Showing 525 items

matching use of machinery

-

Whitehorse Historical Society Inc.

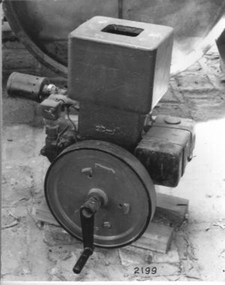

Whitehorse Historical Society Inc.Equipment - Stationary Motor

Used by Ted Beddiscomb of Gormandale near Traralgon, brother in law of donor. Ted was a dairy farmer and used the motor for about 10 years to pump water. It is possible it was on his farm for some years prior to this. Tom did some reconditioning and preservation on the unit.3 HP 4 cycle motor primarily used to belt drive other equipment such as pumps and machinery on a farm etc. Petrol driven, magneto ignition and water cooled.Bronze plate 'The Rosebery Engine C25387 RPM 1000 HP3 manufacturer Westinghouse Rosebery Ltd Sydney. 3C-103 on water jacket; 3D-1 on engine housing; 3C-15 on flywheel.rural industry, farm machinery, machinery, engines - internal combustion -

Whitehorse Historical Society Inc.

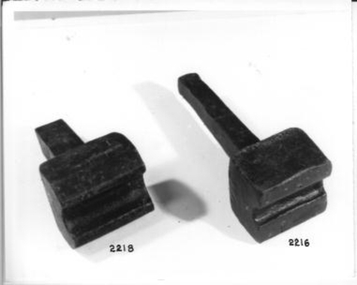

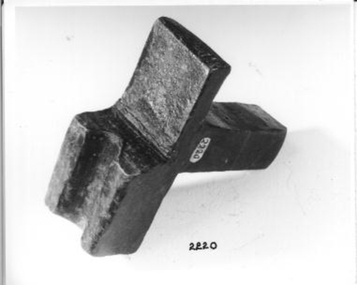

Whitehorse Historical Society Inc.Tool - Bottom Swage, c1920

... Mitcham melbourne rural industry farm machinery trades ...Bottom swage used with top swage to round of rods etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Bottom Swage, c1920

... Mitcham melbourne rural industry farm machinery trades ...Bottom swage used with top swage to round up rods etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

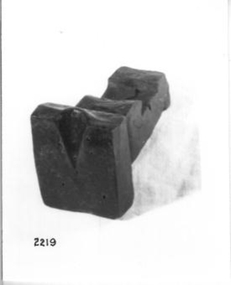

Whitehorse Historical Society Inc.Tool - Bottom swage, c1920

... Mitcham melbourne rural industry farm machinery trades ...Bottom swage used with top swage to round up rods etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

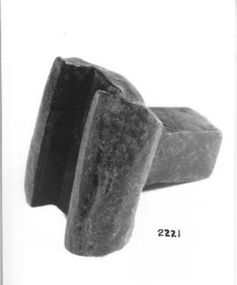

Whitehorse Historical Society Inc.Tool - Bottom swage, c1920

... Mitcham melbourne rural industry farm machinery trades ...Bottom swage used with top swage to round up rods etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Bottom swage, c1920

... Mitcham melbourne rural industry farm machinery trades ...Bottom swage used with top swage to round up rods etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Bottom swage, c1920

... Mitcham melbourne rural industry farm machinery trades ...Bottom swage used with top swage to round up rods etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

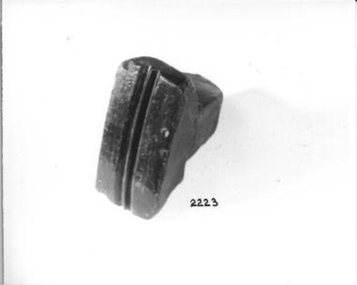

Whitehorse Historical Society Inc.Tool - Bottom swage, c1920

... Mitcham melbourne rural industry farm machinery trades ...Bottom swage used with top swage to round up rods etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Bottom Swage, c1920

... Mitcham melbourne rural industry farm machinery trades ...Bottom swage used with top swage to round up rods etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Bottom Swage, c1920

... Mitcham melbourne rural industry farm machinery trades ...Bottom Swage used with top swage to round up rods etcrural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Bottom Swage, c1920

... Mitcham melbourne rural industry farm machinery trades ...Bottom swage used with top swage to round up rods etcrural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

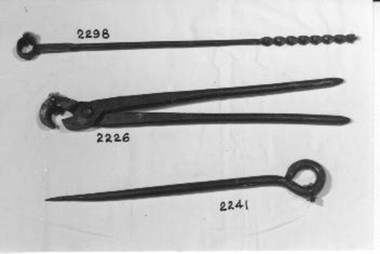

Whitehorse Historical Society Inc.Tool - Tongs, c1920s

... Mitcham melbourne rural industry farm machinery trades ...Used for holding hot steel whilst it was being forged.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Hook, c1920s

... Mitcham melbourne rural industry farm machinery trades ...Hook used in a barn for hanging ropes and harness.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Farriers Hoof Knife, c1920s

... Mitcham melbourne rural industry farm machinery trades ...Used for trimming horses hoofs.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tube Spanner, c1920s

... Mitcham melbourne rural industry farm machinery trades ...Used for tightening nuts on bolts.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Spanner, c1920s

... Mitcham melbourne rural industry farm machinery trades ...Used for tightening nuts on bolts.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

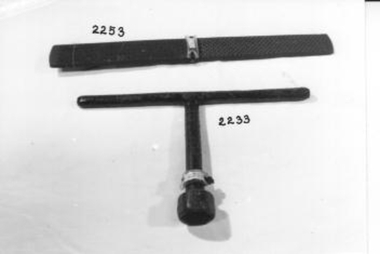

Whitehorse Historical Society Inc.Tool - Wrench, c1920s

... Mitcham melbourne rural industry farm machinery trades ...Tap Wrench. Used to turn tap into a predrilled hole in a piece of metal to cut a screw thread.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Wrench, c1920s

T - Bar tap wrench. Used for tightening nuts on bolts.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

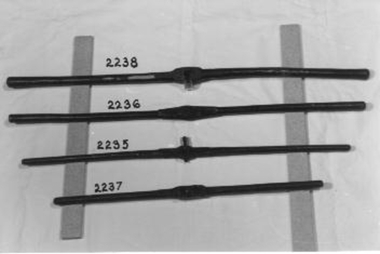

Whitehorse Historical Society Inc.Tool - Twisting Wrench, c1920s

... Mitcham melbourne rural industry farm machinery trades ...Used for twisting square rod whilst held in a vice.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Twisting Wrench, c1920s

... Mitcham melbourne rural industry farm machinery trades ...Used for twisting square rod whilst held in a vice.rural industry, farm machinery, trades, blacksmithing -

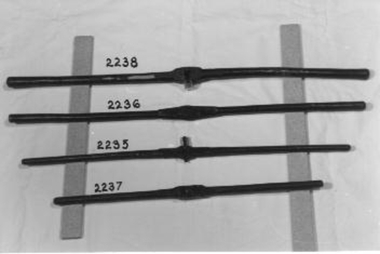

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Twisting Wrench, c1920s

... Mitcham melbourne rural industry farm machinery trades ...Used for twisting square rod whilst held in a vice.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Twisting Wrench, c1920s

... Mitcham melbourne rural industry farm machinery trades ...Used for twisting square rod whilst held in a vice.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tongs, c1920

... Mitcham melbourne rural industry farm machinery trades ...Used to hold hot steel whilst being forged.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Spike, c1920

... Mitcham melbourne rural industry farm machinery trades ...Possibly used for splicing rope.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

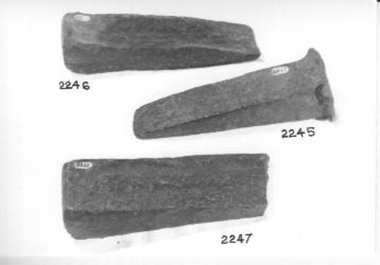

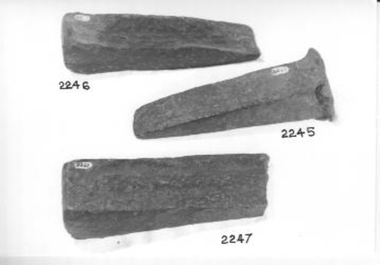

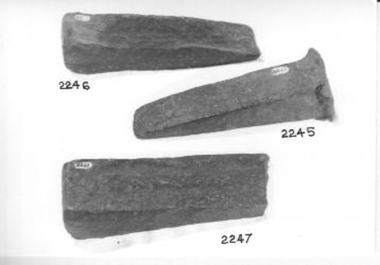

Whitehorse Historical Society Inc.Tool - Steel Wood Wedge, c1920

... Mitcham melbourne rural industry farm machinery trades ...Used with wooden maul for splitting wooden logs etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Steel Wood Wedge, c1920

... Mitcham melbourne rural industry farm machinery trades ...Used with wooden maul for splitting wooden logs etcrural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Steel Wood Wedge, c1920

... Mitcham melbourne rural industry farm machinery trades ...Used with wooden Maul for splitting logs, etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

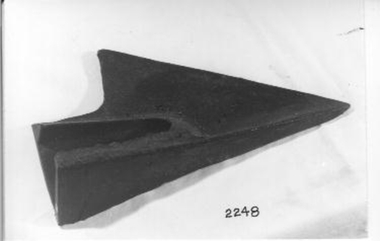

Whitehorse Historical Society Inc.Tool - Plough Shave, c1920

... Mitcham melbourne rural industry farm machinery trades ...Used to plough to open up a furrow to allow for further cultivation by other implements.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Hammer Head, c1920

Condition of faces of hammer head indicates that it may have been used for driving wood wedges, or chisels in stone quarrying.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Sieve, c1920

Wooden frame with steel mesh sieve. Used for sieving coke for blacksmiths forge fire.rural industry, farm machinery, trades, blacksmithing