Showing 49 items

matching tones and i

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Royal Doulton, 1853-1878

The ink bottle was made by the Royal Doulton company which began as a partnership between John Doulton, Martha Jones, and John Wattis an English ceramic and home accessories manufacturer founded in 1815. Operating initially in Vauxhall, London, it later moved to Lambeth, In1882 it opened a factory in Burslem, Stoke on Trent, in the centre of English pottery. The business specialised in making salt-glazed stoneware articles, including utilitarian or decorative bottles, jugs and jars, much of it intended for inns and pubs. The backbone of the business was a wide range of utilitarian wares, mostly stoneware's, including storage jars, tankards and the like, and later extending to pipes for drains, lavatories and other bathroom ceramics. From 1853 to 1902 its wares were marked Doulton & Co., then from 1902, when a royal warrant was given, wares were marked Royal Doulton. The company always made some more decorative items, initially still mostly stoneware, and from the 1860s the firm made considerable efforts to get a reputation for design, in which it was largely successful, as one of the first British makers of art pottery. Initially, this was done through artistic stoneware made in Lambeth, but in 1882 the firm bought a Burslem factory, which was mainly intended for making bone china table wares and decorative items. History of the Loch Ard: The Loch Ard got its name from ”Loch Ard” a loch that lies to the west of Aberfoyle, and the east of Loch Lomond. It means "high lake" in Scottish Gaelic. The vessel belonged to the famous Loch Line which sailed many vessels from England to Australia. The Loch Ard was built in Glasgow by Barclay, Curdle and Co. in 1873, the vessel was a three-masted square-rigged iron sailing ship that measured 79.87 meters in length, 11.58 m in width, and 7 m in depth with a gross tonnage of 1693 tons with a mainmast that measured a massive 45.7 m in height. Loch Ard made three trips to Australia and one trip to Calcutta before its fateful voyage. Loch Ard left England on March 2, 1878, under the command of 29-year-old Captain Gibbs, who was newly married. The ship was bound for Melbourne with a crew of 37, plus 17 passengers. The general cargo reflected the affluence of Melbourne at the time. Onboard were straw hats, umbrellas, perfumes, clay pipes, pianos, clocks, confectionery, linen and candles, as well as a heavier load of railway irons, cement, lead and copper. There were other items included that were intended for display in the Melbourne International Exhibition of 1880. The voyage to Port Phillip was long but uneventful. Then at 3 am on June 1, 1878, Captain Gibbs was expecting to see land. But the Loch Ard was running into a fog which greatly reduced visibility. Captain Gibbs was becoming anxious as there was no sign of land or the Cape Otway lighthouse. At 4 am the fog lifted and a lookout aloft announced that he could see breakers. The sheer cliffs of Victoria's west coast came into view, and Captain Gibbs realised that the ship was much closer to them than expected. He ordered as much sail to be set as time would permit and then attempted to steer the vessel out to sea. On coming head-on into the wind, the ship lost momentum, the sails fell limp and Loch Ard's bow swung back towards land. Gibbs then ordered the anchors to be released in an attempt to hold their position. The anchors sank some 50 fathoms - but did not hold. By this time the ship was among the breakers and the tall cliffs of Mutton Bird Island rose behind. Just half a mile from the coast, the ship's bow was suddenly pulled around by the anchor. The captain tried to tack out to sea, but the ship struck a reef at the base of Mutton Bird Island, near Port Campbell. Waves subsequently broke over the ship and the top deck became loosened from the hull. The masts and rigging came crashing down knocking passengers and crew overboard. When a lifeboat was finally launched, it crashed into the side of Loch Ard and capsized. Tom Pearce, who had launched the boat, managed to cling to its overturned hull and shelter beneath it. He drifted out to sea and then on the flood tide came into what is now known as Lochard Gorge. He swam to shore, bruised and dazed, and found a cave in which to shelter. Some of the crew stayed below deck to shelter from the falling rigging but drowned when the ship slipped off the reef into deeper water. Eva Carmichael a passenger had raced onto the deck to find out what was happening only to be confronted by towering cliffs looming above the stricken ship. In all the chaos, Captain Gibbs grabbed Eva and said, "If you are saved Eva, let my dear wife know that I died like a sailor". That was the last Eva Carmichael saw of the captain. She was swept off the ship by a huge wave. Eva saw Tom Pearce on a small rocky beach and yelled to attract his attention. He dived in and swam to the exhausted woman and dragged her to shore. He took her to the cave and broke the open case of brandy which had washed up on the beach. He opened a bottle to revive the unconscious woman. A few hours later Tom scaled a cliff in search of help. He followed hoof prints and came by chance upon two men from nearby Glenample Station three and a half miles away. In a complete state of exhaustion, he told the men of the tragedy. Tom then returned to the gorge while the two men rode back to the station to get help. By the time they reached Loch Ard Gorge, it was cold and dark. The two shipwreck survivors were taken to Glenample Station to recover. Eva stayed at the station for six weeks before returning to Ireland by steamship. In Melbourne, Tom Pearce received a hero's welcome. He was presented with the first gold medal of the Royal Humane Society of Victoria and a £1000 cheque from the Victorian Government. Concerts were performed to honour the young man's bravery and to raise money for those who lost family in the disaster. Of the 54 crew members and passengers on board, only two survived: the apprentice, Tom Pearce and the young woman passenger, Eva Carmichael, who lost her family in the tragedy. Ten days after the Lochard tragedy, salvage rights to the wreck were sold at auction for £2,120. Cargo valued at £3,000 was salvaged and placed on the beach, but most washed back into the sea when another storm developed. The wreck of Lochard still lies at the base of Mutton Bird Island. Much of the cargo has now been salvaged and some items were washed up into Lochard Gorge. Cargo and artefacts have also been illegally salvaged over many years before protective legislation was introduced in March 1982. One of the most unlikely pieces of cargo to have survived the shipwreck was a Minton majolica peacock- one of only nine in the world. The peacock was destined for the Melbourne 1880 International Exhibition. It had been well packed, which gave it adequate protection during the violent storm. Today the Minton peacock can be seen at the Flagstaff Hill Maritime Museum in Warrnambool. From Australia's most dramatic shipwreck, it has now become Australia's most valuable shipwreck artifact and is one of very few 'objects' on the Victorian State Heritage Register.An early utilitarian stoneware item made by a well-known company that specialised in making salt-glazed items that later earned a reputation for making stoneware art objects. Of additional significance is that it was recovered from the wreck of the Loch Ard. A shipwreck that is of additional significance as it is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefacts from Loch Ard and its collection is significant for being one of the largest accumulations of artefacts from this notable Victorian shipwreck of which the subject items are a small part. The collections objects give us a snapshot of how we can interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time. Through is associated with the worst and best-known shipwreck in Victoria's history. Salt glazed stoneware ink bottle, large capacity, tapered lip and body, two-tone brown with some encrustation on surface, still sealed with cork. Inscription in clay. Recovered from the wreck of the LOCH ARD.Stamped into clay "DOULTON LAMBETH"flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, ink bottle, bulk ink bottle, writing accessory, stationery, stoneware, doulton lambeth, royal doulton, writing equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Jug

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/The form of the jug has been in use for many centuries.Stoneware jug. Two tone brown glaze with pierced lip behind spout. Spout chipped.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jug, ceramic jug -

Nillumbik Shire Council

Nillumbik Shire CouncilPainting: Walter MAGILTON, Walter Magilton, Sunlight and Shadows, Warrandyte, 2011

Walter Magilton's professional painting career is highlighted by numerous solo exhibitions, five of which have been in Great Britain. He has also won countless prizes, which include many 'Best in Show' awards. Walter is represented in a great number of private and corporate national and international collections, including ART Bank, in approximately twelve countries.This painting is a one of a series of approximately eight works of the river at Warrandyte and the local creeks, with particular emphasis on the reflections in the water and of the wattle growing along the banks. I was particularly inspired by Penleigh Boyde who did similar work while living in Warrandyte in the early 1920s.'Sunlight and Shadows, Warrandyte' is an oil on canvas painting depicting the Warrandyte landscape, featuring a winding creek with beautiful reflections cast upon it. The colour palate comprises muted green and earth tones, with a vivid aqua for reflective water.walter magilton, nillumbik, warrandyte -

National Wool Museum

National Wool MuseumClothing - 1984 Los Angeles Olympics Men's Opening Ceremony Shirt, c. 1984

On the 1984 Los Angeles Olympic Uniforms donator Doug wrote- During the 1980s the Australian wool industry was at its most prosperous times with record numbers of sheep producing wool receiving ever increasing values due to the success of the Reserve Price Scheme, and the overall guidance of the Australian Wool Corporation (AWC). As a humble technician, my role was a low profile newly created position of “Controller, Technical Marketing” where wool was to be marketed on its technical properties, as distinct from the “Product Marketing Group” which exploited trhe traditional high profile approach of marketing wool;s superior fashion attributes. The Woolmark was the tool central to this approach. When the forthcoming Los Angeles Olympic Games was announced, the Product Marketing Group seized upon the chance to show the world that we could make top fashion garments and display them on our elite athletes on the world stage. A concept was launched using a contemporary top designer, Adel Weiss, with the most exclusive fabrics and knits available, and all with a lot of hype. This launch failed dismally for the following reasons- - The designer did a wonderful job presenting an excellent fashion range on perfect skinny models. The AOC however wanted a uniform which had an obvious Australian appearance when fitted to elite, and frequently muscular, athletes. - The fabrics chosen did not reflect the performance required by travelling athletes, there was no recognition of the need for ‘easy care.’ - There was no recognition given to the problem of measuring, manufacturing and distribution of a range of articles when the selected athlete could be domiciled anywhere in Australia. - There was no appreciation of such historical facts as Fletcher Jones, who had been unofficial suppliers dating back to the 1954 Olympics in Melbourne, and the Fletcher Jones board member, who was also an AWC board member, and was not in favour of the change. The project passed from Product Marketing to Public Relations, a big spending off-shoot of the AWC Chairman David Asimus, and due to the day to day operations of the project was passed to me and PR took care of the financial matters. The first task was to meet with the AOC and find out exactly their requirements. This lead to the production of a design and manufacturing brief, cointaining exact time lines for each event required to ensure an appropriate uniform on every athlete chosen to represent his/her country on the date given for the Opening Ceremony in Los Angeles. Working backwards the timeline becomes- 1. Noted the exact date of the Opening Ceremony. 2. Estimated the date for distributing completed garments to each athlete. 3. Estimated the time span available for measuring each athlete and commence making each component of the ensemble to the individual measurements of each athlete. 4. Decided the date for making the final choice of uniform design concept. 5. Decided the date for distribution of the design brief to selected designers. These five steps were spread out over a two year period. The Commonwealth Games occur midway between each Olympic Games, work on the Olympic uniform commences the week after the Commonwealth Games closing ceremony and MUST be ready by the prescribed day two years hence. The project also had to remain cognisant of trade politics existing within the span of the task, as well as the temperament of designers in general. It is no overstatement to say that in the past every designer in Australia believed they could, and should, be chosen to design the Australian Uniform. The final choice of designer almost always faced criticism from the fashion press and any designer who had been overlooked. However, with the contenders receiving an exacting brief the numbers of serious contenders greatly reduced. The Los Angeles Olympic Uniforms. A further reason for the AWC bid failure to design the LA uniform was that the AOC had already chosen Prue Acton to design it. This was based on her proven performance during previous games as she had a talent for creating good taste Australiana. Her design concepts also considered the effect when they were viewed on a single athlete as well as the impact when viewed on a 400 strong team coming on to the arena. A blazer trouser/skirt uniform in bright gold was chosen for the formal uniform. It was my task to select a pure wool faille fabric from Foster Valley weaving mill and have sufficient woven and ready within the prescribed timeline. The trouser/skirt fabric selected was a 60/40 wool polyester plain weave fabric from Macquarie Worsted. This fabric had a small effect thread of linen that was most attractive when dyed to match some eucalyptus bark Prue had brought back from central Australia. For the Opening Ceremony uniform, Prue designed a series of native fauna, a kookaburra for the men’s shirt and a pleated skirt with a rural scene of kangaroos, hills and plants. This presented an insurmountable printing challenge to the local printing industry as it had an unacceptably large repeat size and the number required (50) was also commercially unacceptable. The solution was a DIY mock up at RMIT and the employment of four student designers. The fabric selected for this garment was a light weight 19 micron, pure wool with a very high twist yarn in alternating S and Z twist, warp and weft. This fabric proved to be the solution to a very difficult problem, finding a wool product which is universally acceptable when worn next to the sin by young athletes competing in the heat of a Los Angeles summer. Modifications to this fabric were developed to exploit its success when facing the same problem in future games. Garment Making- The most exacting garment in the ensemble is the tailored blazer, plus the related trouser/skirt. Unfortunately tailoring athletes that come in various shapes and sizes such as; - Weight lifters develop an enormous chest, arms and neck size. A shirt made to a neck size of 52 would produce a shirt with cuffs extending well beyond the wearer’s hands. - Basketball players are up to 7 feet tall and garments relying ona chest measurement grading would produce a shirt with cuffs extending only to elbow length. - Swimmers develop enormous shoulders and slim hips, cyclists by contrast develop thighs I liken to tree trunks and a uniform featuring tight trousers must be avoided at all cost. Suffice to say many ensembles require specialist ‘one off’ treatment for many athletes. Meanwhile there is a comfortable in between group who can accept regular sizes so you can cater for these by having back up stock with plenty of built in contingencies. Athletes may be domiciled anywhere in Australia, this creates a fundamental problem of taking their measurements. The Fletcher Jones organisation was key to answering this problem due to their presence in every capital city, as well as many provincial towns around Australia. Each athlete on being selected for the Olympic Team was simultaneously requested to visit their nearest Fletcher Jones shop. The standardised measurement data collected was shared with the other manufacturers, e.g. Pelaco Shirts, Holeproof Socks and Knitwear, Maddison Belts, and even Hush Puppy Shoes. As the time for the Games approached the AOC made arrangements for combining meeting of all. Selected available athletes at the Australian Institute of Sport, Canberra, where, among other things, they were fitted and supplied with their uniform. The method evolved as follows.Men’s cream coloured button up, collared shirt. Images of a kookaburra have been printed onto the shirt, a single kookaburra on the left breast and a pair of kookaburras on the reverse of the shirt. The kookaburras are printed in a brown tone to complement the cream colour of the fabric.On tag - FMaustralian wool corporation, 1984 los angeles olympics, olympic uniforms, men's uniforms, sport, athletes -

National Wool Museum

National Wool MuseumArchive - Advertisement, Onkaparinga Woollen Mill Company, 1956

Note from collector- "For more than 100 years blankets were made all over Australia in over 100 woollen mills. My aim, is to preserve 100 examples of these wonderful pieces of history. Ten years ago I started collecting the iconic Onkaparinga travel rugs, so that on movie nights at home there would be plenty to go around. Everyone had their favourite; even the cat had his own – a small red tartan one. Keeping an eye out for those travel rugs at op-shops and markets, collectable stores and bazaars, led to noticing vintage blankets. I'd never really thought about them before or paid much attention though of course I had grown up with them at my grandmother's. When I discovered my first Laconia cream blanket with blue stripes, my eyes just went gaga. Well that was it, I was hooked and since then over 500 blankets have passed through my hands. These common, everyday items, found in all households for so many decades, were traditional engagement gifts. Pairs were prized wedding presents turning into family heirlooms. They were fashionable dressers of beds, givers of warmth, bestowers of security and reliability. The comfort found in these objects resonates with almost all of us; we grew up with them ourselves or fondly recall them in a grandparent’s home. There is no modern replacement with the integrity of these old blankets, many of them now older than most of us. They are romantic, sensible, special, familiar, nostalgic and nothing else feels so appropriate in so many situations. No offense to the great Aussie doona, but from hippie to hipster, at a music festival, picnic, campsite or couch, a vintage blanket is something coveted by all. This industry that employed tens of thousands and must have been such a huge contributor to the economy is almost completely lost now. Blanket Fever is an ode to everything that came before: the land, the sheep, the shearers, the hands, the mills, the weavers, the designers, the distributors, the department stores. To the grandparents that gave them, the people that received them, the families that kept them; thank you. I’m passionate about my collection of Australian blankets manufactured in mostly Victoria, South Australia and Tasmania from the 1930s to the end of the 1960s. The collection has blankets from each of these four decades representing the styles and fashions of their time and includes dated advertisements which help determine the eras the blankets are from." Tonight sleep deep in blankets of purest wool (lady making bed and range of blankets) Tonight sleep deep in blankets of purest wool toned in the softest of pastel checks to make a bed lovely and warm/Onkaparinga, the worlds finest blanket from the world's finest wool/Onkaparinga new pastel multi-check blankets/Buy Well-Buy Wool/Obtainable from leading stores throughout Australiablanket, blanket fever, wool, onkaparinga, advertisement, australian women's weekly -

National Wool Museum

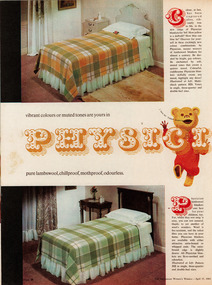

National Wool MuseumArchive - Advertisement, Collins Bros Mill Pty Ltd, 1964

Collector's note: "For more than 100 years blankets were made all over Australia in over 100 woollen mills. My aim, is to preserve 100 examples of these wonderful pieces of history. Ten years ago I started collecting the iconic Onkaparinga travel rugs, so that on movie nights at home there would be plenty to go around. Everyone had their favourite; even the cat had his own – a small red tartan one. Keeping an eye out for those travel rugs at op-shops and markets, collectable stores and bazaars, led to noticing vintage blankets. I'd never really thought about them before or paid much attention though of course I had grown up with them at my grandmother's. When I discovered my first Laconia cream blanket with blue stripes, my eyes just went gaga. Well that was it, I was hooked and since then over 500 blankets have passed through my hands. These common, everyday items, found in all households for so many decades, were traditional engagement gifts. Pairs were prized wedding presents turning into family heirlooms. They were fashionable dressers of beds, givers of warmth, bestowers of security and reliability. The comfort found in these objects resonates with almost all of us; we grew up with them ourselves or fondly recall them in a grandparent’s home. There is no modern replacement with the integrity of these old blankets, many of them now older than most of us. They are romantic, sensible, special, familiar, nostalgic and nothing else feels so appropriate in so many situations. No offense to the great Aussie doona, but from hippie to hipster, at a music festival, picnic, campsite or couch, a vintage blanket is something coveted by all. This industry that employed tens of thousands and must have been such a huge contributor to the economy is almost completely lost now. Blanket Fever is an ode to everything that came before: the land, the sheep, the shearers, the hands, the mills, the weavers, the designers, the distributors, the department stores. To the grandparents that gave them, the people that received them, the families that kept them; thank you. I’m passionate about my collection of Australian blankets manufactured in mostly Victoria, South Australia and Tasmania from the 1930s to the end of the 1960s. The collection has blankets from each of these four decades representing the styles and fashions of their time and includes dated advertisements which help determine the eras the blankets are from. Physician - the most beautiful blankets (double page)Vibrant colours or muted tones are yours in/Physician/pure lambswool, chillproof, mothproof, odourlessblanket, blanket fever, wool, collins bros mills, physician, geelong, advertisement, australian women's weekly -

Kew Historical Society Inc

Kew Historical Society IncPhotograph, The "Q" Theatre Guild, Gay Rosalinda, 1960

The "Q" Theatre Guild was formed out of the Kew Light Opera Company in 1957. It marked the transition of the company that had initially been directed by Lance Nicholls to one directed by Beatrice Oakley. It continued to perform in the Kew Recreation Hall, but, with its demolition in 1960, and the opening of the new Kew City Hall in Cotham Road, moved its productions to that venue. Productions of the "Q" Theatre Guild included The Geisha (1957), Maritana (1958), They All Do It (1959), Blossom Time (1959), Love's A Luxury (1959), There And Back & The Bohemian Girl (1960), Die Fledermaus (1960), Gay Rosalinda (1961), The Land Of Smiles (1961), Kisses For A Kid & Hansel And Gretel (1961), Die Fledermaus (1962), Monsieur Beaucaire (1964), Macbeath or The Beggar's Opera, and So To Bed.The scrapbook of annotated photographs, programmes, and newspaper reviews of which this item is a part was assembled by Marion Tilley, wardrobe mistress for, and performer in, productions by the Kew Light Opera Company and the "Q" Theatre Guild. It is significant as a remarkably complete document of theatre performances in Kew, Victoria during the 1950s and 1960s. The scrapbook, and the items individually catalogued within it, have artistic and aesthetic significance within the history of performing arts in Victoria in the middle of the 20th Century. They have social significance in that they reveal socio-cultural values and preoccupations during the period. The records also act as a history of arts activities in the Kew Recreation Hall and later in the Kew City Hall as entertainment and community arts and music precincts.Sepia-toned photograph of a group of performers in the "Q" Theatre Guild's performances of Gay Rosalinda, an arrangement of Johann Strauss' Die Fledermaus. The performance took place in the new Kew City Hall, with scenery created by Robert Jewell and Claud Ward. Costumes were designed and made by Marion Tilley. Marion Tilley, the creator of the scrapbook, wrote the following underneath the photograph: "Jean Hayles, Apthorpe, English, Robert Preston in my crinoline I wore for Centenary Ball. Apricot & black trim. Mum made it. Marion Smith."performing arts -- kew (vic.), scrapbooks, marion tilley collection, 'q' theatre guild, musical comedy -- melbourne -- victoria, kew city hall -- cotham road -- kew (vic.) -

National Wool Museum

National Wool MuseumTextile - Jumper, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Two-tone brown jumper with vertical ribbed pattern, raglan sleeves, ribbed collar and cuffs. knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

Vision Australia

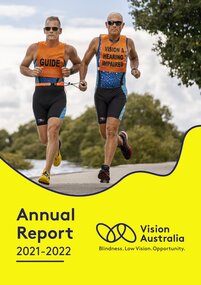

Vision AustraliaAdministrative record - Text, Vision Australia 2021-2022 Annual Report, 2022

Annual report providing overview of activities and achievements including: due to a second year of COVID disruptions 20% of services were delivered by telehealth, launch of "Happy Pants" program for children under 10, audio description services provided for Melbourne Theatre Company streaming of 'As You Like It', Feelix Library now offering Lego Braille Bricks kits to borrowers, partnership with Amazon to connect to VA offices through Alexa, and return of the Bendigo Easter Egg Hunt.1 volume with illustrations providing overview of organisational achievementsvision australia, corporation records, andrew moffat, ron hooton, katie spence, sanjiv rajendran, laura hendrey, gurleen chona, kieran jiwa, jessica gallagher, katie farrell, anthony carbines, nastasia campanella, callum padgett, ellie hudson, michelle percuoco, carly shedden, natalie kaine, rebecca kent, stephanie micallef, tones and i, lina xi, paige coleman, walter mcguire, bec murrell, natasha maclaren jones, tony broun -

Mrs Aeneas Gunn Memorial Library

Mrs Aeneas Gunn Memorial LibraryBook, George Routledge and Sons, The Ethics of the Dust

The following lectures were really given, in substance, at a girls' school (far in the country); which, in the course of various experiments on the possibility of introducing some better practice of drawing into the modern scheme of female education, I visited frequently enough to enable the children to regard me as a friend. The Lectures always fell more or less into the form of fragmentary answers to questions; and they are allowed to retain that form, as, on the whole, likely to be more interesting than the symmetries of a continuous treatise. Many children (for the school was large) took part, at different times, in the conversations; but I have endeavored, without confusedly multiplying the number of imaginary speakers, to represent, as far as I could, the general tone of comment and inquiry among young people.Index, notes, p.230.non-fictionThe following lectures were really given, in substance, at a girls' school (far in the country); which, in the course of various experiments on the possibility of introducing some better practice of drawing into the modern scheme of female education, I visited frequently enough to enable the children to regard me as a friend. The Lectures always fell more or less into the form of fragmentary answers to questions; and they are allowed to retain that form, as, on the whole, likely to be more interesting than the symmetries of a continuous treatise. Many children (for the school was large) took part, at different times, in the conversations; but I have endeavored, without confusedly multiplying the number of imaginary speakers, to represent, as far as I could, the general tone of comment and inquiry among young people. john ruskin 1819-1900, ethics -

National Wool Museum

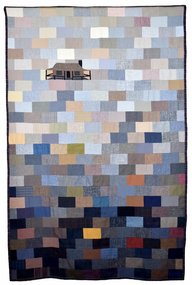

National Wool MuseumTextile - Quilt, Judy Turner, The Fading Dream of Australian Home Ownership, 1989

‘The Fading Dream of Australian Home Ownership’ was made by Judy Turner in 1989 for her son Nicholas (then 14 years) after a family discussion about mortgages and rising interest rates (17% at the time), out of concern for his generation. “Perhaps this will keep my son warm when he can’t afford a house”, wrote Judy at the time. As a quilting teacher for over thirty years, Judy was well aware of the ‘wagga’ tradition of making do with what you have and reusing resources to make something useful. The quilt was made using approximately 270 different men’s woollen suiting samples. The fabrics in the quilt were a gift from Micheal Haze who was a travelling men’s ware salesman and friend of the artist’s late husband. The suiting samples were used just as they were, without cutting, and are stacked liked house bricks. The pieces have been machine pieced and tied. The quilt has woollen backing, with no batting. Judy’s son Nicholas, always interested in drawing, and keen to see what his mother was making, helped with the drawing and design of the house. The quilt has been exhibited in Canberra, Armidale and Sydney and featured in publications in Australian and Japan. Judy’s work has been exhibited Nationally and Internationally, including in Japan, Korea, Germany, Switzerland and the United States of America. Judy’s work has featured extensively in publications around the world, and has received many awards. Her work is held in public and private collections across Australia and the USA. As well as a successful career as an artist, Judy spent three decades imparting skills to the next generation as a patient and skilled teacher. ARTIST STATEMENT The medium of my artistic practice is quilt making and my focus is the use of colour and speedy, accurate and efficient methods of making successful quilts. In 1995 I developed an original technique of applying woollen yarn to a woollen background, focusing on the subtle blending of colour to express an idea. Author of Awash With Colour (1997) and co-author with Margaret Rolfe of Successful Scrap Quilts (2002).Quilt featuring block pieces in tones of grey, blue, tan and brown, graduating in light to dark tones from top to bottom. The top third features a house with a verandah.quilt, wagga, home, house, housing affordability, design -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePostcard - Local Postcards, Joseph Jordan Photographic Studio, Nov 1908 - early 1909

ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., they standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough southwest Victoria Crew: 29 The Falls of Halladale was a four-masted sailing ship built-in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. The lines flag was of red, blue and white vertical stripes. The Falls of Halladale had a sturdy construction built to carry maximum cargo and able to maintain full sail in heavy gales, one of the last of the ‘windjammers’ that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new, raised catwalk-type decking allowed the crew to move above the deck stormy conditions. This idea is still used today in the most modern tankers and cargo vessels and has proved to be an important step forward in the safety of men at sea. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roofing tiles (roof slates), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the night of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m offshore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. These 5 postcards have photographic images taken while the Falls of Halladale was stuck on the reef near Peterborough. They are not stamped or dated but four of the images show the ship still in fairly good condition with her stern very low in the water so can be dated to around late November 1908 to January 1909 and the fifth image shows the ship beginning to disintegrate soon after. The image on Postcard 8658.3 was taken by Joseph Jordan (a well-known Warrnambool photographer who had his own studio in Liebig Street, Warrnambool). The other four images were supposedly taken by the sender (Bob) and converted to postcards. Amateur photography in Australia in the early 1900's was becoming very popular (and accessible) to the average person. Many newspapers published advertisements and articles about photography and photographic supplies. In 1903 in America, George Eastman designed and marketed the "Model 3A Folding Pocket Kodak" which used postcard-size negatives and provided the average person with a camera with which to make real photo postcards. As they became popular, George Eastman was able to develop and market a wide range of supplies for the amateur photographer to develop and print their own photographs onto a postcard backing at home. Four of the postcards were addressed to "Miss M. Kerr, Leura, Camperdown". Mary Agnes Kerr (1888 - 1943) was the daughter of William and Mary Ann Kerr (nee Spence) who owned "Leura Farm" at Camperdown. Mary Agnes Kerr went on to marry James Young Caldwell (a local tailor and mercer) in 1917. James Yong Caldwell came to Camperdown around 1908 and was employed as a draper. The postcards were signed "Bob". On postcard 5658.2 he has written his name with quotation marks around it - suggesting "Bob" is a nickname. He writes about the weather, meeting a friend, sending fish to Mary Agnes' family and the cargo expected to be washed up on the beach. On postcard 8658.4 he wrote about being busy after the wreck and supplying the shipwrecked crew with boots and pants which suggests "Bob" may be James Caldwell (the mercer and tailor).The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976). These postcards are significant as examples of the continued interest the locals around the district of Peterborough showed towards the Falls of Halladale wreck and its disintegration during the next few months. Four of the postcards are also significant examples of the new hobby of photography that was available to the average person during the beginning of the 20th century.Set of 5 postcards showing different images of the Falls of Halladale sailing ship after it became stuck on a reef near Peterborough. None of the postcards are dated or stamped. Postcard 8658.1 has a sepia toned image of the Falls of Halladale, with its stern sitting very low in the water. It has many of its sails unfurled and there is a rocky headland in the foreground. A very small figure appears to be on the edge of the cliff. The back of the postcard has a handwritten message addressed to "Miss M Kerr, Leura, Camperdown" and is signed "Love Bob". Postcard 8658.2 has a sepia image of the Falls of Halladale taken some months after it had been stuck on the reef. Its sails are missing and only two broken masts remain. A large rock is visible in the front right hand side of the photo. There is a handwritten message on the back signed by "Bob". Postcard 8658.3 has a black and white image of the Falls of Halladale showing her almost side on with her stern very low in the water and still in full sail. The words "Falls of Halladale. No 1" are printed on the lower left side of the image. The back is labelled "Jordan Series". There is no message written on the back. Postcard 8658.4 has a sepia toned image of the Falls of Halladale facing two rocky headlands. She is showing full sail and the sea appears calm. There is a handwritten note on the back addressed to "Miss M Kerr" from "Bob". Postcard 8658.5 has a sepia image of a side view of the Falls of Halladale with her stern very low in the water and her sails are all up. The sea is calm and a rocky reef can be seen in the foreground. It has a handwritten note on the back from "Bob" to "Miss M Kerr" of Leura, Camperdown.Back of postcard 8658.1- "POST" "EMPIRE" "CARD" "FOR CORRESPONDENCE" "FOR ADDRESS ONLY" "STAMP" "Miss M Kerr / Leura / Camperdown" "Looking forward to letter today" "Hope fish arrived / allright. Don't / know for sure / what day I will / be going to Town / to buy. Some day / this week / Love Bob Back of postcard 8658.2 - "POST CARD"/ "CORRESPONDENCE" "ADDRESS ONLY" "93"/ "Friday / This is a contrast to the first/ I sent you. Having glorious weather / Saw Saw (Saul)? on Thursday at Peterborough / He is having a grand holiday / Expecting letter on /Tuesday Fondest Love / "Bob" Front of postcard 8658.3 - "Falls of Halladale. No 1" Back of postcard 8658.3 -"Post" "Card"/ Printed in Great Britain" /"This space may be used for Communication" "The Address to be written / here" "Jordan Series" Back of postcard 8658.4 -"POST" "EMPIRE" "CARD"/ "FOR CORRESPONDENCE" "FOR ADDRESS ONLY" / "STAMP" "Miss M Kerr/ Leura / Camperdown"/ "We are/ very busy. The / wreck is about / 11/2 other side of / Peterborough./ Fondest Love, Bob "Had to supply sailors with Boots Pants etc/ 25 pairs Boots, good order ah!" Back of postcard 8658.5 - "POST" "EMPIRE" "CARD" / "FOR CORRESPONDENCE" "FOR ADDRESS ONLY" / "STAMP"/ "Miss M Kerr / Leura / Camperdown" "Tuesday / Her estimated / value cargo included/ is (pounds)100,000. When / she breaks up the coast / will be strewn with / wreckage as the cargo / includes Rolls Paper./all sorts machinery thousands / cases Benzine etc/ love Bob flagstaff hill maritime museum and village, warrnambool, peterborough, great ocean road, falls of halladale, shipwreck, postcards, photographic images, mary agnes kerr, leura farm, camperdown, jordan series, handwritten notes, photographs, george eastman, 3a folding pocket kodak camera -

Bendigo Military Museum

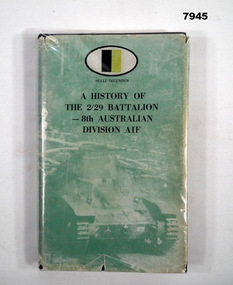

Bendigo Military MuseumBook - BATTALION HISTORY WW2, 2/29 Battalion AIF Association/1983", "A HISTORY OF THE 2/29 BATTALION - 8th AUSTRALIAN DIVISION AIF", 1983 First Edition

Refer Cat No. 7944. Item in the collection of "Arthur E. Tranter". V50166 - VX52843 2/29th Bn. P.O.W.Hard cover book with dust cover. First Edition Book. Hard cover - cardboard, black colour buckram adhered cover. Dust cover - paper, with black print on front and spine. Cover ilustration - muted green colour tones of a tank and roadblock - "Muar Road Battle". Plastic cover - clear soft plastic - protective cover with adhesive tape. 224 pages, cut, plain white paper. Illustrated with black and white photographs and maps. A number of pages have handwritten notes in grey lead pencil and blue ink pen. P.186 has an added note on paper. Handwritten owner's name front end paper. Page 186 - note on paper, blue ink pen. "P.186/ This section by R.F. Nelson/ describes my experience/ fairly well./ I was with him throughout the whole/ term of imprisonment". Front end paper - handwritten owner's name - blue ink pen "Arthur E. Tranter/ 24-4-83".plublications, book, 2/29 battalion, ww2, arthur e tranter -

Bendigo Military Museum

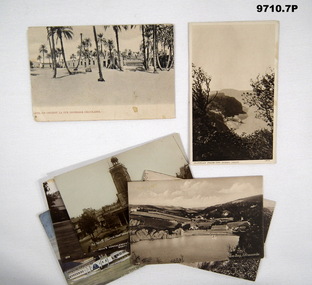

Bendigo Military MuseumPostcard - PHOTOGRAPHIC POSTCARDS WW1, C.1918

Items in the collection relating to C.J.C. McQuie MM, refer Cat No 9680P for his service details. .1) Postcard dated 13.9.18, to McQuie's Mother, talks about his eyes getting better and that there are 2,000 lads in the Hospital. .2).3).4) Postcards dated 15.9.18. McQuie relates how he has just been appointed 2nd Lieutenant and maybe moved to an Officers Hospital. .5).6).7) Postcards dated 18.9.18, to McQuie's Mother, relates how he is now out of bed, slowly getting better. .8) Postcard dated 22.9.18, McQuie talks about the Postcard picture and his collection of Postcards on bridges. .9) Postcard dated 19.10.18. The sender appears to be Ronald Ernest McQuie No 1977 3rd Reinforcements 21st BN. .10) Postcard dated 11.11.18, "Armistice signed, I have just been before a Board. Fortnight home service then G.S."Ten Postcards. .1) B&W view of Beaufort War Hospital, text on rear in purple. .2) .3).4) Sepia tone with views around Bristol, text on rear in purple, cards are numbered 1,2 & 3. .5).6).7) Sepia tone with views around Bristol, text on rear in purple, cards are numbered 1,2 & 3. .8) Sepia tone with view of Bristol area, text on rear in purple. .9) B&W with view of Castle Walls, text on rear in black, Piece of LH corner missing. .10) Sepia tone with view in a Church Salisbury, text in black.1) to .7) All have, "Ward 20 Beaufort War Hospital". four have "Bristol" on as well. .8) "Bristol" .9) "France, Best wishes for a happy Xmas and a peaceful new year". .10) "11.11.18 Salisbury"postcards, photos, mcquie -

Bendigo Military Museum

Bendigo Military MuseumPostcard - PHOTOGRAPHIC POSTCARDS WW1, 1915 - 1919

Items in the collection relating to C.J.C. McQuie MM, refer Cat No 9680P for his service details. .1) The card is to McQuie’s Mother, in pencil “Postcard views of Eygpt only”. .2) on rear in purple Talks about the area being owned by a Countess and wanting to keep it in its natural state. .3) On rear in black, “A very pretty site from the hills above”. 4.) On rear in black, “Another view from Hursborough”. .5) On rear in blue, “Talks about the Church being designed by Christopher Wren & was destroyed by fire in1675”. .6) On rear in purple, “I could not get them all in the one envelope, C. McQuie MM”. .7) Addressed to McQuie’s Father, in blue pen, “Talks about having a good time & card signed y a German girl, C.H. KKylre? And a traveller with him, A.J. Terry Lieut AIF”Seven postcards, diffferent tones, none dated, all with text on rear. .1) B&W scene of buildings & palms in Eygpt. .2) Sepia tone view over Clovelly from Hobby Drive. .3) Sepia tone View Lee Bay Ilfracombe. .4) Sepia tone view Ilfracombe, Chamber Combe Valley. .5) Sepia tone scene All Saints Church Northampton. .6) Sepia tone scene St John’s Convalescent Home Northants. .7) Colour drawing, on the Rhine, red stamp on.postcards, photos, mcquie -

Bendigo Military Museum

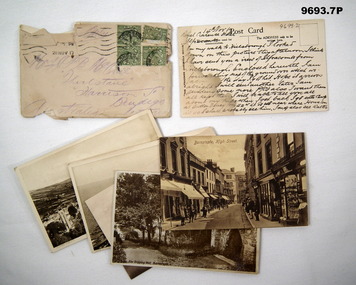

Bendigo Military MuseumPostcard - ENVELOPE AND POSTCARDS WW1, C.1917

The postcards are addressed to the Mother of C.J.C. McQuie MM, all written in 1917. .2) Card talks about his leave plus sending a map home of the ground over where he was W.I.A. Card scene is Hele Beach Ifracombe. .3) "Combe Martin" .4) "The Torrs Walk Ifracombe. .5) "Ifracombe, Santern Hill & Hillsborough". .6) "The Dripping Well Barnstaple" .7) "Barnstaple High Street" Items in the collection relating to C.J.C. McQuie MM, refer cat No 9680P for his service details. All the postcards are in sepia tone. .1) Envelope light brown colour, has 4 green stamps, addressed in purple indelible pen. .2) Postcard, view across a valley, text on rear in black pen. .3) Postcard, view across a Valley, text on rear in black pen. .4) Postcard, view from Cliffs to Ocean, text on rear in black pen. .5) Postcard, view across Ocean to Hills. .6.) Postcard, view of a well in a garden. .7) Postcard, street view in a town..2) On rear, "14th Nov17, Royal Clarence Hotel Ifracombe" .3) On rear, "This is a view of Hillsborough" .4) On rear, "Walked around here yesterday & then to L...& Bull Pt Lighthouse" .5) On rear, "Royal Clarence Hotel Ifracombe 16/11/17 - Great views from the top of this hill - I am walking to Barnstable today, 12 miles from here"postcards, mcquie -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPostcard - Westerson/postcard, Regal Postcard Co Sydney, 1900 c

Message on back posted Dec 09 to Mrs A Westerson Cliff Crest Cunningham Dear Jennie Many thanks for PN will send shoes Tuesday or Wednesday I paid the freight on that parcel I sent so I will call and see about it when I go in...... was so bad. Do you get many crayfish Hope you are all well as we are Love Yours LauraBlue toned postcard of Sydney University showing building surrounded by vegetation, gate in foreground Sydney N.S.W. buildings, correspondence -

Lakes Entrance Historical Society

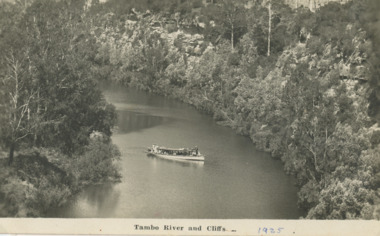

Lakes Entrance Historical SocietyPostcard, W S Vogt Bairnsdale, Tambo River Swan Reach Victoria, 1925 c

Note with photograph says This is a view of the Tambo River about a mile and a half up from where I am staying. The river here is narrow owing to cliffs with love from Arthur. Maybe Archie MacArthers boat GowrieSepia toned postcard of a passenger launch on the Tambo River below the cliffs upstream from Swan Reach Victoriaboats and boating, rivers, tourism -

Bendigo Military Museum

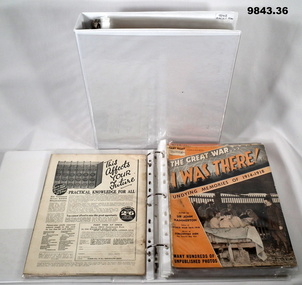

Bendigo Military MuseumMagazine - PICTORIAL COLLECTION, 1914-18, The Amalgamated Press Ltd, "THE GREAT WAR...I WAS THERE!", 1938 -1939

Information from Magazine front cover; "Part Five to complete in about 40 Parts/ THE GREAT WAR/ I WAS THERE/ UNDYING MEMORIES OF 1914-1918/ edited by Sir John HAMMERTON/ Editor of WORLD WAR 1914-1918/ Writer of FORGOTTEN MEN/ The Famous War Film/ MANY HUNDREDS OF/ UNPUBLISHED PHOTOS". Part of the William (Bill) THOMASON Collection. Refer Cat No. 4136P for more items.Magazine Collection stored in clear plastic A4 pockets in two folders. Folder One; 1. to 17. Folder Two; 18. to 36. Folders - 3 metal ring, cardboard and plastic cover. A4 clear plastic binder pockets. 1. to 36. Cover, heavy paper with black and orange colour print on front. Illustrated on front sepia toned photographs of soldiers in various battle locations. Back - advertisements in black and white print. 40 pages approx, cut, plain, off white paper. Illustrated black and white and sepia photographs with related articles in black print. BINDER ONE 1. Part Five October 31st 1938. 2. Part Six November 8th 1938. 3. Part Seven November 15th 1938. 4. Part Eight November 22nd 1938. 5. Part Nine November 29th 1938. 6. Part Twelve December 20th 1938. 7. Part 13 December 27th 1938. 8. Part 14 January 3rd 1939. 9. Part 15 January 10th 1939. 10. Part 16 January 17th 1939. 11. Part 17 January 24th 1939. 12. Part 18 January 31st 1939. 13. Part 19 February 7th 1939. 14. Part 20 February 14th 1939. 15. Part 22 February 29th 1939. 16. Part 23. Cover missing. 17. Part 24 March 14th 1939. BINDER TWO 18. Part 25 March 21st 1939. 19. Part 26 March 28th 1939. 20. & 21. Part 27 April 4th 1939. 22. Part 29 April 18th 1939. 23. Part 30 April 25th 1939. 24. Part 34 May 23rd 1939. 25. Part 35 May 30th 1939. 26. Part 37 June 13th 1939. 27. Part 38 June 20th 1939. 28. Part 40 July 4th 1939 29. Part 41 July 11th 1939. 30. Part 44 August 1st 1939. 31. Part 45 August 8th 1939. 32. Part 47 August 22nd 1939. 33. Part 48. August 29th 1939. 34. Part 49 September 5th 1939. 35. Part 50 September 12th 1939. 36. Part 24 March 14th 1939. Adhesive white label - black ink print - price label "Price in Australia/ and New Zealand 1/-".publications, magazines, pictorial, ww1, william (bill) thomason collection