Showing 66 items

matching textile fibres

-

Glenelg Shire Council Cultural Collection

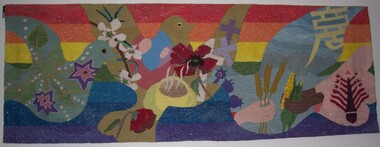

Glenelg Shire Council Cultural CollectionTextile - Tapestry, Portlands Fibre Group, Women's View On Peace, 1987

... On Peace Textile Tapestry Portlands Fibre Group Portland Fibre ...International Year of Peace TapestryTapestry depicting three outlines of doves, with depictions within their outlined shape of stars, flowers, and two sets of (depicted in white and brown) holding wheat and corn. The background is composed of rainbow colours arranged in horizontal strips, with red at the top and indigo at the base.textile, international year of peace, tapestry, wool, weave -

Wangaratta Art Gallery

Wangaratta Art GallerySculpture, Tulla Carson, Gathering - How to Walk in Two Worlds, 2017

Gathering is a series of contemplative sculptural objects that represent a visual continuity between the Australian landscape and the city. They embody totemic beings which hold the beliefs, values and attitudes of an individual who resides within the urban context, yet has a deep connection to place through their engagement with temporal moments and meaningful interactions. They aim to facilitate dialogue between the viewer and the viewed, seeking to re-orient an individual's perception, awareness and values surrounding the importance of fostering a connection and sense of place with the land we walk on.Wangaratta Art Gallery Collection. Purchased with funds from the Friends of Wangaratta Art Gallery.A contemporary sculpture made using weaving techniques to create a mesh-like linen cylinder tuft with raw cotton fibre mounted upon a limestone base.sculpture, textile, tulla carson -

Wangaratta Art Gallery

Wangaratta Art GalleryTextile, Treahna Hamm, Cormorant, 2011

... natural and man made fibres. Cormorant Textile Treahna Hamm ...The cormorant weaving was depicted through the traditional weaving method of the blanket stitch of the Yorta Yorta people. As birds are very significant and important in Aboriginal culture, the cormorant was created to represent the meaning of Wangaratta for the local people and wider community. The weaving is an extension of my series of works which represent wildlife along the waterways, particularly in the North East of Victoria and within my tribal homelands. In 2001 I was taught to weave at a weaving workshop held at Gas Works in Port Melbourne by old aunties from Victoria and South Australia which included Yvonne Koolmatrie. A body of my weaving works, which include turtles and spirits, is held at the National Gallery of Victoria. Other collections which hold my fibre weavings are the National Museum of Australia, Albury Museum and Wagga Wagga MuseumWangaratta Art Gallery CollectionA textile sculpture of a cormorant woven from natural and man made fibres.cormorant, treahna hamm, yorta yorta people, traditional weaving, weaving -

National Wool Museum

National Wool MuseumQuilt, Green Ladder

Winner of Expressions 2008: The Wool Quilt Prize Artist Statement: 'My friend Vriginia named this quilt for me and I thought "of course". A ladder is a means of rising or climbing and I began this work woth a sense of freedom. In this case freedom from entrapment of thought, feeling and creativity.'W7184 'Green Ladder' Catalogue for 'The New Quilt 2003: an exhibition of contemporary quilt textiles' Jo Steele's entry in 'The New Quilt 2003' catalogue Jo Steele's Curriculum Vitae Photocopy from Quilters Guild Magazine, 1998. Jo Steele's 'Eggshells & Iron Bars' Photocopy from catalogue '2002: One step further marvellous minatures', including Jo Steele's entry. Photocopy from '2007 Australian Cotton Fibre Expo'. Jo Steele entry 704. Includes first prize certificate for Section 7: Contemporary Quilting and Patchwork. Certificate awarded to Jo Steele for 'Chill Out!' 2004. Winner 'Fashion Extravaganza' Category. Photocopy from catalogue for 'Territory Craft 30th Alice Craft Acquisition'. Jo Steele entry 133. Photocopy from catalogue for 'The 29th Alice Craft Acquisition'. Jo Steele entries 143 and 144.Jo Steel 34 Neale Street Katoomba 2780 NSW 0413 074 604 'Green Ladder'quilting textile art, steele, ms jo, quilting, textile art -

National Wool Museum

National Wool MuseumTextile - Textile fragment, c.1797

Woollen fabric fragment from the wreck of ship "Sydney Cove" found underwater after many years.Small fragment of woven woollen fabric, brown colour. with some white fibres through it. The fragment is frayed and coming apart. It is boxed in a circular clear plastic lidded container, taped and with a typed paper label on the lid.Wording: Fabric scrap from/wreck of ship "Sydney Cove"/ NWM 940112";Method: typed;Location: on label on lidwool - history textile history textile mills textile mills, wool - history, textile history, textile mills -

National Wool Museum

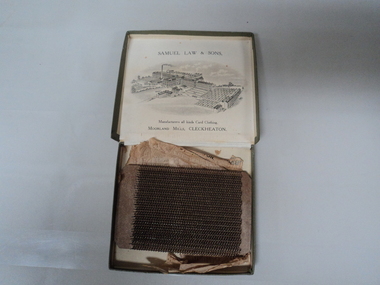

National Wool MuseumSample, Card Clothing

Card clothing sample manufactured by Samuel Law and Sons, Cleckheaton and probably sent to the Collins Bros Mill at the same time as W621. Card clothing is defined as 'the leather or other stiff material which holds the wire staples, the points of which project outwardly and form the carding teeth which operated on the fibres.' This fits into a carding machine ("The Textile Industries" vol. 8 - William S. Murphy, 1911).Card clothing sample, comprising rows of bent wires mounted on a thick rectangular leather base. Wrapped in tissue printed with an engraving of the factory where it was made and housed in an olive green lidded cardboard box, the interior of which is printed with an image of the manufacturer's factory.SAMUEL LAW & SONS, / Manufacturers all kinds Card Clothing. / Moorland Mills. / CLECKHEATON, England. SAMPLE OF CARD CLOTHING / FROM / SAMUEL LAW & SONS, / (branch of the English Card Clothing Company, Limited). / CLECKEATON. / MOORLAND MILLSsamuel law and sons collins bros mill pty ltd, carding, card clothing -

National Wool Museum

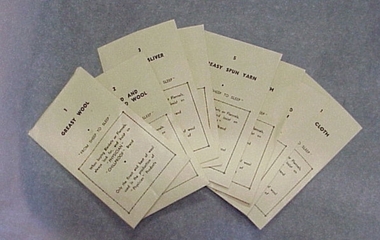

National Wool MuseumSamples, "From Sheep to Sleep"

Samples of wool, fibres and cloth demonstrating the processes in the creation of blankets, from greasy wool to finished cloth, produced by Collins Bros Pty Ltd.Samples of wool, fibres and cloth demonstrating the processes in the creation of blankets, from greasy wool to finished cloth, produced by Collins Bros Pty Ltd."From Sheep to Sleep" when buying Blankets or Flannels, always look for, and insist on "PHYSICIAN' 'CHILLPROOF' Brand Only the finest and best of wool used in the production of "Physician" Productstextile industry - education, collins bros mill pty ltd, blankets -

National Wool Museum

National Wool MuseumBook, Fibre and Fabric

"Fibre and Fabric: the wool, cotton, textile and allied industries in Melbourne's West" - Gary Vines, 1993. This book is a short history of the wool, cotton, textile and allied industries of the area west of Melbourne. It looks at how, why and when these industries developed and their effect upon the cultural and geographic landscape.textile industry - history woollen mills - history, textile industry - history, woollen mills - history -

Stawell Historical Society Inc

Stawell Historical Society IncArchive - Laboratory Books, Spinning in the 70's, P.R. Lord

From Dye Laborataory AUNDE / Norwellan North Western Woolen Mills became Norwellan Textiles then AUNDEPurple cover with black image of FibreJohn Bennett April 71manufacturing -

Stawell Historical Society Inc

Stawell Historical Society IncBook - Laboratory Reference Book, Handbook of Polyolefin Fibres, J. Gordon Cook

Textbook. Lab Reference - Norwellan & AUNDE North Western Woolen Mills became Norwellan Textiles then AUNDEDark Blue hardcover with light blue Dust CoverJohn T Bennett Lyddon Hall Leeds 8/10/1969manufacturing -

Stawell Historical Society Inc

Stawell Historical Society IncBook - Laboratory Reference Book, Fibre Structure, J.W.S. Hearle and R.H. Peters

Textbook. Lab Reference - Norwellan & AUNDE North Western Woolen Mills became Norwellan Textiles then AUNDEDark Blue hardcover with light blue Dust CoverJohn T Bennett Lyddon Hall Leeds 8/10/1969manufacturing -

Stawell Historical Society Inc

Stawell Historical Society IncBooklet - Laboratory Reference Book, The Chemistry of Wool and Related Fibres, by J.B. Speakman

Lecture Notes Reprinted from The Journal of the Textile Institute, Lab Reference - Norwellan & AUNDE North Western Woolen Mills became Norwellan Textiles then AUNDELight Green soft cover booklet with Dark Blue title on covermanufacturing -

National Wool Museum

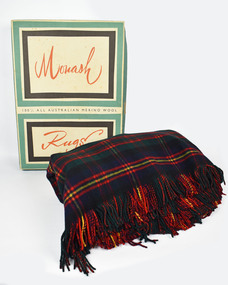

National Wool MuseumTextile - Rug, Returned Soldiers and Sailors Mill, 1963

The Returned Soldiers and Sailors Mills was located near the Barwon river on Pakington Street, Geelong, where its building still stands. The mill was established in October 1922 with capital acquired from War Gratuity Bonds. The mill produced fine grade woollen products with its speciality being ‘Retsol’ travelling rugs. The mill first began to run into financial troubles with the ‘Credit Squeeze’ or the ‘Holt Jolt’ of the early 1960s. This saw import restrictions lifted which triggered the start of a minor recession and a rise in unemployment. Included in these troubles was the RS&S Mill which saw the number of employees gradually decrease and business declining with cheaper imports beginning to grab an expanding part of the market share. The mill was eventually purchased by Godfrey Hirst in 1973 who tried to continue operations without success and in June 1975 textile production at the site ceased. Outside of financial considerations contributing to the closure of Woollen Mills in this period was the declining need for heavier fabrics as in-home heating and insulation improved. This need had been replaced for a demand for ever softer, finer and lighter worsted fabrics for more casual clothing. Modern day textile production requires fewer steps in the processing of materials for this use. This meant large factory complexes such as early woollen mills like the RS&S mills were no longer required. Compared to modern textile production which can spin a fine yarn out of synthetic fibre or imported cotton easily, spinning fine yarn from medium quality wool at a textile factory was cumbersome and no longer financially viable to suit new consumer demands. This rug provides context to this statement. It was gifted to Shirley and Gordon Green as a wedding present in November 1963 by one of Gordon's colleagues in the wool industry. Living in areas such as Neutral Bay, the Hornsby area and later in life retiring to the Central Coast, the blanket was too heavy for use in these weather conditions and hence it stayed in its original box for nearly 60 years. Top and bottom of rug has frilled edges. Pattern is titled the 'Clan Cameron' and is repeated in a 7x7 grid. Front of rug has a red background with 4 vertical and horizontal lines. All is surrounded by a yellow boarder. Label is stitched into the bottom right corner. Reverse of rug also has a repeating 7x7 grid. Blue background with thick green horizontal stripe. Yellow and red boarder to the grid with 4 red vertical and horizontal lines making up the interior. Rug measure 1550 x 2040mm, approximately the same size as a queen size mattress.Wording, Bottom right corner. THE GEELONG R.S&S. WOOLEN MILLS/ PURE/ WOOL/ AUSTRALIA/ The John Monash Rug (cursive)/ The Clan Cameron (cursive)rs&s mills, textile manufacture, rug, clan cameron, sydney greasy wool exchange -

National Wool Museum

National Wool MuseumPicker

... them with other fibres. Typically, at a textile mill... them with other fibres. Typically, at a textile mill ...Wool picking machine designed to separate locks of wool before it is carded and spun. The picker opens the wool’s locks which makes it easier to send the fleece through a carding machine. It does this by teasing the fibres (which can also be done by hand just by pulling the lock structure apart), but a picker does this in bulk and much quicker than what can be done by hand. It is possible to spin fibres directly after the picking stage; however, it is usually more desirable to card and blend them with other fibres. Typically, at a textile mill, a picking machine can separate enough lengths of fibre for a full day’s work after just a single hour. It will also help to remove any vegetation matter or other any unwanted elements that may be present in the wool. The quality of the casting on this machine suggest that it was made locally, either in Australia or New Zealand. Mike Leggett, the donor of the machine, acquired it from New Zealand where the seller said it had been used by his father to pick wool to make hand stuffed horse saddles. Mike attempted to used it a couple of times to pick alpaca hair, but the speed of the attached motor caused damage to the fibres. The motor is thought to be an added attachment, sometime around the 1960s judging by its age, while the machine itself is thought to be dated around the 1920s. The machine works by inserting wool through the rollers. Initially there was a conveyor belt feeder system which was powered by the handle on the side. This conveyor belt has been removed however, most likely due to age and deterioration. Wool is now fed through the initial teeth and is met by a spiked rotating drum which works to separate the fibres. The separated fibres would then complete a loop of the drum before being dispatched somewhere below, around where the motor presently sits, at a rapid rate of speed. Typically this wool will be collected in a closet or large catchment area, as can be seen from the 8:47 minute marker in the linked video (link - https://www.youtube.com/watch?v=kMjx-t3tH3A). It is not apparent how the wool is collected with this machine. Red and green machine with four green legs currently attached to a wooden pallet with wheels for easy movement. The green legs lead up to a red central circular barrel from which many attachments are present. Also present on the wooden pallet is a small black motor which is attached by a rubber belt to the central drum inside the red barrel. The belt spins the wooden drum via a dark red circular plate attached to the side of the drum. On the other side of the red barrel, a green handle extends for turning the picker’s conveyor belt feeder system. Two green walls extend forward from the central red barrel, guarding either side of where the conveyor belt would have been. At the start of these walls is a wooden cylinder, which the conveyor belt would have wrapped around, followed by two interlocking gears which rotate and accept the fed wool. The red roof extends over the central cylinder from here, securing the wool inside and protecting hands from the heavily spiked internal wooden cylinder which rotates and separates (picks) the wool. Extending over the top of this red roof is a green handle which reaches to the back of the machine (not pictured). Here it accepts a weight to ensure pressure is always present for the initial feeder interlocked gear teeth. There are two large gear cogs on the rubber belt side of the machine and 3 small gear cogs on the handle side of the machine, all coloured green. A green handle is also present at the rear of the machine, below the location from which the weight is hanging. A power cable extends from the motor and there are two adjustable metal rods on the top of the machine, the purpose of these rods is presently unknown. Black texter. On top of drum. Wording: HG3707 Wording. Imprint: BRACEWIND BLYN On motor. Wording AEIwool picking, textile manufacturing, wool processing -

National Wool Museum

National Wool MuseumCarpet Samples, Godfrey Hirst and CO. Pty Ltd, c.1990

Carpet samples created by Godfrey Hirst, a carpet mill whose history spans back to 1865 when the Victorian Woollen and Cloth Manufacturing Company began operations in Geelong and was purchased in the 1890s by the man Godfrey Hirst. Godfrey Hirst’s entrepreneurial skills and knowledge of the industry led to the great success which saw the company expand in multiple forms over the next century and a half. Today, thousands of metres of carpet are produced by Godfrey Hirst every day, and their flooring can be found in millions of homes. These 6 carpet samples date from the early 1990s and each have a unique colour pattern and design.Each carpet sample is made with a pile fibre that is 100% wool. The primary backing of the carpet is a woven polypropylene with a secondary backing a woven jute. Carpet 8102.1's colour name is Slate. It has a dark grey background with a red and blue diagonal stripe. The pattern repeats in a 10cm x 11.5cm block. Carpet 8102.2’s colour name is Terracotta. It is a mostly block pink colour with no repeating pattern. It has occasional flicks of grey. Carpet 8102.3’s colour name is Arctic Night. It has white, light blue and grey colours repeating one after another in a diagonal line. Carpet 8102.4’s colour name is Ivory. It has a brown background with a cream colour diamond. The pattern repeats in a 15cm x 15cm block. Carpet 8102.5’s colour name is Glenwood. It has a thin darker green and lighter green horizontal stripe spanning its entire width. These stripes repeat the height of the carpet. Carpet 8105.6’s colour name is also Ivory. It has a brown background with a cream colour leaf pattern. The pattern repeats in a 92cm x 92cm block.Wording on rear: Numerous. See Media.godfrey hirst, carpet, textile manufacture -

National Wool Museum

National Wool MuseumTool - Drum Carder, Kacoonda, c.1980

This drum carder was purchase by Gill Stange at the Whittlesea Show in the late 1980s. The carder allowed Gill to spin fleece from her own Merino sheep. Merino is a difficult wool to spin when compared to other popular varieties, such as Corriedale or crossbred wool. The carder helped her to tease out the fleece, slightly separating the fibres before spinning. It also allowed for easier removal of foreign matters, such as seeds and mud. Little is known about the Kacoonda brand who produced the carder. They were Australian based and appear to have only operated throughout the 1980s.The carder has one large central roller with two smaller rollers on either side. The larger roller rotates in the inverse direction of the two smaller rollers. The carding cloth is a mint green in which closely spaced wire pins are embedded. The shape, length, diameter, and spacing of these wire pins is that of a standard carder. On one side of the carder a handle is found that is used to spin the three rollers. Additionally on this side is a sticker which reads “The Kacoonda Carder. Subject to Patent Action”. A Silver grip for the easy movement of the carder can also be found high on this side. On the opposite side of the carder, many nuts and plates can be found which hold the rollers in place. This is opposed to the other side of the carder, which has a brown plastic cover plate attached underneath the handle. The walls providing a path for the carded wool to follow when being carded, are made of wood. The carder comes complete with a teasing tool. This tool has the same mint green carding cloth as the carder’s rollers. It is attached to a simple wood handle for ease of use.Wording, green, printed. Sticker on side of carder. “The Kacoonda Carder / SUBJECT TO PATENT ACTION”whittlesea show, drum carder, textile production, carding wool, kacoonda -

National Wool Museum

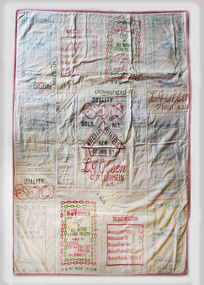

National Wool MuseumTextile - Quilt, Mrs Beryl Andersen, Chicken Feed Wagga, 1995-2001

Norma Dessent (the donor) was cleaning out her Mother-in-law Amy Dessent’s home, after she passed away in 1995. She came across a collection of gunny sacks for chicken feed, potatoes, and flour. Norma gave the bags to her good friend Beryl Andersen, thinking she might be able to make use of the material in her quilting. Many years later in 2001, Beryl gave Norma this quilt made in a wagga style out of the bags. This was both a great surprise and a great delight for Norma. Amy Dessent was a housewife. Her chickens were her friends, keeping her company as she worked in her renowned garden and while she cooked and maintained a beautiful home. Typically, Amy would have a dozen chickens clucking around at a time. In the style of the time, everything was kept for a possible repurposing later in life, such as these gunny sacks. The Chicken Feed Wagga was created in Ballarat by Mrs Beryl Andersen. Beryl was the inaugural president of the Hamilton Quilters Guild and is a well-known quilter. Perhaps her best-known work was the “Quilt for Hope”, a living memorial for victims of institutional church-related sexual abuse. More information about this quilt can be found on the following link. https://www.nationalquiltregister.org.au/quilts/quilt-of-hope/). The wool blanket used as a backing belonged to Beryl’s mother. Beryl’s mother married in 1930 and the blanket is thought to have been a present from this wedding, making the blanket close to a century old. Norma donated the quilt to the National Wool Museum in 2021 as a result of downsizing. She no longer had room for the quilt to hang on her wall. Before downsizing, the quilt had hung in the entryway to her home for the last two decades.Wagga style quilt made with a appliqué top layer of gunny sacks that once held chicken feed, flour, and potatoes. The insulating internal material is not known. The backing fabric is made from a cream woollen blanket. The edges are bound with a material of a red and white plaid. The gunny sacks are quilted together with a machine stitch of red thread. The sacks contain imagery pertaining to their previous use. Some sacks have an image of a chicken applied with blue, red, or green ink. Other sacks contain imagery of potatoes. While other sacks contain information “Minimum Crude Protein 14%, Minimum Crude Fat 3%, Maximum Crude Fibre 7%”. One of the sacks shows a handwritten price for a bag of chicken feed in a red ink.Numerous. See multimediaquilts, wagga, gunny sacks, upcycle -

National Wool Museum

National Wool MuseumPamphlet, Worsted Card for Man-Made Fibres Type CS-2

"Worsted Card for Man-Made Fibres, Type CS-2" - Befama Bielska Fabryka Maszyn Wlokienniczych; sole exporters: Metalexport, Warsaw, Poland, c.1950.textile machinery, metalexport bielsko textile machinery works, carding, yarn - worsted -

National Wool Museum

National Wool MuseumBook, Wool: the fashion fibre

"Wool: the fashion fibre" - Australian Wool Corporation, c.1985. Examines the use of wool for womens garments and includes descriptions of processes and styles.fashion textile production, australian wool corporation, fashion, textile production -

National Wool Museum

National Wool MuseumBook, Wool: eminently suitable

"Wool: the fashion fibre" - Australian Wool Corporation, c.1985. Examines the use of wool for mens garments and includes descriptions of processes and styles.fashion textile production, australian wool corporation, fashion, textile production -

National Wool Museum

National Wool MuseumBook, Proceedings of the International Wool Textile Research Conference Australia 1955 vol. D

"Proceedings of the International Wool Textile Research Conference Australia 1955; vol. D physics of wool and other viseo-elastic fibres", produced by CSIRO.csiro -

National Wool Museum

National Wool MuseumBook, Manual for the dyeing of wool, hair and bristles, and wool in combination with other fibres

"Manual for the dyeing of wool, hair and bristles, and wool in combination with other fibres"- I G Farbenindustrie Aktiengesellschaft, 1932.textile industry, dyeing -

National Wool Museum

National Wool MuseumBook, The wool year book 1962

... (incorporating the Rayon and Synthetic Fibres Annual) 1962" Textile ..."Textile Mercury Limited: the wool year book (incorporating the Rayon and Synthetic Fibres Annual) 1962"textile industry - history textile machinery, textile mercury ltd, textile industry - history, textile machinery -

National Wool Museum

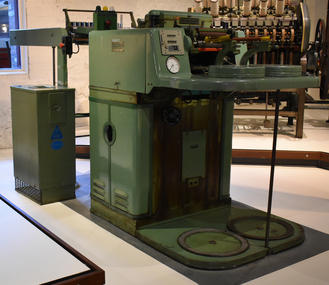

National Wool MuseumMachine - French Comb, Schlumberger & Cie, 1964

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. Machine has been completely rebuilt and set up by Nick Sokolov of Comb Research and Development with the help of Bruce Hill and others. NSC Schlumberger Comb PB25L machine No 3953, year of manufacture 1964. A rectilinear version of the Noble Comb, this machine separated long and short fibres. Donated to the National Wool Museum by Port Phillip Wool Processing Pty Ltd in 1993.French comb machine. 1962 Shlumberger and Co, France Model PB 251 NO. 3953.french comb, wool processing, textile industry, factory, machine, comb, restoration, fibres -

National Wool Museum

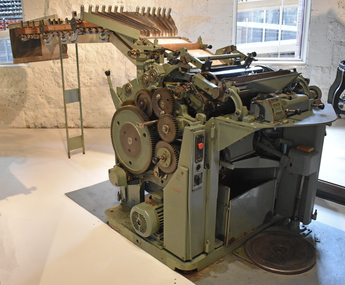

National Wool MuseumMachine - Gill Box, Deutscher Spinnereimaschinenbau Ingolstadt, 1963

This machine uses a series of combs attached to bars that move with increasing speed away from a starting point. This draws-out and aligns the wool fibres to produce a gilled top. The gilling process is also used in other positions along the worsted production line. A gill box draws and combs the fibres prior to spinning. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Gill box. Green painted steel.Deutscher / Spinnereimaschinenbau / Ingolstadt / 1963deutscher spinnereimaschinenbau ingolstadt, gilling, gill box, textile industry, wool processing, factory, machine, mills, spinning, fibre, comb -

National Wool Museum

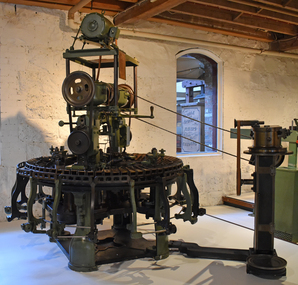

National Wool MuseumMachine - Noble Comb, Prince Smith & Sons, Burlington Shed, Keighley, 1915

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. A Nobel Comb separates short (Noils) fibres while also blending long (Tops) fibres together. The long fibres are used for worsted materials while the short fibres are used for woollen fabrics. Woollen materials are soft, bulky and fuzzy, such as a picnic blanket; whereas worsted materials are fine, smooth and crisp, such as a suit jacket. The Valley Worsted Mills in Geelong, now the Little Creatures Brewery, ran 12 noble combs up until 1981. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Noble Comb with plates - 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box). 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box).wool manufacturing, noble comb, textile industry, geelong, little creatures brewery, valley worsted mills, fibres, wool, factory -

National Wool Museum

National Wool MuseumBook, Fibre and Fabric

"Fibre and Fabric: the wool, cotton, textile and allied industries in Melbourne's West" - Gary Vines, 1993. This book is a short history of the wool, cotton, textile and allied industries of the area west of Melbourne. It looks at how, why and when these industries developed and their effect upon the cultural and geographic landscape.FIBRE AND FABRIC / Gary Vines / Melbourne's Living Museum of the West Incorportatedtextile industry - history woollen mills - history, textile industry - history, woollen mills - history -

Parks Victoria - Days Mill and Farm

Parks Victoria - Days Mill and FarmTextile - Assorted textile objects

Two cloth bags, one with a drawstring. Both bags have inscriptions. Also a portion of string fibres and a double headed brush - each brush head wound with wire.On bag with drawstring, the British coat of arms then , "WALKERS / PARK.R & CO / Patent Shot / LONDON / No. 2". On other bag, "HAMEL / VICTORIA TOWER / PATENT SHOT / No 2". -

RMIT Design Archives

RMIT Design ArchivesTextile - Woman's dress, Norma Tullo, Garment Designer, Shirley Lyle, Textile Designer, Woman's Dress

This light woollen evening dress is made from Peppinella, a new fabric Norma Tullo introduced into her range in 1973. The fabric was used exclusively by Tullo, and came from the wool of Peppin Merino (first introduced into Australia in 1858 by the Peppin brothers). According to the papers of the day Tullo’s 1973 winter collection featured ‘St. Trinian’s styles to garments dripping lace, in bold plain colours to floral prints.” Shirley Lyle designed the floral fabric. Norma Tullo (1935-2019) was one of the leading fashion designers of her time, establishing her label in 1956. After establishing a business the Old Metropole Arcade in Melbourne in 1956, with three sewing machines, Tullo's ready to wear fashions for young women became sought after, and her business flourished. In 1966 the Japanese department store chain Isetan Co Ltd began to mass-produce her garments for their stores across Japan. Tullo closed her label in 1977, and later worked for Fletcher Jones. Ann Carew, 2020The dress is historically significant as a dress designed by Norma Tullo, a leading fashion designer of the 1960s and 1970s. During this period the Australian Wool Industry strove to promote wool, and to develop light woollen fabrics to compete with new synthetic fibres such as rayon. The garment is historically significant for the use of a merino wool showcasing its versatility for dress fabrics. Full length woman's dress with full skirt and long sleeves, collared with open neck and pleat work on bodice. Material is predominately red with a repeated pattern featuring posie of blue and mauve flowers.Inscribed, black label on back neck left of zip, 'TULLO/IN/PEPPINELLA/AUSTRALIA MERINO WOOL'; Inscribed, white satin label on back neck right of zip, 'DRY CLEAN ONLY'; Inscribed, white satin label underneath above label, 'SIZE 12/To Fit Bust 34"/To Fit Waistwool, rmit design archives, rmit university, woman's dress, textile design, australian fashion -

National Wool Museum

National Wool MuseumFunctional object - Yarn Spinner and Accessories, John Nesbitt, 19th Century

Nino Corda was a Geelong based textile designer who worked at various textile mills between 1957 & 2003. He travelled the world in search of the latest fashions and techniques and developed timeless designs that were much loved by Australians. These items are on rotational display at the National Wool Museum’s ‘In the Factory’ exhibition. For many years, Nino also worked as part of the Honorary Staff of the National Wool Museum. His passion for the world of textiles provided energy and knowledge to the visitors and staff of the museum. Although Nino has now retired from his honorary position and has hung up his Australian Tartan vest, these items will continue to serve the community in sharing the stories of Australian Textile design.Custom made wooden hinged box with a hook latch. Brass yarn spinner, attached to a mahogany wood plinth base, which spins fibre into cord/yarn/thread. It has dials to set the rate that it spins. Metal plaque with black inlaid enamel lettering. Small cork inlay. Brass rod with hinge and wingnut, and ball at end. Ball at end has an adjustment mechanism. Rod also has an adjustable circular collar. Pair of curved tweezers. Circular magnifying glass on long thin handle. Glass has two concave lenses. Weaving sample in shades of blue, green and brown. Twill weave. Alternate pattern samples separated by red thread.Brass plaque on base of spinner: 42 MARKET St / John Nesbitt / REGd TRADE MARK / LIMd / MANCHESTER Underside of wooden plinth: 4976apparatus, textile, testing, spinning, nino corda, magnifyer, tools, brass, mahogany, tweezers, yarn, spinner, design, john nesbitt, manchester, england, 19th century, engineering, manufacturing