Showing 35 items

matching yarn - woollen

-

National Wool Museum

National Wool MuseumBook, Wool Textile Research

... descriptions of wool, production of woollen fabric and yarn and current..., standard descriptions of wool, production of woollen fabric ..."Wool Textile Research; CSIRO Research for Australia 9". Contains articles re: the latest CSIRO research (as of 1986) into areas such as wool marketing, wool cleaning, standard descriptions of wool, production of woollen fabric and yarn and current research trends.wool marketing woolclassing, csiro, scouring, dyeing, wool marketing, woolclassing -

National Wool Museum

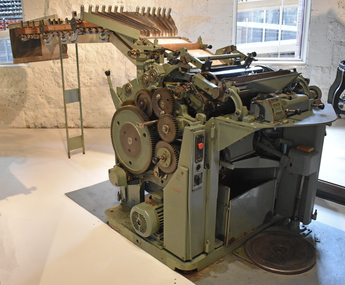

National Wool MuseumMachine - French Comb, Schlumberger & Cie, 1964

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. Machine has been completely rebuilt and set up by Nick Sokolov of Comb Research and Development with the help of Bruce Hill and others. NSC Schlumberger Comb PB25L machine No 3953, year of manufacture 1964. A rectilinear version of the Noble Comb, this machine separated long and short fibres. Donated to the National Wool Museum by Port Phillip Wool Processing Pty Ltd in 1993.French comb machine. 1962 Shlumberger and Co, France Model PB 251 NO. 3953.french comb, wool processing, textile industry, factory, machine, comb, restoration, fibres -

National Wool Museum

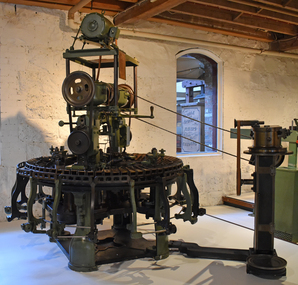

National Wool MuseumMachine - Noble Comb, Prince Smith & Sons, Burlington Shed, Keighley, 1915

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. A Nobel Comb separates short (Noils) fibres while also blending long (Tops) fibres together. The long fibres are used for worsted materials while the short fibres are used for woollen fabrics. Woollen materials are soft, bulky and fuzzy, such as a picnic blanket; whereas worsted materials are fine, smooth and crisp, such as a suit jacket. The Valley Worsted Mills in Geelong, now the Little Creatures Brewery, ran 12 noble combs up until 1981. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Noble Comb with plates - 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box). 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box).wool manufacturing, noble comb, textile industry, geelong, little creatures brewery, valley worsted mills, fibres, wool, factory -

National Wool Museum

National Wool MuseumCone

Designed for nce only use. Used for holding the yarn during yarn dyeing. The process was called "pressure dyeing" for a small amount of yarn. Doesn't create an even dye effect.Wangaratta Woollen Millsweaving mills, wangaratta woollen mills -

National Wool Museum

National Wool MuseumTextile - McGregors Yarn, J.L. McGregor Pty Ltd, c.1988

The yarn was made in Geelong in the late 1980's or early 1990's by local woolen manufacturer J.L. McGregor Pty Ltd. The company closed in the early 1990s. The McGregor family still live in the Geelong area.A ball of grey yarn, 50% wool and 50% acrylic with a plastic label surrounding the wool with the product details.On Label: McGregors 50 Grams at standard condition 50% Wool 50% Flame resistant Acrylic Below Logo: Wool and Nu Acrylicwool, j.l. mcgregor pty ltd, yarn, geelong wool, geelong, geelong woollen mills