Showing 503 items matching " innovations"

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

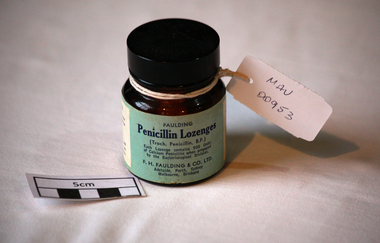

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Glass, brown bottle 'Penicillin Lozenges', 20thC

F. H. Faulding & Co was a pharmaceutical company founded in Adelaide, South Australia in 1845 by Francis Hardey Faulding 1816 – 1868, a native of Swinfleet, Yorkshire, He arrived in Sydney on the Nabob in February 1842,and travelled on the brig Dorset to Adelaide in May, where he opened a pharmacy at 5 Rundle Street in 1845.The pharmacy flourished, so he purchased a warehouse in Clarence Place in the city and transferred the manufacturing and wholesale arms of the business there. In 1861 he entered into partnership with Luther Scammell (1826–1910).a Yorkshireman, who had received medical training at Guy's Hospital, and arrived in Adelaide in 1849. Faulding died in 1868 and Scammell took over the business, however he was forced to retire in 1889 when the Bank of Adelaide threatened foreclosure after a series of failed mining and pastoral speculations. Two of his sons, Luther Robert Scammell FCS LSA ( 1858 – 1940) and William J. Scammell ( 1856 – 1928) acquired the manufacturing and wholesaling operations, and the business name, in 1888; the retail shops were sold to reduce the debt to the bank.The company expanded under the two brothers and later two sons of each became directors of the company. In June 1921 Faulding & Co. became a private company, with L.R. Scammell as chairman and managing director. He continued to run the firm's affairs until 1935.Two of the Faulding company's major innovations were the development of a process for distillation of eucalyptus oil, and the development of the test for determining the eucalyptol content of the oil. Faulding's success was founded on eucalyptus oil, which formed the basis of an antiseptic marketed as "Solyptol" (for soluble eucalyptus oil). The test became the industry standard, and the British Pharmacopoeia standard method in 1898. Other well-known products were Milk Emulsion (a pleasant alternative to cod-liver oil), Solyptol Soap, (which won a gold medal at the Franco-British Exhibition in London in 1908), Solyptol disinfectant, junket tablets, cordials, essential oils for perfumery and reagents such as Epsom salts, most produced in its factory in Thebarton The Faulding Co. built success around optimising the delivery of oral dosage form drugs. A brown glass bottle with a plastic screw top that contained 'Penicillin Lozenges' made by F.H. Faulding Co. Ltd . AustraliaFAULDING / Penicillin Lozenges / ( Troch. Penicillin B.P.) /......... / F.H.Faulding & Co. Ltd. / Adelaide, Perth, Sydney, / Melbourne, Brisbane on back DIRECTIONS......pharmacy, medicines, f.h. faulding co. ltd, penicillin lozenges, antibiotics, dentists, glassware, bottles, moorabbin, bentleigh, cheltenham -

Department of Energy, Environment and Climate Action

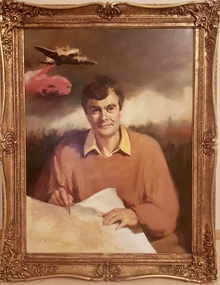

Department of Energy, Environment and Climate ActionPainting - Conrad Wood

Conrad Wood (Woody) graduated from the Victorian School of Forestry in 1957, and after postings with the Forests Commission Victoria (FCV) at Swifts Creek and Sirex surveys, he gravitated into the Forest Protection Division in Head Office in the early 1960s. He championed the setting up of proper contractual arrangements for aviation and was involved in implementing the first ongoing, organised contracts for firebombing in eastern Victoria in the 1960s. An early recipient of a prestigious Churchill Fellowship, Woody travelled extensively throughout 1969 in North America and Europe studying aviation in forestry and firefighting. Afterwards he was very active amongst the Churchill alumni. Woody had a passion for innovation and new technology and was instrumental in introducing new aircraft types and new approaches for forest firefighting and forest management. Amongst many other things, he played a major role in organising the trial of a RAAF C130 equipped with MAFFS for firebombing in south-eastern Australia in 1982-84, even piloting the lead plane. His inimitable style was crucial in successfully bringing together the cultures of the myriad organisations involved. Con advocated for the introduction of helicopters. He developed aerial fertilising and seeding techniques for forest management. He even managed to get involved in cloud seeding experiments for forest fire suppression and for improving water yield. Along with aviation, Conrad was passionate about literature, football, politics, food, drink, motorbikes, gardening and Glen Iris, to name a few. He was a committed campaigner on social justice issues and for many years read for vision-impaired people on public radio. He died in 2014. This painting of Woody by notable Australian artist Joyce McGrath OAM (also a Churchill Fellow) was done in the 1980s. Joyce asked Conrad to sit for this portrait which she planned to enter the Doug Moran National Portrait Prize. The portrait hung in Churchill House in Canberra, but when a new building was erected, it was returned to the artist/owner. The painting is now owned by Clare Harwood and is on permanent loan to the Forests Commission Retired Personnel Association (FCRPA) and is displayed at DEECA's Altona Museum.Painting of Conrad Wood by Australian artist Joyce McGrath OAMbushfire, bushfire aviation -

Federation University Historical Collection

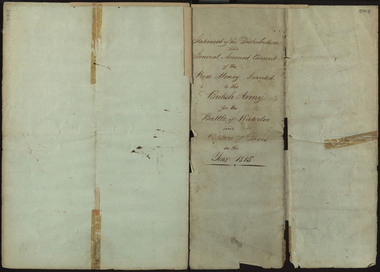

Federation University Historical CollectionDocument, Statement of the Distribution and General Account Current of the Prize Money Granted to the British Army for the Battle of Waterloo and Capture of Paris in the Year 1815, 1815

The Napoleonic Wars were a period of conflict from 1803-1815, caused by unresolved tensions following the end of the French Revolution. Coalitions of European powers fought against Napoleon Bonaparte and the French army, who were defeated at the Battle of Waterloo on the 18th June 1815, in Belgium. The conclusion of the battle would mark a period of sustained peace for Europe, that would bring with it cultural and technological innovation. This document in illustrative of the prize money awarded to different groups of soldiers following the Capture of Paris, separated into different classes. The first class consisted of General Officers, the second of Field Officers and Colonels, the third of Captains, the fourth of Subalterns, the fifth of Serjeants and the sixth of Corporals, Drummers and Privates. The Commander in Chief of the Army also received £61, 178/3/ 5 1/2. In addition to the money given to these classes, which approximately totaled £486,246 / 18/ 1 3/4, a total of £30,000 was paid to the Bank of England and £7,204 / 16/ 7 1/4 was paid to the Chelsea Hospital, to a grand total of £558,940/ 12/ 3. This money given to the Chelsea Hospital was part of the Army Prize Money Act 1814 (54th Geo. 3 c. 86, 14th July 1814), which when passed through parliament entailed that any prize money unclaimed or forfeited would be paid to the Chelsea Hospital. The Royal Hospital Chelsea is a charitable institution which provides support to war veterans and has existed since the reign of Charles II. The document goes into further details of the payments made to specific regiments, who include members of the British cavalry and artillery, rifleman, staff corps and foreign soldiers enlisted to aid with the campaign. The award of prize money following battle was meant to serve as an incentive for aggression and victory, in addition to helping deter looting of the deceased possessions. A paper watermark '1810' on the handwritten document suggests it is an original, and therefore was probably in the possession of a battle participant, most likely of a higher rank. The provenance of the document is unknown but one possibility is through former Ballarat School of Mines staff member Hester Darby, whose parents were Ernest Darby and Leah Hynam. Her maternal line boasted a Battle of Waterloo veteran. A number of handwritten pages 48 cm. x 34.5 cm. (slightly larger than A3) which has been folded in half, and in half again. When attempts were made to tape the torn document together, one page was taped in the wrong order. The top of the third page aligns with the bottom of the fourth page, the top of the fourth page with the bottom of the third. Corrections to this have been made in the transcript. DESCRIPTION ON DISCOVERY: "BALLARAT - Copy of an historic document of prize money paid after the battle of Waterloo and capture of Paris in 1815 has been found among old papers at the Ballarat School of Mines. The full amount of prize money was stated at "£558,913 10/10." Scores of regiments had their shares varying probably, according to the numbers. The document will be retained in the School of Mines Museum, ... (Age, 21 March 1941)The paper has an 1810 watermark on the paper as well as a watermark for S&C Wise. duke of wellington, waterloo, battle of waterloo, napoleon, napoleon bonaparte, british army, paris, darby, veteran, 1815, prize money, waterloo verterans, hester darby -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Digital photographs, L.J. Gervasoni, Xavier College Chapel, c2016, c2016

Xavier College was first opened by the Society of Jesus (the Jesuits) in 1878. It belongs to a worldwide network of over 2,000 Jesuit educational institutions. The original Senior Campus location on Barkers Road, Kew is a culmination of modern innovation and rich historical preservation. The land on which Xavier stands was known as Mornane’s Paddock and was purchased by the Jesuits in 1872 from Patrick Mornane on a 20-year interest-free purchase plan. This enabled the Jesuits to get on with the funding and building of the College buildings almost immediately. Foundations for the South Wing commenced in 1872, with the front of the building completed in time for classes to begin in 1878. Many of the first boarders transferred from St Patrick’s College in East Melbourne. With the closure of St Patrick’s years later, many students, associated lay staff and Jesuits also transferred to Xavier College. Over the following century, Xavier College grew with two junior campuses; Burke Hall Campus and Kostka Hall Campus. In recent years, extensive refurbishments, renovations and improvements have moulded the properties into the beautiful sites they are today. In 2002 at our Burke Hall campus and in 2005 at our Kostka Hall campus, the College expanded its educational program, opening Early Years centres to provide the scope for a Jesuit education from the earliest ages. For the first time in the College’s history, girls were admitted to the Early Years, breaking the long-standing tradition of Xavier being a boys-only school. In 2021, after 85 years of inspiring education experiences, our Kostka Hall campus closed its gates for the final time. In 1920, Archbishop Daniel Mannix donated the house and land known as Studley Hall to Xavier College for use as a preparatory school. The property had been purchased and donated to Mannix by Mr T.M. Burke, a Catholic businessman. In 1921, Xavier Preparatory School opened and was later renamed Burke Hall in 1926 in honour of Mr Burke. The Kostka Hall location was opened in 1937 and was named in honour of St Stanislaus Kostka. To establish the second preparatory school, the Jesuits purchased two Brighton properties in mid-1936. Both were promptly remodelled to provide the facilities required for school life. (https://xavier.vic.edu.au/xavier-history, accessed 15/05/2025) Colour photograph of the section of the Chapel at Xavier College, Kew, Victoria. heritage, kew, xavier college, chapel, catholic, st francis xavier, xavier chapel -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Digital photographs, Clare Gervasoni, Melbourne Views from Xavier College Chapel, 2025, 05/2025

Xavier College was first opened by the Society of Jesus (the Jesuits) in 1878. It belongs to a worldwide network of over 2,000 Jesuit educational institutions. The original Senior Campus location on Barkers Road, Kew is a culmination of modern innovation and rich historical preservation. The land on which Xavier stands was known as Mornane’s Paddock and was purchased by the Jesuits in 1872 from Patrick Mornane on a 20-year interest-free purchase plan. This enabled the Jesuits to get on with the funding and building of the College buildings almost immediately. Foundations for the South Wing commenced in 1872, with the front of the building completed in time for classes to begin in 1878. Many of the first boarders transferred from St Patrick’s College in East Melbourne. With the closure of St Patrick’s years later, many students, associated lay staff and Jesuits also transferred to Xavier College. Over the following century, Xavier College grew with two junior campuses; Burke Hall Campus and Kostka Hall Campus. In recent years, extensive refurbishments, renovations and improvements have moulded the properties into the beautiful sites they are today. In 2002 at our Burke Hall campus and in 2005 at our Kostka Hall campus, the College expanded its educational program, opening Early Years centres to provide the scope for a Jesuit education from the earliest ages. For the first time in the College’s history, girls were admitted to the Early Years, breaking the long-standing tradition of Xavier being a boys-only school. In 2021, after 85 years of inspiring education experiences, our Kostka Hall campus closed its gates for the final time. In 1920, Archbishop Daniel Mannix donated the house and land known as Studley Hall to Xavier College for use as a preparatory school. The property had been purchased and donated to Mannix by Mr T.M. Burke, a Catholic businessman. In 1921, Xavier Preparatory School opened and was later renamed Burke Hall in 1926 in honour of Mr Burke. The Kostka Hall location was opened in 1937 and was named in honour of St Stanislaus Kostka. To establish the second preparatory school, the Jesuits purchased two Brighton properties in mid-1936. Both were promptly remodelled to provide the facilities required for school life. (https://xavier.vic.edu.au/xavier-history, accessed 15/05/2025) Colour photograph of the Melbourne highrise from the Chapel at Xavier College, Kew, Victoria. heritage, kew, xavier college, chapel, catholic, st francis xavier, xavier chapel -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Digital photographs, Clare Gervasoni, Exterior Views of Xavier College, 2025, 05/2025

Xavier College was first opened by the Society of Jesus (the Jesuits) in 1878. It belongs to a worldwide network of over 2,000 Jesuit educational institutions. The original Senior Campus location on Barkers Road, Kew is a culmination of modern innovation and rich historical preservation. The land on which Xavier stands was known as Mornane’s Paddock and was purchased by the Jesuits in 1872 from Patrick Mornane on a 20-year interest-free purchase plan. This enabled the Jesuits to get on with the funding and building of the College buildings almost immediately. Foundations for the South Wing commenced in 1872, with the front of the building completed in time for classes to begin in 1878. Many of the first boarders transferred from St Patrick’s College in East Melbourne. With the closure of St Patrick’s years later, many students, associated lay staff and Jesuits also transferred to Xavier College. Over the following century, Xavier College grew with two junior campuses; Burke Hall Campus and Kostka Hall Campus. In recent years, extensive refurbishments, renovations and improvements have moulded the properties into the beautiful sites they are today. In 2002 at our Burke Hall campus and in 2005 at our Kostka Hall campus, the College expanded its educational program, opening Early Years centres to provide the scope for a Jesuit education from the earliest ages. For the first time in the College’s history, girls were admitted to the Early Years, breaking the long-standing tradition of Xavier being a boys-only school. In 2021, after 85 years of inspiring education experiences, our Kostka Hall campus closed its gates for the final time. In 1920, Archbishop Daniel Mannix donated the house and land known as Studley Hall to Xavier College for use as a preparatory school. The property had been purchased and donated to Mannix by Mr T.M. Burke, a Catholic businessman. In 1921, Xavier Preparatory School opened and was later renamed Burke Hall in 1926 in honour of Mr Burke. The Kostka Hall location was opened in 1937 and was named in honour of St Stanislaus Kostka. To establish the second preparatory school, the Jesuits purchased two Brighton properties in mid-1936. Both were promptly remodelled to provide the facilities required for school life. (https://xavier.vic.edu.au/xavier-history, accessed 15/05/2025) Colour photograph of the buildings and Chapel at Xavier College, Kew, Victoria. heritage, kew, xavier college, chapel, catholic, st francis xavier, xavier chapel -

Victorian Aboriginal Corporation for Languages

Victorian Aboriginal Corporation for LanguagesPeriodical, Australian Institute of Aboriginal and Torres Strait Islander Studies, Australian Aboriginal studies : journal of the Australian Institute of Aboriginal and Torres Strait Islander Studies, 2008

1. Rock-art of the Western Desert and Pilbara: Pigment dates provide new perspectives on the role of art in the Australian arid zone Jo McDonald (Australian National University) and Peter Veth (Australian National University) Systematic analysis of engraved and painted art from the Western Desert and Pilbara has allowed us to develop a spatial model for discernable style provinces. Clear chains of stylistic connection can be demonstrated from the Pilbara coast to the desert interior with distinct and stylistically unique rock-art bodies. Graphic systems appear to link people over short, as well as vast, distances, and some of these style networks appear to have operated for very long periods of time. What are the social dynamics that could produce unique style provinces, as well as shared graphic vocabularies, over 1000 kilometres? Here we consider language boundaries within and between style provinces, and report on the first dates for pigment rock-art from the Australian arid zone and reflect on how these dates from the recent past help address questions of stylistic variability through space and time. 2. Painting and repainting in the west Kimberley Sue O?Connor, Anthony Barham (Australian National University) and Donny Woolagoodja (Mowanjum Community, Derby) We take a fresh look at the practice of repainting, or retouching, rockart, with particular reference to the Kimberley region of Western Australia. We discuss the practice of repainting in the context of the debate arising from the 1987 Ngarinyin Cultural Continuity Project, which involved the repainting of rock-shelters in the Gibb River region of the western Kimberley. The ?repainting debate? is reviewed here in the context of contemporary art production in west Kimberley Indigenous communities, such as Mowanjum. At Mowanjum the past two decades have witnessed an artistic explosion in the form of paintings on canvas and board that incorporate Wandjina and other images inspired by those traditionally depicted on panels in rock-shelters. Wandjina also represents the key motif around which community desires to return to Country are articulated, around which Country is curated and maintained, and through which the younger generations now engage with their traditional lands and reach out to wider international communities. We suggest that painting in the new media represents a continuation or transference of traditional practice. Stories about the travels, battles and engagements of Wandjina and other Dreaming events are now retold and experienced in the communities with reference to the paintings, an activity that is central to maintaining and reinvigorating connection between identity and place. The transposition of painting activity from sites within Country to the new ?out-of-Country? settlements represents a social counterbalance to the social dislocation that arose from separation from traditional places and forced geographic moves out-of-Country to government and mission settlements in the twentieth century. 3. Port Keats painting: Revolution and continuity Graeme K Ward (AIATSIS) and Mark Crocombe (Thamarrurr Regional Council) The role of the poet and collector of ?mythologies?, Roland Robinson, in prompting the production of commercial bark-painting at Port Keats (Wadeye), appears to have been accepted uncritically - though not usually acknowledged - by collectors and curators. Here we attempt to trace the history of painting in the Daly?Fitzmaurice region to contextualise Robinson?s contribution, and to evaluate it from both the perspective of available literature and of accounts of contemporary painters and Traditional Owners in the Port Keats area. It is possible that the intervention that Robinson might have considered revolutionary was more likely a continuation of previously well established cultural practice, the commercial development of which was both an Indigenous ?adjustment? to changing socio-cultural circumstances, and a quiet statement of maintenance of identity by strong individuals adapting and attempting to continue their cultural traditions. 4. Negotiating form in Kuninjku bark-paintings Luke Taylor (AIATSIS) Here I examine social processes involved in the manipulation of painted forms of bark-paintings among Kuninjku artists living near Maningrida in Arnhem Land. Young artists are taught to paint through apprenticeships that involve exchange of skills in producing form within extended family groups. Through apprenticeship processes we can also see how personal innovations are shared among family and become more regionally located. Lately there have been moves by senior artists to establish separate out-stations and to train their wives and daughters to paint. At a stylistic level the art now creates a greater sense of family autonomy and yet the subjects link the artists back in to much broader social networks. 5. Making art and making culture in far western New South Wales Lorraine Gibson This contribution is based on my ethnographic fieldwork. It concerns the intertwining aspects of the two concepts of art and culture and shows how Aboriginal people in Wilcannia in far western New South Wales draw on these concepts to assert and create a distinctive cultural identity for themselves. Focusing largely on the work of one particular artist, I demonstrate the ways in which culture (as this is considered) is affectively experienced and articulated as something that one ?comes into contact with? through the practice of art-making. I discuss the social and cultural role that art-making, and art talk play in considering, mediating and resolving issues to do with cultural subjectivity, authority and identity. I propose that in thinking about the content of the art and in making the art, past and present matters of interest, of difficulty and of pleasure are remembered, considered, resolved and mediated. Culture (as this is considered by Wilcannia Aboriginal people) is also made anew; it comes about through the practice of artmaking and in displaying and talking about the art work. Culture as an objectified, tangible entity is moreover writ large and made visible through art in ways that are valued by artists and other community members. The intersections between Aboriginal peoples, anthropologists, museum collections and published literature, and the network of relations between, are also shown to have interesting synergies that play themselves out in the production of art and culture. 6. Black on White: Or varying shades of grey? Indigenous Australian photo-media artists and the ?making of? Aboriginality Marianne Riphagen (Radboud University, The Netherlands) In 2005 the Centre for Contemporary Photography in Melbourne presented the Indigenous photo-media exhibition Black on White. Promising to explore Indigenous perspectives on non-Aboriginality, its catalogue set forth two questions: how do Aboriginal artists see the people and culture that surrounds them? Do they see non-Aboriginal Australians as other? However, art works produced for this exhibition rejected curatorial constructions of Black and White, instead presenting viewers with more complex and ambivalent notions of Aboriginality and non-Aboriginality. This paper revisits the Black on White exhibition as an intercultural event and argues that Indigenous art practitioners, because of their participation in a process to signify what it means to be Aboriginal, have developed new forms of Aboriginality. 7. Culture production Rembarrnga way: Innovation and tradition in Lena Yarinkura?s and Bob Burruwal?s metal sculptures Christiane Keller (University of Westerna Australia) Contemporary Indigenous artists are challenged to produce art for sale and at the same time to protect their cultural heritage. Here I investigate how Rembarrnga sculptors extend already established sculptural practices and the role innovation plays within these developments, and I analyse how Rembarrnga artists imprint their cultural and social values on sculptures made in an essentially Western medium, that of metal-casting. The metal sculptures made by Lena Yarinkura and her husband Bob Burruwal, two prolific Rembarrnga artists from north-central Arnhem Land, can be seen as an extension of their earlier sculptural work. In the development of metal sculptures, the artists shifted their artistic practice in two ways: they transformed sculptural forms from an earlier ceremonial context and from earlier functional fibre objects. Using Fred Myers?s concept of culture production, I investigate Rembarrnga ways of culture-making. 8. 'How did we do anything without it?': Indigenous art and craft micro-enterprise use and perception of new media technology.maps, colour photographs, b&w photographswest kimberley, rock art, kuninjku, photo media, lena yarinkura, bob burruwal, new media technology -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Diving Compressor, Siebe Gorman & Co. Ltd, 1880-1890

This compressor was part of the E.G. Ward Collection. It is connected to the diving suit and boots also in our collection. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water-pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12 bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunneling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr. E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The compressor is a very significant item as it gives a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. Siebe & Gorman the company that made the equipment was a leading inventor, developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job during the early days of marine exploration.A single cylinder divers' pump by Siebe Gorman & Co Ltd, London, eccentric hand cranked in brass mounted mahogany case with instructions to the underside of the lid, brass covered pressure gauge and air outlet, brass makers plaque to the front, water inlet and outlet to the rear, green painted lifting rings. Machinery has some blue painted areas on the metal.Plate on the back 'WATER SUPPLY" "WATER OVERFLOW" "WATER DRAIN-IN" Pressure gauge dial "BOURDON'S PRESSURE GAUGE" STEBE GORMAN & CO. LONDON", "LBS PRESSURE" "FEET OF SALT WATER" Plate on the front " PATENT, Siebe Gorman & Co Ltd Submarine Engineers" below emblem (Lion, Crown, Horse)flagstaff hill, warrnambool, flagstaff-hill, maritime-museum, diving compressor, london, siebe gorman & co ltd, marine technology, life saving, deep sea diving, maritime museum, maritime village, manine history -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Diving Suit, boots and weight, 1900

This diving suit with helmet, boots and weight is part of the E.G.Ward collection, along with the diving compressor and a photograph of a diver in this equipment. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12-bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunnelling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A.Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire-fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The items are very significant as a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. The company that made the equipment was a leading inventor,developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job.Diving suit including helmet, boots and a weight. Diving suit is made of canvas with knitted cuffs. The helmet is metal. The boots have a thick sole and thick leather upper that is held on with leather straps and buckles. The toe of the boot is heavy metal. The weight is worn next to the trunk of the diver and it has an inscription to mark the front. It is worn with straps and buckles holding it in place. Royal Navy Admiralty Pattern 6 bolt No 3 light Siebe Gorman light diving helmet circa 1960 used by the Royal Navy before and after World War 2"Siebe Gorman & Co Ltd Marine Engineers London. Patent" with "E G Ward" on front and back plate. On weight "FRONT"flagstaff hill, warrnambool, diving suit, siebe gorman and co ltd., siebe gorman and co ltd marine engineers london, marine engineers, diving helmet, diving boots, diving weight, marine diving, maritimemuseum, maritime village, maritime history, marine technology, life saving, deep sea diving -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Diving compressor and helmet, 1944

Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water pumps, refrigeration equipment, and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards, and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12 bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering, and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air, and under the sea (including mine rescue, tunneling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A.Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman's fortunes began to decline as an aging Sir Robert Davis failed to invest, or change the company's business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire-fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998). (For information regards the diving helmet & Frank King see Notes Section at the end of this document)The items are very significant as a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. The company that made the equipment was a leading inventor,developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job. Frank Kings' diving helmet and compressor (communication pipe stored separately). Compressor is hand cranked. US Navy diving helmet, Mark V. Two maker's plates attached. Made in 1944.On rear "WATER SUPPLY" On front 'PATENT" " Logo: Images (Lion, Crown, Horse, Shield within an oval) "SIEBE, GORMAN & Co. Ltd. SUBMARINE ENGINEERS, LONDON.flagstaff hill, warrnambool, maritime museum, great ocean road, us navy diving helmet, commonwealth government salvage, diving helmet, marine salvage, frank king, diver, siebe. gorman & co ltd, submarine equipment, diving equipment, communication under water, hand cranked, diving compressor -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWood Sample, c. 1854

This sample of wood is from the American clipper ship LIGHTNING was a 3 masted, fully rigged extreme clipper ship. She was commissioned by James Baines, of the Black Ball Line in Liverpool, England, during the time of the Australian Gold Rush for the trade of passengers and cargo between England and Australia. Her cargo listed early consignments of livestock and animals, including rabbits sent to Thomas Austin of Barwon Park, Winchelsea, Victoria. The LIGHTNING was built in 1854 by shipbuilder Donald McKay, of East Boston, USA. She was described as spacious and comfortable, and one of the smartest ships known. The LIGHTNING set many speed records for her sea crossings, and became one of the most famous of the racing clippers and one of the fastest ever launched. In 1854, with Captain ‘Bully’ Forbes and Mate ‘Bully’ Bragg, LIGHTNING made the return trip from Melbourne to Liverpool in only 64 days, 3 hours and 10 minutes; a record for all time. Captain Enright became the new Master of LIGHTNING soon afterwards. He has been described as one of the finest mariners in the Australian trade. One of Captain Enright’s innovations was to publish a ship’s paper called The Lightning Gazette. (Captain Forbes had left to captain the SCHOMBERG.) In January 1855 Capt. Enright sailed the LIGHTNING from Liverpool with over 700 passengers and returned home carrying gold as her cargo. In 1857, for a very brief time under Capt. Byrne the LIGHTNING was used as a troop ship, taking British officers and soldiers, stores and ammunition, to fight in India. In 1859 she then returned to her run between Liverpool and Melbourne, apart from 1867 when she made a special trip between Melbourne and Port Chalmers in New Zealand. In 1869 the LIGHTNING was sold to Thomas Harrison of Liverpool, and she continued to sail for the Black Ball Line. Master of LIGHTNING, Captain Henry Jones, sailed her to Geelong in October 1869, and whilst docked, he had her loaded with a cargo of wool, copper, wire, tallow and other goods. At about 1am on 31st October 1869, whilst still docked and fully laden, a fire was noticed on the LIGHTNING. Efforts to extinguished the fire were unsuccessful, so she was towed to the shoals in Corio Bay, where she eventually sank, losing all cargo but no lives. The area is now known as Lightning Shoals. The LIGHTNING is listed on the Victorian Heritage Register VHR S415. She is historically significant for being one of the fastest wooden ships ever built, the first clipper built in the USA for British owners and being the worst shipping disaster in Geelong's history. It spent its whole career carrying cargo and immigrants from England to Australia.Sample, wooden, varnished, from wreck the Lightning. Has a groove along one edge.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sailing ship lightning, extreme clipper ship, american clipper ship, record breaking clipper ship, james baines, black ball line, donald mckay shipbuilder, captain ‘bully’ forbes, australian immigration, liverpool to melbourne migration, captain enright, captain byrne, captain henry jones, lightning shoals geelong, rabbits introduced to australia, wood sample from a ship -

Flagstaff Hill Maritime Museum and Village

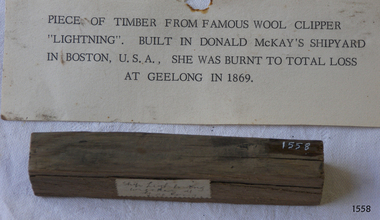

Flagstaff Hill Maritime Museum and VillageWood Sample, c. 1854

This piece of wood is from the American clipper ship LIGHTNING was a 3 masted, fully rigged extreme clipper ship. She was commissioned by James Baines, of the Black Ball Line in Liverpool, England, during the time of the Australian Gold Rush for the trade of passengers and cargo between England and Australia. Her cargo listed early consignments of livestock and animals, including rabbits sent to Thomas Austin of Barwon Park, Winchelsea, Victoria. The LIGHTNING was built in 1854 by shipbuilder Donald McKay, of East Boston, USA. She was described as spacious and comfortable, and one of the smartest ships known. The LIGHTNING set many speed records for her sea crossings, and became one of the most famous of the racing clippers and one of the fastest ever launched. In 1854, with Captain ‘Bully’ Forbes and Mate ‘Bully’ Bragg, LIGHTNING made the return trip from Melbourne to Liverpool in only 64 days, 3 hours and 10 minutes; a record for all time. Captain Enright became the new Master of LIGHTNING soon afterwards. He has been described as one of the finest mariners in the Australian trade. One of Captain Enright’s innovations was to publish a ship’s paper called The Lightning Gazette. (Captain Forbes had left to captain the SCHOMBERG.) In January 1855 Capt. Enright sailed the LIGHTNING from Liverpool with over 700 passengers and returned home carrying gold as her cargo. In 1857, for a very brief time under Capt. Byrne the LIGHTNING was used as a troop ship, taking British officers and soldiers, stores and ammunition, to fight in India. In 1859 she then returned to her run between Liverpool and Melbourne, apart from 1867 when she made a special trip between Melbourne and Port Chalmers in New Zealand. In 1869 the LIGHTNING was sold to Thomas Harrison of Liverpool, and she continued to sail for the Black Ball Line. Master of LIGHTNING, Captain Henry Jones, sailed her to Geelong in October 1869, and whilst docked, he had her loaded with a cargo of wool, copper, wire, tallow and other goods. At about 1am on 31st October 1869, whilst still docked and fully laden, a fire was noticed on the LIGHTNING. Efforts to extinguished the fire were unsuccessful, so she was towed to the shoals in Corio Bay, where she eventually sank, losing all cargo but no lives. The area is now known as Lightning Shoals. The LIGHTNING is listed on the Victorian Heritage Register VHR S415. She is historically significant for being one of the fastest wooden ships ever built, the first clipper built in the USA for British owners and being the worst shipping disaster in Geelong's history. It spent its whole career carrying cargo and immigrants from England to Australia.Sample of wood from the wool clipper LIGHTNING, 1854-1869, The sample has a label and a card with information about the ship and a person. Card, typewritten, "PIECE OF TIMBER FROM FAMOUS WOOL CLIPPER / "LIGHTNING". BUILD IN DONALD McKAY'S SHIPYARD / IN BOSTON, U.S.A.. SHE WAS BURNT TO TOTAL LOSS / IN GEELONG IN 1869"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sailing ship lightning, extreme clipper ship, american clipper ship, record breaking clipper ship, james baines, black ball line, donald mckay shipbuilder, captain ‘bully’ forbes, australian immigration, liverpool to melbourne migration, captain enright, captain byrne, captain henry jones, lightning shoals geelong, rabbits introduced to australia, wood sample from lightning -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWood Sample, c. 1854

This sample of wood is from the American clipper ship LIGHTNING was a 3 masted, fully rigged extreme clipper ship. She was commissioned by James Baines, of the Black Ball Line in Liverpool, England, during the time of the Australian Gold Rush for the trade of passengers and cargo between England and Australia. Her cargo listed early consignments of livestock and animals, including rabbits sent to Thomas Austin of Barwon Park, Winchelsea, Victoria. The LIGHTNING was built in 1854 by shipbuilder Donald McKay, of East Boston, USA. She was described as spacious and comfortable, and one of the smartest ships known. The LIGHTNING set many speed records for her sea crossings, and became one of the most famous of the racing clippers and one of the fastest ever launched. In 1854, with Captain ‘Bully’ Forbes and Mate ‘Bully’ Bragg, LIGHTNING made the return trip from Melbourne to Liverpool in only 64 days, 3 hours and 10 minutes; a record for all time. Captain Enright became the new Master of LIGHTNING soon afterwards. He has been described as one of the finest mariners in the Australian trade. One of Captain Enright’s innovations was to publish a ship’s paper called The Lightning Gazette. (Captain Forbes had left to captain the SCHOMBERG.) In January 1855 Capt. Enright sailed the LIGHTNING from Liverpool with over 700 passengers and returned home carrying gold as her cargo. In 1857, for a very brief time under Capt. Byrne the LIGHTNING was used as a troop ship, taking British officers and soldiers, stores and ammunition, to fight in India. In 1859 she then returned to her run between Liverpool and Melbourne, apart from 1867 when she made a special trip between Melbourne and Port Chalmers in New Zealand. In 1869 the LIGHTNING was sold to Thomas Harrison of Liverpool, and she continued to sail for the Black Ball Line. Master of LIGHTNING, Captain Henry Jones, sailed her to Geelong in October 1869, and whilst docked, he had her loaded with a cargo of wool, copper, wire, tallow and other goods. At about 1am on 31st October 1869, whilst still docked and fully laden, a fire was noticed on the LIGHTNING. Efforts to extinguished the fire were unsuccessful, so she was towed to the shoals in Corio Bay, where she eventually sank, losing all cargo but no lives. The area is now known as Lightning Shoals. The LIGHTNING is listed on the Victorian Heritage Register VHR S415. She is historically significant for being one of the fastest wooden ships ever built, the first clipper built in the USA for British owners and being the worst shipping disaster in Geelong's history. It spent its whole career carrying cargo and immigrants from England to Australia.Sample wooden rectangular from the clipper Lightning, which burned out at Geelong 31 Oct 1869.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, sailing ship lightning, extreme clipper ship, american clipper ship, record breaking clipper ship, james baines, black ball line, donald mckay shipbuilder, captain ‘bully’ forbes, australian immigration, liverpool to melbourne migration, captain enright, captain byrne, captain henry jones, lightning shoals geelong, rabbits introduced to australia, wood from sailing ship, shipwreck-coast, flagstaff-hill-maritime-village, lightning -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Kitchen Equipment, Coolgardie Safe, c1900

The invention of the Coolgardie Safe is credited to Arthur Patrick McCormick, a contractor in Coolgardie, and later the Mayor of Narrogin. Coolgardie is in the Eastern Goldfields region of Western Australia. Gold was first discovered there in 1892; the townsite became a municipality in 1894, and by 1898 its population of 15,000 made it the third largest town in Western Australia after Perth and Fremantle. In the last decade of the 19th century, Coolgardie was the capital of the West Australian goldfields. Being 180 kilometres from the nearest civilisation, food supplies were initially scarce and expensive. As fresh food was a valuable commodity there was incentive to preserve it, and keep it out of reach of scavengers such as birds, dingos, dogs, ants, and flies. It was in an effort to do this, in the extreme heat of the Australian Interior, that McCormick came up with his design for the Coolgardie Safe. McCormick noticed that a wet bag placed over a bottle cooled its contents. He further noted that if this bottle was placed in a breeze, the bag would dry out more quickly, but the bottle would get colder. What McCormick had discovered was the principle of evaporation: ‘to change any liquid into a gaseous state requires energy. This energy is taken in the form of heat from its surroundings.’ Employing this principle, McCormick made a box for his provisions which he covered with a wet hessian bag. He then placed a tray on top, into which he poured water twice daily. He hung strips of flannel from the tray so that water would drip down onto the hessian bag, keeping it damp. As the water evaporated, the heat dissipated, keeping the food stored inside cool and fresh. The success of McCormick’s invention would not have worked without a steady supply of water. Fresh water was scarce in the eastern goldfields at this time but the demand for water from a steadily growing population encouraged innovation. The solution was to condense salt water. Heating salt water in tanks produced steam that was condensed in tall cylinders, cooled and then collected in catchment trays. By 1898 there were six companies supplying condensed water to the goldfields, the largest company producing 100,000 gallons of water a day. In the early 20th century, Coolgardie Safes were also manufactured commercially. These safes incorporated shelving and a door, had metal or wooden frames and hessian bodies. The feet of the safe were usually placed in a tray of water to keep ants away. (MAV website) The early settlers of Moorabbin Shire depended on this type of Food Safe to protect their food from flies and vermin as they established market gardens in the fertile area around the notorious Elster Creek A metal framed, 4 sided structure standing on 4 legs with 2 hinged doors on one side, a metal tray at base of food safe and a metal cover over top. Ridges on which to rest trays carrying food are inside safe. The Safe is enclosed by fly-wire mesh.'...IN.....GEELONG' A manufacturer's oval metal plate is embossed on one side of Safe but it is illegible.elster creek, moorabbin, brighton, dendy's special survey 1841, market gardens, infant mortality, disease, cemeteries, fruit, vegetables, pioneers, coolgardie safe, mccormick arthur patrick, dendy henry, vaccination, jones martha, jones ethel may -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWeapon - Ammunition, Before 1878

The objects are a small sample of small gauge lead shot raised by Flagstaff Hill divers from the LOCH ARD shipwreck site in 1976. Companion pieces are in the Maritime Village collection. The three masted, iron hulled, LOCH ARD was wrecked against the tall limestone cliffs of Mutton Bird Island in the early hours of the first of June 1878. Included in her diverse and valuable cargo were 22 tons of lead shot, packed in cloth bags and wooden casks. Bulk quantities of lead shot, uniformly round balls of dull grey metal ranging from 2mm “birdshot” to 8mm “buckshot”, were routinely exported to the Australian colonies. Shot was used mostly as projectiles fired from smooth bored guns to bring down moving targets such as wild ducks and small game. It was also useful as ballast, when a dense, “pourable” weight was required to fill cavities or establish volume within a measuring container. The production of consistently round spheres of lead shot required the pouring of molten metal through a sieve and then a long drop through the atmosphere to a water filled basin for final cooling and collection. This “shot tower” process was first patented by William Watts of Bristol in 1782. His calculation of a 150 feet fall was not only to form evenly spherical droplets through surface tension, but also to provide partial cooling and solidification to each shot before they hit the water below. The value of his innovation was the minimising of indentation and shape distortion, avoiding the expense of re-smelting and re-moulding the lead. Lead shot was already being produced in Australia at the time the LOCH ARD loaded her cargo and left Gravesend on the second of March 1878. James Moir constructed a 157 feet circular stone shot tower near Hobart in 1870, with a peak annual production of 100 tons of lead shot sold in 28 pound linen bags. However colonial demand exceeded this source of local supply. The continued strength of the market for lead shot in the Colony of Victoria prompted substantial investment in additional productive capacity in Melbourne in the next decade. In 1882 Richard Hodgson erected the 160 feet round chimney-shaped Clifton Hill shot tower on Alexandra Parade (VHR H0709) and in 1889 Walter Coop built the 160 feet square tower-shaped Melbourne Central shot tower on La Trobe Street (VHR H0067). At its peak, the Coop Tower produced 6 tons of lead shot per week, or 312 tons per annum. The shipwreck of the LOCH ARD is of State significance – Victorian Heritage Register S417 Flagstaff Hill’s collection of artefacts from LOCH ARD is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. It is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417). The collection is significant because of the relationship between the objects, as together they have a high potential to interpret the story of the LOCH ARD. The LOCH ARD collection is archaeologically significant as the remains of a large international passenger and cargo ship. The LOCH ARD collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the LOCH ARD, which was one of the worst and best known shipwrecks in Victoria’s history. A quantity of 2mm and 4mm lead shot ammunition retrieved from the LOCH ARD shipwreck site. They are concreted together by sediment. There are (6) small pieces with some single shot and a larger conglomerate of cemented shot. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, lead shot, colonial industry, melbourne shot towers, victorian metallurgy, colonial imports -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Block (sailing), Burrows, Ship Candler, c. 1869

The Lightning was an American-built sailing ship and it is believed the rope block was part of the ship’s rigging or included as cargo. The plaque on the block mentions that the item was, “as supplied by Burrows Ship Chandlers” in 1869. The plaque could also mean that the rope block was supplied by the firm Burrows, Ship Chandler and Shipping Stock, as a replacement block for the Lightning. The American vessel named “Lightning” was a 3-masted, fully rigged extreme clipper ship. She was commissioned by James Baines, of the Black Ball Line in Liverpool, England, during the time of the Australian Gold Rush for the trade of passengers and cargo between England and Australia. Her load listed on early consignments included livestock and animals, including rabbits sent to Thomas Austin of Barwon Park, Winchelsea, Victoria, where the challenging association between Australia's agriculture and the imported rabbits started. The Lightning was built in 1854 by shipbuilder Donald McKay, in East Boston, USA. She was described as spacious and comfortable and regarded as one of the smartest ships of the time. The vessel set many speed records for her voyages and became one of the most famous of racing clippers and one of the fastest ever launched. In 1854, with Captain 'Bully' Forbes and Mate 'Bully' Bragg, Lightning made the return trip from Melbourne to Liverpool in only 64 days, 3 hours and 10 minutes; a record. Captain Enright became the new Master of LIGHTNING soon after this record was established and was regarded as one of the finest mariners in the Australian trade. One of Captain Enright's innovations was to publish a ship's paper called "The Lightning Gazette". What is of additional historic interest is that captain "Bully Forbes" had left the Lightning to captain the ill-fated Schomberg. In 1857, for a very brief time under Capt. Byrne the Lightning was used as a troopship, taking British officers and soldiers, stores and ammunition, to fight in India. In 1859 she then returned to her normal route between Liverpool and Melbourne, apart from 1867 when she made a special trip between Melbourne and Port Chalmers in New Zealand. In 1869 the Lightning was sold to Thomas Harrison of Liverpool, and continued to sail for the Black Ball Line. Master of Lightning, Captain Henry Jones, sailed her to Geelong in October 1869, and whilst docked, he had her loaded with a cargo of wool, copper, wire, tallow and other goods. At about 1 am on 31st October 1869, whilst still docked and fully laden, a fire was noticed on the vessel. Efforts to extinguish the fire were unsuccessful, so she was towed to the "Lightning Shoals" in Corio Bay, where she eventually sank, losing all cargo but no lives. The Lightning is listed on the Victorian Heritage Register (Ref S 415). The vessel is historically significant for being one of the fastest wooden ships ever built. it was notable as the first clipper built in the USA for British owners and as a shipping disaster in Geelong's history. The Lightning spent its whole career carrying cargo and immigrants from England to Australia. Its documented voyages give us a snapshot into shipping history, not only of Australia in the mid-19th century but how the world's commercial transport functioned o promote trade and emigration during this time.Large ship's block, wood, with two wooden sheaves and fibre straps, eye and thimble. The metal plaque attached to the block has an inscription. The block was used on the ship "Lightning".Plaque inscription: "BLOCK OFF THE LIGHTNING / AS SUPPLIED BY / BURROWS SHIPS CHANDLERS / & SHIPPING STOCK CORIO BAY / 1863" (or 1869)flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, sailing ship lightning, extreme clipper ship, american clipper ship, record breaking clipper ship, james baines, black ball line, donald mckay shipbuilder, captain ‘bully’ forbes, australian immigration, liverpool to melbourne migration, captain enright, captain byrne, captain henry jones, corio bay geelong, lightning shoals geelong, rabbits introduced to australia, burrows and bascombe, burrows, ship chandler, corio bay, burrow's ship chandlers and shipping stock, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph, 31st October 1869

This photograph was taken at the scene of the fire on the LIGHTNING, in Corio Bay, Geelong on 31st October 1869. The American clipper ship LIGHTNING was a 3 masted, fully rigged extreme clipper ship. She was commissioned by James Baines, of the Black Ball Line in Liverpool, England, during the time of the Australian Gold Rush for the trade of passengers and cargo between England and Australia. Her cargo listed early consignments of livestock and animals, including rabbits sent to Thomas Austin of Barwon Park, Winchelsea, Victoria. The LIGHTNING was built in 1854 by shipbuilder Donald McKay, of East Boston, USA. She was described as spacious and comfortable, and one of the smartest ships known. The LIGHTNING set many speed records for her sea crossings, and became one of the most famous of the racing clippers and one of the fastest ever launched. In 1854, with Captain ‘Bully’ Forbes and Mate ‘Bully’ Bragg, LIGHTNING made the return trip from Melbourne to Liverpool in only 64 days, 3 hours and 10 minutes; a record for all time. Captain Enright became the new Master of LIGHTNING soon afterwards. He has been described as one of the finest mariners in the Australian trade. One of Captain Enright’s innovations was to publish a ship’s paper called The Lightning Gazette. (Captain Forbes had left to captain the SCHOMBERG.) In January 1855 Capt. Enright sailed the LIGHTNING from Liverpool with over 700 passengers and returned home carrying gold as her cargo. In 1857, for a very brief time under Capt. Byrne the LIGHTNING was used as a troop ship, taking British officers and soldiers, stores and ammunition, to fight in India. In 1859 she then returned to her run between Liverpool and Melbourne, apart from 1867 when she made a special trip between Melbourne and Port Chalmers in New Zealand. In 1869 the LIGHTNING was sold to Thomas Harrison of Liverpool, and she continued to sail for the Black Ball Line. Master of LIGHTNING, Captain Henry Jones, sailed her to Geelong in October 1869, and whilst docked, he had her loaded with a cargo of wool, copper, wire, tallow and other goods. At about 1am on 31st October 1869, whilst still docked and fully laden, a fire was noticed on the LIGHTNING. Efforts to extinguished the fire were unsuccessful, so she was towed to the shoals in Corio Bay, where she eventually sank, losing all cargo but no lives. The area is now known as Lightning Shoals. The LIGHTNING is listed on the Victorian Heritage Register VHR S415. She is historically significant for being one of the fastest wooden ships ever built, the first clipper built in the USA for British owners and being the worst shipping disaster in Geelong's history. It spent its whole career carrying cargo and immigrants from England to Australia.Black and white photograph of the burning of the clipper Lightning in Corio Bay Geelong, Sunday Oct 31st 1869. Photograph shows the Lightning in the process of burning, smoke billowing above the deck. Another sailing ship, plus several small boats, are in the bay, with a crowd on the pier.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, sailing ship lightning, extreme clipper ship, american clipper ship, record breaking clipper ship, james baines, black ball line, donald mckay shipbuilder, captain ‘bully’ forbes, australian immigration, liverpool to melbourne migration, captain enright, captain byrne, captain henry jones, corio bay geelong, lightning shoals geelong, rabbits introduced to australia, historic photograph of shipwreck lightning, shipwreck-coast, flagstaff-hill-maritime-village, clipper lightning, photograph -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph, Lightning, 31st October 1869

This photograph shows the remains of the clipper ship LIGHTNING as it continues to burn to its end in Corio Bay, Geelong, 31st October 1869. The American clipper ship LIGHTNING was a 3 masted, fully rigged extreme clipper ship. She was commissioned by James Baines, of the Black Ball Line in Liverpool, England, during the time of the Australian Gold Rush for the trade of passengers and cargo between England and Australia. Her cargo listed early consignments of livestock and animals, including rabbits sent to Thomas Austin of Barwon Park, Winchelsea, Victoria. The LIGHTNING was built in 1854 by shipbuilder Donald McKay, of East Boston, USA. She was described as spacious and comfortable, and one of the smartest ships known. The LIGHTNING set many speed records for her sea crossings, and became one of the most famous of the racing clippers and one of the fastest ever launched. In 1854, with Captain ‘Bully’ Forbes and Mate ‘Bully’ Bragg, LIGHTNING made the return trip from Melbourne to Liverpool in only 64 days, 3 hours and 10 minutes; a record for all time. Captain Enright became the new Master of LIGHTNING soon afterwards. He has been described as one of the finest mariners in the Australian trade. One of Captain Enright’s innovations was to publish a ship’s paper called The Lightning Gazette. (Captain Forbes had left to captain the SCHOMBERG.) In January 1855 Capt. Enright sailed the LIGHTNING from Liverpool with over 700 passengers and returned home carrying gold as her cargo. In 1857, for a very brief time under Capt. Byrne the LIGHTNING was used as a troop ship, taking British officers and soldiers, stores and ammunition, to fight in India. In 1859 she then returned to her run between Liverpool and Melbourne, apart from 1867 when she made a special trip between Melbourne and Port Chalmers in New Zealand. In 1869 the LIGHTNING was sold to Thomas Harrison of Liverpool, and she continued to sail for the Black Ball Line. Master of LIGHTNING, Captain Henry Jones, sailed her to Geelong in October 1869, and whilst docked, he had her loaded with a cargo of wool, copper, wire, tallow and other goods. At about 1am on 31st October 1869, whilst still docked and fully laden, a fire was noticed on the LIGHTNING. Efforts to extinguished the fire were unsuccessful, so she was towed to the shoals in Corio Bay, where she eventually sank, losing all cargo but no lives. The area is now known as Lightning Shoals. The LIGHTNING is listed on the Victorian Heritage Register VHR S415. She is historically significant for being one of the fastest wooden ships ever built, the first clipper built in the USA for British owners and being the worst shipping disaster in Geelong's history. It spent its whole career carrying cargo and immigrants from England to Australia.Black and white photograph of the burning of the sailing ship LIGHTNING, 31st October 1869 in Corio Bay, Geelong. The photograph shows the ship with only 2 masts remaining, still billowing smoke. Below the photograph is the photograph's title.Title hand written 'LIGHTNING"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sailing ship lightning, extreme clipper ship, american clipper ship, record breaking clipper ship, james baines, black ball line, donald mckay shipbuilder, captain ‘bully’ forbes, australian immigration, liverpool to melbourne migration, captain enright, captain byrne, captain henry jones, corio bay geelong, lightning shoals geelong, rabbits introduced to australia, burning of the lightning, historic photograph of shipwreck lightning -

Geoffrey Kaye Museum of Anaesthetic History

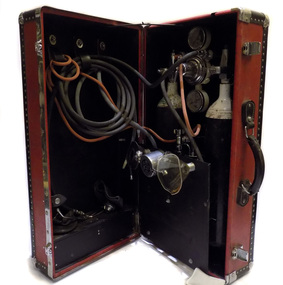

Geoffrey Kaye Museum of Anaesthetic HistoryEquipment - Resuscitator Unit, c. 1960