Showing 4741 items matching "read"

-

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - Staff Nott Street Primary School 1990, 1990

All teachers named below photograph. Colour photograph with 2 rows of teachers. The sign in front reads Nott Street Primary School Staff, 1990.education - primary schools, shirley heller, nott street primary school, nola jones, helen pruis, marilyn tulloch, pam park, sue gladman, nancy johnstone, lucia oukliez, debra stripeikis, ruth burgess-smith, carolyn withers, ron bowles, bart hopkins, diane moseley, jan snowden, sandy bassoukos -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - Staff Nott Street Primary School 1991, 1991

All teachers named below photograph. Colour photograph with 2 rows of teachers. The sign in front reads Nott Street Primary School Staff, 1991.education - primary schools, shirley heller, nott street primary school, nola jones, helen pruis, marilyn tulloch, nancy johnstone, debra stripeikis, ruth burgess-smith, diane moseley, sandy bassoukos, mary walker, bart hopkins, pamela park, oriana diamandis -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - Staff Nott Street Primary School 1992, 1990

All teachers named below photograph. Colour photograph with 2 rows of teachers. The sign in front reads Nott Street Primary School Staff, 1992.education - primary schools, shirley heller, nott street primary school, nola jones, helen pruis, marilyn tulloch, nancy johnstone, debra stripeikis, ruth burgess-smith, carolyn withers, ron bowles, bart hopkins, diane moseley, jan snowden, sandy bassoukos, jenny harding, julie ziakos, ouriana diamandis -

Port Melbourne Historical & Preservation Society

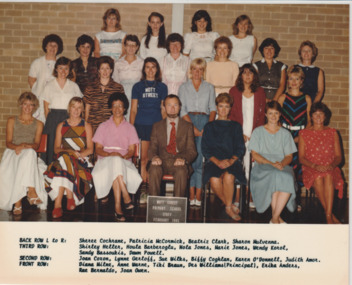

Port Melbourne Historical & Preservation SocietyPhotograph - Staff Nott Street Primary School 1985, 1985

All teachers named below photograph. Colour photograph with4 rows of teachers. The sign in front reads Nott Street Primary School Staff, 1985education - primary schools, shirley heller, nott street primary school, nola jones, sandy bassoukos, sherre cochrane, patricia mccormick, beatriz clark, sharon mulvenna, houla barberoglu, marie jones, wendy korol, dawn powell, sue wilkes, biffy coghlan, karen o'donnell, judith amor, diane milne, anne warne, tikki braun, des williams, erika anders, rae benaldo, joan owen, joan coxton, lynne gerloff -

Port Melbourne Historical & Preservation Society

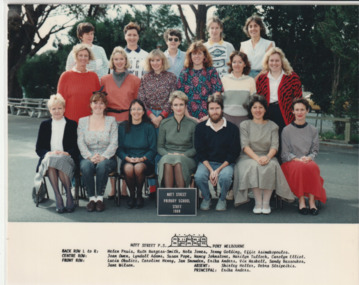

Port Melbourne Historical & Preservation SocietyPhotograph - Staff Nott Street Primary School 1989, 1989

All teachers named below photograph. Colour photograph with 3 rows of teachers. The sign in front reads Nott Street Primary School Staff, 1989.education - primary schools, nott street primary school, sandy bassoukos, erika anders, lucia okuliez, jane wilson, ruth burgess-smith, helen pruis, lyndall adams, carolyn elliot, jenny golding, effie assimakopoulos, susan pope, nancy johnstone, marilyn tulloch, caroline henry, jan snowdon, vin maskell -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Domestic Object - WHITE CHINA PLATE

White china plate showing a scene of Collins Street Melbourne, sticker on back reads from Dorothy Fields.domestic equipment, food consumption, plates -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - HANRO COLLECTION: HANRO GIRLS

Photograph. Black and White Photo of 7 of the girls from Hanro, markings on rear of photo read 'Hanro Girls'.organization, business, hanro girls, hanro -

Victorian Aboriginal Corporation for Languages

Victorian Aboriginal Corporation for LanguagesCD with Book, Sue Atkinson, Bartja and Mayila : Yurri's manung : Yurri's birthday, 2013

Three stories in the Yarn Strong Sista series of books read by Yorta Yorta elder Aunty Zeta Thomson.CDyorta yorta, barmah forest, juvenile fiction -

Wangaratta High School

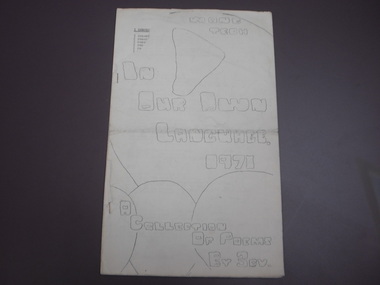

Wangaratta High SchoolWTS Student Creative writing book, 1971

White stapled booklet containing a collaboration of poems by students of Wangaratta Technical School. A drawing of balloons and text reads: WANG TECH IN OUR LANGUAGE 1971 A COLLECTION OF POEMS BY 3CV -

Wangaratta High School

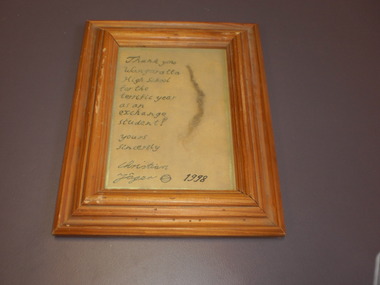

Wangaratta High SchoolWHS Framed letter, 1998

Small letter from a 1998 exchange student written on brown paper with a lock of hair included. Text reads:Thank you Wangaratta High School for the terrific year as an exchange student! yours sincerely, Christian Jager -

Wangaratta High School

Wangaratta High SchoolWHS Framed Certificate

White certificate with a beige, orange and blue border, mounted on cream backing and a brown wooden frame. Text reads:Certificate of Accreditation presented to Wangaratta High School by the minister for education and training for successfully meeting the standards for Performance and Development Culture Accreditation. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - PETER ELLIS COLLECTION: HOLDEN CAR

Colour photograph. White car. FJ Holden, (1954-1956). Back of photo reads: Peter Ellis's carperson, individual, peter ellis car -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - PETER ELLIS COLLECTION: BOY PLAYING GUITAR

Colour photgraph. Boy sitting on chair playing lute. Back of Photo reads: Anton Marrone Bgo Bank.photo, individual, male -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - PETER ELLIS COLLECTION: PETER ELLIS, 30th March, 1996

Colour photograph. Man holding knife. Cake on table. Peter Ellis. Back of photo reads: Peter's 50th.photo, individual, peter ellis -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - PETER ELLIS COLLECTION: EMU CREEK BUSH BAND

Black and white photograph. White edges. Emu Creek Bush Band. Back of photo reads: Emu Creek.entertainment, music, emu creek bush band -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - PETER ELLIS COLLECTION: BUSH BAND

Colour photograph. Bush band playing in front of big fawn shed. Back of photo reads: 20/1entertainment, music, bush band -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - PETER ELLIS COLLECTION: DANCING

Colour photograph. People dancing on bitumen in front of big fawn shed. Back of photo reads: 1A/2entertainment, dance, dance festival -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - PETER ELLIS COLLECTION: DANCING

Colour photograph. People dancing on wooden stage. Period style clothing. Back of photo reads:12/1entertainment, dance, bush dance -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - PETER ELLIS COLLECTION: DANCING

Colour photograph. People dancing on wooden stage in front of marquee. Flagpole. Back of photo reads: 9/1entertainment, dance, bush dance -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - PETER ELLIS COLLECTION: EMU CREEK BUSH BAND

Colour photograph. Emu Creek Bush Band. Instruments. Back of photo reads: Photo shoot - 1st CD.entertainment, music, emu creek bush band -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - PETER ELLIS COLLECTION: PETER ELLIS

Colour photograph. Peter Ellis no beard no glasses. John Williams. Back of photo reads: Peter minus beard.entertainment, music, musicians -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - PETER ELLIS COLLECTION: GROUP

Colour photograph. People seated at tables Peter Ellis laughing. Back of photo reads: The first photo of recognition.photo, person, peter ellis -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Booklet, British Army, Manual of Map Reading, Air Photo Reading and Field Sketching, Part III: Air Photo Reading, 1957, (Copy 1), 1956

A red cardboard cover with black information on the front. Top right hand corner reads WO Code No.9085british army, map reading, air photo reading, field sketching, booklet -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Booklet, British Army, Manual of Map Reading, Air Photo Reading and Field Sketching, Part III: Air Photo Reading, 1957 (Copy 2), 1956

A red cardboard cover with black information on the front. Top right hand corner reads WO Code No.9085british army, map reading, air photo reading, field sketching, booklet -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Booklet, British Army, Manual of Map Reading, Air Photo Reading and Field Sketching, Part II: Air Photo Reading, 1958, 1958

A red cardboard cover with black information on the front. Top right hand corner reads WO Code No.9484british army, map reading, air photo reading, field sketching, air auto reading, booklet -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Peter Bassett-Smith, 20th Anniversary of Eltham District Historical Society, afternoon tea in Senior Citizens' Centre, 10 October 1987, 10/10/1987

L-R: Mrs Beryl Read, Mrs Dorothy McBride, Mr Jock Read, Mrs Kath Stephenson, Mrs Joan AcklandColour photograph1987, activities, senior citizens' centre -

Vision Australia

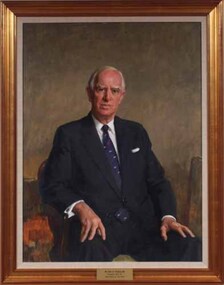

Vision AustraliaPainting - Artwork, Portrait of John Wicking, 1980

Framed portrait of John Wicking who was President of the Association for the Blind 1973-1984 as well as a generous benefactor. It is part of a series of paintings commissioned by the AFB Board to commemorate the work of past presidents of the organisation. Mr. Wicking wears a navy suit, white shirt and navy blue Kiwi tie. He was Managing Director and Chairman of Kiwi International when he was introduced to the Committee in 1971. With a natural air of authority, he was known to be both strong and wise. One of the first hurdles Mr Wicking faced following his election as President in 1973 was understanding the health service system and sorting out the differing views of committee members over recommendations for projects costing hundreds of thousands of dollars with no funds to implement them. The ten years of his Presidency were a time of exceptional growth and expansion. He was instrumental in acquiring an adjacent property to those already owned in Glenferrie Road in 1974 at a cost of $120,000, on which the Low Vision Clinic was erected – the first of its type in Australia. Land was also bought in both the metropolitan and country areas for future expansion. Day care centres were opened in Ballarat and Bendigo and new metropolitan services commenced. Mr Wicking formed a committee to explore the possibility of a radio station people unable to read standard print. As a result 3RPH commenced broadcasting in 1981. After his retirement as President, Mr. Wicking continued as a committee member until 1994. In 1995 he was instrumental in the establishment of the Tilly Aston Heritage Collection, on which he served as Chairman until sadly passing away in 2002. 1 art original in old gold frameThe plaque at the base of the painting reads 'Mr John O. Wicking AM / President 1973-1984 / Association for the Blind'. association for the blind, john wicking -

Flagstaff Hill Maritime Museum and Village

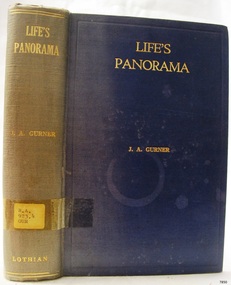

Flagstaff Hill Maritime Museum and VillageBook, Life's Panorama

Warrnambool's Mechanics' Institute (or Institution as it was sometimes called) was one of the earliest in Victoria. On 17th October 1853 a meeting was held where it was resolved to request the Lieutenant Governor of the Colony to grant land for the erection of a Mechanics' Institutes building. A committee was formed at the meeting and Richard Osburne chaired the first meeting of this committee. The land on the North West corner of Banyan and Merri Streets was granted but there were no funds to erect the building. The Formal Rights of the Warrnambool Mechanics' Institute's encompassed its aims and these were officially adopted in1859; "This Institution has for its object the diffusion of literary, scientific, and other useful knowledge amongst its members, excluding all controversial subjects, religious or political. These objects are sought to be obtained by means of a circulating library, a reading room, the establishment of classes, debates, and the occasional delivery of lectures on natural and experimental philosophy, mechanics, astronomy, chemistry, natural history, literature, and the useful and ornamental arts, particularly those which have a more immediate reference to the colony." The Warrnambool Mechanics' Institute opened its first reading room in November1884 in the National School building at the corner of Banyan and Timor Streets. The Institute was funded by member subscription, payable on a quarterly, half yearly or yearly basis. Samuel Hannaford, the Manager of the Warrnambool Bank of Australasia, was the first Honorary Secretary of the Mechanics' Institutes, and an early President and Vice-President. He also gave several of the early lectures in the Reading Room. Another early Secretary, Librarian and lecturer was Marmaduke Fisher, the teacher at the National School. Lecture topics included The Poets and Poetry of Ireland', 'The Birth and Development of the Earth', 'The Vertebrae - with Remarks on the pleasures resulting from the study of Natural History' and 'Architecture'. In 1856 the Reading Room was moved to James Hider's shop in Timor Street, and by 1864 it was located in the bookshop of Davies and Read. In the 1860's the Mechanics' Institute struggled as membership waned but in 1866, after a series of fund raising efforts, the committee was able to purchase land in Liebig Street, on a site then called Market Square, between the weighbridge and the fire station. A Mechanics' Institute building was opened at this site in August 1871. The following year four more rooms were added to the main Reading Room and in 1873 the Artisan School of Design was incorporated into the Institute. The same year Joseph Archibald established a Museum; however it deteriorated when he was transferred to Bendigo in 1877. In 1880, with Archibald's return to Warrnambool, the Museum was re-established, and in 1885 a new building was built at the back of the Institute to accommodate the re-created School of Design, the Art Gallery and the Museum. In 1887 the Museum section was moved to the former court house in Timor Street (for some time the walls of the building formed part of the TAFE cafeteria but all is now demolished)). In 1911 the Museum was transferred back to the original building and the management of the Mechanics' Institute was handed over to the Warrnambool City Council. The Museum and Art Gallery became one and housed many fine works of art, and the Library continued to grow. The building was well patronised, with records showing that at the beginning of the 20th century there were between 500 and 800 visitors. During World War One the monthly figures were in the thousands, with 3,400 people visiting in January 1915. The Museum was a much loved Institution in Warrnambool until the contents of the Museum and Art Gallery were removed to make room for the Warrnambool City Council Engineers' Department. The contents were stored but many of the items were scattered or lost. When the original building was demolished the site became occupied by the Civic Centre, which included the new City Library. (The library was temporarily located in the old Palais building in Koroit Street.) In the process of reorganisation the Collection was distributed amongst the community groups: -The new City Library took some of the historic books and some important documents, historic photographs and newspapers. -The Art Gallery kept the 19th Century art collection and some of the artefacts from the museum. -The Historic Society has some items -The State Museum has some items -Some items were destroyed -Flagstaff Hill Maritime Village has old newspapers, Government Gazettes, most of the Mechanics' Institute Library, ledgers and documents connected to the Mechanics' Institute Library, some framed and unframed art works and some photographs. The Warrnambool Mechanics' Institute Library book collection is deemed to be of great importance because it is one of the few collections in an almost intact state, and many of the books are now very rare and of great value. Life's Panorama being Recollections and Reminiscences of Things Seen, Things Heard, Things Read Author: J A Gurner Publisher: Lothian Publishing Co Date: 1930Label on spine cover with typed text RA 923.4 GUR Pastedown front endpaper has sticker from Warrnambool Public Librarywarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, great ocean road, book, warrnambool library, warrnambool mechanics’ institute, mechanics’ institute library, victorian library board, warrnambool books and records, warrnambool children’s library, warrnambool public library, life's panorama, j a gurner -

National Vietnam Veterans Museum (NVVM)

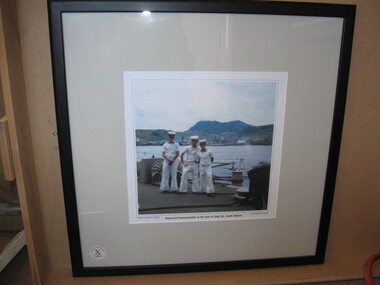

National Vietnam Veterans Museum (NVVM)Photograph, Young and Impressionable, In The Port Of Vung Tau, South Vietnam

In a black frame a coloured photograph of three silors dressed in white uniform standing on the deck of a ship in the Port of Vung Tau, South Vietnam. Botton left hand side of the photograph reads Voyagers to Vietnam Collection. Bottom right hand side of the photograph reads Copyright Peter ManoelVoyagers to Vietnam Collection, Copyright Peter Manoelphotograph, vung tau, cerberus collection, ran -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Photograph, APC Being Unloaded From HMAS Sydney At Vung Tau

In a black frame a coloured photograph of two men looking at the water. suspended from a crane is an APC being unloaded at Vung Tau from HMAS Sydney, bottom left hand side reads Voyages To Vietnam Collection, bottom right hand side reads Copyright Ian Stacker.Voyages To Vietnam Collection. Copyright Ian Stacker.photograph, armoured personnel carrier, hmas sydney, vung tau, cerberus collection