Showing 613 items

matching the beeches

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane. Stamped JAS Burden (owner) also No 2flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Richard Routledge, Mid 19th to early 20th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a little known maker, this item would have been made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. At a time when to produce a decorative moulding for a piece of furniture, door trims etc. had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Moulding plane round type Marked Routledge 64 Bull Street also stamped (JAS Burden owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, William Bishop, 1818

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about William Bishop is that he made planes in Grey Coat St Westminster, London, around 1818. He is listed in business directories of the time but nothing before or after this date. There are many of his decorative moulding planes of all sizes and designs for sale and given that his moulding planes are vintage his wood planes are well sought after by collectors today. A vintage tool made by a little known maker, this item was made for cabinet makers and individuals who worked in wood and needed a tool that could produce a ornamental finish to timber. These profiled planes came in various shapes and sizes to achieve the required decorative finish. This item is a significant tool from the late 18th to early 19th century that today is quite rare and sought after by collectors of vintage tools. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Plane Moulding Hollow type Marked Burden (Owner) also stamped JB and Iflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Richard Routledge, Mid 19th to early 20th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a little known maker, this item would have been made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. At a time when to produce a decorative moulding for a piece of furniture, door trims etc. had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Moulding plane round type Marked Routledge 64 Bull Street, also stamped No 12 (JAS Burden owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood smoothing plane, G Davis, 1821-1876

A smoothing plane used for making a flat and smooth finish to timber items predominantly used in furniture or cabinet work or other wooden objects. Traditionally, planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile or a flat and smooth finish with the blade secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of smoothing and moulding planes for the full range of work to be performed. For example large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about George Davis is he and his successors made planes in Birmingham, England, from about 1821 to 1876. There are many of his tools including smoothing and decorative moulding planes of all sizes and designs for sale around the world and that his wood working planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals who worked in wood and needed a tool that could produce a smooth finish to timber. These types of planes came in various shapes and sizes to achieve the required finish. This item is a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Smoothing plane known as a coffin plane due to it's shapeStamped GM inside W (owner) maker possibly G Davisflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane, moulding, single bead reeding plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Richard Routledge, 1869- Early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use to produce a decorative moulding for a piece of furniture, door trims etc or other timber items that had to be accomplished by using hand tools and in particular one of these types of planes. Profiled planes came in various shapes and sizes to achieve the required decorative finish. A significant tool from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Moulding plane size No 2Marked Routledge Birmingham. Stamped JAS Burden (Owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, Routledge, 1869-1910

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by an early tool manufacturer Richard Routledge, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce an ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc. or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century by a known maker that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves handmade shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane Side Bead 5/8 type with a single Box 5/8" "Routledge Birmingham " also inscribed "J.A.S. Burden" (owner of the plane)flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, great ocean road, plane, moulding, routledge, side bead, single box, moulding plane, richard routledge, jas burten -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Richard Routledge, 1869-early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use to produce a decorative moulding for a piece of furniture, door trims etc. or other timber items that had to be accomplished by using hand tools and in particular one of these types of planes. Profiled planes came in various shapes and sizes to achieve the required decorative finish. A significant tool from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Side bead single box Moulding plane 1''Stamped JAS Burdenflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Richard Routledge, 1869- Early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use to produce a decorative moulding for a piece of furniture, door trims etc or other timber items that had to be accomplished by using hand tools and in particular one of these types of planes. Profiled planes came in various shapes and sizes to achieve the required decorative finish. A significant tool from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Plane, Moulding, HollowI M and Denham stamped one end (owners)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel hacksaw 'Marples', 20thC

A hacksaw is a fine-toothed saw, originally and principally for cutting metal. They can also cut various other materials, such as plastic and wood; for example, plumbers and electricians often cut plastic pipe and plastic conduit with them. On hacksaws, as with most frame saws, the blade can be mounted with the teeth facing toward or away from the handle, resulting in cutting action on either the push or pull stroke. In normal use, cutting vertically downwards with work held in a bench vice, hacksaw blades should be set to be facing forwards. Joseph Marples & Son Pty Ltd Traditional Craftsmans Hand Tools made in Sheffield. The finest quality hand made tools, backed by over 170 years of manufacturing heritage. .In the 1840’s Joseph Marples was one of several ‘Marples’ (most of which were related) in Sheffield manufacturing joiners tools, such as brass inlaid rosewood & ebony braces, boxwood spokeshaves, beech planes, gauges and squares. The business has remained within the family to this date, and has been based in Sheffield since those early days. Although modern technology has been used in some instances, many of the traditions of manufacturing fine hand tools has remained the same using selected materials and hand finishing, indeed the same threads are used in the gauges as were used over 100 years ago. A steel hacksaw. 'Marples' with bladeMARPLEStools, woodwork, metalwork, carpentry, pioneers, market gardeners, early settlers, moorabbin, cheltenham, bentleigh, ormond, joseph marples & son pty ltd, sheffield , england, -

Otway Districts Historical Society

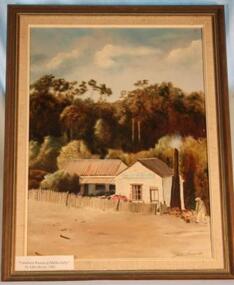

Otway Districts Historical SocietyPainting - Oil painting, framed, The Luncheon Rooms at Melba Gully, 1981

Forming the headwaters of the Johanna River and noted for its majestic Myrtle Beech and Blackwood trees, in 1921 the property came into the possession of Mrs Jessie Fry, wife of Mr Thomas Fry, a well-known and respected local bushman and timber getter. Here the family lived and it was Mrs Fry who named the place 'Melba Gully'. Sometime in the late 1920s Mrs Fry was approached by Pioneer Tours, the bus company, to see if she would provide lunches and afternoon teas for their passengers travelling between Apollo Bay and Port Campbell. Mrs Fry rose to the challenge; the Melba Gully Luncheon Rooms were built adjoining the Fry home and she was in business. Mrs Fry was unfailing in her courtesy and kindness. She was also a splendid cook, known for her feather-light scones and sponges. Home-produced strawberries and cream were a special treat. Visitors were also taken on a tour of 'The Gully', often guided by one of her young sons. Melba Gully Visitors Book is testimony to her many satisfied customers. Tom and Jessie Fry sold the property on her retirement in 1947 and the tearooms ceased to operate. It again changed hands in 1958 to Otway residents Mr and Mrs Axel Madsen, and in 1975 they made the magnificent gesture of gifting the 48 hectare Melba Gully to the people of Victoria..Framed painting in oils of a weatherboard house with picket fence, before a backdrop of forest. A figure chopping wood is at the right.Signature of artist John Driver, 1981melba gully, jessie fry, thomas fry, buses, tours, weatherboard house, john driver -

Otway Districts Historical Society

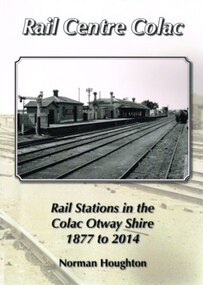

Otway Districts Historical SocietyBook, Norman Houghton, Rail Centre Colac, 2014

Colac was the centre of a spidery rail network over which were carted anything and everything by Victorian Railways, the common carrier throughout the area. The main line through the region was the 35 km rail route from Birregurra (and thence to Geelong) though Colac to Pirron Yallock (and thence to Warrnambool and Port Fairy) from March, 1877, to July, 1883. The first branch line ran from Irrewarra to Beeac in 1889, which then extended in stages to Cressy and on the Ballarat. The second branch line was the 31 km long Birregurra to Forrest in 1891. The cost of building railways into mountainous terrain meant the third branch line was a narrow-gauge 2 foot 6 inch line, first of all to Beech Forest in 1902, and then to Crowes in 1911, for a total of 71 km. The final rail connection was the 16 km branch from Colac to Alvie to facilitate the transport of onions, opening in 1923. Each line had its own character and peculiarities derived from its foundation, geography and economic base. As a general rule, the loadings on the branch lines had greater output tonnage than inwards, the reverse of the main line. The lines traversed agricultural and timber areas where inputs like seed, grass, fertiliser and labour were minor, compared with the output, timber, wool, cream, butter, cheese fruit, potatoes, onion, grain and livestock.Rail Centre Colac. Rail stations in the Colac Otway Shire, 1877 to 2014. Norman Houghton. 1st ed. Norman Houghton; Geelong (Vic); 2014. vi, 262 p.; illus., maps, index. Soft cover.colac; cressy; forrest; beech forest; crowes -

Otway Districts Historical Society

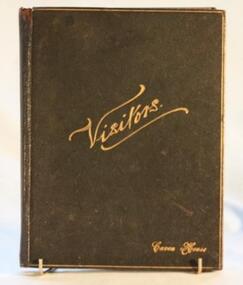

Otway Districts Historical SocietyBook - Visitors Book, Melba Gully Visitors Book, 1937-1958

Forming the headwaters of the Johanna River and noted for its majestic Myrtle Beech and Blackwood trees, in 1921 the property came into the possession of Mrs Jessie Fry, wife of Mr Thomas Fry, a well-known and respected local bushman and timber getter. Here the family lived and it was Mrs Fry who named the place 'Melba Gully'. Sometime in the late 1920s Mrs Fry was approached by Pioneer Tours, the bus company, to see if she would provide lunches and afternoon teas for their passengers travelling between Apollo Bay and Port Campbell. Mrs Fry rose to the challenge; the Melba Gully Luncheon Rooms were built adjoining the Fry home and she was in business. Mrs Fry was unfailing in her courtesy and kindness. She was also a splendid cook, known for her feather-light scones and sponges. Home-produced strawberries and cream were a special treat. Visitors were also taken on a tour of 'The Gully', often guided by one of her young sons. Melba Gully Visitors Book, running from November 1937 until the end of 1958, is testimony to her many satisfied customers. Tom and Jessie Fry sold the property on her retirement in 1947 although the tearooms continued to operate. It again changed hands in 1958 to Otway residents Mr and Mrs Axel Madsen, when it finally closed, and in 1975 they made the magnificent gesture of gifting the 48 hectare Melba Gully to the people of Victoria..Melba Gully Visitors Book. Foolscap, leather-bound, lined pages with margin approximately 30mm from left. Added, 24 p. unlined quarto.Full of inscriptions, cover to coverlavers hill, melba gully, jessie fry, thomas fry, axel madsen -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Chair, early 29th century

The Bentwood chair has been called ‘the world’s most popular chair’. The original Bentwood chair, was designed by German-Austrian cabinet maker and Master Joiner, Michael Thonet (b.1796 - d.1871) and introduced to the market in 1859. Thonet started his business in his home town of Boppard as an independent cabinet maker in 1819. In the 1830’s he began trying to make furniture from glued (laminated) and bent wooden slats. Over the next few years his attempts to patent this process failed in Germany, Great Britain, France, and Russia. He then began using lightweight, strong wood and bending it into elegant, comfortable furniture. The Bentwood technology took Thonet years to perfect. In simple terms, the wooden rods or lengths were wet by soaking or steaming, bent into shape and then held in place until they hardened into the moulded curved shape or pattern. The wood usually chosen for the bentwood chairs was maple or beech. Thonet had revolutionised an older process by industrialising the process. The dowels of wood were cut and prepared as components of furniture, treated by the ‘bentwood’ process, then ready immediately for assembling with very little extra workmanship needed. Thonet held 2 patents for this process, the second one ended on 10th July 1869 and was non-renewable. At the Trade Fair at Koblenz of 1841 Prince Klemens Wenzel von Mettemich was very impressed with Thonet’s furniture, especially the chairs. In 1842 Thonet sold his Boppard business and emigrated to Vienna, and began working, along with his sons, on the interior decoration of the Palais Leichtenstein, for the Carl Leistler establishment. In 1849 he began his own business again, the Gebruder Thonet to include his sons (translated “Brothers Thonet”). He produced the “No. 1” Bentwood chair. He received a bronze medal for his Vienna bentwood chairs at the World Fair in London in 1851, and a silver medal in Paris in 1855. In 1856 he opened a new factory in Koritchan (Moravia), where there were extensive woods of beech trees available for his enterprise. In the next years, five more Eastern European production sites were established in Bystritz (1862), Nagy-Ugrócz (1866), Wsetin (1867), Hallenkau(1867) and Nowo-Radomsk(1880). Thonet’s 1859 No. 14 “chair of chairs” (or “Konsumstuhl Nr. 14” – coffee shop chair no. 14) was the most famous of all of Thonet’s Bentwood chairs. In 1867 he received a gold medal at the Paris World Fair. This new style of furniture making became very popular. Up until 1830 50 million of these chairs had been produced. By the 1870’s Thonet owned offices in almost 20 countries, with sales locations across Europe, in Chicago and New York. In 1889 he set Thonet set up a head office in Frankenberg, Hesse. Bentwood models designed in the mid to late 19th century featured hand-caned or laminated wood seats and were usually stamped with the country of origin. The Bentwood elements were the backrest, seat rim and legs. Typically the seat was covered with ‘bucket’ leather. After the Patent ran out in 1869, companies such as Jacob & Josef Kohn began the production of bentwood furniture.The popularity of the Bentwood chair that was introduced by Michael Thonet in the 1850s is due to its versatility and timeless quality. Its style, whether varnished or painted, suits any room in the house. The lightweight chairs are also popular for café and restaurant seating, as well as for public gatherings. They can be easily moved around and grouped in a variety of ways to suit any occasion.Chair, bentwood, pair of two. Backrest has full length inverted U inside frame. Support rail and wire reinforcing between legs. 3692.01 seat has floral pattern pressed into wood 3692.02 seat is plain (replacement seat). Made by Harnison & Co.3692.01 chair's marks; Label ""HARNISON & CO./ NEUSOL / BUDAPEST" and "WIENER NOBEL" and "(symbol) N inside circle, under Crown" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, domestic furniture, dining furniture, bentwood chair, harnison & co., neusol, budapest, wiener nobel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Sides & Skinner, First half of the 20th century

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces. The name spokeshave dates back to at least the 16th century, though the early history of the tool is not well documented. The name spokeshave reflects the early use of the tool by wheelwrights. The first spokeshaves were made of wood usually beech with steel blades, before being largely superseded by the development of metal-bodied spokeshaves in the latter half of the 19th century, though many woodworkers still use wooden spokeshaves. Due to their widespread use and versatility vintage wooden spokeshaves remain commonly available and relatively low in price. Spokeshaves consist of a blade or iron secured to the body or stock of the tool, which has two handles one for each hand. The bottom surface of the tool is called the sole. The blade can be removed for sharpening, and adjusted to vary the depth of the cut. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached, as with a draw knife. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. There are a wide variety of different types of spokeshave, suited to different trades and applications. A now vintage tool made by an Australian manufacture in NSW who specialised in making pruning shears, hacksaw frames and heel shaves under the Erskin brand name. This tool is now sought after by collectors even though it was probably made in the first quarter of the 20th century. It gives a snapshot of how carpenters work with wood by hand showcasing their craftsmanship. Hollow face Spokeshave, metal body with black enamel finish. Erskin stamped on frontflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spokeshave, cabinet makers tools, wood working, cutting tool, shaping tool -

Otway Districts Historical Society

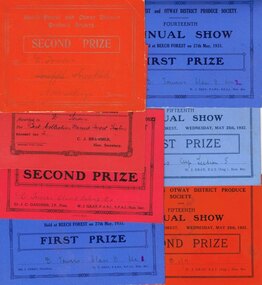

Otway Districts Historical SocietyPrize, Beech Forest and Otway District Produce Society, Prizes, 1922-1932, See individual prizes

Beech Forest and Otway District Produce Society: (a) Second Prize, D. Towers, for Snowflake, A.W. MacKenzie, Secretary. (b) Seventh Annual Show, 1923, Second Prize, D. Towers, for Best Collection Dressed Forest Timbers, exhibit no. 2, C.J. Brammer, Hon. Secretary. (c) Twelfth Annual Show, Second Prize, D. Towers, Class B Section 2 Ex 1, Cr. J.C. Gardner JP, Pres., W.J. Gray FABI SFAI, Hon. Sec. (d) Fourteenth Annual Show, 27 May 1931, First Prize, D. Towers, Class B Sec 1, Mr J. Perry, President, W.J. Gray FABI SFAI, Hon. Sec. (e) Fourteenth Annual Show, 27 May 1931, First Prize, D. Towers, Class B Sec 2, Mr J. Perry, President, W.J. Gray FABI SFAI, Hon. Sec. (f) Fifteenth Annual Show, 25 May 1932, First Prize, D. Towers, Cup Section 5, J.A. Perry, Pres., W.J. Gray, FCI (Eng.), Hon. Sec. (g) Fifteenth Annual Show, 25 May 1932, Second Prize, D. Towers, B 1/7, J.A. Perry, Pres., W.J. Gray FCI (Eng.), Hon. Sec.beech forest; otway; produce; prize; -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, John Manners, 1792-1822

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: We know little of John Manners other than his firm was acquired by Alexander Mathieson & Sons in 1822, Mathieson were one of the leading makers of hand tools in Scotland at this time. 1792 was deemed by Mathieson & Sons to be that of its foundation and it was in all likelihood the year in which John Manners had also set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, it is presumed having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker, from 1822 we hear nothing regards what happened to John Manners.A vintage tool made by a known maker John Manners the item is a significant wood working tool from the late 18th century that today is quite rare. As this maker sold his business to Alexander Mathieson another collectable tool maker in the early 19th century. This item would be sought after by wood working tool collectors and it gives us a snapshot of how cabinet makers went about creating furniture during this time period. Wood Moulding plane Side Bead - Single Box type Stamped Manners (Maker) (also inside stamped GN, & W, M. Nicol also F W. probably owners of item over the years.)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood smoothing plane coffin pattern, 18th to early 19th century

Being smaller than other bench planes, the coffin-shaped smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more manoeuvrable. A vintage tool made by an unknown 18th or early 19th-century woodworking tool maker. This item would have been made for individuals or cabinet makers that worked in wood and needed a tool that could produce a flat smooth finish to timber. These tools were used before routers and spindle moulders came into use in the late 19th and early 20th centuries before this time producing either a decorative moulding or a smooth finish to furniture timber, door trims etc had to be accomplished using hand planing tools and in particular one of these types of planes. Traditionally wood planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding or had a flat blade used for achieving a flat and smooth finish to timber. The blade or iron was likewise formed to the intended moulding profile or for smoothing and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers' shop might have many, perhaps hundreds, of moulding and flat-bladed planes for a full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. These vintage planes are well sought after by collectors of antique tools due to their rarity. A significant tool from the 18th to early 19th century by an unknown maker that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves handmade show the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber furniture item. Smoothing Plane Coffin type. Stamped GM inside "W" indicating sizeflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing Wood Plane Coffin Pattern, 18th to Early 19th Centuries

Being smaller than other bench planes, the coffin shaped smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more manoeuvrable. A vintage tool made by an unknown 18th or early 19th century woodworking tool maker. This item would have been made for individuals or cabinet makers that worked in wood and needed a tool that could produce a flat smooth finish to timber. These tools were used before routers and spindle moulders came into use in the late 19th and early 20th centuries before this time to produce either a decorative moulding or a smooth finish to furniture timber, door trims etc had to be accomplished using hand planing tools and in particular one of these types of planes. Traditionally wood planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding or had a flat blade use for achieving a flat and smooth finish to timber. The blade, or iron was likewise formed to the intended moulding profile or for smoothing and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding and flat bladed planes for a full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. These vintage planes are well sought after by collectors of antique tools due to their rarity. A significant tool from the 18th to early 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber furniture item. Wood smoothing plane known as a coffin plane due to it's shape, wood insert screwed on front of base. Stamped "MILLER". Inscribed "X" (probably the size)flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cabinet makers tools, woodworking tools, wood plane, smoothing plane, timber finishing, furniture manufacture -

Wodonga & District Historical Society Inc

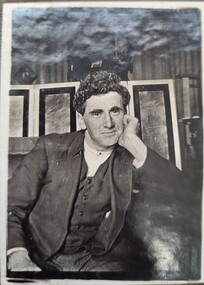

Wodonga & District Historical Society IncAlbum - Rev. Alexander Sutherland Bremner

Alexander Sutherland Bremner was born in Lyster, Scotland in about 1890. He migrated to South Australia and by 1914 was stationed in Mount Gambier as a missionary in connection with St Andrew’s Presbyterian Church. At that stage he was a student of Divinity. He moved to Victoria and served in Beech Forest and Kyabram. After three years in Kyabram, Reverend Bremner transferred to Wodonga in April 1919. Although only in Wodonga for two years, Reverend Bremner quickly became highly regarded in the community for the compassion he brought to his calling. He was particularly concerned about the welfare of boys in Wodonga and became involved in the Scouts as well as establishing the Wodonga Boys’ Club. Although the Boys’ Club had been formed through the Church it was open to all local boys. Tragedy struck on 20th November 1920 when Reverend Bremner was accompanying a group of boys on an outing to the Wodonga Creek. In order to stop the boys from entering a deep water hole he positioned himself on a log between it and the shallower water. Unfortunately he slipped off the log himself and fell into the waterhole. He was unable to swim and despite the best efforts of one of the boys to rescue him, he drowned. To add further to the tragedy, his fiancé was on her way to Wodonga by train to visit Reverend Bremner for the weekend. She could not be advised of his death before arriving at the station where she expected him to be waiting. As a mark of respect, a hall was erected at the back of the Wodonga Presbyterian Church in High Street to serve as a kindergarten and Sunday School. It was officially opened on Sunday 6th November 1921 and named Bremner Hall.This album is significant because it documents the service and untimely death of a highly regarded Minister of the Presbyterian Church in Wodonga.A small brown photo album containing photos and newspaper articles chronicling the drowning of Reverend Alexander Sutherland Bremner in Wodonga.reverend a.s. bremner, presbyterian church, bremner hall -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - Roland Jahne Collection - See Description for details

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing Wood Plane, John Welsh & Co, 1845-1850

A vintage tool made by a obscure early 19th century woodworking Scottish tool maker. This item would have been made commercially for firms and individuals that worked in wood and needed a tool that could produce a flat smooth finish to timber. These tools were used before routers and spindle moulders came into use in the late 19th and early 20th centuries before this time to produce a decorative moulding or to smooth a piece of furniture timber, door trims etc. had to be accomplished using hand tools and in particular one of these types of planes. The subject item is a smoothing plane Known as a Coffin Plane due to its shape. Traditionally wood planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding or had a flat blade use for achieving a flat and smooth finish to timber. The blade, or iron was likewise formed to the intended moulding profile or for smoothing and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding and flat bladed planes for a full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about John Welsh is that he was a tool maker and possibly a retailer that operated a business in Dundee Scotland between 1845-1850. This is the only record we have to date that he existed and is from the Master Catalogue of Scottish woodworking tool makers. His tools in particular moulding planes are well sought after by collectors of vintage tools due to their rarity. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves handmade shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Wood Plane Rounded base, blade attached. Owner J Huband Marked J Welsh, Dundee maker and "J Huband" (Owner)flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, plane, compass plane, j welsh, j huband -

Puffing Billy Railway

Puffing Billy Railway6A - Victorian Railways Na class steam locomotive, 1901

6A Built in 1901 and painted two-tone green, this locomotive was issued to the Colac to Beech Forest line and was used in that line’s construction. Over the years, it saw service on all four lines, but mostly on the Colac to Crowes and Upper Fern Tree Gully to Gembrook lines. It was temporarily withdrawn from service in 1958 and returned to service at Belgrave in 1962 for the reopening of this line where it saw almost continuous service until being withdrawn in 1983. It has been restored, as far as possible, to its original condition with original design side tanks, low bunker, original size windows, etc., but a steel cow-catcher in place of the original style wooden one. It also has its original colour scheme of two-tone green with white lining. Loco: 6A In service Thursday, 18th July 1901 Livery two-tone green Owner Puffing Billy Gauge 762mm / 2' 6' Status Preserved - Operational Service History : Jul 1901 Colac - initial allocation of a new locomotive Jul 1901 - Nov 1908 Colac Mar 1909 - May 1909 Wangaratta Jun 1909 - Other Oct 1909 - Oct 1910 UFTG. Nov 1910 - Feb 1912 Colac May 1912 - Jun 1912 Wangaratta Jul 1912 - Sep 1914 Moe Oct 1914 - Aug 1924 Colac May 1925 - Jul 1927 UFTG. Aug 1927 - Oct 1928 Moe Jan 1929 - Sep 1930 UFTG. Sep 1930 - Jun 1932 Moe Dec 1932 - Workshops May 1933 - Colac Sep 1933 - May 1936 Moe Jun 1936 - Oct 1936 Workshops Oct 1936 - May 1942 UFTG. Sep 1942 - Apr 1949 Colac May 1949 - Apr 1950 Workshops May 1950 - Dec 1957 UFTG. Feb 1958 - Apr 1962 Workshops May 1962 - Belgrave - In Active Service at Puffing Billy Railway BelgraveVictorian Railways - Narrow Gauge NA class steam locomotive number 6A Victorian Heritage Register (VHR) Number H2187 Puffing Billy Locomotives and Rolling Stock Collection Dates that 6A worked on the Gembrook Line Nov-1909 to Nov-1910 May-1925 to Aug-1927 Jan-1929 to Sep-1930 Oct-1936 to Sep-1942 May-1950 to Feb-1958 May-1962 - Returned to Gembrook railway Oct-1977 - Transferred to PBR ownershipSteam Locomotive - with wrought iron frame with cast iron cylinders6Apuffing billy, victorian railways, narrow gauge, steam locomotive, 6a, 6na -

Warrnambool and District Historical Society Inc.

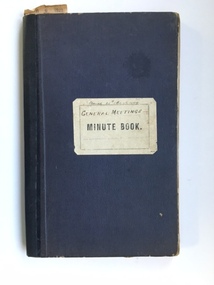

Warrnambool and District Historical Society Inc.Document - Minutes Books, Woollen Mills 1909- 1923 1933-1945, C 1909 C 1933-1945

The minutes book of the Warrnambool Woollen Mill are an important record of the beginnings of one of Warrnambool's major industries for close to one hundred years. They record the struggle in the early days of 1909 and 1910 to raise the capital. Also mentioned is the support which had been given by local people of small means who were prepared to back the enterprise while those with financial means had been rather more reserved. Apart from a Mr Vidler all the initial directors were initially working in an honorary capacity. They lamented the fact that local banks held half a million pounds on fixed interest so there was no shortage of money. The first directors were appointed in March 1909 : Jas. Worland, W H Philpott, G S Mackay, E H Price, S McDonald, J C Beeching, W Rogers ,J Marfell, J Deany, Jas Duirs, Jas. Ponting, H Jessen, S Nettleton, J Blain, J Gooden, Drs. Holmes, Henderson and Powell. Mr J E Bennett was secured as first manager of the mill in 1910 Over the ten year period of this book there is much discussion on possible returns and share prices as well as decisions relating to the operation of and production from the mill. Within four years they were using more yarn than they were producing. Electricity was connected around 1914 and by 1915 shareholders were receiving eight percent return on their investment and were also contributing to the first world War effort by supplying blankets. Assets continued to accumulate and building was also continued with sandstone being quarried from the site and rain water tanks and asphalt floors installed, all contributing to savings. By 1917 The Warrnambool Woollen Mill was considered to be one of the states best investments and it continued to prosper through the years. The second minutes book likewise records similar events and circumstances for the period 1933-1945. This like wise is an interesting period, covering the period of the second World War. In 1955 the Warrnambool Woollen Mill formed a partnership with the Wangaratta Woollen Mills. Dunlop bought the mill in 1968. From that time until its closure in 2000 it had a number of different owners, the last being the Smith Family Industries. These minutes books hold an important information regarding the establishment and early operation of one of Warrnambool's major industries. The mill itself has strong connection to the Warrnambool community and many of the names mentioned as directors and shareholders have held positions within the community as businessmen and city officials. These minutes add another dimension to their contribution to Warrnambool..1Navy blue hard card cover with cloth spine. White label glued to front cover.186 pages.There are handwritten entries in black ink which are interspersed with reports from newspaper. .2 Pale grey cloth cover on early Kalamazoo filing system 612 pages of typed minutes . .1There are dates from 1910 through to 1923. Minutes have been signed by chairman of directors, M Saltau.label on front cover has blue stamp, The Warrnambool Woollen Mill Company. hand written above in black ink "opened 24th March 1909." .2 dated from May 1933 to September 1945. Signatures include M Saltau, James Disckson and Fletcher Jones.warrnambool, warrnambool woollen mill, first minutes book warrnambool woollen mill, minutes book, warrnambool woollen mill 1909, minutes book warrnambool woollen mill 1945 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Auburn Tool Company, 1870 to 1893

Moulding Plane: A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. Auburn Tool Company: The Auburn Tool Company is known to exist from 1864 to 1893. George Casey reorganized the firm of Casey, Clark and Company as a joint-stock company in 1864, under the company name of Auburn Tool Company. The 1865 New York State Census noted the firm as a manufacturer of the plane, plane irons, and skates. The production that year was listed as 30,000 pairs of skates and 35,000 planes along with 25,000 dozen plane irons. The plane irons carried the trademark "Thistle". Both skates and plane irons were made from welded wrought iron and cast steel. The Auburn Tool Company was among the five leading plane manufacturing firms existing in the mid to late 19th century USA. Others were: H. Chapin's Son; Greenfield Tool Company; and Sandusky Tool Company. Auburn Tool Company, with these others, was also a founding member of the Plane Makers Association, organized around 1858 to fix prices. Most of the companies tools were manufactured by prisoners and in 1866 the firm was outbid for prison labour by J M Easterly and Co. After losing the contract with the prison authority they constructed a new building and continued in the plane manufacturing business with private labour. The 1870 US Census reported the firm had 21 machines, driven by water power, employing 66 males, producing annual products valued at us$70, 000. After A. Howland and Company was dissolved in 1874, the Auburn Tool Company again resumed using contract labour at the State Prison until 1877. The Auburn Tool Company merged with the Ohio Tool Company of Columbus, Ohio, on Nov 14, 1893. Although plane manufacturing was continued at Auburn until after 1907, after this merger the firm went under the name of the Ohio Tool Company. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. It also gives an insight into how many manufacturing companies bid for the rights to use prison labour to make their products at this time in our history. Decorative wood Moulding, plane Round type Auburn New York. Owner A Neudt Size 14 flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - Roland Jahne Collection - See Description for details

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, 1819-1901

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The Holtzapffel dynasty of tool and lathe makers was founded in Long Acre, London by a Strasbourg-born turner, Jean-Jacques Holtzapffel, in 1794. The firm specialized in lathes for ornamental turning but also made a name for its high-quality edge and boring tools. Moving to London from Alsace in 1792, Jean-Jacques worked initially in the workshop of the scientific-instrument maker Jesse Ramsden, Anglicizing his name to John Jacob Holtzapffel. In 1794 he set up a tool-making partnership in Long Acre with Francis Rousset and they began trading under the name of John Holtzapffel. From 1804 he was in partnership with the Mannheim-born Johann Georg Deyerlein until the latter died in 1826, trading under the name Holtzapffel & Deyerlein. Holtzapffel sold his first lathe in June 1795, for £25-4s-10d, an enormous price at the time. All of Holtzapffel's lathes were numbered and by the time he died in 1835, about 1,600 had been sold. The business was located at 64 Charing Cross, London from 1819 until 1901 when the site was required "for building purposes". The firm then moved to 13 and 14 New Bond Street and was in premises in the Haymarket from 1907 to 1930. John's son, Charles Holtzapffel (1806–1847) joined the firm in 1827, at around which time the firm became known as Holtzapffel & Co. Charles continued to run the business after his father's death. He wrote a 2,750-page treatise entitled Turning and Mechanical Manipulation, published in 1843 which came to be regarded as the bible of ornamental turning. The final two volumes were completed and published after his death by his son, John Jacob Holtzapffel (1836–1897). When Charles Holtzapffel died in 1847 his wife Amelia ran the business until 1853. John Jacob II, the son of Charles and Amelia, was head of the firm from 1867 until 1896. A nephew of John Jacob II, George William Budd (1857–1924) became head of the firm in 1896. His son John George Holtzapffel Budd (1888–1968) later ran the business. By the early twentieth century, ornamental turning was going out of fashion, and the firm sold its last lathe in 1928. A vintage tool made by a well-known firm made for firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane Holtzaffel 64 Charing & Owner J Heath 9/16" marked opposite endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, plane, j heath -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Smoothing Plane, Late 19th to Early 20th century

A Jack plane is used for smoothing timber that is used in the manufacture of furniture or other wooden objects. Traditionally, smoothing planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to smooth or even out timber. The blade or iron was likewise secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding and smoothing planes for the full range of work to be performed. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm. A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used for the smoothing of a piece of timber that was then used in some form of cabinet manufacture or wood working. A significant item from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made. Jack Plane; a wooden smoothing plane, made by Alex Mathieson & Son, Glasgow. Plane has inscriptions."Alex Mathieson & Son Glasgow" Stamped "GN" inside with a "W" on endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jack plane, smoothing plane, woodworking tool, woodwork, cabinet making -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, 1819-1901

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The Holtzapffel dynasty of tool and lathe makers was founded in Long Acre, London by a Strasbourg-born turner, Jean-Jacques Holtzapffel, in 1794. The firm specialized in lathes for ornamental turning but also made a name for its high-quality edge and boring tools. Moving to London from Alsace in 1792, Jean-Jacques worked initially in the workshop of the scientific-instrument maker Jesse Ramsden, Anglicizing his name to John Jacob Holtzapffel. In 1794 he set up a tool-making partnership in Long Acre with Francis Rousset and they began trading under the name of John Holtzapffel. From 1804 he was in partnership with the Mannheim-born Johann Georg Deyerlein until the latter died in 1826, trading under the name Holtzapffel & Deyerlein. Holtzapffel sold his first lathe in June 1795, for £25-4s-10d, an enormous price at the time. All of Holtzapffel's lathes were numbered and by the time he died in 1835, about 1,600 had been sold. The business was located at 64 Charing Cross, London from 1819 until 1901 when the site was required "for building purposes". The firm then moved to 13 and 14 New Bond Street and was in premises in the Haymarket from 1907 to 1930. John's son, Charles Holtzapffel (1806–1847) joined the firm in 1827, at around which time the firm became known as Holtzapffel & Co. Charles continued to run the business after his father's death. He wrote a 2,750-page treatise entitled Turning and Mechanical Manipulation, published in 1843 which came to be regarded as the bible of ornamental turning. The final two volumes were completed and published after his death by his son, John Jacob Holtzapffel (1836–1897). When Charles Holtzapffel died in 1847 his wife Amelia ran the business until 1853. John Jacob II, the son of Charles and Amelia, was head of the firm from 1867 until 1896. A nephew of John Jacob II, George William Budd (1857–1924) became head of the firm in 1896. His son John George Holtzapffel Budd (1888–1968) later ran the business. By the early twentieth century, ornamental turning was going out of fashion, and the firm sold its last lathe in 1928. A vintage tool made by a well-known firm made for firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane Holtzaffel 64 Charing & Owner J Heath 9/16" marked opposite endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, plane, j heath -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Late 19th to Early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm. A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Side bead Moulding Plane Alex Mathieson & Son. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village