Showing 39 items

matching yarn - worsted

-

National Wool Museum

National Wool MuseumBook, How to Know Textiles

"How to Know Textiles" - Cassie Paine Small, 1932.textile fibres weaving machine knitting yarn production cotton silk, lace, dyeing, cloth - woollen, cloth - worsted, rayon, textile fibres, weaving, machine knitting, yarn production, cotton, silk -

National Wool Museum

National Wool MuseumPhotograph

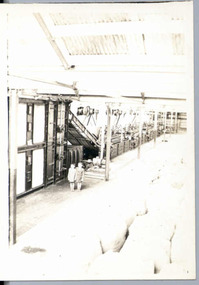

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the area and machines used for blending (the mixing of various fibres to produce the required quantity of yarn). The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, blending -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the area and machines used for blending (the mixing of various fibres to produce the required quantity of yarn). The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, blending -

National Wool Museum

National Wool MuseumPhotograph

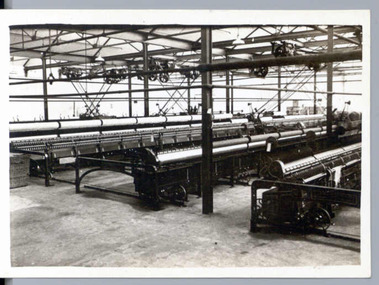

... Worsted Mill Spinning Machinery Yarn - woollen Interior of Valley ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning mule for woollen threads. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - woollen -

National Wool Museum

National Wool MuseumPhotograph, Foster Valley Mill

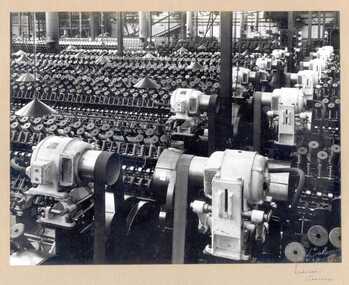

Interior view of machinery at Foster Valley Mill. Shows the winding (or twisting) machinery (where the spun yarn is threaded onto bobbins).Spinning machinery within the Valley Mill.T. Lockwood Lockwood / GEELONGtextile mills operation, valley worsted mill, winding machinery, textile mills - operation -

National Wool Museum

National Wool MuseumPhotograph, Foster Valley Mill

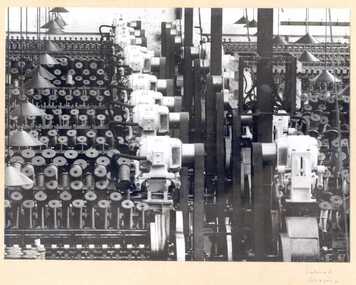

Interior view of machinery at Foster Valley Mill. Shows the winding (or twisting) machinery (where the spun yarn is threaded onto bobbins).Spinning machinery in the Valley Mill.T. Lockwood Lockwood / GEELONGtextile mills operation, valley worsted mill, winding machinery, textile mills - operation -

National Wool Museum

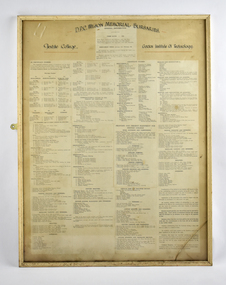

National Wool MuseumPhotograph - Framed Printed Coursework, Gordon Institute of Technology, Textile College, 1950

... . The courses include Woolcombing, Worsted Spinning, Woollen Yarn... of Technology in 1950. The courses include Woolcombing, Worsted Spinning ...Framed papers outlining the courses and coursework for the Textile College at the Gordon Institute of Technology in 1950. The courses include Woolcombing, Worsted Spinning, Woollen Yarn Manufacture, Designing, Weaving and Turning and Finishing. A digital copy of this item was made for the National Wool Museum Collection, with the original remaining with the donor. Digital TIFF file, 100 MB, showing image of framed printed paper.D.P.C. WILSON MEMORIAL BURSARIES. / Textile College / Gordon Institute of Technology. / GENERAL INFORMATION / TERM DATES 1950 ...courses, gordon institute of technology, textile college, geelong, woolclassing, weaving, spinning, coursework, 1950 -

National Wool Museum

National Wool MuseumClothing - Shirt, 1925-1938

Male wool shirt made in Bradford, U.K. The shirt is cut from first fabric woven from 100% traceable Australian wool. Bradford Mills differ to Australian mills in that the entire process of producing worsted material does not take place at the one firm/factory. Rather it is split between many firm/factories specialising in their task in the production of worsted material. For example, the wool goes from merchants to combers to produce tops, the tops to spinners to produce yarn and then the yarn is sold to manufactures who weave it into cloth. After the weaving is done the cloth has to be sent to the dryers and finishers, who scour, dye and finish the cloth. Finally, the finished cloth is purchase by a fresh set of merchants, who will later sell the cloth elsewhere in England or abroad. At each these steps a new firm is handling the wool/cloth making it hard to track lineage of wool through this process and hence hard to guarantee 100% Australian wool. This shirt was purchased and worn by the donor’s husband, George H. Gerber, an Australian Wool Buyer. The shirt was purchased on one of George’s trips to Bradford in the U.K. on company business. Gerber was a second-generation Wool Traders in his family. His father, also named George H. Gerber, worked for Kreglinger & Furneau. He worked for them in Boston, U.S.A. before he died from the Spanish Flu in 1918. The company then promised a job to his oldest son (donor’s husband) once he finished school. Thus, George came to be trained as a Fine Wool Classer by Kreglinger & Furneaux (Aust.) Pty Ltd where he was employed as a Wool Buyer all his working life. He retired in 1969 as the head of their Australian office when the company was taken over Also of note, the shirt was sold with 2 add-on collars. Having additional collars was advantageous as changing only the collar increased the number of days the shirt could be worn without washing. Cream coloured shirt with black and red single thread verticle stripes.“Grandpa” collar (with 1 of its 2 supplied add-on collars included). French cuffs. Sold with 2 add-on collars, hence both ends of the collar have buttonholes to take a stud, and a partially-opened button-hole is at the centre of the neck on the outside of the collar for a second stud.Letering label on shirt: GENT’S OUTFITTER Herbert Winfield 23 CHEAPSIDE, BRADFORDbradford, u.k, kreglinger & furneaux (aust.) pty ltd, 100% australian wool -

National Wool Museum

National Wool MuseumStencil - HUDDERSFIELD

This stencil was used as a location stamp for the transportation of wool bales. HUDDERSFIELD Valley Worsted Mills is located in Geelong. Stencils marked HUDDERSFIELD would have been transported to the Worsted Mills to be made into yarn and fabric.Wool bale stencil - HUDDERSFIELDHUDDERSFIELDwool - transportation, wool sales