Showing 353 items matching "polishing iron"

-

Unions Ballarat

Unions BallaratLeaflets, pamphlets, periodicals, newspapers, cuttings and roneoed material retained by the Council, 1891-1962

TBATBATwo boxes, paper. 1. Anti-Hanging Committee - regarding hanging. 1962. 2. Ballarat Banking Co. Ltd. Chairman's address and 145th report. August 1954. 3. Country Municipal Association circular regarding conference on centralisation, Ballarat. 22 November 1916. 4. Geelong Town Band's weekly performance programme. n.d. 5. Ironmasters' Association of Victoria rules and regulations agreed upon at the General Iron Trades' Conference, Melbourne. 1891. 6. Melbourne Eight Hours Anniversary programme. 1901. 7. Museum of Applied Science of Victoria, on gas from our brown coal. n.d. 8. New Australian Trade Unionist Committee regarding rally to protect shooting of Polish workers. 195-? 9. Circular from Ballarat Trades and Labour Council to Ironmoulders' Society regarding the Congress. 1891. 10. List of subjects to be discussed at Congress. 11. Circular from Melbourne Trades Hall Council regarding financial help for Congress. 1891. 12. Reports of Standing Orders Committee appointed by the Congress, 23-29 April 1891. 13. Trade Mark Committee report. 14. Committee on Federation report. 15. Draft scheme of Federation (Australasian Federation of Labor). 16. Draft scheme of Federation (Australasian Federation of Labor) to the Labour Councils and Unions of Australasia. (2 copies.) 17. Asian and Pacific Regions Peace Conference, Peking, October 1962. Report on Peking, Melbourne. 1962. (2 copies). 18. Australian Bureau of Census and Statistics. Labour and Industrial Statistics, Melbourne. 1911. 19. Australia. Laws, Statutes, etc Trade Marks Bill, 1905. Workers' Trade Marks. Melbourne, 1905. 20. Australian Council of Trade Unions. Agenda paper for ... Congress, 1953. Melbourne, 1953. 21. Australian Labor Party. Work of the Labor government. Melbourne, 1928. 22. Australian Textile Union, Victorian Branch. Wages Sheet. Melbourne, 1953? 23. Baker, W.A. The Commonwealth Basic Wage. 1907-1953. Sydney, 1953? 24. Building Workers' Industrial Union. Building Workers support your convention. n.p. 1954? 25. Carters' and Drivers' Union. Committee of Management. Important to members of Carters and Drivers' Union. Melbourne, 1936. 26. Dougherty, Tom. Santamaria unmasked. Melbourne, 1954? 27. Eight Hours' Anniversary Sports Programme, 1893. Ballarat 1893. 28. Eight Hours' Anniversary Programme, 1894. Ballarat, 1894. 29. Fadden, Arthur W. The menace of political banking. Sydney, 1945. 30. Federated Clerks' Union, Victoria Branch. The Fennessy Story. The Braun Story. n.p., 1954. 31. Federated Clerks' Union, Victoria Branch. Manifesto, n.p., 1955. 32. Greater Ballarat Association. Seventeenth annual report. Ballarat, 1954. 33. Langridge, H.E. Employers in the Labor Party. Melbourne, 1914. 34. Metal Trades Federation. National Conference of Federal Council and delegates from State branches. Sydney, 1960. 35. Municipal Association of Victoria. Arbitration aware regarding employment of members of the Municipal Officers Association of Australia. Melbourne, 1950. 36. Municipality of the Town of Ballarat East. Annual report, 1919. Ballarat, 1919. 37. Plumbers and Gasfitters Employees' Association of Australia. Melbourne Branch. Why did Menzies abdicate when he had a working majority and 18 months to go? Melbourne, 1955? 38. Plumbers and Gasfitters Employees Union of Australia, Melbourne Branch. Who are the wreckers in the Australian Labor Party? Melbourne, 1955. 39. Spence, W.G. The ethics of New Unionism. Sydney, 1892. (42 copies) 40. Trades Hall Council, Melbourne. Statement of accounts, 1959. Melbourne, 1959. 41. Universal Business Directories (Australia) Pty. Ltd. Home edition for Ballarat. Melbourne, 1954. 42. Victoria, Apprenticeship Commission. Twenty-seventh annual report. Melbourne, 1956. 43. Victorian Labor College. Labor Colleges. Melbourne 191? (3 copies) 44. W.F. Williams. An appeal to the workers of Victoria. n.p., 19?? 45. Workers' Industrial Union of Australia. Preamble, classification and rules. Melbourne 1919? 46. ACTU Bulletin, 1955, Vol 2, No. 2 47. Amalgamated Engineering Union monthly journal, 1954, No. 3. March 48. American Economist, (New York), 1893, Vol 12, No 12, September 49. Australian Worker, (Sydney), 1955, Vol 64, No. 10, May; No. 15, September (held by ANU and at Trove online) 50. Building Workers' Organiser, official organ of the Building Trades Federation, 1954, June 51. Bulletin issued by the Economic Information Service, Melbourne. No. 2 1954, Nos. 10, September; 13 August; 1956, No 14, January 52. Ballarat Courier, 1890, Vol 46, No. 7096, April 53. Ballarat Star, 1888, Vol 33, No. 95, April 54. The Clerk, official journal of Federated Clerks' Union, Victorian Branch, 1955, Vol 10, No. 2, February/March 55. Common Cause, official journal of the Miners' Federation of Australia 1954 Vol 19, No. 10, March; No. 12, April 1955 Vol 20, No. 12, April; No. 19, May 1955 Vol 20, No. 23, June; No 28 July 1955 Vol 20, No. 29, August 1956 Vol 21, No. 17, May 56. Evening Echo, Ballarat, 1915, No. 6673, September 57. Evening Post, Ballarat, 1889, Vol 38, No. 6326, March 58. Industrial Herald, published by Labor Press, Geelong 1952 Vol 34, No. 35, June 1954 Vol 36, No. 20, March; No. 23, April 1954 No. 36, July; No. 39 July 1958 Vol 40, No. 19, March 59. Labor Call, published by Industrial Printing and Publicity Co., Melbourne. 1953, Vol 46, No. 2417, September 60. Labor Supplement. 1952, November 1954, February; March 61. Light, Ballarat diocesan journal. 1955, September. 62. Locomotive journal, published by the Australian Federated Union of Locomotive Enginemen. 1954, Vol. 16, No. 4, January. 63. People's Tribune Supplement, ed. by E.E. Jones, Melbourne. 1886, Vol 5, No. 20, April. 64. Railways' Union Gazette, published by J.D. Michie, Melbourne. 1919, June, Frank Byett in memoriam edition. 65. Rehab News issued by Central Ex-Servicemen's Office, Melbourne. 1946, Vol 2, No. 30, May. 66. Sheet Metal Workers, official organ of the Sheet Metal Working, Agricultural Implement and Stovemaking Union of Australia, Sydney. 1954, No. 107, February. 67. Socialist Comment, Socialist Party of Australia, Melbourne. 1937, No. 2, February. 68. Tocsin, A.L.P. Victorian Branch. 1955?, No. 2, October; No. 4, December. 1956, No. 5, February. 69. Tribune, CPA Sydney. 1965, No. 958, August. 70. UN World, published by Egbert White, New York. 1948, Vol 2, No. 11, December. 71. Miscellaneous newspaper cuttings. Posters 72. Eight Hours' Anniversary, Ballarat, 22 April 1892. 73. Eight Hours' Anniversary, Ballarat, 21 April 1894. 74. Eight Hours' Anniversary, Ballarat, 21 April 1913. 75A. Eight Hours' Anniversary, Ballarat, 3 April 1922. 75B. Electoral Rolls, persons entitled to be enrolled and to vote, 1922. 76. Progress, prospectus of debentures to publish a daily Labour paper to be called "Progress". 1904, Vol 1, No. 1, December. Cards 87. Smoke night social 88. Bi-election 89. How to vote card Roneoed material 77. Circular letter regarding new morning newspaper. n.d. 78. Circular letter from Trades Hall Council, Melbourne. 21 March 1955. 79. Article, History of the recent ALP dispute. n.d. 80. Article: What is freemasonry (from Ballarat St. Patrick's Gazette, October 1854). (2 copies) 81. Information summary of HRH Duke of Edinburgh's study conference on the human problems of industrial communities. ALP Broadcasts from Station 3KZ 82. Incentive payments by Norman A. Gibbs. 17 August 1953. 83. Escalating wages by F.J. Riley. 25 February 1954. 84. Margins by F.J. Riley. 4 March 1954. 85. Freezing margins by F.J. Riley. 17 March 1954. 86. The struggle across the Ages (No. 2) by F.J. Riley. 7 May 1954. ballarat trades and labour council, ballarat trades hall, unions, anti-hanging committee, hanging, ballarat banking co. ltd., country municipal association, geelong town band, ironmasters' association of victoria, general iron trades' conference, museum of applied science of victoria, new australian trade unionist committee, ironmoulders' society, melbourne trades hall council, btlc, intercolonial trades and labor union congress, 7th., trade mark committee report, committee on federation report, australasian federation of labor, asian and pacific regions peace conference, australian bureau of census and statistics, abs, australian bureau of statistics, trade marks bill, actu, australian council of trade unions, australian labor party, alp, australian textile union, w.a. baker, building workers' industrial union, carters and drivers' union, tom dougherty, eight hours' anniversary sports programme, labour and industrial statistics, workers' trade marks, building workers, santamaria, arthur w. fadden, federated clerks' union, fennessy, braun, greater ballarat association, h.e. langridge, metal trades federation, municipal association of victoria, ballarat east, plumbers and gasfitters employees' union of australia, menzies, w.g. spence, new unionism, universal business directories, victoria apprenticeship commission, victorian labor college, w.f. williams, workers' industrial union of australia. preamble, classification and rules. melbourne, 1919?, amalgamated engineering union, american economist, australian worker, building workers' organiser, building trades federation, economic information service, the courier, ballarat star, the clerk, common cause, miners' federation of australia, evening echo, evening post, industrial herald, labor call, labor supplement, light journal, locomotive journal, australian federated union of locomotive enginemen, people's tribune supplement, railways union gazette, frank hyett, rehab news, central ex-servicemen's office, sheet metal worker, sheet metal working, agricultural implement and stovemaking union of australia, socialist comment, tocsin, tribune, un world, eight hour anniversary, electoral rolls, progress, freemasonry, st patrick's gazette, hrh duke of edinburgh, incentive payments, wages, f.j. riley -

Buninyong & District Historical Society

Buninyong & District Historical SocietyPhotograph - Original B/W Photograph, Clive Brooks, Buninyong Cemetery, Monument for George Innes and his daughter, 9/4/1994

Part of series to record changes in BuninyongGrave of Buninyong Pioneer.A B/W and a colour photo, monument, polished granite, pillar on engraved plinth, urn cap, cast iron fence, for early settler George Innes and his daughter.. in Buninyong Cemetery.buninyong, cemetery, headstone, graves, innes, king of splitters, pound, buninyong defiance mine -

Buninyong & District Historical Society

Buninyong & District Historical SocietyPhotograph - Original B/W Photograph, Clive Brooks, Buninyong Cemetery, graves of (Francis) Moss and Tresise, 9/4/1994

Part of series to record changes in BuninyongGrave of Buninyong Pioneer.A B/W and a colour photo, monument, polished granite, pillar on engraved plinth, urn cap, cast iron fence, for early settler George Innes and his daughter.. in Buninyong Cemetery.buninyong, cemetery, headstone, graves, francis moss, tresise, apples -

Mont De Lancey

Mont De LanceyBed, c1900

Mass produced. Owned and used by Wandin Sebire. Iron framed "4 poster" bed with polished steel decorative work. Steel - mesh and wooden frame, includes mattress and bolster.bed, bedroom suites -

Mont De Lancey

Mont De LanceyBall and Ring Bunion Stretcher

Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron ball and ring bunion stretcher.boot stretchers -

Mont De Lancey

Mont De LanceyLasts

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.2 x wooden Lasts (Adult size) with metal screws. 1 x cast iron Last (Child size) with holes in base and a removable elevated top.Wooden: Size 6 (80) Cast Iron: Size 9 Dbootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Last on a four-footed base/stand. Last is removable from stand, and can be moved into different positions on top of the stand.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron double-ended Lap Last.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyHeel and Sole Cutters, Mobbs & Lewis

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron pieces - 1 Heel cutter and 1 Sole cutter.bootmaking tools -

Mont De Lancey

Mont De LanceyHalf-Moon Knife

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron handmade knife with a wooden handle, attached by a nail.bootmaking tools, cutting tools -

Mont De Lancey

Mont De LanceyCircular Welt Cutter, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Welt Cutter with a wooden handle. -

Mont De Lancey

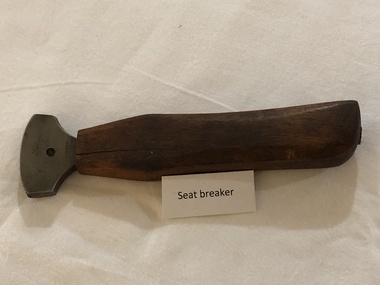

Mont De LanceySeat Breaker

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Seat Breaker with a wooden handle. -

Mont De Lancey

Mont De LanceyFudge Wheel

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Fudge Wheel with a wooden handle. -

Mont De Lancey

Mont De LanceyHammer and 2 Knives/Cutters

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron hammer with a wooden handle. Larger Cutter/knife, cast iron with a wooden handle. Smaller Cutter/knife, cast-iron with a wooden handleHammer: "London" Larger knife: "Pettys Sheffield".bootmaking tools, hammers, cutting tools -

Mont De Lancey

Mont De LanceyBootmaking Equipment

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Heel plate. Miscellaneous Sole plates. Hobnails and a tin of wooden sprigs.bootmaking tools, nails -

Mont De Lancey

Mont De LanceyHeel Shave and 2 Heels

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Heel Shave. 1 larger Leather heel piece. 1 smaller Leather heel piece.bootmaking tools, shaves -

Mont De Lancey

Mont De LanceyAwls and Awl Tips

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.5 x Cast iron Awls, all with wooden handles. 1 x container of spare Awl metal tips.bootmaking tools, awls, piercing tools -

Mont De Lancey

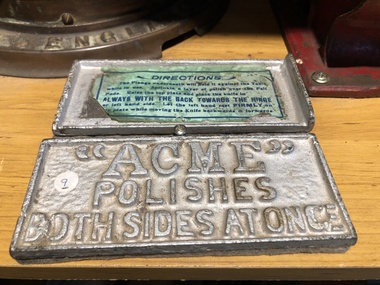

Mont De LanceyKnife Cleaner, Circa 1910

Cast iron static type knife cleaner'"Acme" Polishes Both Sides At Once'knife cleaners -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Flat or sad iron, c1900

Sad irons, also called flat irons or smoothing irons, are shaped pieces of metal that are flat and polished on one side and have a handle attached to the other, created for the purpose of de-wrinkling fabric. “Sad” is an Old English word for “solid,” and the term “sad iron” is often used to distinguish the largest and heaviest of flat irons.This iron is representative of the domestic appliances used throughout Australia up until electricity became widely available for domestic use.A small cast iron flat iron. The triangular shape of the iron made it easier to iron around buttonsdomestic appliances, flat irons, sad irons -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Pair of Flat Irons, c1890s - 1910

Sad irons, also called flat irons or smoothing irons, are shaped pieces of metal that are flat and polished on one side and have a handle attached to the other, created for the purpose of ironing fabric. “Sad” is an Old English word for “solid,” and the term “sad iron” is often used to distinguish the largest and heaviest of flat irons. They often had a trivet on which to rest the hot iron. These irons are representative of domestic appliances used prior to the advent of electricity in the home.A pair of triangular flat irons. They are made of solid cast iron with hollow iron handles. Flat irons were commonly heated on trivets in front of open fires, or on the tops of closed ranges. They were made in numbered series which related to their size, but there did not appear to be any standardisation in the series between manufacturers.domestic appliances, flat irons, sad irons -

Woodend RSL

Woodend RSLKnife sheath

This knife and scabbard belongs to Lindsay Fankhouser, who wore it on his ankle when he served as an engineer/ crewman in the RAAF (Iroquois and Hercules) during the Vietnam war. He used this knife many times a day while he was serving. It is a brown leather knife sheath, with a decorative front and two canvas straps attached at the back. The shorter strap is located at the bottom of the sheath and the longer strap is located just below the belt loop. Both straps are fixed in place with stitching. The top strap has a square of stitching, while the bottom strap has two lines of stitching that follows the stitching of the sheath. The belt loop is at the top of sheath and is a fixed flap of leather that is folded across the top and also holds the handle of the knife in place using a circular hole that fits around the butt of the knife. The bottom canvas strap has three adjustable brass male press studs on the left side as well as the fixed female one on the right. The top canvas strap has four adjustable brass male press studs on the right side as well as as the fixed female one on the right. The sheath is held together by stitching and five iron rivets. There is one on the point of the sheath, two on either side of the top, and two more 51mm below the top two. 46mm above the sheath, there are another two iron rivets on either side. Above that on the holding flap, there are two iron rivets just above the circular hole on either side. On the flap, around the hole there are three brass flat-headed split pins, one on either side and one on the front. At the top of the sheath, above the decorative embossing, there is a dark brown jagged cut strip of fixed leather. All the leather on the object is a reddish-brown, while the canvas and stitching is light beige. The end stitching on the canvas straps is dark grey. The front of the sheath is polished leather, while the back is rough.On back of belt loop flap, there is an embossd manufactuing patent number; PATENT Nr152.463 On face of the sheaf there embossed decoration. It depicts a lion with stylised decorative foliage and above the lion there is a fleur de lise. Above that it reads Soallingen Norge.norway, norge, soallingen, knife, small knife, hunting, scabbard, sheath, vietnam, lindsay fankhouser, raaf -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCraft - Ship Model, Joseph Conrad, 20th century

The ship model of the Joseph Conrad represents the craft of ship model making, which has been enjoyed by many people over the years. Although the model is made from modern materials, it shows the elements of a sailing ship of a bygone era. About the sailing ship JOSEPH CONRAD: - The vessel Joseph Conrad began as the Danish iron-hulled sailing ship Georg Stage, launched in 1882. It was used as a training ship for Danish sailors. In 1905, while docked in Copenhagen, the ship was rammed by a larger ship, and 22 boys were killed while sleeping in the hull. The ship was later raised and on guard during World War I. Alan Villiers was an Australian author of seafaring books as well as a sailor. He bought the wooden sailing ship George Stage and renamed it Joseph Conrad in honour of the renowned Polish-born maritime author and once the captain of the barque Otago. In 1934 Villers sailed the ship on a two-year voyage around the world. In 1936, it was sold to an American, who later donated it for use again as a training ship. After World War II the ship was no longer used, and in 1947 it was transferred to the Mystic Seaport Museum for training use again as well as an exhibit. JOSEPH CONRAD (1857-1927): - Joseph Conrad was Polish-born and became a British subject in 1886. He was a renowned marine fiction writer and also, for a short time, a mariner and Captain. As a boy of 13 years old, Joseph Conrad desired to be a sailor. At 19, he joined the British merchant marines, working in several roles. He eventually qualified as a captain but only served in this role once, from 1888-89, when he commanded the barque Otago sailing from Sydney to Mauritius. In 1889 he also began writing his first novel, Almayer’s Folly. He retired from life as a mariner in 1894, aged 36. Conrad’s visits to Australia from 1878 to 1982, and his affection for Australia, were later commemorated by a plaque in Circular Quay, Sydney. Conrad continued as an author. It is said that many of the characters in his books were inspired by his maritime experiences and the people he had met. By the end of his life, he had completed many stories and essays, and 19 novels, plus one incomplete novel titled ‘Suspense’ that was finished and published posthumously. Shortly before he passed away, in 1924, Conrad was offered a Knighthood by Prime Minister Ramsay MacDonald for his work but declined the offer. The ship model represents the design of sailing ships built in the 1880s and can be used as a reference in understanding the construction of the ships of the Victorian era. The model is important for its connection to the vessel Joseph Conrad which was used as a training ship for seafarers, and even now is used to teach maritime skills, as well as an exhibit, in the maritime museum, Mystic Seaport. The model's name is significant for its association of its name with the famed early 20th-century maritime author, Joseph Conrad.Ship model; A three-masted sailing ship named the Joseph Conrad, with cabins on deck, lifeboats, a ladder on the side and a figurehead on the bow. The hull is black at the top and red below. The ship's name is painted on both sides of the bow. JOSEPH CONRADflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, joseph conrad, captain joseph conrad, maritime author, marine author, nautical author, sailor, seafarer, ship model, two-masted ship, iron hull, sailing ship, georg stage, 1882 ship, danish ship, training ship, boys killed, alan villiers, ship joseph conrad, mystic seaport, museum ship, otago -

Victorian Railway History Library

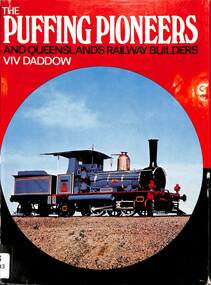

Victorian Railway History LibraryBook, Daddow, Vivian, The Puffing Pioneers - and Queensland's Railway Builders, 1975

INTRODUCTION Until well into the twentieth century, driver, fireman and guard — with a locomotive — set out on something resembling a safari. Tucker boxes crammed with food, a change of clothing, a roll of blankets, and armed with a sheaf of time-tables, they worked trains hither and thither not to return home for almost a week. But the passing of time, plus union pressure, brought an end to the need for "waltzing Matilda". Not only blankets but sheets, pillow slips, then later mosquito nets, along with other aids to civilized living, were provided by the Department in living quarters away from home. Few wives took kindly to the chore of selecting and preparing food and packing tucker boxes. Railwaymen seeking board and lodgings in a new depot could receive a set-back by being told "no tucker boxes packed". Until pooling of locomotives in depots became the order, a driver and fireman had "their own engine", and great was the competition between engine crews to display the best groomed horse. Much time might be spent outside rostered working hours cleaning their engine with kerosene and polishing with tallow and bath brick. So spotless and sparkling were some that a proud engineman would say a clean white handkerchief could be rubbed even over a hidden part. While miners talked of what made their day, farmers discussed crops and harvests, seamen their ships, and trainers and jockeys their horses, wherever steam men gathered, discussion soon turned to locomotives and the trains they hauled. Like jockeys with their mounts, iron horses with excellent traits were praised while those with annoying peculiarities were criticized and remedies suggested. Methods of firing to get best results from slow steaming locos were debated. Driver warned driver of weaknesses found in locomotives on recent "trips", spoke of developing defects calling for close attention — this one is "knocking Badly on one side", that one "priming badly (give her a good blow down before leaving the shed)", another with a "big end inclined to run hot", one with "a lot of slop in the boxes", one "getting down on the springs", or the sloth that was slow pulling on steep climbs to the chagrin of a driver striving to run on time. Things of no small concern when handling a locomotive on a train for a shift of maybe eight hours straight, or ten, even twelve, and on occasions longer. Foreknowledge of the particular loco allotted his train on the next job could fill the preceding hours for a driver or fireman with pleasant contentment, or with nagging trepidation and disgust……index, ill, p.217.non-fictionINTRODUCTION Until well into the twentieth century, driver, fireman and guard — with a locomotive — set out on something resembling a safari. Tucker boxes crammed with food, a change of clothing, a roll of blankets, and armed with a sheaf of time-tables, they worked trains hither and thither not to return home for almost a week. But the passing of time, plus union pressure, brought an end to the need for "waltzing Matilda". Not only blankets but sheets, pillow slips, then later mosquito nets, along with other aids to civilized living, were provided by the Department in living quarters away from home. Few wives took kindly to the chore of selecting and preparing food and packing tucker boxes. Railwaymen seeking board and lodgings in a new depot could receive a set-back by being told "no tucker boxes packed". Until pooling of locomotives in depots became the order, a driver and fireman had "their own engine", and great was the competition between engine crews to display the best groomed horse. Much time might be spent outside rostered working hours cleaning their engine with kerosene and polishing with tallow and bath brick. So spotless and sparkling were some that a proud engineman would say a clean white handkerchief could be rubbed even over a hidden part. While miners talked of what made their day, farmers discussed crops and harvests, seamen their ships, and trainers and jockeys their horses, wherever steam men gathered, discussion soon turned to locomotives and the trains they hauled. Like jockeys with their mounts, iron horses with excellent traits were praised while those with annoying peculiarities were criticized and remedies suggested. Methods of firing to get best results from slow steaming locos were debated. Driver warned driver of weaknesses found in locomotives on recent "trips", spoke of developing defects calling for close attention — this one is "knocking Badly on one side", that one "priming badly (give her a good blow down before leaving the shed)", another with a "big end inclined to run hot", one with "a lot of slop in the boxes", one "getting down on the springs", or the sloth that was slow pulling on steep climbs to the chagrin of a driver striving to run on time. Things of no small concern when handling a locomotive on a train for a shift of maybe eight hours straight, or ten, even twelve, and on occasions longer. Foreknowledge of the particular loco allotted his train on the next job could fill the preceding hours for a driver or fireman with pleasant contentment, or with nagging trepidation and disgust…… railroads -- queensland -- history, railroads -- australia -- queensland -- history.