"alstergren-timber-cabbage-tree rem-lottie cook-house-alstergren's-timber-mill bread-knife-orbost-hardware -

Cheese World Museum

Cheese World MuseumSign, Supplier gate sign, c1970

Supplier identification gate sign used to identify a farm for milk collection by factory milk tankers. The sign showed the factory supplier's name and farm number. EJ (Ted) Delaney farmed at Nirranda South and was a company director for several years.Beige steel supplier identification gate sign with green lettering and Warrnambool Cheese and Butter Factory Co Ltd logo printed on top left hand corner.WCBF E.J.DELANEY 211/ Warrnambool Cheese and Butter Factory Co Ltd. Established 1888rural industry, agriculture, allansford, delaney ej (ted), warrnambool cheese and butter factory co ltd, milk suppliers, dairying, signs -

Cheese World Museum

Cheese World MuseumCheese press, Perfect Cheese company

Perfect Cheese Company was founded in 1930 by newly-arrived Italian migrant Natale Paquale Italiano. The company specialised in traditional Italian-style cheese but also produced Greek, Cypriot and Maltese origin cheeses. The cheeses were sold in Australia and Italy with all products being matured and non-processed. The company remained in operation until the early 2000s.This cheese press is significant as it represents the machinery used by an early cheese production company.Stainless cheese press machine with three steel supports and two threaded rods will spring tension wheels to screw down to pressurise the hoops containing cheese.J & T YOUNG AYR UKallansford, perfect cheese company, avery, cheese manufacturing, dairy industry -

Cheese World Museum

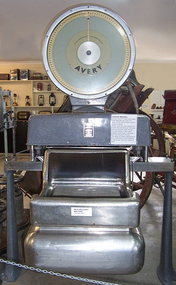

Cheese World MuseumMilk weighing machine, Perfect Cheese company weighing machine

Perfect Cheese Company was founded in 1930 by newly-arrived Italian migrant Natale Paquale Italiano. The company specialised in traditional Italian-style cheese but also produced Greek, Cypriot and Maltese origin cheeses. The cheeses were sold in Australia and Italy with all products being matured and non-processed. The company remained in operation until the early 2000s.This weighing machine is significant as it represents the machinery used by an early cheese production company.Large metal machine with cast iron with a cast iron frame and a stainless steel rectangular bowl in a cradle. The round weighing scale at the top shows a weight scale up to 1100 pounds. A mesh stainless steel baffle strains the milk.Made in England Birmingham - AVERY SOLE AGENTSallansford, perfect cheese company, avery, cheese manufacturing, dairy industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Coopers Adze, Mathieson and Son, First quarter of the 20th Century

An adze is an ancient and versatile cutting tool similar to an axe but with the cutting edge perpendicular to the handle rather than parallel. Adzes are used for smoothing or carving wood in hand woodworking, and as a hoe for agriculture and horticulture. Two basic forms of an adze are the hand adze (short hoe) a short handled tool swung with one hand and the foot adze (hoe) a long handled tool capable of powerful swings using both hands, the cutting edge usually striking at foot or shin level. Mathieson & Sons Maker: In 1792 John Manners had set up a workshop making woodworking planes at 14 Saracens Lane Glasgow. He also had employed an apprentice Alexander Mathieson (1773-1851). But in the following year at Saracen's Lane, the 1841 census describes Alexander Mathieson as a master plane-maker now at 38 Saracen Lane with his son Thomas Adam working with him as a journeyman plane-maker. Presumably, Alexander must have taken over the premises and business of John Manners. Now that the business had Thomas Adam Mathieson working with his father it gradually grew and became more diversified, and it is recorded at the time by the Post-Office Glasgow Annual Directory that by 1847-1848 Alexander Mathieson was a “plane, brace, bit, auger & edge tool maker” In 1849 the firm of James & William Stewart at 65 Nicholson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas company went on to acquire the Edinburgh edge-tool makers “Charles & Hugh McPherson” and took over their premises in Gilmore Street. In the Edinburgh directory of 1856/7, the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicholson Street and Paul's Work, Gilmore Street Edinburgh. The 1851 census Alexander is recorded as working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 Post-Office Glasgow Annual Directory the firm is now listed as Alexander Mathieson & Son, with further entries as "turning-lathe and vice manufacturers". By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, off the Gallowgate area, and that through further diversification was also manufacturing coopers' and tin men's tools. The ten-yearly censuses report the firm's growth in 1861 stating that Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm so the company was still in his fathers' name. In September 1868 Thomas Mathieson put a notice in the newspapers of the Sheffield & Rotherham Independent and the Sheffield Daily Telegraph stating that his firm had used the trade-mark of a crescent and star "for some time" and that "using or imitating the Mark would be proceeded against for infringement". The firm had acquired its interest in the crescent-and-star mark from the heirs of Charles Pickslay, the Sheffield cutler who had registered it with the Cutlers' Company in 1833 and had died in 1852. The year 1868 seems also to be the one in which the name Saracen Tool Works was first adopted; not only does it figure at the foot of the notice in the Sheffield press, it also makes its first appearance in the firm's entry in the Post-Office Glasgow Annual Directory in the 1868/9 edition. As Thomas Mathieson's business grew, so too did his involvement in local public life and philanthropy. One of the representatives of the third ward on the town council of Glasgow, he became a river Bailie in 1868, a magistrate in 1870 and a preceptor of Hutcheson's Hospital in 1878. He had a passion for books and was an "ardent Ruskinian". He served on the committee handling the bequest for the setting up of the Mitchell Library in Glasgow. When he died at Coulter Maynes near Biggar in 1899, he left an estate worth £142,764. The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages and other industries, both locally and far and wide.Coopers Adze steel with wooden handle No 194 A Mathieson & Sons Glasgowflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, 37 Brougham Street, Eltham, July 2009, 2009

... melbourne industries brougham street Balanar Steel Fabricating TJ's ...Colour photographindustries, brougham street, balanar steel fabricating, tj's hairdressing and beauty supplies -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, 39 Brougham Street, Eltham, July 2009, 2009

... melbourne industries brougham street Balanar Steel Fabricating ...Two colour photographsindustries, brougham street, balanar steel fabricating, eltham collision care centre, ideal electrical lighting data -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw Vice and Spanner, Henry Disston & Sons, Early 20th century

Henry Disston (1819-1878) was born in England and later moved to America. He has been noted in a biography as a "Pioneer Industrialist Inventor". In 1840 he began making and selling his own saws in Philadelphia, USA, growing to become the world's largest saw manufacturer. Tools made by Henry Disston and his company have the reputation of being the finest tools money can buy.The saw sharpening vice and its shifting spanner are significant for their connection with Henry Distton & Sons, renowned for high quality hand saws and associated tools. In 1855 Henry Disston cast a crucible saw sharpening steel, the first person to ever do so in America. The hand tools are also important for their association with the early building industry. Saw sharpening vice with accompanying saw tooth shifting spanner. The vice has a ball and socket clamp. The top of the vice has a saw clamp with wide jaws. The metal surface has remnants of black paint. Inscription is cast into the jaws of the vice. It was made by Henry Disston & Sons"HENRY DISSTON & SONS"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, vice, saw sharpening vice, saw sharpening tool, saw tooth, shifting spanner, woodworking tool, henry disston, disston & co, hand saw, handsaw, hand tools, carpentry, boat building -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCalipers, Moore & Wright, 1925-1935

Established in 1906, Frank Moore soon became well known amongst discerning tradespeople for the quality & accuracy of his tools. The Company was acquired by John Shaw & Son in 1945 & James Neill & Co in 1970. Currently part of the Bower Meteorology UK Group, they still produce superb tools & measuring instruments in Sheffield. The subject item is made from high-grade carbon silver tool steel with the patented 'Firm Lock' joint, that identifies the maker as Moore & Wright.A tool used for external measurement of items made by a maker who patented the "firm lock" jointing system now used on many different types of tools in many different industries. These items are now collectible and quite rare as a result are sought by tool collectors in the USA and UK.‘Firm Joint’ external measuring calipers believed made by Moore & Wright. Impressed into the metal "L A J S" (Probably the owner and company that used the item nothing to do with manufacturing) flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, calipers, callipers, external calipers, outer caliper, pottery tools, masonry tools, glass making tools, external measurement -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bench Saw Vice, Henry Disston & Sons, 1910 -1925

The subject item is a saw blade sharpening clamp that attaches to a bench allowing the operator to sharpen the teeth on a saw with a file while keeping the saw blade in an upright position. Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world the ”Keystone Saw Works” on the Delaware River. Some five years later, Disston built a furnace possibly the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons set the standards for American saw makers, both in terms of producing high-quality saws and developing innovative manufacturing techniques. Disston also started making files in 1865. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets, Disston sought to establish his business away from this cramped area. It took over 25 years to move the entire facility to Tacony. This Philadelphia neighborhood seems to have been the only company town in the United States established within an existing city. At its peak of operations, Disston Saw Works employed 8,000 people and the factory covered 300 acres. The company, known as Henry Disston and Sons, Inc by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's Armour plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A significant American company that pioneered the making of high-quality steel and saws along with other tools and accessories. The subject item is significant as it was made at a time when the company was in its hay day. Adjustable Ball & Socket Saw Sharpening vice, cast iron, with clamp to attach to a workbench. Made by Henry Disston & Co. No 1 painted greyflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, saw clamp, henry disston & sons, saw sharpening, tool accessories, wood saws -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedean drill, Late 19th Century

The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples have no makers names.A vintage drilling tool, the item therefore could have been used in various industries or professions where precise drilling is required. Archimedean drill with Rosewood hand, brass grip and fittings Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw gauge, Henry Disston, 1890-1920

Disston Saw Works of Philadelphia was one of the better known and highly regarded manufacturers of handsaws in the United States. During the Machine Age, the company was known as Henry Disston & Sons, Inc. a supplier of industrial saw blades. History: The story of handsaws in the United States mirrors the technical and development of steel in Sheffield, England, which was the center of handsaw production during the 18th century and through most of the 19th century. England's political and economic lock-on steel making in the colonies held American saw makers at bay until well after the Revolutionary War. American steel producers were unable to compete until the US government introduced import tariffs to level the playing field in 1861. Henry Disston: Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He had emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world, the Keystone Saw Works. Some five years later, Disston built a furnace—perhaps the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons began to set the standards for American saw makers, both in terms of producing high-quality saws and files in 1865 through his development of innovative manufacturing techniques. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets. It took over 25 years to move the entire facility to Tacony. Henry Disston was renowned for having one of the first industries that exhibited environmental responsibility, as well as a paternalistic view towards his employees. For example, he had thousands of homes built in Tacony for his workmen. Funds to purchase these homes were made available through a building and loan association set up by the Disston firm. His caring influence on the community was evident in everyday life. To meet employees' cultural needs, a hall and a library were built with Henry Disston agreeing to pay a fixed sum towards its maintenance. The Tacony Music Hall was erected in 1885, also with the assistance of Disston money. Henry Disston had fallen ill by 1877 and never truly recovered; he suffered a stroke and died the next year. This came only one and a half years after seeing his products receive the highest honors at the great Philadelphia Centennial Exposition of 1876. His vision of a working-class community and the completion of the transfer of his enormous saw plant was carried out by his wife and his sons. The company, by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's armor-plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A tool used to set and sharpen cross cut saws used to fell trees for building construction made by a well known American maker whos firm pioneered the making of saws and their related items including files.combination cross cut saw raker and gauge/jointerDisston USA in the castingflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMast Collar, c. 1886

The husband of the donor of this mast collar chanced to be staying a night at a motel in Peterborough, along the Great Ocean Road in Victoria. He had a keen interest in maritime items and recognise the mast collar at the motel’s back fence line. The motel owner told his guest the story of a customer, a doctor, who had organised and paid for divers to raise the mast collar from a local shipwreck, the Falls of Halladale. Shortly afterwards the doctor passed away, so the mast collar had remained at the motel site. The owner was leaving the motel the following week and wasn’t at all interested in the artefact. He was very happy for his guest to remove it. It took five men to load the mast collar up for the trip to the new owner’s two storey shed in Ballarat. It stayed there undercover, in the company of his collection of 5 buggies, for the next 40 or so years until the property was for sale. A friend, who realised the significance of the mast collar, suggested that it be donated to Flagstaff Hill Maritime Village where other artefacts from the Falls of Halladale, such as the slate tiles, were on display. This mast collar, or masthead, from the Falls of Halladale would have been used to join two sections of one of the tall masts. As sailing ships became larger there was a need for taller masts or spars, which became difficult or impossible to find. To overcome this problem mast was divided into sections; lower and top or upper mast (on some of the ‘tall ships’ a mast could be divided into three or even four sections). The Falls of Halladale was a four-masted British barque built-in 1886. On what turned out to be her fatal journey, she had left New York for Melbourne in late 1908. She ran aground on a reef close to the shore west of Peterborough, South West Victoria, on November 14th. All 29 crew eventually landed safely onshore. The wrecked ship stayed on the reef for several months as locals watched the sails slowly deteriorate. The salvaged cargo included slate tiles, as mentioned above, and many of these have been used on the roof of buildings at the Flagstaff Hill Maritime Village. The iron-hulled, four-masted barque, the Falls of Halladale, was a bulk carrier of general cargo. She left New York in August 1908 on her way to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual beautiful green American slates (roofing tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. Three months later and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29 The Falls of Halladale was a four-masted sailing ship built-in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. The lines flag was of red, blue and white vertical stripes. The Falls of Halladale had a sturdy construction built to carry maximum cargo and able to maintain full sail in heavy gales, one of the last of the ‘windjammers’ that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new, raised catwalk-type decking allowed the crew to move above the deck stormy conditions. This idea is still used today on the most modern tankers and cargo vessels and has proved to be an important step forward in the safety of men at sea. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roofing tiles (roof slates), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the night of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on the south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m offshore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. This mast collar is significant due to its association with the ship FALLS OF HALLADALE, which is listed on the Victorian Heritage Register, VHR S255 The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976). Mast collar, steel, salvaged from the shipwreck FALLS OF HALLADALE, wrecked off the coast of Peterborough, South West Victoria. Oval shaped a band of metal with a straight band of same heights attached between the long sides. Two metal loops are attached to the outside of the oval shape, next to the crossing band. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, falls of halladale, shipwreck peterborough vic, sailing ship mast collar, masthead of sailing ship, falls of halladale mast collar, masthead, mast collar, ship rigging 1908, russell & co. -

Federation University Historical Collection

Federation University Historical CollectionExercise Book, Tests on Stainless Steel, A.G.Hale

... ballarat ballarat school of mines and industries a.g. hale ...Black covered exercise book, with many brochures and tables insertedballarat, ballarat school of mines and industries, a.g. hale, stainless steel -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Equipment - Barbers’ Equipment, hair clippers steel 'Brown & Sharpe", c1940

1833 Brown & Sharpe was founded in Providence, Rhode Island by David Brown and his son Joseph R. Brown. David Brown retired in 1841 and Joseph Brown formed a partnership with Lucian Sharpe in 1853. During the 19th and 20th centuries, Brown & Sharpe was one of the best-known and most influential machine tool builders and was a leading manufacturer of instruments for machinists (such as micrometers and indicators ) and helped establish: The American wire gauge (AWG) standards for wire; The Brown & Sharpe taper in machine tool spindle tapers; and The Brown & Sharpe worm threadform for worm gears. .Like most machine tool builders, Brown & Sharpe rode a business cycle roller coaster during 1920- 40. After being kept very busy during World War I, builders suffered a slump in the post–World War I recession and depression of 1920–21. The Roaring Twenties brought renewed sales, but then the Great Depression slashed them. The armament-build-up period of 1936 to 1940 again renewed machine tool activity, and then the World War II materiel effort exploded demand, pushing it to record heights and employed 11,000 workers. Brown and Sharpe machine tools were a mainstay of American metal manufacturing until the late 20th Century and could be found in most machine shops and factories that worked with metal. Brown and Sharpe made callipers and micrometers that were essential to products built to fine tolerances. Shortly after World War II, Henry D. Sharpe, Jr. succeeded his father as president of Brown & Sharpe Manufacturing Company, at which point it evolved into a new and modern company built, or at least designed, to last. The firm stopped producing its old stalwarts: sewing machines, hair clippers, and certain categories of machine tools and employment dropped to 3,500 in 1976. Due to industrial disputes in the 1980’s B&S started focusing more on developing Coordinate-Measuring Machines. The company began to lose money as it shifted production away from machine tools and toward advanced metrology equipment, losing $14.6 million in 1990 and employed only 700. In 1994 Brown & Sharpe acquired DEA of Italy, an established manufacturer of CMMs. In 2001, substantially all of the assets of the Brown & Sharpe Manufacturing Company, including the intellectual property, designs, trademarks, facilities and inventory, were acquired by Hexagon AB, Switzerland, without the acquisition of the Brown & Sharpe Manufacturing Company itself. A set of manual barbers’ hair clippers with an adjustable wing screw, from Brown and Sharpe, Manufacturing Company Ltd., Providence, Rhode Island, USA. Chrome plated, in fair condition, c1940on Right handle; MADE BY BROWN & SHARPE MFG. CO. POV. R.I. / PAT'D IN GREAT BRITAIN, EN FRANCE, S.G.D.G. / U.S.A. PATENTS JULY 1-79, JUNE 3-84, AUG 23- 92 on top blade ; BRESSANT / TRADEMARK on base of lower blade ; No. 2* barbers, hairdressers, hair clippers, brown and sharpe manufacturing company, providence rhode island, hexagon ab, switzerland, great britain, france, ww1 1914-1918, ww11 1939-1945, great depression 1930, micrometers, tools, precision instruments, brown david, brown joseph r , sharpe lucian, sharpe henry d jnr, american wire gauge standard, sewing machines, metrological tools, worm gears, spindle tapers, screw machines, moorabbin, bentleigh, cheltenham, city of moorabbin industries, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, cutlery butter knife, c1930

Rodd's was established by George & Ernest Rodd in Melbourne in 1919.They were manufacturers and wholesalers of precious metal jewellery. Later they began to manufacture high quality silver plated cutlery under the brand name “Rodd”. They then expanded into holloware when they took over Platers Pty. Ltd. who produced a very high quality range of silver plated Sheffield Reproduction Silverware, under the brand name “Hecworth”. Rodd’s established a large factory at 150 Barkly St., St. Kilda, Melbourne. During WW2 with a staff some 200, the factory produced ordnance components to help with the war effort. Rodd’s established sales offices in the main city centres of all States. The company prospered. In December, 1960, Rodd [Australia] Ltd. was merged with Mytton’s Ltd., Melbourne, and became part of the newly formed company Mytton Rodd [Australia] Ltd. Mytton’s were also producers of silver plated cutlery under the brand name “Grosvenor” and were strong competitors to the Rodd brand of cutlery Australia wide. It was a friendly take over and the Directors of Rodd [Aust.] Ltd. were appointed to the board of Mytton Rodd [Aust.] Ltd., and some to the Holding Company Mytton’s Ltd. Mytton’s were heavy manufacturing engineers producing a large range of stainless steel products including: kitchen sinks of various design, beer barrels [9 and 18 gallon kegs] for the breweries, milk vats for cooling and storing milk on dairy farms, a large range of dairy and industrial vessels, road transport tanks, LPG tanks, low pressure pre-mix vessels for the soft drink industry. They also produced a range of domestic bathes, steel railway sleepers, using their 3000 ton hydraulic presses. Mytton’s also had their own non ferrous foundry and rolling mill which produced nickel silver sheet used in the manufacturer of their silver plated cutlery. They also produced copper sheet for their own and industrial use. Mytton’s had factories in York St., South Melbourne and Port Melbourne. Rodd [Aust.] Ltd. set up a manufacturing, distribution plant in Auckland, New Zealand, circa 1960. This company began producing precious metal jewellery in a rented space in the premises of Matthey Garret Ltd., Bullion Merchants, in Drake St., Auckland. Later they moved into their own building in Sale St., Auckland. The company prospered and purchased land and built a factory at 121 Apirana Ave. Glen Innes, Auckland, circa 1964. ( B. McCulloch Rodd Pty Ltd)A butter knife with stainless steel blade and bone handle c1930on blade; RODD / STAINLESScutlery, stainless steel, cheltenham, moorabbin, bentleigh, early settlers, rodd aust ltd, mytton rodd pty ltd, aukland, port melbourne -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, mens' 'Gillette' safety razor, c1950

A safety razor is a shaving implement with a protective device positioned between the edge of the blade and the skin. The initial purpose of these protective devices was to reduce the level of skill needed for injury-free shaving, thereby reducing the reliance on professional barbers for providing that service and raising grooming standards. The term was first used in a patent issued in 1880, for a razor in the basic contemporary configuration with a handle attached at right angles to a head in which a removable blade is placed (although this form predated the patent). 1847 William S. Henson. patented a "comb tooth guard or protector" which could be attached both to the hoe form and to a conventional straight razor. May 1880 by Fredrik and Otto Kampfe of Brooklyn, New York, improved the 'safety razor' and it differed from the Henson design in distancing the blade from the handle by interposing,, "a hollow metallic blade-holder having a preferably removable handle and a flat plate in front, to which the blade is attached by clips and a pivoted catch. 1900 King C. Gillette had the revolutionary idea of disposable blades so thin and so strong they were deemed impossible to forge by MIT-trained scientists. By 1901, he’d proven them wrong with his breakthrough innovation. The success of Gillette's invention was largely a result of his having been awarded a contract to supply the American troops in World War I with double-edge safety razors as part of their standard field kits (delivering a total of 3.5 million razors and 32 million blades for them). The returning soldiers were permitted to keep that part of their equipment and therefore easily retained their new shaving habits. The subsequent consumer demand for replacement blades put the shaving industry on course toward its present form with Gillette as a dominant force. Plastic disposable razors and razors with replaceable disposable blade attachments, often with one to three cutting edges (but sometimes with four and as of recently, five cutting edges), are in common use today. A steel 'Gillette' safety razor gillette co ltd, cheltenham, moorabbin, maynard dennis, sfety razors, safety razor blades -

Bendigo Historical Society Inc.

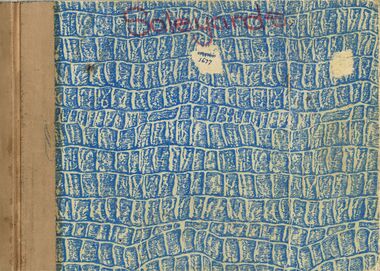

Bendigo Historical Society Inc.Book - BENDIGO SALEYARDS COLLECTION: PURCHASE REQUISITION BOOK

City of Bendigo Purchase Requisition, dated from 22/7/1988 to 17/7/1989. Numbered from 62301 to 62400. Book has a blue and white crocodile skin pattern on the cover and has Sale yards written in red pen at the top of the front cover The spine is bound with tan coloured tape. Pages are white with a blue carbon copy. A blue card attached to the back cover is used between each requisition. Purchases and repairs were authorised by J Richmond and J M Criminis. Purchase Requisitions were used for repairs, stationary, purchase of small equipment and tools.bendigo, council, cattle markets, bendigo saleyards collection - purchase requisition book, debbie smart, alan ritchie, city of bendigo, j richmond, brb electrics, n harris, hume & user, bolton's, fletcher & sons ballarat, w buries, bendigo mower service, bolts and fasteners, all ball?, cig, dalgety farmers, bendigo stainless steel, cattleguard, bp, robot plant, golden square small engines, sandhurst machinery power tools, cambridge press, sandhurst hire, all bull cattle colour, w d mason, data land, rover grip industries, charlie mason, northern seed supply, j m crimmins, beaurepaires, golden triangle, telecom, awm electrical, bendigo bearings, repco, tubemakers, mcilwraith, abbotts, holls electrical, midland irrigation, h j reece, moss electric, bruce's discount house, v comer, paul postema, andrew rosen, peter berens, golden triangle, bbc hardware, all bull, ocean action pty ltd, beth or gill wedmore, compare australia, data land, bendigo computer co, bendigo data processing, j redmond, dalgety, repco -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - CASTLEMAINE GAS COMPANY COLLECTION: PHOTO EXCAVATION

Worker in trench on a pipe laying machine. Orange safety netting attached to steel posts surrounds this large trench. 2 pieces of short tubing on ground next to safety fence.Kodakorganisation, industry, gas and fuel -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - CASTLEMAINE GAS COMPANY COLLECTION: PHOTO EXCAVATION

pipe in trench ready to be connected to old pipe. Orange safety netting attached to steel post surrounds the trench,2 tyres to left of pipe, white drum with lid also to left.Kodakorganisation, industry, gas and fuel -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BENDIGO BUTTER FACTORY : DISPLAY NOTES

Explanatory notes for a display of photographs of the Bendigo Butter Factory. Date given on the reverse of the title photograph is 1950-1955. In another photograph there is a calendar with the date March 1957. These notes, mounted on cardboard relate to the photograph 11011.15. The notes as written - Cream in stainless steel holding vats prior to churning.bendigo, industry, bendigo butter factory. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BENDIGO BUTTER FACTORY : DISPLAY NOTES

Explanatory notes for a display of photographs of the Bendigo Butter Factory. Date given on the calendar in the photograph is March 1957. These notes, mounted on cardboard relate to the photograph 11011.25. The notes as written - After unloading, the cans are weighed and graded for quality and then tipped into stainless steel receiving vats.bendigo, industry, bendigo butter factory.