Showing 56 items

matching weighing machine

-

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Singer Electric Sewing Machine, The Singer Manufacturing Company, 1950

... , this machine weighed only 10 Kgs. It is mounted on a wooden base... as it only weighed about 10 KG. This sewing machine is of local ...Singer was first established as I. M. Singer & Co. in 1851 by Isaac Merritt Singer with New York lawyer Edward C. Clark. Best known for its sewing machines, it was renamed Singer Manufacturing Company in 1865, then the Singer Company in 1963. The Singer company began to market its machines internationally in 1855 and won first prize at the Paris world's fair that year. They had offices established in both Sydney and Melbourne by the mid-1960s. The company demonstrated the first workable electric sewing machine in 1910. Singer was also a marketing innovator and a pioneer in promoting the use of instalment payment plans, making their machines more affordable for many people. According to its serial number, this machine was manufactured in 1950 and was one of the new models designed to be more portable as it only weighed about 10 KG.This sewing machine is of local, national and international significance as it represents developments in technology and the impact this had upon the work of women.The Singer 99 was a sturdy and reliable machine that was easy to use. Lighter than other machines of its time, this machine weighed only 10 Kgs. It is mounted on a wooden base with a small compartment under the balance wheel to store accessories and bobbins. It has a 'Bentwood' (polished plywood) cover which also provided some room for storage. The machine is driven by a small electric motor and a light to illuminate the work area. It is decorated with gold decals and a filigree pattern. It includes a knee control which is inserted in a hole at the front of the machine. The serial number EG045782 indicates it was manufactured in 1950.Across the top in gold script: "The Singer Manufacturing Co. / Made in Great Britain" On light cover: "SINGER" Plate with specifications also attached. On front of machine in oval badge: A CENTURY OF SEWING SERVICE/ THE SINGER MANFG. CO. 1851 - 1951singer sewing macnine, domestic appliances, women's work, technology -

Lara RSL Sub Branch

Lara RSL Sub BranchFramed Picture Print of a Lancaster Bomber

The Lancaster Bomber was one of the most famous aircraft of World War II. It first saw service in 1941 and became the RAF’s main bomber during the war. The first prototype Lancaster flew in January, 1941. A total of 7,377 Lancasters were made, after the first one rolled off the production line in October, 1941. It carried a crew of 7 and could fly at about 454 kmh. The plane was just over 21 metres long, had a wingspan of 31 metres and a flying range of 4,000 km. The Lancaster was normally armed with 8 Browning machine guns, as well as bombs. Some planes were modified so they could carry the so called Grand Slam bomb, weighing 10,000 kg. During World War II, Lancasters flew over 156,000 sorties, or raids. They dropped over 50 million incendiary bombs and over 608,000 tons of explosive bombs.One of the most famous bombing raids was a 1942 raid on Cologne, Germany. Over 1,000 bombers dropped bombs on the industrial city, destroying over 600 acres. Many Lancaster crew members were given medals for heroic actions while flying. Guy Gibson had flown 170 missions by the age of 24 and was awarded the Victoria Cross. Towards the end of World War II, Lancaster Bombers dropped food into the occupied Netherlands.Rectangular shaped glass covered picture frame with photo print of a Lancaster Bomber.lancaster bomber, ww2, avro, lara r.s.l. british aircraft. -

Lara RSL Sub Branch

Lara RSL Sub Branch18 Pounder shell ashtray, Souvenir, 1927

Artillery shells were designed to be recycled and spent shells were returned to the munitions factory for re-filling, a mark engraved upon the head-stamp at each re-filling. Millions upon millions of shells were recycled and re-fired. Relationships with ‘objects’ were forged as recycled objects of conflict were welcomed into people’s homes. Such objects were embodied with personal experiences of war, later to become objects textured with memory, remembrance, and longing – attributes that clearly go beyond an object’s form and function. 18-Pounder Artillery Shells: The Great War Recycled and Re-Circulated Categories :Material Culture Machine Subscribe Share on facebook Share on twitter The intention of war is to kill, to maim and to destroy using, for example, the agency of 18-pounder artillery shells (so-called because they weighed 18 pounds). The shells were loaded in to the 18-pounder field guns used by the Royal Artillery and targeted to destroy German batteries and trenches as well as to shoot down aeroplanes. Horse-drawn field gun, Canal du Nord, France. Taken by First World War photographer David McLellan. Available via the National Library of Scotland as CC BY-NC-SA Horse-drawn field gun, Canal du Nord, France. Taken by First World War photographer David McLellan. Available via the National Library of Scotland as CC BY-NC-SA In Under Fire, Henri Barbusse recounts how the incessant and diabolical din of war constantly bombarded the soldier body with the unendurable noise of bursting shells that caused pain to the ears (Barbusse 2010 [1933]: 207). The noise was so ‘monstrously resounding’ that one felt ‘annihilated by the mere sound of the downpour of thunder’ (Barbusse 2010 [1933]: 206). Artillery shells were designed to be recycled and spent shells were returned to the munitions factory for re-filling, a mark engraved upon the head-stamp at each re-filling. Millions upon millions of shells were recycled and re-fired. A mound of spent shell cases, Nord, Nord-pas-de-Calais, France. Taken by war photographer, Tom Aitken, 1918. Available via the National Library of Scotland as CC BY-NC-SA. A mound of spent shell cases, Nord, Nord-pas-de-Calais, France. Taken by war photographer, Tom Aitken, 1918. Available via the National Library of Scotland as CC BY-NC-SA. People’s experience of the First World War did not end with the armistice. Whilst the noise of the artillery had ceased, the noise of war was remembered. Harry Patch on arriving home injured recalled being ‘jumpy for a while’ with the least noise prompting him to dive for cover (2009: 114). Something else materialised. Relationships with ‘objects’ were forged as recycled objects of conflict were welcomed into people’s homes. Such objects were embodied with personal experiences of war, later to become objects textured with memory, remembrance, and longing – attributes that clearly go beyond an object’s form and function. The head-stamp of these particular shells displays the British broad arrow and the initials ‘EOC’ indicates that they were made at the Elswick Ordnance Company, England; the initials ‘CF’ signal that the charge was loaded with cordite, a standard propellant. Spent shells were illicitly scavenged from massive mounds by both soldiers and civilians alike to become personal souvenirs or to swap or sell. Spent artillery shells were crafted, often using a hammer and a bent nail. The crafting of trench art reflects the construction of an identity that offers momentary relief from the hell experienced in the trenches. The lid of an 18Pounder shell which has been adapted for use as an ash tray.Lot 27 1927, 18Pr, III, EOC, C/F, Defence broad arrow, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBolt Cutter, 1878

Cyrus Chambers was a self-described mechanic who started out winding bobbins in his father's woollen mill and went on to invent machines that changed their industries. Cyrus Chambers came from Quaker parents the ninth of thirteen siblings, he once said a year before his death. “I believe I have succeeded because, first, I was industrious; second, because I made a study of the subject that was before me.” At age 7, Chambers went to work in his father’s mill. His job was to monitor bobbins—wooden spindles around which thread was wound and to remove and replace them as they became full. "There was no child labour law at that time," he later recalled. Chambers loved machinery and always regarded himself as a mechanic rather than an inventor. At age 16, Chambers was sent to learn dentistry with an older brother, (Edwin) who was already in the field and willing to take him on as an apprentice. Chambers was talented at working with small parts. He used his brother's dental instruments to build a miniature high-pressure steam engine of silver. It ran at 3,000 revolutions per minute and weighed less than a half-ounce. At that time it was the smallest engine that had ever been constructed. The engine was displayed at the 1876 Centennial and is now in a permanent collection at the Franklin Institute USA. Chambers major invention was the paper folding machine and came from reading that school teachers made less than the young girls who were employed to fold book pages as they came off the press. He told friends that his first efforts were to make the machine that would fold newspapers after demonstrating his device he met with Horace Greeley of the New York Tribune who advised Chambers would never invent the machine that would be able to fold his newspaper or books. In less than a year Chambers had built a full-size machine capable of folding large newspapers and books and was installed at J B Lippincott & Co folding pages for the "Comly Speller" this machine ran successfully for twenty-five years until the printing works burnt down. Chambers then went into partnership with a brother and they established the firm "Chambers, Brother & Co" at a plant in Philadelphia. It was also observed in 1910 and a fact that there was not a periodical or newspaper printed or recently published book that had not gone through one of Chambers inventions. Chambers went on to produce many mechanical inventions and improvements to existing tools and machinery most notable was his invention for the machine that would make clay bricks. This machine made forty bricks per hour and by the end of Chambers life after many improvements, it could make more than four hundred. Although there were a large number of bold cutters made of this patent at Cyrus Chamber’s foundry in Philadelphia, the item is associated with a notable American inventor of the nineteenth century. This particular patent for a bolt and rivet cutter won Chambers the prestigious Elliott Cresson Medal. This cutter is just one of the many inventions and mechanical improvements that Cyrus Chambers made during his lifetime, contributing to the ongoing development of mechanical improvements that were occurring in American industry of the time and therefore a notable addition to the Flagstaff collection.Cast iron bolt cutter with removable tempered steel cutter. Chambers New No. 2.Raised embossed lettering on cast body of cutter "New No 2" on one side, "Chambers Bros & Co" on the other sideflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cyrus chambers, bolt cutter, paper folding machine, brick making machine, elliot cresson, elliot cresson medal, franklin institute, gold medal, rivet cutter -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Platform Scales

Thaddeus Fairbanks (1796 –1886) was an American inventor. of heating and cook stoves, cast iron ploughs, and other items. His greatest success was the invention and manufacture of the platform scale, which allowed the weighing of large objects accurately. Fairbanks was born in Brimfield, Massachusetts, on January 17, 1796, the son of Joseph Fairbanks (1763–1846) and Phebe (Paddock) Fairbanks (1760–1853). His uncle was Ephraim Paddock, the brother of Phebe Paddock. In 1815 he moved to St. Johnsbury, Vermont, and set up a wheelwright's shop above his father's gristmill. In 1820 he married Lucy Peck Barker and In 1824 he built an iron foundry. his brother Erastus joined him to establish E. and T. Fairbanks, a partnership to manufacture heating stoves, cast iron ploughs a design for which he patented in 1826. In 1830 Fairbanks and Erastus became interested in the raising and processing of hemp. Fairbanks went on to patent a hemp and flax dressing machine and became the manager of the St. Johnsbury Hemp Company. He also built a set of scales that would measure large loads of hemp accurately, as there were no reliable scales at the time. Upon the success of building these scales, his brothers recommended that he make and sell these for general use. Fairbanks' most famous invention then became the platform scale for weighing heavy objects. These are commonly known as the Fairbanks Scales, for which he patented his original design in 1830. Before this time, accurate weighing of objects required hanging them from a balancing beam as a result, particularly heavy or ungainly objects could not be weighed accurately. A platform scale, if large enough, could weigh an entire wagon. By placing a full wagon on the scale, unloading it, and then placing it on the scale when empty, it became possible to easily and accurately calculate the weight and value of farm produce and other loads. In 1834 Fairbanks and his brother formed "E. and T. Fairbanks and Company" to manufacture and sell these platform scales. These scales were well known in the United States and around the world resulting in the company doubling in volume every three years from 1842 to 1857. There was a temporary slow down during the American Civil War, however, the business took off again after the war. Their partnership was incorporated in 1874 into a firm known as "Fairbanks Scale Company". These platform scales revolutionized weighing methods of large loads and have been in use ever since. Portable platform scales are found in almost every hardware store, physician's office, and manufacturing factory throughout the United States and the world. The first railway track platform scale patent was granted to Fairbanks on January 13, 1857, as Patent No. 16,381. In 1916 the company was purchased by ”Fairbanks, Morse and Company”. Ownership of the company has since changed several times, but Fairbanks Scales continue to be made in St. Johnsbury Vermont to this day. Fairbanks had received 43 patents in his lifetime with the last one at the age of 91. He died on April 12, 1886, and is buried at St. Johnsbury, Vermont, at the Mount Pleasant Cemetery. An early example of the first type of platform scale that revolutionised the weighing of goods throughout the world made in the USA around the turn of the 19th century. Commercially built platform scale on wheels. Cast iron base supports iron weighing platform with wooden floor. At back, square hollow wooden post supports a hooded rod which bears the weight of the platform and which hooks onto a brass balancing arm, marked in pounds up to 50. There is a cylindrical sliding weight and on the end a loop for a metal weight holder. The holder is designed for three circular pieces of metal with a slit to the centre. The weights used are 50, 100 and 200 lbs.Embossed to base Fairbanks Patent No 11 1/2, flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, platform scales -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTypewriter Mechanical Portable, 1950s

The Olivetti company was founded in Italy in 1908.This particular typewriter is a Olivetti Lettera 22, oblique front stroke and portable manufactured after 1950. The 1950s and 1960s was a time when British manufactured goods were still purchased by many Australian consumers. The later 1960s onwards, there was a shift, mainly in the cities, to European made goods. The invasion of Japanese manufactured goods was relatively slower, especially in rural areas. The demand for long lasted and dependable merchandise was in the rural area still the most important criteria. The ease of setting up this typewriter and its compact mobility was its major benefit to trades people and travelling professionals, e.g. rural doctors, other medical professionals, accountants, lawyers and educators. This item facilitated the growing numbers of professional nomads requiring a relatively light office stationery package e.g. travelling novelist, writer, businessman and academics. This typewriter needed no electrical or battery power to operate it. Outback Australia, where at this point in time, was still relatively isolated from a good available electrical power reticulation and battery power, and therefore could not be totally measured as a highly efficient office environment.Although this typewriter was purchased from a business in Penrith, Sydney, N.S.W., it is significant that it travelled easily to the Kiewa Valley, demonstrating the mobility of certain sections of the community. This typewriter was designed by an Italian industrial designer, Marcello Nizzoli, in line with the art deco style of the 1930s and the colour and flexibility of the vibrant 1950s. The underlying theme of manufacturing in the 1950s was to produce equipment that was more efficient than what was inherited from the earlier period of 20th century. Improvements were made to this Olivetti typewriter by Giuseppe Beccio by reducing the number of parts made from 3,000 to 2,000. This reduction of parts and therefore cost of production was the major principle of the Japanese manufacturing juggernauts of the post World War II era. Efficiency and low costs material was becoming prime factors in the success of rural industries from the 1960s. Competition from overseas producers was starting to affect rural industries and the removal of the large range of tariff protection, especially rural products, required not only a shift of farm management but a more efficient cost savings modus operandi. This Olivetti Lettera 22, oblique front stroke portable (weighs 4kg) mechanical typewriter has a coral coloured plastic casing. The keys are made of black hardened plastic with white lettering, numbers and symbols (imperial fractions, and pound). It has a QWERTY keyboard as opposed to the Italian QZERTY. It has a lever to move the ribbon between black, neutral (for mimeograph stencils)and red colours (a red key is provided for highlighting specific words,letters or symbols) . This machine is fitted with only a black ribbon. It has a black rubber paper rollers and chromed metal parts on the carriage way. It has four rubber feet underneath the main body. On the left side of the roller there is a lever to adjust the roller from fixed (when mobile) through 1,2 and 3 line space gradients. This model has a key for zero but not one for the number one (uppercase letter l is used) see KVHS 0459 for the carrying bag.On the cover over the ribbon wheels letter strikers has a plate marked "Lettera 22" and the back plate behind the paper roller and in front of the paper supports has a silver metal label marked "olivetti made in great britain".commercial, mobile office equipment, mechanical typewriter -

Cheese World Museum

Cheese World MuseumButter printer, J Bartram & Son, c1900

The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. This butter cutter is part of the collection of items given into the care of the Cheese World Museum. It was in the early 1900s for hand-use in home dairies or small factories. An example of an early butter packaging machine.Wooden Eureka brand butter printer and weigher with dovetailed corners on the bulk butter box, wooden rollers for moving butter along once cut and wire cutter.Eureka/J Bartram & Son/sole makers Uebergang No. U027butter cutters, uebergang, allansford, dairy manufacture -

Cheese World Museum

Cheese World MuseumCentrifuge, electric

This Babcock tester was used in the laboratory at the Kraft cheese factory, Allansford. When it was superseded it was passed to one of the users of the machine, Les O'Callaghan, president of the Warrnambool & District Historical Society who placed it in the historical society collection. In 2009 when the historical society premises were upgraded there was insufficient room to store the tester so it was donated to Cheese World Museum. The machine was used to test the butterfat content of milk. Prior to dairy factories coming into existence farmers made butter individually on farms. There was no need for milk testing until farmers supplied factories for payment. Payment was based on a gallon of milk weighing 10lbs (pounds) and this led to richer milk, containing a high degree of butterfat for use in buttermaking, being paid at the same rate as lesser quality milk. In 1890 Stephen Moulton Babcock, an American professor at the University of Wisconsin-Madison, developed a method of determining the amount of butterfat in milk, thus providing a standardised and fairer system for payment. Babcock Test Process 1. 18 grams of milk (17.6ml) was put into a test tube 2. The same amount of sulphuric acid was added 3. A centrifuge at 50ºC was rotated at more than 900 revs per minute 4. The fat floating on top of the liquid in the test tube was measured The Babcock Test provided fairer compensation to farmers and also helped produce a consistent product for consumers. It also allowed for selective breeding when dairy herd testing evolved. ‘The Babcock Test is so simple that it can be used by any careful person, and it is inexpensive to operate. From the very beginning it was so complete in every detail that no change has had to be made in it.’ (Babcock Test http://www.en.wikipedia.org/wki/Babcock_test 31 March 2009) Round green metal container with opening lid. Inside houses a spinning rotor with 20 test tube holders around the outside in two circular rows.7173 BABCOCKTESTER 190allansford, dairy manufacturing, milk testing, babcock test, babcock, stephen moulton, butter, warrnambool cheese and butter factory company -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Scale, Computing Scale Company, 1897-1900

In 1885 Julius Pitrat of Gallipolis, Ohio, patented the first computing scale. Six years later, Edward Canby and Orange Ozias of Dayton, Ohio, purchased Pitrat's patents and incorporated The Computing Scale Company as the world's first computing scale vendor. And four years after that, The Computing Scale Company introduced the first automatic computing scale In 1911. the Computing Scale Company merged with the International Time Recording Company and Tabulating Machine Company to form the Computing-Tabulating-Recording Company, a business that was renamed IBM in 1924. An early example of a hanging clock face scale patented in October 1897 and made by a company that pioneered the first computing scales used in retail businesses. This company went on to become incorporated with IBM that late became an international computer manufacturer.Scale, patented Oct 12, 1897. Measures in pounds and ounces, up to 10lb. Red indicator needle. Two adjustment screws. Ring on the top for mounting. Marked "The Computing Scale Co Dayton Ohio"Marked "The Computing Scale Co Dayton Ohio"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, scale, computing scale, computing scale company, weighing instrument -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Platform Scales, Thaddeus Fairbanks, 1880-1910

Thaddeus Fairbanks (1796 –1886) was an American inventor. of heating and cook stoves, cast iron ploughs, and other items. His greatest success was the invention and manufacture of the platform scale, which allowed the weighing of large objects accurately. Fairbanks was born in Brimfield, Massachusetts, on January 17, 1796, the son of Joseph Fairbanks (1763–1846) and Phebe (Paddock) Fairbanks (1760–1853). His uncle was Ephraim Paddock, the brother of Phebe Paddock. In 1815 he moved to St. Johnsbury, Vermont, and set up a wheelwright's shop above his father's gristmill. In 1820 he married Lucy Peck Barker and In 1824 he built an iron foundry. his brother Erastus joined him to establish E. and T. Fairbanks, a partnership to manufacture heating stoves, cast iron ploughs a design for which he patented in 1826. In 1830 Fairbanks and Erastus became interested in the raising and processing of hemp. Fairbanks went on to patent a hemp and flax dressing machine and became the manager of the St. Johnsbury Hemp Company. He also built a set of scales that would measure large loads of hemp accurately, as there were no reliable scales at the time. Upon the success of building these scales, his brothers recommended that he make and sell these for general use. Fairbanks' most famous invention then became the platform scale for weighing heavy objects. These are commonly known as the Fairbanks Scales, for which he patented his original design in 1830. Before this time, accurate weighing of objects required hanging them from a balancing beam as a result, particularly heavy or ungainly objects could not be weighed accurately. A platform scale, if large enough, could weigh an entire wagon. By placing a full wagon on the scale, unloading it, and then placing it on the scale when empty, it became possible to easily and accurately calculate the weight and value of farm produce and other loads. In 1834 Fairbanks and his brother formed "E. and T. Fairbanks and Company" to manufacture and sell these platform scales. These scales were well known in the United States and around the world resulting in the company doubling in volume every three years from 1842 to 1857. There was a temporary slow down during the American Civil War, however, the business took off again after the war. Their partnership was incorporated in 1874 into a firm known as "Fairbanks Scale Company". These platform scales revolutionized weighing methods of large loads and have been in use ever since. Portable platform scales are found in almost every hardware store, physician's office, and manufacturing factory throughout the United States and the world. The first railway track platform scale patent was granted to Fairbanks on January 13, 1857, as Patent No. 16,381. In 1916 the company was purchased by ”Fairbanks, Morse and Company”. Ownership of the company has since changed several times, but Fairbanks Scales continue to be made in St. Johnsbury Vermont to this day. Fairbanks had received 43 patents in his lifetime with the last one at the age of 91. He died on April 12, 1886, and is buried at St. Johnsbury, Vermont, at the Mount Pleasant Cemetery. An early example circa 1900 of the first type of platform scales used in a grocery store. This design for accurately measuring goods that were sold over the counter revolutionised the weighing of goods throughout the world. Platform scale metal black with removable tray & pan. Has horizontal brass arm with a brass slide weight black removable weight hook and 2 x 2 lb. weights. Fairbanksflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Victorian Interpretive Projects Inc.

Victorian Interpretive Projects Inc.Photograph - Digital, Troopship Wiltshire, 1918, c1918

The HMAT A18 Wiltshire (1912-1922) weighed 10,390 tons with an average cruise speed of 13.5 knots or 25.00 kmph. Described as a refrigerated steamship it was b uilt 1912 by John Brown, Clydebank for the Federal S N Co Ltd, London and was propelled by a twin screw, quadruple expansion engine 2 x 4 cylinders each 6500 hp. Owned by the Commonwealth & Dominion Line Ltd, London, it was leased by the Commonwealth until 2 October 1917. It embarked from Egypt on 2 February 1918. On 18 October 1914 at Melbourne embarked the 4th Light Horse Regiment (Victoria) A, B & C squadron & their Machine Gun Section, the 2nd Field Ambulance (Victoria) First Division. The disembarked the 4th Light Horse Regiment in Egypt on 10 December 1914. On 01 November 1914 The Wiltshire assembled with the first convoy at King George's Sound, Albany Western Australia in transporting the first detachment of the Australian and New Zealand Imperial Expeditionary Forces. It completed nine transport voyages from Australia commencing 18 October 1914 until final voyage from Sydney 9th November 1918. During that time The Wiltshire carried the 4th Field Artillery Brigade (Victoria) 2nd Division Artillery and their 1st Reinforcements, 1st Division Ammunition Column 1st Division Artillery 4th Reinforcements, thirty-four Infantry Battalion Reinforcements, the 10th, 11th & 12th Field Artillery Battery (Victoria) 4th Field Artillery Brigades, the 4th Brigade Ammunition Column 4th Field Artillery Brigade, the 1st Siege Artillery Brigade 15th Reinforcements, the 4th Light Horse Regiment (Victoria) A, B & C squadron & their Machine Gun Section, six Light Horse Brigade Reinforcements, the 1st Veterinary Section (New South Wales) 11th Reinforcements, the 1st Mobile Veterinary Section (New South Wales) 1st Division 11th Reinforcements, the 2nd Mobile Veterinary Section (Victoria, New South Wales) 2nd Division 11th Reinforcements, the 1st Cyclist Battalion (New South Wales and Queensland) 3rd Reinforcements, the 2nd Field Ambulance (Victoria) First Division & Medical Officers. After the conclusion of World War One is was wrecked Rosalie Bay, Great Barrier Island New Zealand 31 May 1922 on passage London for Dunedin. Onboard was a crew of 103 plus 1 stowaway, and 10,000 ton of general cargo. No lives lost and is now a well frequented 'Dive' wrecksite. (http://www.flotilla-australia.com/hmat.htm#A18)Photographic postcard of the troopship Wiltshire out at sea.world war one, world war, wiltshire, troop ship, mmm -

Puffing Billy Railway

Puffing Billy RailwayNew Record Saw Bench, circa 1930's

Saw Bench - New Record Saw Bench Timber framed with steel wheels, belt driven saw blade powered by a Rosbery internal combustion engine. The Rosebery Engine No C28437 R.P.M 800 H.P. 6 Manufactured By Westinghouse Rosebery Pty.Ltd. Sydney Rosebery Engine Works Ltd began as the engine and pump manufacturing division of Buzacott & Company, and in 1923 became an incorporated company. In 1935, Westinghouse gave Rosebery Engine Works the right to manufacture and sell nearly all Westinghouse products. The name of the company then changed to Westinghouse Rosebery Ltd From the late nineteenth century, petrol engines gradually supplanted steam engines for running a wide range of machines, and in turn petrol engines were largely supplanted by electric motors. The Champion was a successful small petrol engine made by the large Sydney company, Westinghouse Rosebery, based on the American-designed Fuller and Johnson engine. With hopper cooling and a fuel tank between the skids, and weighing only 240 pounds (109 kg), it was easy to mount on wheeled transport, making the Champion a self-contained mobile source of power. Engines of this type were used in rural areas for driving chaff cutters, small saw benches, pumps and orchard sprayers. These engines were also commonly used in both rural and urban areas for powering concrete mixers. Both Westinghouse Rosebery in NSW and Toowoomba Foundry in Queensland made these engines in large quantities, beginning in the 1920s when tariff protection made local manufacturing viable. The production of small petrol engines continued in Australia until the 1970s, when reduced tariff protection led to increased competition from cheaper imported engines. Historic - Industrial Timber working - belt driven saw blade powered by a Rosbery internal combustion engine. Timber framed with steel wheels, belt driven saw blade powered by a Rosbery internal combustion engine. The Rosebery Engine No c28437 R.P.M 800 H.P. 6 Manufactured By Westinghouse Rosebery Pty.ltd. Sydneysaw bench, puffing billy, new record, internal combustioin, westinghouse rosebery pty.ltd., rosebery pty, internal combustion engine. -

Tatura Irrigation & Wartime Camps Museum

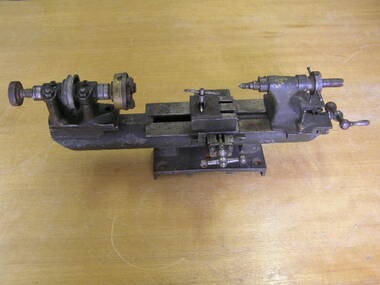

Tatura Irrigation & Wartime Camps MuseumTool - Lathe, Metal Lathe

Made at a forge outside the camp 3 perimeter by Gotthilf Kaltenbach & Manuel Kaltenbach. It is made from British Army scrap metal. Used for fine metal turning. The Witworth gauges were not used in Central Europe after 1918. The motor that was on it was a small electric sewing machine motor which was discarded about ten years ago in Germany. Sent from Germany by Elfriede & Paul Faig.Handmade metal turning lathe, 600mls long and weighing 16 kg. Made at a forge site outside the camp perimeter. All dimensions are in imperial inches, all threads are Witworth gauges. Painted in British Army colours.tatura, camp 3, lathe, metalworking, paul faig, gotthilf kaltenbach, manuel kaltenbach -

National Wool Museum

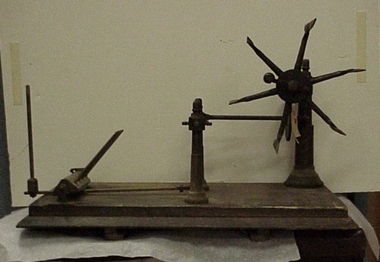

National Wool MuseumMachine - Wrap Reel

Wrap reel manufactured at Valley Worsted Mill and possibly used in the laboratory. "Wrap reels were used to check the yarn count in a spinning mill. A set length of yarn was wound off several test bobbins and weighed, if the weight was not the correct amount expected the spinning machines draft could be re calculated and the machine draft wheel ( cog ) changed to achieve the required count". - Greg AldridgeA small hand operated wrap reel. The reel is on a wooden base, the winding mechanism is metal and turned by a wooden handle. There is a metal plaque on the base inscribed MAKERS VWM. A wood and metal yarn feeder has broken off its mount.MAKERS/ VWMtextile machinery textile production weaving, valley worsted mill valley worsted mill, warping machinery, textile machinery, textile production, weaving, wrap reel, skein winder -

Dandenong/Cranbourne RSL Sub Branch

Dandenong/Cranbourne RSL Sub BranchWeapon - Bayonet & Scabbard

The Pattern 1907 bayonet, officially called the Sword bayonet, pattern 1907 (Mark I), was a British bayonet designed to be used with the Short Magazine Lee Enfield (SMLE) rifle. The Pattern 1907 bayonet was used by the British and Commonwealth forces throughout both the First and Second World Wars. The Pattern 1907 bayonet consisted of a one-piece steel blade and tang, with a cross guard and pommel made from wrought iron or mild steel, and a grip usually of walnut secured to the tang by two screws. The entire bayonet was 21+3⁄4 inches (550 mm) long and weighed 16+1⁄2 ounces (470 g), although the weight of production models varied from 16 to 18 ounces (450 to 510 g). The Pattern 1907 bayonet's blade was 17 inches (430 mm) long. A shallow fuller was machined into both sides of the blade, 12 inches (300 mm) long and extending to within 3 inches (76 mm) of the tip, with variations due to the judgement of individual machinists.[2][3] The Pattern 1907 bayonet was supplied with a simple leather scabbard flitted with a steel top-mount and chape, and usually carried from the belt by a simple frog. The Pattern 1907 bayonet attached to the SMLE by a boss located below the barrel on the nose of the rifle and a mortise groove on the pommel of the bayonet.[2][4] The combined length of the SMLE and Pattern 1907 bayonet was 5 feet 2 inches (1.57 GR 1907 6.......'17 Wilkinson Stamped on right side of base of blade with various symbols on the left side. Hand carved on RHS Bakelite part of handle K ? (EFX) on LHS - MB -

National Wool Museum

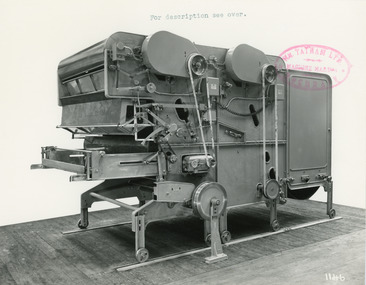

National Wool MuseumPhotograph - Product Photograph, Automatic Feeding Machine

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Automatic Feeding Machine automatically dispenses wool to a carding machine, so that an even, constant supply is received. This eliminated the manual labour previously needed for the initial weighing and feeding of wool. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866, Tatham developed innovative textile machinery and sent their products to Australia and other countries around the world.Two black and white photos of an Automatic Feeding Machine in a landscape format. The first photo is of the front of the machine, the second is of the rear.8037.1 - Front - top margin: For description see over. Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1146 Rear - 78” wide Automatic Feeding Machine having Dual Hoppers in which the first and large section feeds the second Hopper so as to maintain a constant level of material in the latter. The driving of both spiked lattices is by electro-magnetic clutches, the one in the first Hopper being actuated by a sensitive feeler motion in the second, the second spiked lattice however, being controlled, of course, from the Scale Pan. Through a mercury switch. The scale is of our latest super-sensitive pattern mounted diagonally across the Feed. Only the opening doors are used in the actual weighting and the trap doors placed over the scale which close immediately the correct weight is deposited, operate through a solenoid. The machine incorporates many other features and is arranged to divide for facility in cleaning. 8037.2 - Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1147 Rear - Showing opposite side of Dual Automatic Feed illustrated in photo 1146textile machinery, automatic feeding machine, tatham, feeding machine -

National Wool Museum

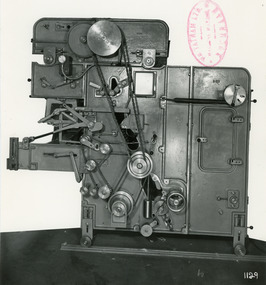

National Wool MuseumPhotograph - Product Photograph, Patent Automatic Feed Machine

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. An Automatic Feeding Machine automatically and sequentially supplies uncarded wool to carding machines, The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Automatic Feed Machine in a portrait format. Black wiritng on the rear, typed with a typewriter.Front - mid left corner - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1129 Rear - Patent Automatic Feed with Extended Hopper fitted with balanced pressure plate which operates through Variable Speed Device to regulate speed of spiked lattice in accordance with material in Hopper. Electro-Magnetic Clutch Drive to spiked lattice controlled by Mercery Switch on scale arm. Diagonal Scale Pan with improved knife edge suspension. Dual Trap Doors over Pan actuated by Solenoid. Automatic device to slow spiked lattice just prior to weigh being obtained. Ball or roller bearings to main shaft, combs and other parts. Self-aligning bearing to timing shaft etc.textile machinery, tatham, wool manufacture, carding, automatic feeding machine, wool -

Vision Australia

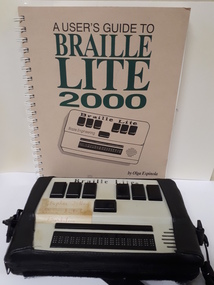

Vision AustraliaMachine - Object, Blaze Engineering, Braille Lite

The Braille Lite harnessed the advantages of a computer to write in Braille and provides responses either in Braille or synthetic voice. Weighing around a kilogram, it was considered a lightweight notebook that also could be connected to other computers and stored Braille in it's inbuilt hardware. 1 beige rectangle with 7 raised buttons, a long space bar and refreshable braille display in black, held in a black plastic carrying case + printed instruction bookBraille Lite (R) Sticker attached over 'Blaze Engineering'.braille equipment, stephen jolley -

Vision Australia

Vision AustraliaDocument - Image, 1934 - 1954 - 50 Years of Talking Book Service, 1984

The Talking Book Library of the Royal Victorian Institute for the Blind is celebrating its 50th anniversary during 1984. This service began in 1934 with 78 rpm records. These were later superceded by 33rpm records which remained in use until 1960. The first cassettes were imported from England and weighed 7 lb. along with the player which weighed 28 lb. These 18 track cassettes usually contained one whole book. In the early 1970's a change was made to smaller cassettes containing 12 hours of recorded material on 6 tracks. The latest system currently being introduced is the Library of Congress 4 Track System utilising cassettes which play for 6 hours and machinery which is adaptable to the conventional 2 track system cassette. The Talking Book Library today provides services to 2500 readers as opposed to only 500 in 1964. The service is free of charge to anyone who is visually handicapped and includes talking books, talking book machines, mail service, servicing of machines at regular intervals and any modifications that may be required. Over 1600 cassettes are handled daily. The library currently holds over 3500 individual titles. Catalogues are available in print, audio and braille format. Once selection is made, borrowers may receive at least 3 books at any one time. Other services include current magazines, foreign language books, newspapers and magazines and regional country newspapers. Many books are recorded at the R.V.I.B. by our volunteer readers while others are bought from similar agencies in Australia and overseas. The department of the R.V.I.B. relies almost entirely on voluntary donations from the public. Other services provided by the Royal Victorian Institute for the Blind Community Resources Section, Aids & Equipment Shop, Tertiary Resource Service, Industrial Department, Retired Personnel Allowance, Children's Services, Social Services, Housing Loans, Vocational Development1 digital image of typewritten pageroyal victorian institute for the blind, talking books -

Vision Australia

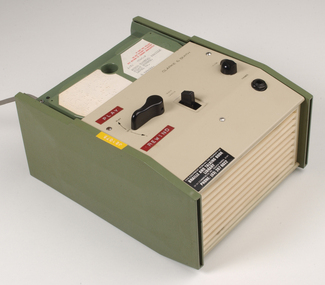

Vision AustraliaMachine - Object, Clarke & Smith talking book player, 1950's

The first tape based talking book machine from the late 1950s, produced by Clarke & Smith, that allowed the listener to hear up to 20 hours of recordings. Although bulky (each tape cartridge alone weighed over 2 kgs), the MK1 was the first magnetic, multi-track tape produced and considered quite novel for it's time. The cartridge designed to be played on the Clarke & Smith Model12 Talking Book gramophone was designed to house the pick up mechanism (the phono cartridge which contains the stylus) in the lid, so that visually impaired people could just close the lid to play the record. Initially these players designed to handle only 24 rpm, but soon added 33 rpm and 16 rpm options via the dial located on the left hand corner of the disk base. Directions for using as well as reminders to use on alternating current only are located inside the lid. On the side of the player are two plastic dials: one for turning on and volume, the other for tone.Metal record player housed in a brown wooden carry case, with a speaker grill in the front, two plastic dials on the side and an electric cord extending from the back of the case.Manufactured for Nuffield Talking Book Libraryaudio equipment, clarke and smith -

Parks Victoria - Maldon State Battery

Parks Victoria - Maldon State BatteryBox, tool

Used to store tools and other assorted items associated with Maldon State Battery..1 storage box with compartments and lid, painted green, made from wood, leather and are chains attatched from box to lid, trapeze shape, .3 grooves on top of box parallel to wooden supports on lid, latch, nails and bolts attatching wood and inner compartments, leather straps on innner lid and inside main compartment for holding tools, main compartment contains torn newspapers, severed cloths, pieces of rock, pipe peices made of metal and plastic, assortment of metal pieces, paint lids, green bucket with grease, food packaging, tap/valve, metal mesh, leather and plastic pieces, 2 keys/padlocks, nails, nuts, assortment of tools, wooden pieces, wooden handle for screwdriver, broken chair, chalk, pieces of ceramic (Bendigo pottery) , pocket handle with inscription, bottle lids, plastic container, rope/belt for machines, piece of belt, broken canvas strap, peices of broken dark brown glazed textured pottery, large circular threaded joins, large elboiw threaded elbow joins .2 upper left compartment containing brush head, sandpaper and assorted rusty metal objects .3 upper middle compartment containing rusty weighing hook, rusty bolt and scrap metal .4 upper right compartment containing broken tan pottery, rusty threaded T join, unknown green paper with inscription .5 lower left compartment containing white cotton waste, assorted circular rusty metal objects, assorted rusty nails and washers, orange lid with insciption, nut and bolt .6 lower left middle compartment containing unknown assorted metal objects, peice of broken clamp and felt .7 lower right middle compartment containing large rusty nuts and unknown rusty metal objects .8 lower right compartment containing assorted threaded rusty circular metal objects, rusty nut and bolt, metal pump part, rusty mobil oil tin 20litres, old newspaper scraps, -

Vision Australia

Vision AustraliaEquipment - Object, Specto Ltd, Clarke and Smith talking book machine with tapete

In 1965 the Clarke & Smith Talking Book Cassette Cartridge made it's debut at the Olympia Show. Popularly known as a 'tapete', it weighed considerably less than the earlier book cassette cartridges and allowed for up to 6 tracks (13 hours recording time) to be played.Clarke and Smith talking book cassette cartridge player consisting of plastic rectangular case with buttons for navigational controls, light green front and top of machine and darker green on sides, power cord and 5 buttons. Also includes tapete "Words for murder perhaps" by Edward Candy and ready by Stanley Pritchard.Clarke & Smith Track change Play -- Off Volume Phones This equipment remains the property of the Braille & Talking Book Library, 31-51 Commercial Road, South Yarra, 3141. Phone: (03) 267 6022 Dyna Tape labels: J21075 Play Rewindaudio equipment, clarke and smith -

Vision Australia

Vision AustraliaEquipment - Object, Clarke & Smith, Clarke & Smith cartridge player, 1950-1960's

The first tape based talking book machine from the late 1950s, produced by Clarke & Smith, that allowed the listener to hear up to 20 hours of recordings. Although bulky (each tape cartridge alone weighed over 2 kgs), the MK1 was the first magnetic, multi-track tape produced and considered quite novel for it's time. The cartridge designed to be played on the Clarke & Smith MK1 Talking Book player came in it's own separate container. Each cartridge houses the complete mechanism, track change linkages, replay heads and tape spools, which are stacked on top of each other within the housing. When one track was finished, the user was required to lift the metal cassette, turn it over, and replace it on the turntable. The bulky cartridges were distributed by post or train in strong 'Globite' cases made with reinforced corners and strapped. The costs associated with talking book players were high and individuals/groups/service clubs were asked to sponsor a machine to help those who could not afford to buy or rent one. In this example, a plate attached to the lid indicates who raised the funds: "This talking book/is presented to you/by Tallimba Branch/ of CWA of NSW." Please note: despite images, there are no cartridges with this model.Metal talking book machine housed in a brown wooden carry case. There are two plastic knobs on the front facing right hand side, and an electric cord extending from the back of the case. To the left of the knobs is a speaker grille. Also includes talking book cartridge 'The darling buds of May'.audio equipment, clarke and smith -

Broadmeadows Historical Society & Museum

Broadmeadows Historical Society & MuseumMachine - Scales

Fairbanks weighing scales (to weigh 2 lb) - Fairbanks' most famous invention then became the platform scale for weighing heavy objects. This item is significant as it demonstrates a by-gone method of weighing mail. It is also significant as it uses pre-metric measurements, placing its age before 1966.Post office scales with two dishes and five weights ranging from 1 oz to 2 lb.To weigh 2 lb - Fairbanks, Birminghamscales, postage, mail -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesMachine - Scales, W & T Avery Ltd, Set of manual scales with weights, Mid 20th Century

Avery metal manual scales with measurement in grams - with adjustable chrome feet. Accompanied by an array of weights of varying brands (Mercury, MSC, unmarked) 2 x 7LB, 3 x 4LB, 1 x 3LB, 1 x 2LB, 3 x 1LB, 8OZ and 4OZ.AVERY FOR TRADE VICTORIAN PATTERN APPROVAL No. V8 To Weigh Chart MARKED BY 2 GRAM DIVISIONS MADE IN ENGLAND BY W&T AVERY LTD BIRMINGHAM No 1215 BFH/S - 680767scales, measurement, weighing, weights -

Churchill Island Heritage Precinct

Churchill Island Heritage PrecinctMachine - Wool Press

The Churchill Island collection includes objects from the 18th and 20th centuries. The collection is presented in sets and series, of which this object belongs to the National Trust sub-collection.Wool presses were used in shearing sheds around the country to create bales of wool by hand in preparation for transport to the wool markets for purchase and distribution. Bales have been used to store and were a standard trading unit for wool for centuries. A standard wool bale holds about 60 compressed wool fleeces and weighs a minimum of 120 kgs. The square shape and weight enabled them to be stacked on wagons or in warehouses, and a large pack horse could carry one on each side. Large, retangular upright metal wool press, unpainted with some surface rust.farm machinery, wool, wool press, hand operated, shearing, national trust