Showing 424 items matching "wool processing"

-

National Wool Museum

National Wool MuseumPhotograph

Depicts the warping operations from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, warping, warping machinery -

National Wool Museum

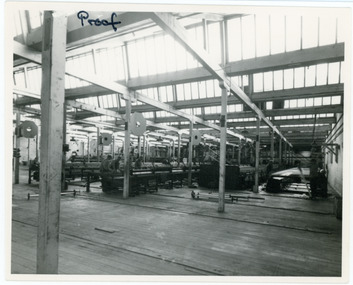

National Wool MuseumPhotograph

Depicts the weaving room from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, weaving machinery -

National Wool Museum

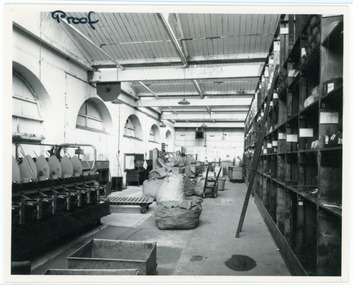

National Wool MuseumPhotograph

Depicts the yarn store from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd -

National Wool Museum

National Wool MuseumPhotograph

Depicts the winding room from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, winding, winding machinery -

National Wool Museum

National Wool MuseumPhotograph

Depicts the winding room from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, winding, winding machinery -

National Wool Museum

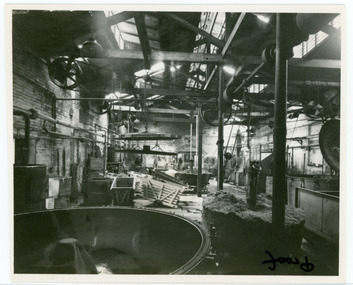

National Wool MuseumPhotograph

Depicts the dyehouse from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, dyeing -

National Wool Museum

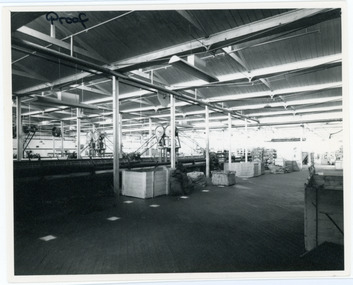

National Wool MuseumPhotograph - Wool Spinning Room, 1966

Depicts the woollen spinning room from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing company and this photo was taken at the time of the takeover.Photograph, black and white. Depicts a room filled with horizontal spinning machinery, powered by drive shafts. There are cases and skips in the foreground.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, spinning, spinning machinery -

National Wool Museum

National Wool MuseumPhotograph

Depicts the woollen spinning room from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, spinning, spinning machinery -

National Wool Museum

National Wool MuseumPhotograph

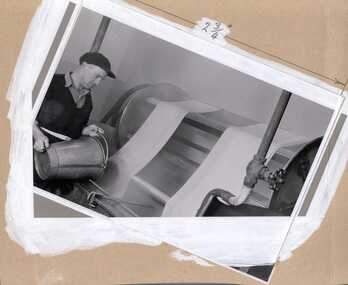

Depicts a wet finishing process within a mill, c.1950s. Possibly some sort of size or mordant is being added to the vat in which the fabric is being dipped. Part of a series of photos depicting the various operations within a textile mill, all of which have been edited for publication.textile mills - operation, wet finishing, sizing, mordanting -

National Wool Museum

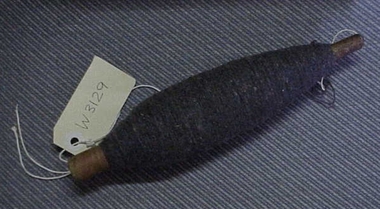

National Wool MuseumBobbin, Mule spinning bobbin

Spool of grey yarn used in the process of mule spinning.weaving mills -

National Wool Museum

National Wool MuseumCone

Designed for nce only use. Used for holding the yarn during yarn dyeing. The process was called "pressure dyeing" for a small amount of yarn. Doesn't create an even dye effect.Wangaratta Woollen Millsweaving mills, wangaratta woollen mills -

National Wool Museum

National Wool MuseumCreel

Used in the weaving process. -

National Wool Museum

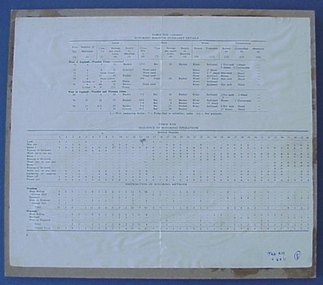

National Wool MuseumSheet, Instruction

Instruction sheet for mill floor operator, Appendix IV Materials Used in Scour, Lathes, Mill & Wash-Off Processes. Scouring Machine Auxiliary Details over.Other side of sheet.textile mills, collins bros mill pty ltd -

National Wool Museum

National Wool MuseumMachine - Knitting Machine, Sock

Knitted fabric is made with a single yarn or sets of yarns moving in only one direction. Whether done by hand or by machine, the process is the same. The knitting needle loops the yarn through itself to make a chain of stitches. These chains, or rows, are connected to produce the knitted cloth. There are two types of commercial knitting machine. A flat-bed has its needles, one for each loop, arranged in a straight line to produce a flat fabric. A circular machine has its needles arranged on a rotating circle. The cloth forms as a tube which can be made into seamless clothing. Personal history of Edna Harris who used the machine.knitting machine, industry, design, socks, clothing, wool -

National Wool Museum

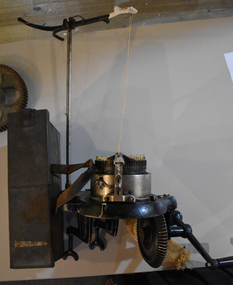

National Wool MuseumMachine - Sock Knitting Machine, G Stibbe and Co, c.1928

Knitted fabric is made with a single yarn or sets of yarns moving in only one direction. Whether done by hand or by machine, the process is the same. The knitting needle loops the yarn through itself to make a chain of stitches. These chains, or rows, are connected to produce the knitted cloth. There are two types of commercial knitting machine. A flat-bed has its needles, one for each loop, arranged in a straight line to produce a flat fabric. A circular machine has its needles arranged on a rotating circle. The cloth forms as a tube which can be made into seamless clothing. Dellruss Pty Ltd original owner Llyold Henry Coburg. Mock ribber fitted post World War 2. In use from c.1928 until 1978.Stibbe Maxim circular sock knitting machine.sock knitting machine, manufacturing, textiles, socks, machines, circular, clothing, industry, wool -

National Wool Museum

National Wool MuseumMachine - Sock Knitting Machine

Knitted fabric is made with a single yarn or sets of yarns moving in only one direction. Whether done by hand or by machine, the process is the same. The knitting needle loops the yarn through itself to make a chain of stitches. These chains, or rows, are connected to produce the knitted cloth. There are two types of commercial knitting machine. A flat-bed has its needles, one for each loop, arranged in a straight line to produce a flat fabric. A circular machine has its needles arranged on a rotating circle. The cloth forms as a tube which can be made into seamless clothing. Griswold bench-type sock knitting machine hand operated by turning the handle.sock knitting machine, textile industry, wool, fashion, clothing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Clothing - Dress, Coat, c1960

Worn by donor at son's wedding.|Jacquard, a complex and intricate weaving process on a power loom invented bt Joseph Jacquard in 1801. It refers to fabrics or textiles woven by this process of punch cards, using damask, twill, silk or plain weave,wool. The design being woven into the material.1960 Apple green dress and matching coat. There is a silver thread through the weave of the material (Jacquard Design - see History). Dress also trimmed with silver braid. Stand up collar. Back zip and self covered buttons.|Matching coat has round neck - two sets of three self covered buttons and loops.costume, female -

![View of the River Murray, near Echuca, showing the Railway Wharf with steamers unloading / [by] Nicholas Caire, circa 1876](/media/collectors/550653872162f11fb04854aa/items/57774776d0cdd10a5c111b2d/item-media/57774888d0cdd10a5c11c099/item-fit-380x285.jpg) Kew Historical Society Inc

Kew Historical Society IncPhotograph, Anglo-Australasian Photographic Company, View of the River Murray, near Echuca, showing the Railway Wharf with steamers unloading, c. 1876

Nicholas Caire was born on Guernsey in the Channel Islands in 1837. He arrived in Adelaide with his parents in about 1860. In 1867, following photographic journeys in Gippsland, he opened a studio in Adelaide. From 1870 to 1876 he lived and worked in Talbot in Central Victoria. In 1876 he purchased T. F. Chuck's studios in the Royal Arcade Melbourne. In 1885, following the introduction of dry plate photography, he began a series of landscape series, which were commercially successful. As a photographer, he travelled extensively through Victoria, photographing places few of his contemporaries had previously seen. He died in 1918. Reference: Jack Cato, 'Caire, Nicholas John (1837–1918)', Australian Dictionary of Biography.An original, rare photograph from the series 'Views of Victoria: General Series' by the photographer, Nicholas Caire (1837-1918). The series of 60 photographs that comprise the series was issued c. 1876 and reinforced a neo-Romantic view of the Australian landscape to which a growing nationalist movement would respond. Nicholas Caire was active as a photographer in Australia from 1858 until his death in 1918. His vision of the Australian bush and pioneer life had a counterpart in the works of Henry Lawson and other nationalist poets, authors and painters.albumen silver photograph on boardprinted in ink on support l.c.: VIEW ON THE RIVER MURRAY, NEAR ECHUCA, SHOWING THE RAILWAY WHARF WITH STEAMERS UNLOADING. / COPYRIGHT REGISTERED. printed in ink on support reverse c.: VIEWS OF VICTORIA. / (GENERAL SERIES.) / No. 7. / VIEW ON THE RIVER MURRAY, NEAR ECHUCA, SHOWING THE RAILWAY WHARF WITH STEAMERS UNLOADING. / The rapidly increasing traffic on the River Murray, with wool, timber, and other colonial produce, has called / into requisition no less than 400 steamers and over 1000 barges. To meet this growing emergency the Victorian / Government has expended several thousand pounds in the erection of a Railway Wharf which during the wool- / season presents a very busy scene, the crowded steamers laden with precious clip taxing to the utmost the / powers of the Railway Department in the process of unloading. The River here is about a quarter of a mile wide, / and is from 60 to 70 feet deep. printed in ink on support reverse l.c.l.: J.W. FORBES, Agent, printed in ink on support reverse l.c.: ANGLO-AUSTRALASIAN PHOTOGRAPHIC COMPANY, MELBOURNE. printed in ink on support reverse l.c.r.: 10 Temple Court, Collins Street West.nicholas caire (1837-1918), landscape photography, river murray, echuca -

National Wool Museum

National Wool MuseumBook

Bound book of wool samples in the grease and throughout the various processing stages, produced by Mr V. Dorron.Bound book of wool samples in the grease and throughout the various processing stages, produced by Mr V. Dorron. Bound book of wool samples in the grease and throughout the various processing stages, produced by Mr V. Dorron.V. DORRON GORDON TECHNICAL COLLEGE GEELONG JUNE 10 1922woolclassing, gordon technical college - woolclassing department, dorron, mr v -

National Wool Museum

National Wool MuseumCloth Sample Cutter

The cutter is placed over finished cloth, inserted block is pressed down to flatten any wrinkles and the needed sample is optain by tapping cutter top with a wooden mallet. The sample is then weighed to ascertain whether the processes have produced the desired result.textile design, collins bros mill pty ltd -

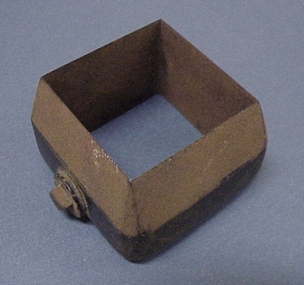

National Wool Museum

National Wool MuseumCloth Sample Cutter

The cutter is placed over finished cloth, inserted block is pressed down to flatten any wrinkles and the needed sample is optain by tapping cutter top with a wooden mallet. The sample is then weighed to ascertain whether the processes have produced the desired result.textile design, collins bros mill pty ltd -

National Wool Museum

National Wool MuseumCloth Sample Cutter

The cutter is placed over finished cloth, inserted block is pressed down to flatten any wrinkles and the needed sample is optain by tapping cutter top with a wooden mallet. The sample is then weighed to ascertain whether the processes have produced the desired result.textile design, collins bros mill pty ltd -

National Wool Museum

National Wool MuseumCloth Sample Cutter

The cutter is placed over finished cloth, inserted block is pressed down to flatten any wrinkles and the needed sample is optain by tapping cutter top with a wooden mallet. The sample is then weighed to ascertain whether the processes have produced the desired result.textile design, collins bros mill pty ltd -

National Wool Museum

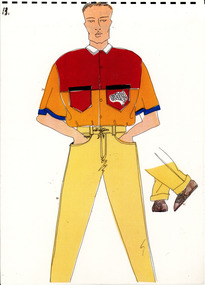

National Wool MuseumWork on paper - Barcelona Olympic Uniform Rejected Design Drawings, Wendy Powitt, c. 1992

A set of laminated A3 sketchbook pages depicting rejected designs for the 1992 Barcelona Olympic Uniforms designed by Wendy Powitt. These designs were rejected during the fabrication process and used at a later time by Doug Pleasance in demonstrations to university/TAFE students.8121.1 - A set of laminated A3 sketchbook pages depicting rejected designs for the 1992 Barcelona Olympic Uniforms designed by Wendy Powitt. The main drawing shows the design for a pair of dark green shorts, a yellow and green striped windcheater with a map of Australia in the centre and a brown belt. 8121.2 - A set of laminated A3 sketchbook pages depicting rejected designs for the 1992 Barcelona Olympic Uniforms designed by Wendy Powitt. The main drawing shows the design for a pair of yellow trousers, a red and orange shirt with blue cuffs and a map of Australia on the right breast pocket. To the right of the main drawing is a detailed drawing of brown leather shoes. 8121.3 - A set of laminated A3 sketchbook pages depicting rejected designs for the 1992 Barcelona Olympic Uniforms designed by Wendy Powitt. The main drawing shows the design for a pair of yellow trousers and a dark green button up shirt. In the top right hand corner there is a smaller depiction of the shirt showing the details. 8121.4 - A set of laminated A3 sketchbook pages depicting rejected designs for the 1992 Barcelona Olympic Uniforms designed by Wendy Powitt. The main drawing shows the design for a pair of yellow trousers and a dark green vest with five buttons in the shape of Australia. To the left of the main design are two smaller images, one showing the details of the pants and the other the detail of the buttons.1992 barcelona olympics, sport, athletes, fashion, design, artwork, drawing, uniform -

National Wool Museum

National Wool MuseumTextile - Skirt, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Red ribbed skirt with elastic waistband.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Skirt, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Red wide ribbed pleated skirt with a plain yoke, navy blue band at bottom edge and elasticated waistband. A purple x is located inside to mark centre back of skirt.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Men's Coat, c1940s

Franco Liburti was wearing this coat when he farewelled his wife Assunta in Naples, Italy in 1957, the day she departed for Australia. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Men's coat featuring a charcoal herringbone weave, with three buttons down the front and on each sleeve cuff.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community, naples -

National Wool Museum

National Wool MuseumTextile - Child's Pinafore, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Red and green plaid children's pinafore with green hem binding and in-built petticoat with lace edging.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Skirt, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Maroon skirt with curved wrap detail with maroon and navy striped ribbing halfway around bottom. The skirt is shaped with darts, has an elastic waistband, and centre back opening with a zip and skirt hook. Maroon lining.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Jumper, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Emerald green jumper with wide rib detailing, triangular detail at cuffs and hem and curved v neck. Shoulder seams are reinforced with woven tape.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community