Showing 14212 items matching "base"

-

Clunes Museum

Clunes MuseumContainer - CHURCH COLLECTION PLATE

USED IN THE FREE PRESBYTERIAN CHURCH. GLENDONALD CHURCH, ONCE ON THE PROPERTY NOW KNOWN AS SNIZORT. CHURCH WAS PULLED DOWN ABOUT 1925 AND THE CONGREGATION TRANSFERRED TO ST. DAVID'S, COGHILLS CREEK.ROUND WOODEN COLLECTION PLATE ON TURNED COLUMN AND BASE, PRE 1884IN PEN ON BASE: COLLECTION PLATE GLENDONALD CHURCH PRE 1884local history, handcrafts, woodwork -

Flagstaff Hill Maritime Museum and Village

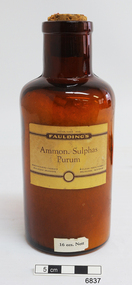

Flagstaff Hill Maritime Museum and VillageMedicine Bottle

This medicine bottle was donated to Flagstaff Hill Maritime Village by the family of Doctor William Roy Angus, Surgeon and Oculist. It is part of the “W.R. Angus Collection” that includes historical medical equipment, surgical instruments and material once belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) as well as Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. ABOUT THE “W.R.ANGUS COLLECTION” Doctor William Roy Angus M.B., B.S., Adel., 1923, F.R.C.S. Edin.,1928 (also known as Dr Roy Angus) was born in Murrumbeena, Victoria in 1901 and lived until 1970. He qualified as a doctor in 1923 at University of Adelaide, was Resident Medical Officer at the Royal Adelaide Hospital in 1924 and for a period was house surgeon to Sir (then Mr.) Henry Simpson Newland. Dr Angus was briefly an Assistant to Dr Riddell of Kapunda, then commenced private practice at Curramulka, Yorke Peninsula, SA, where he was physician, surgeon and chemist. In 1926, he was appointed as new Medical Assistant to Dr Thomas Francis Ryan (T.F. Ryan, or Tom), in Nhill, Victoria, where his experiences included radiology and pharmacy. In 1927 he was Acting House Surgeon in Dr Tom Ryan’s absence. Dr Angus had become engaged to Gladys Forsyth and they decided he would take time to further his studies overseas in the UK in 1927. He studied at London University College Hospital and at Edinburgh Royal Infirmary and in 1928, was awarded FRCS (Fellow from the Royal College of Surgeons), Edinburgh. He worked his passage back to Australia as a Ship’s Surgeon on the on the Australian Commonwealth Line’s T.S.S. Largs Bay. Dr Angus married Gladys in 1929, in Ballarat. (They went on to have one son (Graham 1932, born in SA) and two daughters (Helen (died 12/07/1996) and Berenice (Berry), both born at Mira, Nhill ) Dr Angus was a ‘flying doctor’ for the A.I.M. (Australian Inland Ministry) Aerial Medical Service in 1928 . The organisation began in South Australia through the Presbyterian Church in that year, with its first station being in the remote town of Oodnadatta, where Dr Angus was stationed. He was locum tenens there on North-South Railway at 21 Mile Camp. He took up this ‘flying doctor’ position in response to a call from Dr John Flynn; the organisation was later known as the Flying Doctor Service, then the Royal Flying Doctor Service. A lot of his work during this time involved dental surgery also. Between 1928-1932 he was surgeon at the Curramulka Hospital, Yorke Peninsula, South Australia. In 1933 Dr Angus returned to Nhill where he’d previously worked as Medical Assistant and purchased a share of the Nelson Street practice and Mira hospital from Dr Les Middleton one of the Middleton Brothers, the current owners of what was once Dr Tom Ryan’s practice. Dr L Middleton was House Surgeon to the Nhill Hospital 1926-1933, when he resigned. [Dr Tom Ryan’s practice had originally belonged to his older brother Dr Edward Ryan, who came to Nhill in 1885. Dr Edward saw patients at his rooms, firstly in Victoria Street and in 1886 in Nelson Street, until 1901. The Nelson Street practice also had a 2 bed ward, called Mira Private Hospital ). Dr Edward Ryan was House Surgeon at the Nhill Hospital 1884-1902 . He also had occasions where he successfully performed veterinary surgery for the local farmers too. Dr Tom Ryan then purchased the practice from his brother in 1901. Both Dr Edward and Dr Tom Ryan work as surgeons included eye surgery. Dr Tom Ryan performed many of his operations in the Mira private hospital on his premises. He too was House Surgeon at the Nhill Hospital 1902-1926. Dr Tom Ryan had one of the only two pieces of radiology equipment in Victoria during his practicing years – The Royal Melbourne Hospital had the other one. Over the years Dr Tom Ryan gradually set up what was effectively a training school for country general-practitioner-surgeons. Each patient was carefully examined, including using the X-ray machine, and any surgery was discussed and planned with Dr Ryan’s assistants several days in advance. Dr Angus gained experience in using the X-ray machine there during his time as assistant to Dr Ryan. Dr Tom Ryan moved from Nhill in 1926. He became a Fellow of the Royal Australasian College of Surgeons in 1927, soon after its formation, a rare accolade for a doctor outside any of the major cities. He remained a bachelor and died suddenly on 7th Dec 1955, aged 91, at his home in Ararat. Scholarships and prizes are still awarded to medical students in the honour of Dr T.F. Ryan and his father, Dr Michael Ryan, and brother, John Patrick Ryan. ] When Dr Angus bought into the Nelson Street premises in Nhill he was also appointed as the Nhill Hospital’s Honorary House Surgeon 1933-1938. His practitioner’s plate from his Nhill surgery states “HOURS Daily, except Tuesdays, Fridays and Saturday afternoons, 9-10am, 2-4pm, 7-8pm. Sundays by appointment”. This plate is now mounted on the doorway to the Port Medical Office at Flagstaff Hill Maritime Village, Warrnambool. Dr Edward Ryan and Dr Tom Ryan had an extensive collection of historical medical equipment and materials spanning 1884-1926 and when Dr Angus took up practice in their old premises he obtained this collection, a large part of which is now on display at the Port Medical Office at Flagstaff Hill Maritime Village in Warrnambool. During his time in Nhill Dr Angus was involved in the merging of the Mira Hospital and Nhill Public Hospital into one public hospital and the property titles passed on to Nhill Hospital in 1939. In 1939 Dr Angus and his family moved to Warrnambool where he purchased “Birchwood,” the 1852 home and medical practice of Dr John Hunter Henderson, at 214 Koroit Street. (This property was sold in1965 to the State Government and is now the site of the Warrnambool Police Station. ). The Angus family was able to afford gardeners, cooks and maids; their home was a popular place for visiting dignitaries to stay whilst visiting Warrnambool. Dr Angus had his own silk worm farm at home in a Mulberry tree. His young daughter used his centrifuge for spinning the silk. Dr Angus was appointed on a part-time basis as Port Medical Officer (Health Officer) in Warrnambool and held this position until the 1940’s when the government no longer required the service of a Port Medical Officer in Warrnambool; he was thus Warrnambool’s last serving Port Medical Officer. (The duties of a Port Medical Officer were outlined by the Colonial Secretary on 21st June, 1839 under the terms of the Quarantine Act. Masters of immigrant ships arriving in port reported incidents of diseases, illness and death and the Port Medical Officer made a decision on whether the ship required Quarantine and for how long, in this way preventing contagious illness from spreading from new immigrants to the residents already in the colony.) Dr Angus was a member of the Australian Medical Association, for 35 years and surgeon at the Warrnambool Base Hospital 1939-1942, He served as a Surgeon Captain during WWII1942-45, in Ballarat, Victoria, and in Bonegilla, N.S.W., completing his service just before the end of the war due to suffering from a heart attack. During his convalescence he carved an intricate and ‘most artistic’ chess set from the material that dentures were made from. He then studied ophthalmology at the Royal Melbourne Eye and Ear Hospital and created cosmetically superior artificial eyes by pioneering using the intrascleral cartilage. Angus received accolades from the Ophthalmological Society of Australasia for this work. He returned to Warrnambool to commence practice as an ophthalmologist, pioneering in artificial eye improvements. He was Honorary Consultant Ophthalmologist to Warrnambool Base Hospital for 31 years. He made monthly visits to Portland as a visiting surgeon, to perform eye surgery. He represented the Victorian South-West subdivision of the Australian Medical Association as its secretary between 1949 and 1956 and as chairman from 1956 to 1958. In 1968 Dr Angus was elected member of Spain’s Barraquer Institute of Barcelona after his research work in Intrasclearal cartilage grafting, becoming one of the few Australian ophthalmologists to receive this honour, and in the following year presented his final paper on Living Intrasclearal Cartilage Implants at the Inaugural Meeting of the Australian College of Ophthalmologists in Melbourne In his personal life Dr Angus was a Presbyterian and treated Sunday as a Sabbath, a day of rest. He would visit 3 or 4 country patients on a Sunday, taking his children along ‘for the ride’ and to visit with him. Sunday evenings he would play the pianola and sing Scottish songs to his family. One of Dr Angus’ patients was Margaret MacKenzie, author of a book on local shipwrecks that she’d seen as an eye witness from the late 1880’s in Peterborough, Victoria. In the early 1950’s Dr Angus, painted a picture of a shipwreck for the cover jacket of Margaret’s book, Shipwrecks and More Shipwrecks. She was blind in later life and her daughter wrote the actual book for her. Dr Angus and his wife Gladys were very involved in Warrnambool’s society with a strong interest in civic affairs. Their interests included organisations such as Red Cross, Rostrum, Warrnambool and District Historical Society (founding members), Wine and Food Society, Steering Committee for Tertiary Education in Warrnambool, Local National Trust, Good Neighbour Council, Housing Commission Advisory Board, United Services Institute, Legion of Ex-Servicemen, Olympic Pool Committee, Food for Britain Organisation, Warrnambool Hospital, Anti-Cancer Council, Boys’ Club, Charitable Council, National Fitness Council and Air Raid Precautions Group. He was also a member of the Steam Preservation Society and derived much pleasure from a steam traction engine on his farm. He had an interest in people and the community He and his wife Gladys were both involved in the creation of Flagstaff Hill, including the layout of the gardens. After his death (28th March 1970) his family requested his practitioner’s plate, medical instruments and some personal belongings be displayed in the Port Medical Office surgery at Flagstaff Hill Maritime Village, and be called the “W. R. Angus Collection”. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The collection of medical instruments and other equipment is culturally significant, being an historical example of medicine from late 19th to mid-20th century. Dr Angus assisted Dr Tom Ryan, a pioneer in the use of X-rays and in ocular surgery. Medicine bottle, Faulding's Ammon. Sulphus Purum. 16ozs, from the W.R. Angus Collection. Brown glass, round, wide neck, cork stopper, full of crystals, Large and small labels on front. Emblem on base above "A"Emblem on base above "A"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dr w r angus, dr ryan, surgical instrument, t.s.s. largs bay, warrnambool base hospital, nhill base hospital, mira hospital, flying doctor, medical treatment, medicine bottle, medication, pharmaceutical -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionWeapon - Artillery Shell Casing, unknown

Shell casings were used to hold the propellant charge and projectile in artillery guns.An example of a shell casing used in artillery guns.Cylindrical shaped copper shell case with tapered top. Flat base with small lip. Inside base appears bright silver centre and features a small screw. Base underside: Stamped with a circle, inside of circle appears further markings but they are indistinguishable.war, defence force, ammunition -

Coal Creek Community Park & Museum

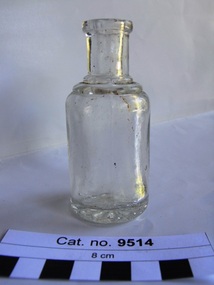

Coal Creek Community Park & MuseumBottle, glass

Round thick clear glass bottle with rounded glass rings at junction of neck and body of bottle. Pattern embossed on base.A 'daisy' flower pattern embossed in base. -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumBottle, glass, Early 1900's

Hexagonal shaped amber glass bottle, fluted on two sides with embossed text on the side between fluted sections and on base.'NOT TO BE TAKEN' on side. 'A G M ' on base.amber glass -

Echuca Historical Society

Echuca Historical Societyletter scales, Est 1766

Metal letter scales with logo on the base serial number on side support Letter support . Scale wheel with numbers on armsDecorative logo on base See Photos -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumPolarimeter #2 part B

Brass cylindrical optical element erected on wooden rectangular base. Scale round perimeter. Label on base: “Nat Phil No. Univ. of Melb” -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Lamp, Ruby glass kerosene lamp, Early 20th century

There is no known history attached to this item. Lamps such as this one were common household items in the 19th century and the first three decades of the 20th century until electrical lighting became common in most households. This item has no known local provenance but it is useful for display as an item that was common in households in the past. This item has a cast iron base in a pyramidal shape with the four sides having identical scrolls and star shapes. A piece of brass attaches the base to a violet-coloured bowl. The bowl contains a white wick. The brass wick holder has an external knob for regulating the light intensity. There is more brass between the bowl and the mantle which is made of plain glass. On the base of the lamp: ‘Rd. No. 207869’ history of warrnambool, social history, ruby glass kerosene lamp -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Seaworks Maritime Museum

Seaworks Maritime MuseumDoll

Japanese doll in traditional dress standing upright supported by black base. Hair is in traditional style with ornaments "WMA 43" Japanese writing in pencil at base -

Orbost & District Historical Society

Orbost & District Historical Societybottle, late 19th -early 20th century

This type of recessed base was commonly pronounced on wine, champagne or spirits bottles. Possibly done for bottle strengthening and stability. The push-up recess used to be formed by physically pushing upwards in the centre of the base with a tool while the glass was still hot and pliable.Glass objects generally include a wide range of shapes and colours with bottles and jars used for alcohol. This bottle is an example of a specific type of base used in bottle manufacturing.Tall brown glass bottle with recessed base. This bottle has a "push-up" or "kick-up" base. bottle glass push-up-base kick-up-base punt -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyFan - S.E.C.V

Electric fans were used for cooling rooms prior to air conditioning.This portable fan was used on the Kiewa Hydro Electric Scheme by office workers.Green metal swivel fan with base, motor and 4 cream angled 'wings' covered by 3 wire rings connected by 6 pieces of curved wire that cover the blades at the side and front. An electric grey rubber cord is attached. There is a lever in the base for moving from 'off to 1.2.or 3' (but no marks to indicate these positions.)Base: "Elcon Fan / Made in Australia"electric fan; state electricity commission of victoria; office equipment; kiewa hydro electric scheme; -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Goblet, Brass Goblet, Mid 20th century

This brass goblet has been used by the now-defunct Apex Cub of Warrnambool as a jar to hold the fines money contributed by members at a meeting. It may have been made in India, North Africa or a Middle East country but nothing is known of its origin or provenance.This goblet’s history is sketchy and it may be of use now in displays. The Warrnambool and District Historical Society has other historical material associated with the disbanded Warrnambool Apex Club.This is a brass goblet (a bowl on a pedestal base). It is etched with ornamental patterns and floral shapes. Handwritten on base of object: ‘W’bool Apex Club Fines Jar’. apex club of warrnambool, warrnambool -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumThroat examiner

Used by Manning Pharmacy, Flinders Street Railway Station, Melbourne, until 1984.Black metal battery case with a globe at one end in the shape of tongue depressor, top and base unscrew from battery holder.Label on base 'Manning . Chemist . Melbourne. -

Dandenong/Cranbourne RSL Sub Branch

Dandenong/Cranbourne RSL Sub BranchSafety Match Container

Brass container with flip up hinged lid to hold matches. Base has match striker lid has ring clip.Engraving on lid and half base diagonally. -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumBottle, glass, Scott & Browne, c. 1890

Tall clear glass bottle for stopper, rectangular in section, impressed panels on three sides and on base with embossed text in the panels and on base.Front 'SCOTTS EMULSION'. Sides ' COD LIVER OIL', 'WITH LIME & SODA'. On base : '6 (?)24' in a triangle.cod liver oil, lime & soda, scotts emulsion, scott & browne -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle - Medical

This bottle was used in the Tawonga District General Hospital which was built in the 1950's specifically for the increase in population due to the Kiewa Hydro Scheme.Brown glass bottle with rectangular base, horizontal shoulders and short narrow neck with thick lip. Heavily embossed on front. Embossed on base. Used to hold tonic.Front: 'This Bottle Always Remains / The Property of / Clements Tonic / Limited Base: 'AGM /3 /....'medical, hospital, tonic, clement's tonic -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionGeneral View of fire basecamp - Altona Museum

Base campView of base camp equipment at the Altona Museumforests commission victoria (fcv), camping equipment, bushfire -

Seaworks Maritime Museum

Seaworks Maritime MuseumDoll

Tall Japanese doll with purple traditional dress standing upright supported by black, square base. Hair is arranged in traditional style with ornaments. "WMA 56" Japanese writing on base -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle - Spirits, Late 1920's to early 1930's

Spirits came in bottles sold at licensed premises either locally or in larger cities visited during shopping expeditions. The shape of bottles varied and were re cycled remaining the property of the manufacturer who paid for their return.Historical: Change of bottles - shape, glass, embossing. Collected by bottle collectors. Aesthetic: Display showing embossing and the shape especially when in good condition.Clear glass bottle used for whisky. Straight sides 190 mm high then a sharp taper to the neck which bulges a little and is 100 mm high. It had a cork stopper. It is embossed on the base.Base: A.G.M. A 6bottle, spirits, whisky -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Caldwell’s Ink Factory, Late 19th to early 20th centuries

This design of the bottle is sometimes called a ‘cottage’ or ‘boat’ shape. The Caldwell’s handmade glass ink bottle was mouth-blown into a three-piece mould, a method often used in the late 19th and early 20th centuries, with the maker's name engraved into the mould section for the base. The glass blower would cut the bottle off the end of his blowpipe with a tool and join a mouth onto the top, rolling the lip. The bottle was then filled with ink and sealed with a cork. This method of manufacture was more time-consuming and costly to produce than those made in a simple two-piece mould and 'cracked' off the blowpipe. The capacity for a bottle such as this was about 3 ½ oz (ounces) equal to about 100 ml. This particular bottle is unusual as it has four sloping indents at the corners of the shoulder, most likely for resting a pen with its nib upwards and the handle resting on a flat surface. Most of the bottles made during this era had horizontal pen rests that were indented into both of the long sides of the shoulder. Pen and ink have been in use for handwriting since about the seventh century. A quill pen made from a bird’s feather was used up until around the mid-19th century. In the 1850s a steel point nib for the dip pen was invented and could be manufactured on machines in large quantities. This only held a small amount of ink so users had to frequently dip the nib into an ink well for more ink. Handwriting left wet ink on the paper, so the blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased as a ready-to-use liquid or in powdered form, which needed to be mixed with water. In the 1880s a successful, portable fountain pen gave smooth-flowing ink and was easy to use. In the mid-20th century, the modern ballpoint pen was readily available and inexpensive, so the fountain pen lost its popularity. However, artisans continue to use nib pens to create beautiful calligraphy. Caldwell’s Ink Co. – F.R. Caldwell established Caldwell’s Ink Company in Australia around 1902. In Victoria, he operated from a factory at Victoria Avenue, Albert Park, until about 1911, then from Yarra Bank Road in South Melbourne. Newspaper offices were appointed as agencies to sell his inks, for example, in 1904 the New Zealand Evening Star sold Caldwell’s Flo-Eesi blue black ink in various bottle sizes, and Murchison Advocate (Victoria) stocked Caldwell’s ink in crimson, green, blue black, violet, and blue. Caldwell’s ink was stated to be “non-corrosive and unaffected by steel pens”. A motto used in advertising in 1904-1908 reads ‘Makes Writing a Pleasure’. Stationers stocked Caldwell’s products and hawkers sold Caldwell’s ink stands from door to door in Sydney in the 1910s and 1920s. In 1911 Caldwell promised cash for returned ink bottles and warned of prosecution for anyone found refilling his bottles. Caldwell’s Ink Stands were given as gifts. The company encouraged all forms of writing with their Australian-made Flo-Eesi writing inks and bottles at their impressive booth in the ‘All Australian Exhibition’ in 1913. It advertised its other products, which included Caldwell’s Gum, Caldwell’s Stencil Ink (copy ink) and Caldwell’s Quicksticker as well as Caldwell’s ‘Zac’ Cough Mixture. Caldwell stated in a 1920 article that his inks were made from a formula that was over a century old, and were scientifically tested and quality controlled. The formula included gallic and tannic acids and high-quality dyes to ensure that they did not fade. They were “free from all injurious chemicals”. The permanent quality of the ink was important for legal reasons, particularly to banks, accountants, commerce, municipal councils and lawyers. The Caldwell’s Ink Company also exported crates of its ink bottles and ink stands overseas. Newspaper advertisements can be found for Caldwell’s Ink Company up until 1934 when the company said they were the Best in the business for 40 years.This hand-blown bottle is significant for being the only bottle in our collection with the unusual sloping pen rests on its shoulder. It is also significant for being made in a less common three-piece mould. The method of manufacture is representative of a 19th-century handcraft industry that is now been largely replaced by mass production. The bottle is of state significance for being produced by an early Melbourne industry and exported overseas. This ink bottle is historically significant as it represents methods of handwritten communication that were still common up until the mid-20th century when fountain pens and modern ballpoint pens became popular and convenient and typewriters were becoming part of standard office equipment.Ink bottle; rectangular base, hand-blown clear glass bottle with its own cork. The bottle has side seams from the base to the mouth, an indented base and an applied lip. The corners of the shoulder sides have unusual diagonal grooves that slope down and outwards that may have been used as pen rests. Inside the bottle are remnants of dried blue-black ink. The glass has imperfections and some ripples on the surface. The bottle has an attached oval black label label with gold-brown printed text and border. The base has an embossed inscription. The bottles once contained Caldwell’s blend of blue black ink.Printed on label; “CALDWELL's BLUE BLACK INK” Embossed on the base "CALDWELLS"flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, ink, nib pen, writing ink, writing, copying, banks, lawyers, commerce, student, permanent ink, blue black ink, stationery, record keeping, handwriting, writing equipment, writing accessory, office supply, cottage bottle, boat bottle, mouth-blown bottle, cork seal, f r caldwell, caldwell’s ink company, albert park, south melbourne, inkstands, stencil ink, copy ink, quicksticker, zac cough mixture, three part mould, cauldwells, cauldwell's -

Clunes Museum

Clunes MuseumDomestic object - IRON

SHELLITE IRON - WOODEN HANDLE - BLUE FUEL CONTAINER - BLUE - MINUS SCREW ON TOP IRON BASE - BLUE AND SILVERKNOB AT BASE OF FUEL TANK MARKED - CLOSElocal history, domestic item, irons, domestic items -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumBottle, glass, Between 1872-1916, reference : bottle manufacturers mark

Oakleigh Leader, Saturday 8 September 1894, page 1,. Advertisement. 'Agents ......H. Davis, Chemist, 299 High Street, St. Kilda.....'. source : TroveRectangular pale blue tinted clear glass bottle with angled corners, embossed text on side and base.'H. DAVIS ST KILDA' on side. 'M' on base. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Malleys Ltd, 1930-1950

This is a steel, bench-mounted, hand-operated (60 rpm) butter churn for making small amounts of butter from cream in the home. It was made by the Sydney firm of Malleys Ltd from the 1930s until the 1950s and came in 3 and 5 quart sizes. Malleys Ltd was established in about 1890 by Francis Malley (1863-1932). This firm was located in the Sydney suburb of Alexandria, in McEvoy Street. They manufactured items for use in the dairy industry, as well as for hardware related to building and plumbing. Many of the Malley dairy products were sold under the "Sunrise" name. Malley retired in 1912. In 1931 there were branches at Parramatta, Hurstville & North Sydney. Butter churns were machines used to produce butter by the violent agitation of separated cream. Depending on the design of the churn, the agitation would be variously achieved by a repetitive thrashing, centrifugal motion or internal paddles. Churns were typically constructed from wood, glass and cast-iron; with tin or steel commonly used for some fixtures. The subject item gives an insight into domestic life where butter was made in the home.Heavy red cast iron base, with a long handle, wooden grip, connected to a shaft along the base, thence, to a cog wheel, and gear, to a second shaft and paddle in a metal basin. Basin has lid, and hole in base with a screw cap to allow the draining of the butter milk. Designed to be placed on a bench, with the handle over the edge. Malleys is written in raised letters on the base, and on the handle, '60 rev. pr. min.'warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, malleys, butter churn, domestic object, dairy machine -

Orbost & District Historical Society

Orbost & District Historical Societyhat stretcher, first half 20th century

Prior to the 1960s, hats were worn by all men. Aluminium hat stretchers were generally in use from the 1920’s. The hat was placed on the aluminium dome shaped piece. When the handle was turned, the dome section split vertically, one section moving away from the fixed half. A graduated scale along the side indicated the size. This item was possibly used in the hat factory in Orbost. Stuart Hats commenced manufacturing hats in about 1948 and closed their factory in Orbost around 1953 probably because of the high transport costs. The company's head factory was in Melbourne. The hats made in Orbost were sold all over Australia as well as in Melbourne at Myers and David Jones. The building became first a Dry Cleaners and then a private home.This item was possibly used by Stuart Hats which was a significant manufacturing business in Orbost in the 1950's employing nearly 20 local people.A hat stretcher consisting of an aluminium dome-shaped piece (on which the hat was placed) and a metal winder. It has been mounted onto a wooden baseOn wooden base : "Restored by John Mundy"millinery hats hat-stretcher -

Bendigo Military Museum

Bendigo Military MuseumAward - SHOOTING TROPHY

Trophy awarded to members of 2 RVR for Best Student on two promotion courses.Gold Trophy cup with two handles mounted on a round black plastic base. On base is the emblem of the Royal Victorian Regiment. Also around base of stand are 9 silver shields with past winners.Trophy engraved "subject two promotion course 2 RVR Best Student." Also engraved 9 previous winners on base.2 rvr, trophy -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Sewing machine, Wilcox & Gibbs, c1870

Willcox and Gibbs: Serial No. 158679. The Willcox & Gibbs Sewing Machine Company was founded in 1857 by James E. A. Gibbs and James Willcox and opened its London Office in 1859 at 135 Regent Street . By 1871 the Company's Chief Office for Europe was at 150 Cheapside, London, this office was later moved (post 1885) to 94 - 96 Wigmore Street, then 37 & 39 Moorgate Street (by 1891 to post 1907) and later 20 Fore Street, London . Right from the initial production the manufacturing of the Company's single thread, chain stitch machine was undertaken by Brown & Sharpe, Rhode Island and this continued up until 1948. A special hand crank mechanism was produced in England for the European market, but the general design of the Willcox & Gibbs remained essentially the same throughout its production. The only major improvement was in 1875 when the glass tension discs were replaced with an automatic tension device which ensured the machine could not get out of adjustment. In addition to the domestic hand and treadle machines the company produced a wide range of industrial models. The Company finally closed in 1973. This Willcox & Gibbs came complete with its wooden carry case. The machine was made in America in the late 1860's but it has the ornate hand crank produced at Coalbrookdale near Telford, England which was, in Victorian times, renown for producing high quality ornate iron castings. This machine has the glass tension discs which were used on domestic models until 1875. The Willcox & Gibbs badge is located on the rear of the base casting and it also has a deep wooden base. The cloth plate has various American patent dates, four dating between 1857 & 1860 relating to J. E. A. Gibbs, three dating between 1860 & 1864 relating to Chas H. Willcox (son of James Willcox), the machine was also licensed under five other patents including the infamous Elias Howe patent of 1846. There are only two English patents one for J. E. A Gibbs and the other for James Willcox. In 1887 a W & G Sewing Machine sold in England for 6 pounds , with its box and bits, at a time when the average wage was less than 10/- shillings per week. The early settlers of Moorabbin Shire had to be self sufficient making their own clothes, tableware, bed coverings, furnishings and equipment. The women were skilled dressmakers and craft workers.Willcox and Gibbs: Serial No. 158679. A single thread, chain stitch Sewing Machine with a special hand crank mechanism produced in England for the European market, and the glass tension discs which were used on domestic models until 1875. This Willcox & Gibbs came complete with its wooden carry case. The machine was made in America c1870 but it has the ornate hand crank produced at Coalbrookdale near Telford, England which was, in Victorian times, renown for producing high quality ornate iron castings. This machine has the glass tension discs which were used on domestic models until 1875. The Willcox & Gibbs badge is located on the rear of the base casting and it also has a deep wooden base. The Willcox & Gibbs badge is located on the rear of the base castingsewing machines, early settlers, pioneers, moorabbin, brighton, gibbs james, willcox james, willcox henry, new york, america, dressmaking, mateial, machine makers, wrought iron work, telford england -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumBottle, glass, 1938-1950's

Trove : The Courier-Mail, Brisbane, Queensland Friday 15 December 1938, page 7, Article : New Canning Company A company under the name of Tassell United Cannery Pty., Ltd., is being formed to operate a pineapple cannery in the new year. It proposes to acquire the business of Glassop and Son, proprietors of Tassell Products, and may engage in inter-State and export trade. It is stated by the promoter that growers and small canners of pineapples fear that the industry may become monopolised and that the new company is being formed to combat any such tendency. TROVE : The Courier-Mail, Brisbane, Queensland Friday 29 December 1950, page 3, Article : Mr. Glassop dies A well-known Brisbane citizen. Mr. S. J. Glassop, 74, has died. He was founder and managing director of Tassell United Cannery, Pty., Ltd. For many years Mr. Glassop was associated with Messrs. R. W. Thurlow and Co., Ltd., Brisbane, and later left this firm to open his own business on the Darling Downs. He later returned to Brisbane to enter the manufacturing business. He was actively connected with the business until his death. Round olive- amber coloured glass bottle with wide neck and shoulder tapering toward base then flaring out again at base. Embossed text on sides and number On side, 'THIS BOTTLE IS THE PROIPERTY OF TASSELL UNITED CANNERY PTY LTD BRISBANE'. On base 'B146', 'AGM'.fruit, cannery, glassop, tassell, pineapple -

Federation University Historical Collection

Federation University Historical CollectionTrophy, Six Meter Henk Miller Line Special: 1975 - 1986, 1975

This perpetual cup was awarded to the winners of the Raft Race held each year on the Hazelwood Pondage, Gippsland. It was an activity held by the students of the Gippsland Institute of Advanced Education, 1975 through to 1986. Known as the 'Six Metre Henk Miller Line Special' The cup was passed to the Federation University Historical Collection at Mt Helen Campus.Silver plated cup on bakelite base. Fine handle each side. Silver plate on base.Base: G I A E - Annual Raft Race - Perpetual Trophy - Hazelwood Pondage Cup: Names of those who participated each yearraft race, perpetual cup, hazelwood pondage, gippsland institute of advanced education, six meter, henk miller -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink well, Circa 19th century

This type of inkwell would have been used in public places such as banks, offices and on ships.Ink well, pewter, capstan design.Flat disc with ink well and pen/quill holders in centre, hinged lid to cover removable well.White ceramic ink well included. Base, well and lid are all decorated with concentric rings. Maker's stamp on base. Circa 19th century. Stamped into base "MADE IN ENGLAND" and another indentifyable symbol. warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, ink well, pewter ink well, writing equipment, stationery accessory, communication