Showing 3961 items matching "machining"

-

National Wool Museum

National Wool MuseumYarn feeder

A yarn feeder, associated with the "Beehive Sock Knitter".A yarn feeder, associated with the "Beehive Sock Knitter".knitting textile machinery machine knitting, hosiery, knitting, textile machinery, machine knitting -

Stawell Historical Society Inc

Stawell Historical Society IncArchive - Laboratory Books, Mechanics of Machines - An Introduction to, J.L.M. Morrison and B. Crossland

From Dye Laborataory AUNDE / Norwellan North Western Woolen Mills became Norwellan Textiles then AUNDEDark Green Cover with artwork or EngineJohn Bennett, Lyddon Hall Leeds 8/10/69manufacturing -

Stawell Historical Society Inc

Stawell Historical Society IncInstrument - Realia, Textile Fabric Pilling Testing Machine, c1950

Used at Norwellan for testing cloth North Western Woolen Mills became Norwellan Textiles then AUNDEWood and iron Instrument with handle that drags metal pin repeatedly over a cloth sample.Peg Load Checked at 2 lbs 20.11.69manufacture -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumSouthern Cross, 1953

Used in 1950’s to power machinesSign at front “ Southern Cross “ $ Green in colour. Mark AX-C1 Air cooled$. An S with a cross is on the drum -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumInformation pamphlet, The Alfa-Laval Homestead Milker

Used in preference to slower hand milking practice after electricity was connected to the farmPaper pamphlet describing parts of the vacuum pump milker. Recommended for herds of ten cows or lessSee photosmilking machine, dairying -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumMachine - Paper Dispenser, Not sure

Used as a wrapping paper dispenser in the Houghton Department and Haberdashery Store Yarrawonga perhaps about the 60'sOld shop fittingMetal and wood structure. Metal uprights with a wooden top and base and metal blade Canberra 24 emblazoned into metal -

Plutarch Project

Plutarch ProjectMachine - Shortwave Radio Antenna, Active Antenna, circa late 1980's

This antenna was used between 1989 and 1990 to help receive the daily news service in the Greek language directly from Athens, Greece. At the time, news from Greece for the Greek people in Australia were arriving in Melbourne a week late, on newspapers from Athens sent through air-mail. These newspapers were displayed at Salapatas and Carras newsagents at Lonsdale street in Melbourne. One thing that was a problem for this service was that the news came at least 7 days late. Using the Shortwave Antenna we could get the latest news from Athens on shortwave radio directly and within an hour these news were recorded on a cassette tape and taken to the Tricom Group P.L. offices in Melbourne (1155 Malvern Road, Malvern 3144). The tape was loaded onto a system which allowed people to call a local phone number and listen to the latest news with a cost of a local call, or a little bit more. As this was prior to the Internet being established around the globe, it was the fastest news service directly from Greece, in the Greek language. It was used for a span of about 12 months, until Tricom closed down their dial-in services, sometime in 1990. The service was captured and loaded onto the system by Iakovos Garivaldis, then an employee of the Tricom Group which was a subsidiary of Southern Cross TV.The Primary significance of this object is of its historical value, social and informative value for the first generation of Greeks in Victoria"World Tuner AT4 SW" antenna with a 920mm fully extended aerial, a tuned circuit and two transistors to prevent loading of the antenna and boost signal output. It is made of plastic, black in colour with the aerial being made of steel. The signals picked up by the antenna are fed via a 15pF ceramic capacitor to a tuned circuit consisting of either VC1a or VC1b and either L1, L2, L3 or L4. The slider switch S1 selects the band to be tuned. The band range is normally from 3 to 30MHz. When S1 is in position A, L1 and VC1a are selected and the antenna can be tuned from 3-9MHz. Similarly positions B, C, and D select higher frequencies up to 30MHz. It was purchased by Iakovos Garivaldis for this use for $119.WORLD TUNER AT4 SW "Amplituned" Shortwave Antennaantenna, radio, short-wave, language, greek -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumSinger Treadle Sewing Machine, 1888

-

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumWashing machine, Hoover Limited, Hoover Electrical Washing Machine, est 1950's

metal square tub with wringer. Instruction sheet enclosedHoover mode lApp marking N/27 type 0343 .240 volts 3.8 amps 50 HZ AC only motor 350 watts serial No 0343 107 10499hoover, washing machine, electric, washing, clothes -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumOffice Equipment, Office Answering Machine

-

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumMachine - Earth Scoop, Gaston Brothers Scoop

-

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, William Pargeter, "Dag" Crusher from Circa late 1980's restoration -- 17 Photos -- Coloured

Photo Album of Woollen Mills Dag Crusher being loaded onto truck to ship to G Callum of Breakwater for restoration by William Pargeter of Geelong. A member of and president of Geelong Vintage Machinery Association. After restoration used by G Callum. industry, machine, agriculture -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

National Wool Museum

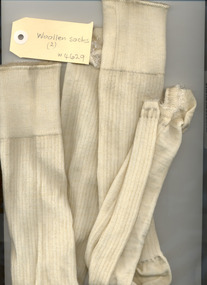

National Wool MuseumSocks

Pair of unfinished, cream socks.machine knitting -

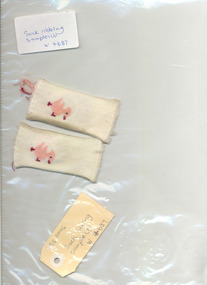

National Wool Museum

National Wool MuseumSample, Textile

From the Scallywags Mill (unconfirmed). Samples of childs socks.machine knitting, scallywags industries -

National Wool Museum

National Wool MuseumBook, Modern Developments in the Australian Wool Industry

"Modern Developments in the Australian Wool Industry", c.1923. Examines the operations of the Yarra Falls Spinning Co. Pty Ltd and the Australian Knitting Mills Limited (makers of Golden Fleece and Kookaburra knitted underwear). Includes photos of processes and of the buildings.Book, front cover: "Modern Developments in the Australia Woollen Industry" c.1923; Yarra Falls Spinning Co. Pty Ltd and Australian Knitting Mills Limited.weaving textile industry - history textile production machine knitting textile mills, yarra falls spinning co. pty ltd australian knitting mills limited, yarn - woollen, cloth - worsted, yarn - worsted, wool tops, yarn - cashmere, logo merino: sheep in australian art and design - exhibition (29/07/2000 - 04/02/2001), weaving, textile industry - history, textile production, machine knitting, textile mills -

National Wool Museum

National Wool MuseumBook, Concerning wool

"Concerning Wool"- The Australian Wool Board and The Associated Woollen and Worsted Textile Manufacturers of Australiatextile production machine knitting wool growing wool processing wool - chemistry, australian wool board associated woollen and worsted textile manufacturers of australia, felting, spinning, textile production, machine knitting, wool growing, wool processing, wool - chemistry -

National Wool Museum

National Wool MuseumBook, How to Know Textiles

"How to Know Textiles" - Cassie Paine Small, 1932.textile fibres weaving machine knitting yarn production cotton silk, lace, dyeing, cloth - woollen, cloth - worsted, rayon, textile fibres, weaving, machine knitting, yarn production, cotton, silk -

National Wool Museum

National Wool MuseumBook, Wool Fabric Resource Guide

"Wool Fabric Resource Guide" - Australian Wool Corporation, c.1985.textile production machine knitting woollen mills, australian wool corporation, cloth - woollen, cloth - worsted, textile production, machine knitting, woollen mills -

National Wool Museum

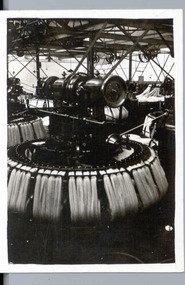

National Wool MuseumPhotograph, Noble Combing Machine, Valley Worsted Mill

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows several Noble combs. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.textile mills, valley worsted mill foster valley mill pty ltd, combing, noble comb -

National Wool Museum

National Wool MuseumShearing Handpiece

Wolseley No. 3 type shearing handpiece. Serial no. 52039.Wolseley no. 3 shearing handpiece.THE / WOLSELEY / SHEEP / SHEAR / 52039shearing, wolseley sheep shearing machine co. ltd -

National Wool Museum

National Wool MuseumShearing Handpiece

Wolseley no.10 shearing handpiece. Helical spine with no.4 style rear joint. Pre 1910.Wolseleyshearing machinery, wolseley sheep shearing machine co. ltd -

National Wool Museum

National Wool MuseumKnitting Machine

Treatment form dated 1988 page 1 Treatment form 1988 page 2 -

National Wool Museum

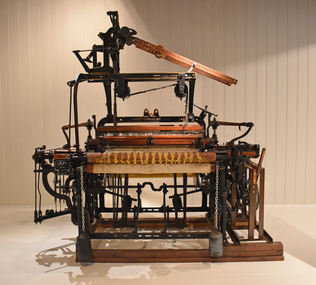

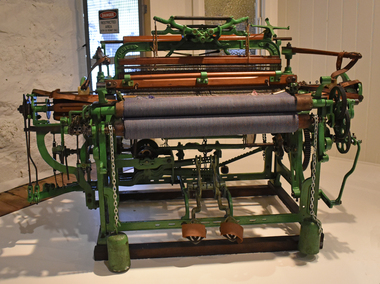

National Wool MuseumMachine - Loom, George Hattersley and Sons Ltd, 1920 - 1935

Weaving is the interlacing of two yarns, one at right angles to the other. Yarns that run the length of the fabric are called the warp. Yarns that run across the fabric are called the weft. Most woven fabrics are produced on a loom. The warp yarns are raised to form an opening - the shed. The weft carrier, usually the shuttle, shoots through the shed. Then the warp yarns change position up and down. Finally, the weft is pushed tight against the previous yarns, gradually building up the fabric. Hattersley dobby loom. In working order, black painted cast iron.weaving, george hattersley and sons ltd, weaving machinery, loom, wool processing, textile industry -

National Wool Museum

National Wool MuseumMachine - Loom, George Hattersley and Sons Ltd, 1920 - 1925

Weaving is the interlacing of two yarns, one at right angles to the other. Yarns that run the length of the fabric are called the warp. Yarns that run across the fabric are called the weft. Most woven fabrics are produced on a loom. The warp yarns are raised to form an opening - the shed. The weft carrier, usually the shuttle, shoots through the shed. Then the warp yarns change position up and down. Finally, the weft is pushed tight against the previous yarns, gradually building up the fabric. Hattersley treadle loom (revolving box hand loom). Beam of loom was removed and sent to Foster Valley Mill in 1989 to be returned via Tom Crocker. The National Wool Museum gratefully acknowledges the contribution of Mr Fred Murgatroyd & Mr Bernard Tolan in making this Hattersley Loom Operational. Green painted Hattersley treadle loom (revolving box hand loom).weaving, george hattersley and sons ltd, weaving machinery, wool processing, loom, restoration -

National Wool Museum

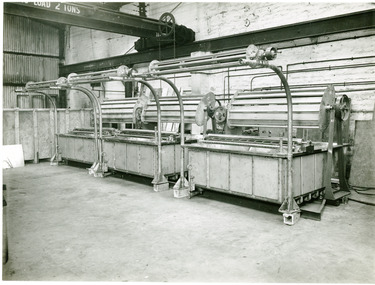

National Wool MuseumPhotograph

Avenue Ironworks John Daglilsh & Sonsmachinery, wince machine -

National Wool Museum

National Wool MuseumPhotograph

J.P. Couper, 147 West R(e)SIC.GENT St, Glasgow C2. Commercial and Technical Photographer. Phone: Douglas 5697machinery, wince machine -

National Wool Museum

National Wool MuseumMachine - Windchest, Prince-Smith & Stells Ltd

Used to collect the combed top from a noble comb. Consists of a cast iron stand and base with steel pinch rollers and a rotating iron feed tube to empty the top into a receiving bin.combing, windchest, machine, wool processing, industry, wool, rollers, bin -

National Wool Museum

National Wool MuseumLid

Lid for shearing hand piece.Lid for shearing hand piece.WOLSELEY 3shearing machinery, wolseley sheep shearing machine co. ltd, de josselin, mr john -

National Wool Museum

National Wool MuseumKnitting Machine, Sock

Suisse