Showing 352 items matching "harvest"

-

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionArmstrong Rapid Log Calculator

Logs were sold to sawmillers from State forest from 1 July 1974 in cubic metres (true volume). Previously sawlogs had been sold on the basis of Hoppus volume. This simple device with two rotating wheels enabled staff in FCV offices to rapidly calculate log volumes from measurements taken in the bush of log girth and length and recorded on paper log dockets. From the early 1980s automated systems became available with the advent of cheap electronic office calculators and simple computers.An early manual device that was superseded by electronic calculatorsOffice Device Twin rollers used to quickly and simply calculate true log volumes using measurements of girth and length. An allowance could also be made for pipe defects. The top roller was for larger diameter logs.Imperial measurement of logs (pre 1976)forests commission victoria (fcv), forest harvesting, forest measurement -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionWright Reciprocating Saw

Continuous cutting chain was patented in 1905 by Samuel Bens of San Francisco, while the first portable chainsaw was developed and patented in 1918 by Canadian millwright James Shand. But the main advancements of modern petrol chainsaws occurred in Europe in the 1920s and 30s where Andreas Stihl is often hailed as the "father of the chainsaw" After the second world war lighter materials, metal alloys and improved engine designs revolutionised the logging and timber industry. This Wright Reciprocating Saw was made in Sheboygan, Wisconsin, between 1960 and 1962. Its a Rare GS-5020A model. It has a 7.06 cu. in. (115.7 cc), two-stroke motor, which weighed 25 lbs. (11.3 kg) complete. The blade doesn't stop reciprocating when the saw is running because it's attached directly to the crankshaft. There is no clutch system.Reciprocating Saw.forests commission victoria (fcv), forest harvesting, hand tools -

Sunbury Family History and Heritage Society Inc.

Sunbury Family History and Heritage Society Inc.Photograph, The Nook

The photograph was taken in The Nook. Terence O'Brien rented the land from Goonawarra from the 1890s to 1905 where he grew cereal crops. The terraces on the hillside were built to grow vines when the property was one of the first vineyards in the area. The men in the image are from L-R: Mr. Heath in the white cutter owned the chaff cutter, John Leyden with hand on fence, Michael Dillon, Terence O'Brien and Phil Ratile are on top of the haystack, Andy Burke standing with hand on hip.The growing and harvesting of cereal crops was an important agricultural industry in the early days of Sunbury's settlement by both the Indigenous People and Europeans.A non-digital photograph black and white photograph of eleven men gathering hay with the aid of a steam traction engine in a wide open valley. A hillside in the distance has been terraced and there is a house on the hill in the distance.the nook, terence o'brien, andy burke, mr. heath, michael dillon, philratile, goonawarra, vineyards -

Merbein District Historical Society

Merbein District Historical SocietyPhotograph, Carting out the fruit on H.R. Curtis' block, unknown

fred curtis, picking, grapes harvest, fruits, h.r. curtis -

Merbein District Historical Society

Merbein District Historical SocietyPhotograph, Raking out the fruit on H.R. Curtis' block, c.1946

charlie king, marjorie curtis, picking, grapes harvest, fruits, h.r. curtis -

Merbein District Historical Society

Merbein District Historical SocietySlide, Grape Pickers, unknown

grape harvest, picking -

Merbein District Historical Society

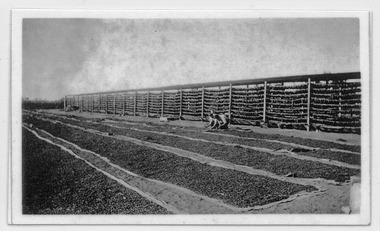

Merbein District Historical SocietyPhotograph, Drying grapes on hessians, 1937

grape harvest - dried fruit -

Merbein District Historical Society

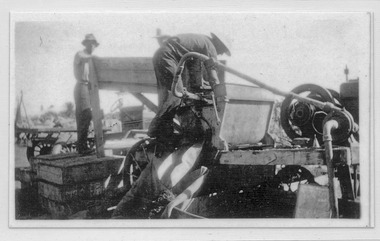

Merbein District Historical SocietyPhotograph, Dipping dried fruit, 1937

grape harvest - dried fruit -

Merbein District Historical Society

Merbein District Historical SocietyPhotograph, Dipping dried fruit, 1937

grape harvest - dried fruit -

Merbein District Historical Society

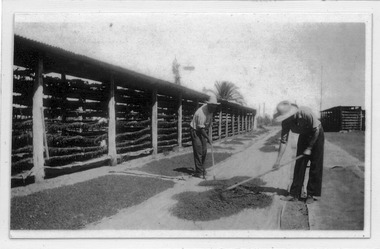

Merbein District Historical SocietyPhotograph, Raking out dried fruit, 1937

grape harvest - dried fruit -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesNewspaper - Newspaper Cutting, The Herald, Burnley Horticultural College, c. 1932

Photographs from newspapers. (1) "How to prune fruit trees was demonstrated by Mr. J. Farrell, orchard superintendent of the Agricultural Department, to students from the Teachers' Training College, who visited the the Horticultural College at Burnley yesterday." (2) "The Harvester Girl cutting the oats at Burnley Horticultural School today." (3) "7 foot delphinium." (4) "Bringing in the Sheaves." (5) "Twin Cucumbers," from the "Herald" 16/2/32.pruning, j. farrell, students, teachers, burnley horticultural college, teacher's training college, harvesting oats, students working outside, cucumbers, delphiniums, fruit trees -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionRakehoe (McLeod Tool)

Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts. However, its believed the now common Rakehoe is an Australian variation of the American McLeod Tool which was developed in 1905 by forest ranger Malcolm McLeod of the Sierra National Forest. The late Athol Hodgson advised that predecessors, Reg Torbet who had been the Chief Fire Officer for the Forests Commission from 1948-1956, along with his QLD counterpart Clive Price, went in late 1951 as Australian delegates on a 10 week fire study tour of Nth America organised by the United Nations. They came back with a couple of McLeod tools from Canada. Cam MacLeod (different spelling) had been the Head of Fire Research for the Canadian Forest Service at the time and had supplied them. The tools were ideal for deciduous forests in the eastern provinces and Clive arranged to have them manufactured in QLD. The Rakho, as it was then spelled, was first issued to FCV crews 65 years ago in 1955-56. The American Pulaski had been trialled, but never found favour with Australian firefighters.Rakhoeforests commission victoria (fcv), hand tools, forest harvesting, bushfire -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionLog Branding Hammers (various)

Metal branding hammers were the most common way to control the sale and movement of hardwood timber produce like logs, railway sleepers, fence posts, and poles from Victorian State forests. Royalty was also paid on this basis. Hammers most commonly had a crown stamp on one end with a unique number in the middle which identified its owner, and a crows foot or broad arrow on the other. The broad arrow was a symbol traditionally used in Britain and its colonies to mark government property. Other local configurations were used by sawmillers, post cutters and pulpwood contactors. Forest regulations state that an authorised officer may use the crown mark to identify produce which has been sold and may be removed from the forest, whereas the broad arrow can be used to brand and mark trees which are not to be felled, or to indicate forest produce which has been seized. Hammers were traditionally only ever issued to forest officers and were an important, and closely guarded tool-of-trade. They were not transferred between staff and lending hammers was not permitted. But it was an onerous task for staff to hammer and tally hundreds of logs, or thousands of fence posts each week, so in about 1990 a system was introduced whereby hammers were allocated to logging contractors to grade logs and tally them instead. But there was still spot checking by authorised officers. A register was kept, and contractors paid a substantial deposit to make sure they didn't lose them, but they occasionally turn up by fossickers with metal detectors. While branding hammers are still used in some smaller locations, plastic tags and barcodes are now more common.Log Grading hammersforests commission victoria (fcv), hand tools, forest harvesting -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionFire beater (canvas)

Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts. However, its believed the now common Rakehoe is an Australian variation of the American McLeod Tool which was developed in 1905 by forest ranger Malcolm McLeod of the Sierra National Forest. The late Athol Hodgson advised that predecessors, Reg Torbet who had been the Chief Fire Officer for the Forests Commission from 1948-1956, along with his QLD counterpart Clive Price, went in late 1951 as Australian delegates on a 10 week fire study tour of Nth America organised by the United Nations. They came back with a couple of McLeod tools from Canada. Cam MacLeod (different spelling) had been the Head of Fire Research for the Canadian Forest Service at the time and had supplied them. The tools were ideal for deciduous forests in the eastern provinces and Clive arranged to have them manufactured in QLD. The Rakho, as it was then spelled, was first issued to FCV crews 65 years ago in 1955-56. The American Pulaski had been trialled, but never found favour with Australian firefighters.Fire Beater (canvas) 1930s designforests commission victoria (fcv), hand tools, forest harvesting, bushfire -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionCutting Wedges

Used to hammer into a saw cut when falling treesThree types of cutting wedges used when falling treesforests commission victoria (fcv), forest harvesting, hand tools -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionPulaski

Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts. However, its believed the now common Rakehoe is an Australian variation of the American McLeod Tool which was developed in 1905 by forest ranger Malcolm McLeod of the Sierra National Forest. The late Athol Hodgson advised that predecessors, Reg Torbet who had been the Chief Fire Officer for the Forests Commission from 1948-1956, along with his QLD counterpart Clive Price, went in late 1951 as Australian delegates on a 10 week fire study tour of Nth America organised by the United Nations. They came back with a couple of McLeod tools from Canada. Cam MacLeod (different spelling) had been the Head of Fire Research for the Canadian Forest Service at the time and had supplied them. The tools were ideal for deciduous forests in the eastern provinces and Clive arranged to have them manufactured in QLD. The Rakho, as it was then spelled, was first issued to FCV crews 65 years ago in 1955-56. The American Pulaski had been trialled, but never found favour with Australian firefighters.Pulaski Fire Tool Combines an axe and a grubbing hoe. Digging end and cutting end with short wooden handleforests commission victoria (fcv), hand tools, forest harvesting, bushfire -

Stawell Historical Society Inc

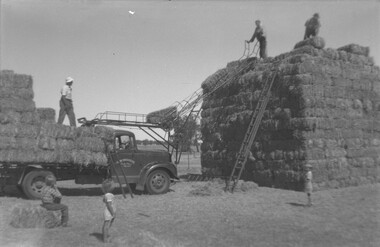

Stawell Historical Society IncPhotograph, Hay Bale Stacking at North Plains, part of old Carrs Plains Property

Bail Elevator loading hay bales from truck c1955Truck and machinery stacking rectangular Straw Hay BalesF W Moodie, North Plains, Stawellfarming, harvesting -

Department of Energy, Environment and Climate Action

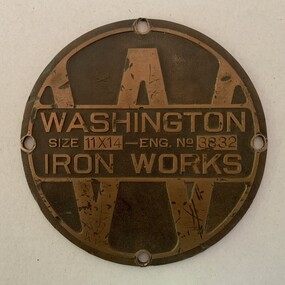

Department of Energy, Environment and Climate ActionWashington Winch - identification Plate

The Washington Winch sits deep in the forest east of Swifts Creek and is the last one of its particular type left in Australia. It was made by the Washington Iron Works company in Seattle. This unique winch was one of two machines imported in 1920 to operate in the Karri forests of WA. Both machines were later purchased by the Forests Commission after the 1939 bushfires for salvage logging at Toorongo to drive elaborate "high lead" cable systems. This particular machine was later sold to Jack Ezard from Swifts Creek in 1959 where it operated on its current site until about 1961. The fate of the second machine is unknown. It was possibly cannibalised for parts. The Ezards were innovative sawmillers who introduced high lead logging into Victoria. They had owned and operated sawmills in the Warburton area from 1907, before shifting to Erica in Gippsland in 1932. Bulldozers and powerful logging trucks eventually made steam and the Washington Winch redundant. The winch is listed on the State Heritage Register. Only one of its kindBrass identification plate recovered from the Washington Winch near Swifts Creek 21 cm in diameter11 x 14 refers to the double drums The serial number is assumed to be 3832forest harvesting -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Thresher drawn by Bullocks

Long team of bullocks pulling a threshing machine. Two people behind the threshing machine on left side.Long team of harnessed bullocks pulling machine with two people standing behind the farm machine.stawell rural harvesting -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Horse drawn plough

Horse drawn plough in rural setting.Three horses, two bay and one grey, pulling a plough with a person on the back in rural scene. stawell rural harvesting -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Horse drawn wagon with teamster

Horse drawn wagon with teamster standing beside the team of horses.Blurred B/W photograph with person standing beside a team of four horses, three bay and one grey.stawell rural harvesting -

Victorian Railway History Library

Victorian Railway History LibraryBook, Daddow, Vivian, The Puffing Pioneers - and Queensland's Railway Builders, 1975

INTRODUCTION Until well into the twentieth century, driver, fireman and guard — with a locomotive — set out on something resembling a safari. Tucker boxes crammed with food, a change of clothing, a roll of blankets, and armed with a sheaf of time-tables, they worked trains hither and thither not to return home for almost a week. But the passing of time, plus union pressure, brought an end to the need for "waltzing Matilda". Not only blankets but sheets, pillow slips, then later mosquito nets, along with other aids to civilized living, were provided by the Department in living quarters away from home. Few wives took kindly to the chore of selecting and preparing food and packing tucker boxes. Railwaymen seeking board and lodgings in a new depot could receive a set-back by being told "no tucker boxes packed". Until pooling of locomotives in depots became the order, a driver and fireman had "their own engine", and great was the competition between engine crews to display the best groomed horse. Much time might be spent outside rostered working hours cleaning their engine with kerosene and polishing with tallow and bath brick. So spotless and sparkling were some that a proud engineman would say a clean white handkerchief could be rubbed even over a hidden part. While miners talked of what made their day, farmers discussed crops and harvests, seamen their ships, and trainers and jockeys their horses, wherever steam men gathered, discussion soon turned to locomotives and the trains they hauled. Like jockeys with their mounts, iron horses with excellent traits were praised while those with annoying peculiarities were criticized and remedies suggested. Methods of firing to get best results from slow steaming locos were debated. Driver warned driver of weaknesses found in locomotives on recent "trips", spoke of developing defects calling for close attention — this one is "knocking Badly on one side", that one "priming badly (give her a good blow down before leaving the shed)", another with a "big end inclined to run hot", one with "a lot of slop in the boxes", one "getting down on the springs", or the sloth that was slow pulling on steep climbs to the chagrin of a driver striving to run on time. Things of no small concern when handling a locomotive on a train for a shift of maybe eight hours straight, or ten, even twelve, and on occasions longer. Foreknowledge of the particular loco allotted his train on the next job could fill the preceding hours for a driver or fireman with pleasant contentment, or with nagging trepidation and disgust……index, ill, p.217.non-fictionINTRODUCTION Until well into the twentieth century, driver, fireman and guard — with a locomotive — set out on something resembling a safari. Tucker boxes crammed with food, a change of clothing, a roll of blankets, and armed with a sheaf of time-tables, they worked trains hither and thither not to return home for almost a week. But the passing of time, plus union pressure, brought an end to the need for "waltzing Matilda". Not only blankets but sheets, pillow slips, then later mosquito nets, along with other aids to civilized living, were provided by the Department in living quarters away from home. Few wives took kindly to the chore of selecting and preparing food and packing tucker boxes. Railwaymen seeking board and lodgings in a new depot could receive a set-back by being told "no tucker boxes packed". Until pooling of locomotives in depots became the order, a driver and fireman had "their own engine", and great was the competition between engine crews to display the best groomed horse. Much time might be spent outside rostered working hours cleaning their engine with kerosene and polishing with tallow and bath brick. So spotless and sparkling were some that a proud engineman would say a clean white handkerchief could be rubbed even over a hidden part. While miners talked of what made their day, farmers discussed crops and harvests, seamen their ships, and trainers and jockeys their horses, wherever steam men gathered, discussion soon turned to locomotives and the trains they hauled. Like jockeys with their mounts, iron horses with excellent traits were praised while those with annoying peculiarities were criticized and remedies suggested. Methods of firing to get best results from slow steaming locos were debated. Driver warned driver of weaknesses found in locomotives on recent "trips", spoke of developing defects calling for close attention — this one is "knocking Badly on one side", that one "priming badly (give her a good blow down before leaving the shed)", another with a "big end inclined to run hot", one with "a lot of slop in the boxes", one "getting down on the springs", or the sloth that was slow pulling on steep climbs to the chagrin of a driver striving to run on time. Things of no small concern when handling a locomotive on a train for a shift of maybe eight hours straight, or ten, even twelve, and on occasions longer. Foreknowledge of the particular loco allotted his train on the next job could fill the preceding hours for a driver or fireman with pleasant contentment, or with nagging trepidation and disgust…… railroads -- queensland -- history, railroads -- australia -- queensland -- history.