Showing 543 items matching "heat"

-

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1964-1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White short-sleeved jumper with all-over pattern of aqua blue diamonds. Blue floated threads slightly show through white on main body, leading to an overall pale blue effect on body, with white collar and cuffs. Closes with three pearlescent plastic buttons at back neck. .2 is a retail tag marked with the style code, and includes generic information on care for garments of different material composition..1) [label stitched into back neck of garment] KATHRYN REGD CREATED BY ROBERT BLAKE .2) [retail tag, intended to be folded in three, printed on both sides] [OBVERSE] KATHRYN Children’s Knitwear STYLE: [blue pen] S/35B SIZE: PRICE: / KATHRYN Garments are… • PRE-SHRUNK • STANDARD MEASUREMENTS • FIT EXACTLY • LAUNDER PERFECTLY / NOW .. KATHRYN GOES TO . . SCHOOL Ask your retailer for SCHOOL PULLOVERS by KATHRYN [REVERSE] WASHING INSTRUCTIONS WOOL Wash frequently to AVOID HEAVY SOILING Wash garment BY HAND, in lukewarm Velvet Soap suds. ON NO ACCOUNT RUB SOAP ON GARMENT. Squeeze suds gently through garment but DO NOT RUB. Rubbing will cause garment to thicken. RINSE AT LEAST TWICE IN CLEAN WATER TO REMOVE ALL SOAP. TO dry, roll garment in a towel to remove excess moisture, turn garment inside out and pull it lengthwise, DRY IN SHADE… AVOID SUNLIGHT. When dry, place brown paper or pressing cloth over garment and press with iron at correct heat. ORLON Wash as wool Lay flat to dry but DO NOT IRON. To keep brushed suits like new, brush frequently with nylon brush supplied. COTTON Wash by hand for preference in Velvet Soap suds. Rinse thoroughly in cold water and remove all excess water before drying on line. Please do not use any harsh detergent or bleach. Designed and manufactured by ROBERT BLAKE Pty. Ltd., MELB. (handwritten in pencil) S35 (untintelligible)/5 / NOW KATHRYN GOES TO SCHOOL Ask your retailer for SCHOOL PULLOVERS by KATHRYNknitwear, children's knitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting, colourwork -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Bottle, Henry Kennedy Pottery, Late 1800s to early 1900s

This bottle was made in Scotland and recovered decades later from a shipwreck along the coast of Victoria. It may have been amongst the ship's cargo, its provisions or amongst a passenger's personal luggage. It is now part of the John Chance collection. Stoneware bottles similar to this one were in common use during the mid-to-late 19th century. They were used to store and transport. The bottles were handmade using either a potter's wheel or in moulds such as a plaster mould, which gave the bottles uniformity in size and shape. The bottle would then be fired and glazed in a hot kiln. Makers often identified their bottles with the impression of a small symbol or adding a colour to the mouth. The manufacturer usually stamped their bottles with their name and logo, and sometimes a message that the bottle remained their property and should be returned to them. The bottles could then be cleaned and refilled. The Barrowfield pottery was founded in 1866 by Henry Kennedy, an Irish native, in the Camlachie district east of Glasgow, close to the Campbellfield and Mount Blue potteries. It is believed that Kennedy started with just one kiln but by 1871 was employing forty men and six boys and such was the success of the enterprise that by 1880, no less than eight kilns were in operation and a year later one hundred and the pottery was employing eighteen people. Stoneware bottle production was a mainstay of the pottery and over “1500 dozen” were being turned out daily along with other wares, including 30-gallon ironstone containers. With so many kilns in operation, six hundred saggars were required every week but, unlike some potteries, these were made on the premises from Garnkirk and Glenboig fire clays. Pottery production reaches a high scale which presented a high risk of fire and Barrowfield was no exception. In April 1884 heat from a kiln set fire to the roof resulting in significant structural damage, the loss of unfinished wares alone amounting to £10,000 a very substantial sum in 1884. The pottery recovered from this reverse but then Henry Kennedy died in July 1890. The terms of his will indicated that he and his sons John and Joseph were partners and this was reflected in a change of title in the 1891-92 Post Office Directory to Henry Kennedy & Sons. Despite the growth of the business there was still space enough, however, to allow china, earthenware and glass retailers Daniel and John McDougall to commence production of their Nautilus wares there in 1894, the success of which allowed them to soon move to permanent quarters at the empty Saracen Pottery, Possil. In around 1900 John Kennedy left to resurrect the liquidated Cleland Pottery and although Barrowfield remained listed as Henry Kennedy & Sons, brother Joseph was in control. In 1911 Henry Kennedy & Sons Ltd was formed, with two of the four directors being the Kennedy brothers. The pottery’s growth to this point was reflected in the eighteen kilns the largest pottery kilns then recorded in Scotland. However, the disruption of the First World War and the combined effects of subsequent economic depression, US prohibition, hygiene regulations and competition from alternative materials posed severe challenges for stoneware potteries in the post-war years as they competed with each other for diminishing markets. Competitors such as Eagle and Caledonian Potteries fell by the wayside and finally, Barrowfield closed in 1929. This stoneware bottle is historically significant for its manufacture and use in the late 19th to the early 20th century. The bottle is also significant as it was recovered by John Chance, a diver, from a wreck on the coast of Victoria in the 1960s-70s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. Stoneware was produced at Barrowfield pottery for the domestic and export markets, with South America being a large market. Barrowfield stoneware can be found throughout the world. Its longevity and abundant production makes the subject item a significant addition to the Flagstaff Hill Maritime Museum collection.Bottle, salt glazed stoneware, beige, some discolouration above base. Chip on base and on neck. Inscriptions stamped near base.Makers lozenge stamped, H Kennedy Barrowfield Pottery GLASGOW at base.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, h kennedy pottery, stoneware, ironstone, pottery, barrowfield glasgow -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumBox, pill, 1930-1940 ref: Museum of Applied Arts and Sciences

As per another example in better condition displayed on shelf above Drawers 1+2 in Chemist ' Beechams Pills as sold by the proprietors St.Helens, Lancashire England. Beechams Pills Ltd. Melbourne VIC'. Earliest mention in Victorian Newspapers TROVE : Argus (Melbourne, Vic. : 1848 - 1957), Friday 19 December 1884, page 7 'A WONDERFUL MEDICINE BEECHAMS PILLS Are admitted by thousands to be worth above a guinea a box for bilious and nervous disorders such as wind and pain in tho stomach, sick headache, giddiness, fulness and swelling after meals dizziness and drowsiness, cold chills, flushings of heat, loss of appetite, shortness of breath costiveness, scurvy, blotches on the skin, disturbed sleep, frightful dreams, and all nervous and trembling sensations, &c The first dose will give relief in 20 minutes This is no fiction, for they have done it in thousands of cases. Every sufferer Is earnestly invited to try one box of these pills, and they will be acknowledged to be WORTH A GUINEA A BOX. For females of all ages these pills are invaluable as a few doses of them carry off all humours and bring about all that is required No female should be with-out them There is no medicine to be found to equal Beecham's Pills for removing any obstruction or Irregularity of the system. If taken according to the directions given with each box they will soon restore females of all ages to sound and robust health For a weak stomach, impaired digestion, and all disorders of the liver they act like "Magic, and a few doses will be found to work wonders upon the most important organs of the human machine They strengthen tho whole muscular system, restore the long lost complexion bring back the keen edge of appetite, and arouse into action with the rosebud of health, the whole physical energy of the human frame These are ' facts ' admitted by thousands embracing all classes of society, and one of the best guarantees to the nervous and debilitated Is Beechams Pills have the largest sale of any patent medicine in the world Full directions are given with each box Sold by all druggists and patent medicine dealers throughout the colonies'. Most recent article in Victorian newspapers : TROVE : Wodonga and Towong Sentinel (Vic. : 1885 - 1954), Friday 24 December 1954, page 1. 'MUM KNOWS BEST SHE KEEPS THE FAMILY FIT WITH BEECHAM'S PILLS SAFE because Beecham's Pills contain no harmful habit-forming drugs-they are a purely vegetable laxative. Pills balanced formula gives natural laxative action without harsh purgative effects banishes constipation. MOTHERS know how to keep growing children in their teens fit and happy-with Beecham' s Pill, the family laxative. TAKE Beecham's Pills WORTH A GUINEA A BOX'. Relevant local newspaper article reference : TROVE : Gippsland Times (Vic. : 1861 - 1954), Thursday 29 October 1942, page 1 'ln times like these old friends are best You will not have to go far before finding a friend who can tell you by personal experience how gentle and reliable Beecham's Pills are--and how effectively they banish head aches. digestive upsets and liverish ness. Purely vegetable....1/-....2/...per box Worth a guinea a box' Cylindrical wooden box with the remains of an orange, red and white printed label on top, containing small orb shaped pills.Label on lid : Beecham's pills...............Beecham's Pills Ltd., Melbourne, Vic.laxitive, pills -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Report, The Commonwealth Engineer, Electrical Engineer, The Electrical Engineer and Merchandiser, Noiseless Tramcar - first Australian Vehicles - Bogies fitted have special noise reducing features, 1917 - 1951

Set of 12 reports, photocopied onto heat sensitive paper from various magazines. Documents match the image numbers. .1 - 2 pages, from The Commonwealth Engineer, 1/10/1917 - "New Cars for the Melbourne Brunswick and Coburg Tramways", written by Straun Robertson. .2 - 2 pages, from The Commonwealth Engineer, 1/3/1919 - "Double Bogie Combination Tram Car - St Kilda Brighton Electric Line". .3 - 2 pages - Electrical Engineer - 15/6/1924 - "One Man cars for Melbourne and Geelong Vic. The Brill Birney Safety Car" .4 - 1 page - Electrical Engineer - 15/11/1925 - "Standard Car for Melbourne Tramways" - has sketch of W2 369. .5 - 2 pages - Electrical Engineer - 15/8/1927 - "New Bogie car for Melbourne Tramways" Y class. .6 - 2 pages - Electrical Engineer -15/3/1936 - "Tramcar of New type for Melbourne - Large car for Two-man or One-man operation" - Y1 class .7 - 3 pages, The Electrical Engineer and Merchandiser - 15/3/1932 - "Modern Tramcars for Melbourne - Design for reduction of noise and construction with electrical Welding" W3 class. .8 - 2 pages, The Electrical Engineer and Merchandiser - 15/11/1933 - "New Tramcars for Melbourne" - has sketch of the W4 class tram. .9 - 3 pages, The Electrical Engineer and Merchandiser - 16/12/1935 - "Melbourne's Lates Tramcars, comfortable Accommodation and modern traction equipment" - W5 class .10 - 3 pages - The Electrical Engineer and Merchandiser - 15/3/1939 - "Improved Type Tramcar - advanced truck design, pneumatically operated doors, special lighting, acceleration 3pmh per sec." SW5 class. .11 - 3 pages - The Electrical Engineer and Merchandiser - 15/9/1950 - "Noiseless Tramcar - first Australian Vehicles - Bogies fitted have special noise reducing features - motor drive through bevel gears, dynamic braking" - PCC 980 (See also Reg Item 5601 for a similar report) .12 - 1 page - handwritten on the rear of a copy of item 11 - Editorial from the Oct. 1951 issue of same magazine looking at the rate of acceleration. Reprint of .7 added 30/7/2019, from papers ex Robert Green - in poor condition, has been folded, both left and right hand edges in multiple tears. The photos are good. Measures 282H x 220W.trams, tramways, mmtb, mbctt, new tramcars, vr, bogie trams, birney, x class, w2 class, y class, y1 class, w3 class, one man trams, w4 class, w5 class, sw5 class, pcc class, tramcar design, electrical engineering -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesPhotograph - Colour slides, Thomas H. Kneen, Burnley Views, 1956-1969

Contributor: T.H. KneenBox of 47 slides, some labelled. (1) "Marjorie Hall 1st Year Student June '56 No. 1872." Working with fruit tree stock. (2) "Orchard June 1956 No. 1710." 2 men and a tractor.(3) "Camp 1957." Wilson's Promontory. (4) View of Drive No. 1677." C. 1958 (5) "GenView No. 1771." (6) "Burnley Gardens Entrance 4.4.58 N0. 1672." (7) "Wilson's Promontory Lilly Pilly Gully Nov 1960." (8) Dec '62." (9) "Dec '62." Kneen child. (10) Luffmann Ponds "Aut. 1962." (11) Grevillea Sep 1963. (12) Sep 1963.Reflection of Crack Willow in Luffmann Ponds. (13) Sep 1963. Orchard blossom. (14) View of Administration Building at sunset Aug 1964. (15) Rose 'Heat Wave.' May 1965. (16) Kneen child sitting under a tree May 1966. (17) 'Department of Agriculture Burnley Gardens' sign May 1966. (18) Administration Building May 1966. (19) Plant Science Block May 1966. ((20) Wintersweet August 1966.(Actually appears to be Witch Hazel Hamamelis mollis.) (21) Student on tractor in the Orchard October 1966. (22) Garden view, view of Principal's Residence through blossom trees October 1966. (23) Students walking through the Gardens October 1966. (24) "Leaf Cuttings Rex begonia 2 October 1966. (25) Emily Gibson beds October 1966. (26) Principal's Residence in a garden view October 1966. (27) Garden view looking towards the Principal's Residence and the Shady Garden October 1966. (28) Drive looking towards the Administration Building from the Plant Research Institute. (29) Kneen child (not Burnley?) (30) Unveiling of Burnley Horticultural College plaque commemorating 75 years, 1891-1966 - Eric Littlejohn, ?, T.H. Kneen. Includes key to Pavilion 1969. (31) "Rose Pruning Demo - Canteen." July 1969. (32, 33) "Rose Pruning Demo 1969." July 1969. (34) "Plant Science Block & College." July 1969. (35) Plant Science Block 6/69." July 1969. (36) "Burnley Gardens 6/69." looking towards Dairy and Yarra Boulevard (37) "Pond No. 1717." (38) "Pond 1748." Kneen children playing by the Luffmann Ponds, Oak tree behind.. (39) Ginkgo leaves June 1967. (42) ? (43) Erithyna caffra in flower (removed 2016) December 1966. ((44) Administration Building and Nursery from PRI." (45) Pelargoniums. (46) Azalea mollis (47) Pelargonium foreground, geranium background.marjorie hall, students, fruit trees, orchard, tractor, wilson's promontory, burnley gardens, entrance, drive, garden view, luffmann ponds, grevillea, rose, kneen family, sign, wintersweet, plant science block, administration building, students working outside, principals residence, plaque, rose pruning demonstrations, ginkgo, pelargoniums, erythryna -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageNail, circa 1810

This copper nail, sometimes known as a ‘Dumpy Bolt’ or spike, was salvaged from the hull of the wreck of the “George III”. It dates back to at least 1810. It was found by an abalone diver on the south east coast of Tasmania. The nail would have been used to hold the layers of the ship’s keel frame and the planking together. The nail has been passed from the abalone diver to an interested business man on a trip to the south of Hobart, on again to the business man’s close friend who then donated it to Flagstaff Hill Maritime Village. The metal of nails such as this one, after being in the sea for a long time, become affected by the natural reaction of the sea water, causing it to degenerate and thin, and the stress from the force of the sea over the years alters its shape. Iron nails had been used on ships previously, but they quickly corroded in the salt; ships needed regular, costly and time-consuming maintenance to replace the iron nails. Towards the end of the 18th century the British Navy trialled the use of copper nails, finding them to be very successful. Merchant ships began to adopt this process in the early 19th century, although it made ship building very expensive and was more often used for ships such as the “George III” that sailed on long voyages. The three masted sailing ship “George III” was a convict transport ship built in Deptford, England, in 1810. On 14th December 1834 she left Woolwich, England, bound for Hobart Town, Van Diemen’s Land (Tasmania), under Captain William Hall Moxey. She was carrying 220 male convicts plus crew, guards and their families, totalling 294 persons (another 2 were during the voyage). Amongst the cargo were military stores including several copper drums of gun powder. On 27th January 1835 the “George III” was near the Equator, about half way into her journey. A fire broke out and the gun powder was in danger of explosion, threatening the whole ship. Two convicts braved the heat and smoke, entered the store and seized the gun powder drums, suffering burns for their efforts but saving a probable disaster. The fire destroyed some of the provisions and food was scarce. Many became ill with scurvy and some died during the journey. Nearing the end of their journey on 10th April 1835 the “George III” was headed through the D'Entrecasteaux Channel, south east Tasmania, between the mainland and Bruny Island. She was sailing in the moonlit night to hasten her arrival in port due to the great number of sick on board. She struck uncharted rocks, known only to the local whalers, between Actaeon Reef and Southport Lagoon and within hours began to break up. The ship’s boats were used to first rescue the women and children. Firearms were used to help quell the panic of the convicts below decks and some were killed by the shots. Many convicts, including the sick, were drowned. In all, 133 lives were lost including 5 of the crew, guards and their families. It was the third worst shipping disaster in Tasmanian waters. A monument in honour of the prisoners who perished in the “George III” has been erected, noting the date of the wreck as “Friday 10th April 1835.” (NOTE: there are a few differences between sources regarding dates of the shipwreck, some saying March and others April 1835. There are also differences in the figures of those on board and the number of lives lost.) The copper nail is significant as an example of sailing ship construction; fasteners used in the early 19th century on ships carrying convicts to Australia. The nail is also significant for its association with the ship “George III”. The “George III” is registered on the Australian National Shipwreck Database, ID 7195 as an Historic Shipwreck. She is the third worst shipwreck in Tasmanian waters. She is also associated with Early Australian History and the transportation of convicts to Australia. The incident of the fire on board and the bravery of the convicts in making the gun powder safe is an example of the social character of the people in early Tasmanian colonisation. Copper nail (also called a Dumpy bolt or spike) from the convict ship George III, wrecked in 1835. Nail is long, bent in an ‘L’ shape about 3/5ths along, tapering from both ends to the bend. Both ends are flat and do not taper to a point, nor have a thread. The shorter end has been polished, showing bright copper. There is pitting along the nail and virdigris is evident on the longer, unpolished end. The nail is displayed with the longer section resting on a wooden board between two ‘U’ shaped uprights, the shorter section upright. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, george iii, ship construction, ship nail, 1835 shipwreck, 19th century shipwreck, william moxey, d'entrecasteaux channel, convict transportation, copper nail, dumpy bolt, spike, keel nail -

Puffing Billy Railway

Puffing Billy RailwayEquipment - Victorian Railways Carriage Foot Warmer

During prestige, long distance train journeys some carriages had air-conditioning, and the majority of passengers had to brave unheated carriages. To offer some comfort during the winter months, the non-air-conditioned carriages were provided with footwarmers. These were metal containers roughly 100 mm thick and 300 mm wide, and about 750 mm long, which were filled with salt crystals (concentrated crystalline hydrated sodium acetate). The footwarmers were covered by sleeves of thick canvas, and two footwarmers were usually placed in each compartment of non-air-conditioned carriages. To activate the chemicals, the footwarmers were heated almost to boiling point. This was done by removing the canvas sleeves and placing the footwarmers in a large bath of very hot water. After they had been heated, they were removed from the bath and the sleeves refitted. They were then ready to be placed in the carriages. The McLaren patent foot warmer was used on railways in New South Wales, Queensland, Victoria and South Australia as well as South Africa and New Zealand. It was during the 1901 royal visit by the Duke and Duchess of Cornwall that these foot warmers were first used in New Zealand in the royal carriage. Before railway carriage heating was introduced, McLaren patent foot warmers were placed on the floor of New South Wales government railway carriages from 1891 to provide a little passenger comfort. The rectangular steel container worked a bit like a hot water bottle but instead of water contained six and a half kilograms of loosely-packed salt crystals, (concentrated crystalline hydrated sodium acetate). This was permanently sealed inside the container with a soldered cap. After the foot warmer was heated in vat of boiling water for about one and a quarter hours the crystals became a hot liquid. (The melting point for sodium acetate is 58 degrees). There was a whole infrastructure of special furnaces set up at stations for the daily heating of foot warmers. By 1914 the Victorian railways had 4,000 foot warmers in service and by 1935 there were 33 furnaces at principal stations to heat them. After about 10 hours the container was picked up by the handle and given a good vertical shake which helped the cooled liquid reform into a solid mass of hot crystals. Staff or sometimes passengers shook them en route when the foot warmers began to get cold. However, as they were heavy this was only possible by fit and agile passengers. At the end of the journey the containers were boiled again for reuse on the next trip. Sodium acetate railway foot warmers were introduced in Victoria in 1889, Adelaide to Melbourne express in 1899. "Shaking up" on this service took place at Murray Bridge and Stawell on the tip to Melbourne and at Ballarat and Serviceton on the trip to Adelaide. The use of foot warmers began to decline in New South Wales from the 1930s with the first trial of carriage air-conditioning in 1936, steam heating from 1948 ad LP gas heating from 1961. By the early 1960s the main services using foot warmers were the overnight mail trains. info from : http://www.powerhousemuseum.com/collection/database/?irn=67564#ixzz4UBNzVf6t Under Creative Commons License: Attribution Non-Commercial There was a whole infrastructure set up at stations for the daily heating of foot warmers in special furnaces. In Victoria alone in 1935 there were 33 heating works.Historic - Victorian Railways - Carriage Heater - Foot warmerA rectangular-shaped stainless steel casing with a welded seam down the back and welded ends. There is a handle at one end for carrying and shaking. Inside the foot warmer are two baffle plates and three trays to contain the sodium acetate. There was a cast-iron ball in each internal compartment. puffing billy, victorian railways, carriage haeter, foot warmer, passenger comfort, station furnace, railway ephemera, early heating methods -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, Mont Albert Central School Grade 1, 1921, 1921

Mont Albert State School was officially opened on 23rd April 1917. The school became Mont Albert Central School in 1918, taking in Forms 1 and 2. The school remained a Central School until 1964, when the secondary years formed the basis of a new High School, the Box Hill North High School, later to be named Koonung Secondary College. This is part of a large collection of material related to the Deakin, Mair and Young families, all with connections to Surrey Hills and Mont Albert. Ernest Lance Young was the son of Ernest Augustus Young (1891-1985) and Ruby Nichell Whitby (1892-1984). Lance was born 24 March 1915 in Surrey Hills. The family lived at 5 York Street, Surrey Hills. Electoral roll for 1937 gives the house name as 'Whitby Lodge'. He married Beryl Mair in 1939 and died on 5 October 1999 at Mont Albert. Electoral rolls list him as a manufacturer. His address after marriage was 11 York Street, Mont Albert. He is buried in Box Hill Cemetery (M-*-0867) along with his father. He served in WW2 (Service Number - VX104733 enlisting at St Kilda) and after returning took over his father's business. Young's Motor Products have manufactured products for the automotive and other related industries, including chemical trades, since 1920. Business history: Young's commenced trading in 1917 when Mr Ernest Augustus Young started selling paint brushes. At this time the company was known as E.A.Young & Co. with business premises in Queen Street Melbourne. Ernest soon expanded into paints and other products for the rapidly growing automotive trade and by 1920 was well recognised as a leading supplier. At this time canvas hoods were the norm and Ernest produced a "Canvas Hood Dressing" which gained acceptance as 'the one to buy'. This product was exported throughout the world. By 1930 Young's range had expanded and the product range included items like distilled water, gasket cement, vulcanising heat patches, rust prevention and many more diverse products. Young's name then, was so well known in Australia and the world, that a letter could be addressed just "Young's Melbourne" and it would reach the company. Young's survived the great depression, but in 1939 the Australian government commandeered the factory with all plant and equipment, thus closing Young's for the duration of the WW2. Ernest continued to make products at home for the war effort. When his son, Lance, returned home from overseas war service in Singapore, the Young's factory was re-established at 405 Canterbury Road, Canterbury near Chatham Station and worked to regain markets lost in the 1940s. By 1980 Lance Young wished to retire, his immediate family didn't want to continue the business and Lance believed Australia would lose a great asset if he just closed the company. He sought to find someone within the motor trade who would uphold the Young's principles of product and service and in 1981 Allan Kennedy & Sons bought the business.Lance Young was retained as an active consultant until his death in October 1999, aged 84. Products: Superseal for radiators, tyre dressing (tyre black), car shampoo, hood dressing, leather and vinyl cleaner. The factory was later elased to B&D Rollerdoors. REF: Personal communication (Laurie Newton, nee Young) and http://youngsmp.com.au/comprof.htm Black and white class photo taken outside the school building. The class of 18 girls and 22 boys is flanked by a male teacher of the LHS of the photo and a female teacher on the RHS. Children are wearing a variety of clothing indicating the absence of an official school uniform.REAR: Possibly 4 different hands as follows: 1. In black ink faded to brown: "January 1921 / Mont Albert State School" 2. "ERNEST" in black biro; looks to be a later insert to "Lance Young" in blue biro or ink. 3. "2nd on left / FRONT ROW legs crossed" in blue biro. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Foundry Patterns set, Briggs Brass Foundry, Early 20th century

The wooden crate contains a set of patterns or moulds that were once used at Briggs’ Brass Foundry for making sand moulds. The traditional method of sand casting is over 2000 years old. It is part of a crafted process used to make brass and copper alloy goods suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-corrosive and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry display was one of the early ‘working craft’ shops at Flagstaff Hill. It included a historic Cornish chimney that was set up as a working model, telling the story of heat from furnaces to smelt metal, which would then be poured into the sand moulds. This chimney is made from specially curved bricks and is about two-thirds of its full height when originally located at the Grassmere Cheese factory. HISTORY of BRIGGS BRASS FOUNDRY: - The family business was founded in 1912 by Herbert Harrison Briggs (1963-1931) with his son George Edward Briggs, trading as Briggs & Son Foundry at 70 Wellington Street, Collingwood. Younger son Cyril Falkiner McKinnon Briggs joined the foundry in 1922, and it was renamed H H Briggs & Sons Foundry. Both sons ran the firm after Herbert’s death in 1931, making products mainly for marine purposes. They became Bell Founders in 1936 and were known for their specialty of high-quality ship bells. They produced miniature varieties of these and other decorative items such as small propellers. The firm became known as Briggs Marine Foundry. The great-granddaughter of Herbert Briggs inherited the Briggs Brass Bell, similar to the one at Flagstaff Hill. Cyril became the sole family member of the firm in 1965. The Briggs Marine was an exhibitor at the 1965 Boat Show, where he advertised as “non-ferrous founders” and “Bell Specialists”. The foundry relocated to Chesterville Rd, Moorabbin. Cyril passed away in 1967. It is thought that either Cyril or his business partner Frank Lee donated the objects from the Briggs’ Foundry around the time when the business moved to Moorabbin. However, Flagstaff Hill hadn’t been thought about until 1972. The donated items were registered in the Collection in 1986 but they could have been in storage from an earlier date. In October of that same year, Briggs Marine restored Schomberg Bell, a shipwreck artefact from the collection at Flagstaff Hill. Peter Oram, who had worked for the previous owners of Briggs Marine as a fitter and turner, took over the firm in 2014, reviving some of the old casts for current use. The business is now located at Seaford in Victoria and is part of Alliance Casting & Engineering Solutions (Alliance Casting Pty Ltd). In 2016 the original Collingwood Foundry building was repurposed as a thriving business hub named The Foundry. The crate and its patterns are significant for their association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. The patterns are associated with the long-running firm, Briggs Brass Foundry, that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine is also associated with the Schomberg Bell in Flagstaff Hill, restoring the bell to is former state to show an example of the bell from a luxury mid-19th century vessel. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. Wooden rectangular crate with removable wooden lid. Inside is a set of wooden patterns of various shapes and sizes for making sand moulds in a metal foundry. The crate is made from thick wooden planks nailed together. The extended wooden struts on the long sides form a frame to hold the wooden lid. A pair of metal handles are at each short end of the crate, fixed with strong metal bolds. Between each pair of handles is an inscription stamped into the wood. The underside of the crate has red paint splashes. There are insect holes in the wood but no sign of current infestation. Stamped: "H.33 / II" (H may be N or a square B)flagstaff hill maritime museum and village, great ocean road, shipwreck coast, pattern, mould, foundry, brass foundry, metal foundry, crate, box, wooden container, briggs, traditional method, trade, sand cast, cast, brass alloy, copper alloy, marine equipment, marine tools, marine fittings, briggs' bronze, copper tin zinc lead, non-corrosive, briggs family, brassware, metalware, foundering, metalwork, maritime, casting, cornish chimney, curved bricks, grassmere cheese factory, 1912, herbert harrison briggs, h h briggs, george edward briggs, briggs & son foundry, collingwood, cyril falkiner mckinnon briggs, cyril briggs, h h briggs & sons foundry, bell founders, schomberg bell, alliance casting & engineering solutions, collingwood foundry, ship chandlers, marine products, flagstaff hill, warrnambool, maritime museum, maritime village, briggs & son brass foundry, briggs marine, moorabbin -

Ballarat Tramway Museum

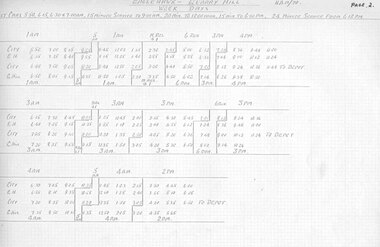

Ballarat Tramway MuseumDocument - Roster, State Electricity Commission of Victoria (SECV), Rosters for Bendigo, 1970

Significant in being a almost complete set of rosters for Bendigo prior to closure - appear to be have been copied for a discussion or information document for management at Ballarat. Need to ascertain whether they line up with the actual last timetable. No Sunday tables given - probably did not change them.Set of photocopies of Rosters for Bendigo. Not sure whether these were actually used or were at the stage of a discussion document - see sheet 30. Photocopied onto foolscap size heat sensitive paper and some loosing information. Sheets have been numbered. Generally dated "HAM/70" Page 1 not location 2 - Eaglehawk - Quarry Hill Weekdays 3 - ditto - continued 4 - Golden Square - North Bendigo Weekdays - two different rosters given on two separate sheets. 5 - Eaglehawk - Quarry Hill Saturdays 6 - ditto continued 7 - Golden Square - North Bendigo - Saturdays 8 - Tables - 1AM, 2AM, 3AM 9 - Tables - 4AM, 5AM, 9AM - second sheet gives slightly different arrangements for 5AM 10 - Tables - 10AM, 11AM, 9Assist - second sheet gives slightly different arrangements for 10 & 11AM 11 - Tables - 2PM, 3PM, 4PM 12 - Tables - 6 run, Meal relief & 1, 11 Assist 13 - Tables - 9PM, 10PM, 16 Assist 14 - Tables - 1AM, 2AM, 3AM Conductors 15 - Tables - 4AM, 5AM, 6 run Conductors 16 - Tables - 2PM, 3PM, 4PM Conductors 17 - Tables - 12 Assist Motorman and 13 Assist Conductor - 2 sheets, can't see a difference. 18 - Tables - Saturday, 1AM, 2AM, 3AM 19 - Tables - Saturday, 4AM, 5AM, 9AM 20 - Tables - Saturday, 10AM, 11AM, 1st relief motorman 21 - Tables - Saturday, 9 Assist, 10 Assist, 14 Assist, 15 Assist 22 - Tables - Saturday, 1PM, 2PM, 3PM 23 - Tables - Saturday, 9PM, 10PM, Gol. Sq. relief Motorman 24 - Tables - Saturday, 1AM, 2AM, 3AM conductors 25 - Tables - Saturday, 4AM, 5AM, 1st Meal relief conductor 26 - Tables - Saturday, 1PM, 2PM, 3PM, conductors 27 - Tables - Saturday, 11 Assist, 12 Assist, 13 Assist - conductor 28 - Standby chart - Weekdays and Saturdays 29 - Rotation Roster for Motorman and Conductors - dated 12/5/1970 30 - Comparisons of Present Roster and proposed roster - includes cost impact analysis - 2 copies held. 31 - folded sheet - Weekday Instructions - poor order photocopied - 2nd copy - minor changes 32 - folded sheet - Saturday Instructions - poor order photocopied 33 - Daily hours of Motorman conductors - Weekdays and Saturday 33A - Hours of Motorman and Conductors - Sunday 34 - Weekly Hours - for motorman and conductors - poor order photocopied and data filled in on photocopy. 39 - Tramways - Motorman and Conductors Rotation Roster - dated 5-3-1970trams, tramways, rosters, timetables, sec, bendigo -

Eltham District Historical Society Inc

Eltham District Historical Society IncMagazine, Sun News-Pictorial, Bush Fires: A pictorial survey of Victoria's most tragic week, January 8-15, 1939, 1939

THE WEEK REVIEWED (Article; Bush Fires: A pictorial survey of Victoria's most tragic week, January 8-15, 1939. Published in aid of the Bush Fire Relief Fund by the Sun News-Pictorial in co-operation with its newsagents, pp2-3) THE fiercest bush fires Australia has known since its discovery are quiescent at the moment, and Victoria, in the comparative coolness of the change which came with rain on Sunday night, has begun·to count its losses. In the fiery eight days, from Sunday to Sunday, at least sixty-six men, women and children have lost their lives in forest fires, or have succumbed to burns and shock; many others have died from heat; and several serious cases of burns are being treated in hospitals. Two babies in Narrandera district have died, and ten others are in hospital, because of milk soured by the record temperatures of those eight days. Forest damage totals at least a million pounds, and incalculable damage has been done to the seedlings which were to have been the forests of the future. Water conservation will be seriously affected by the silting-up of reservoirs and streams from which protective timber has been taken by the all-engulfing flames. More than a thousand houses have been destroyed, and these, with 40 mills, and schools, post-offices, churches, and other buildings, represent a loss of at least half a million. At least 1500 are homeless. For their aid, money raised in appeals has now passed the £50,000 mark, and the biggest relief organisation ever set up in peace time has swung into operation. The First Hint Victoria's first hint of what was to come appeared on Sunday, January 8, when most parts of the State awoke to find a blistering day awaiting. At 12.20 p.m., when the thermometer reached its highest for the day, 109.6 degrees, the first fire victims were at that moment going to their death on a bush track five feet wide off the main road to Narbethong. They were the forestry officers Charles Isaac Demby and John Hartley Barling, who went to warn Demby of his danger when he parted from his companions, and was himself surrounded by the treacherous fire. It was not until 8 o'clock next morning that the tragic news was flashed throughout the State. Searchers found the two charred bodies close together, one seeking protection in the nook of two logs. Barling's watch had stopped at 1.20. In the meantime, tragedy was spreading its cloak. By Monday, big fires were raging at Toolangi, Erica, Yallourn, Monbulk, Frankston, Dromana, Drouin South, Glenburn, and Blackwood, with smaller outbreaks at many other centres. In the ensuing week, while women and children were evacuated as fast as the flames would permit, Erica-scene of the 1926 fire disaster-thrice escaped doom by a change of wind. Indeed, those who have been in the fire country these past days say that the numbers of times a change of wind has saved towns from destruction is amazing. In the towns they speak of miracles. Monday's Miracles The escapes from Monett's Mill at Erica and from the Hardwood Company's Mill at Murrindindi, near where Demby and Barling went to their death, were Monday's miracles. Twenty came out alive from each mill. At the first a 60ft. dugout provided an oven-like refuge; at the second, 12 women and children survived in the smoke-filled gloom of a three-roomed cottage while their eight men, their clothes sometimes afire, poured water on the wooden walls. Three houses out of ten remained when the fire had passed. Record Temperatures Sunday had been the hottest Melbourne day for 33 years; Monday dropped to a 76.1 degree maximum; but Tuesday dawned hotter than ever, the mercury reaching 112.5. By now rumor was racing ahead of fact; whole towns were being reported lost; the alarm was raised for scores of missing persons. But fact soon overtook rumor, and within a few days the staggering toll began to mount to a figure beyond the wildest imaginings of the panic-stricken. Six died from heat on this torrid Tuesday, and the fires spread in a wide swathe from south-west to north-east across the State. Fish died in shallow streams. A curtain of smoke hid the sky from all Victoria, and hung far out to sea. It alarmed passengers on ships. On the Ormonde, on the voyage to Sydney from Burnie, women ran on deck, believing fire had broken out in the hold. Days later the smoke reached New Zealand. In Melbourne thousands of fire-volunteers were leaving in cars: vans, motor-buses-anything reliable on wheels-to aid the country in its grim fight. In the fires at Rubicon and. Narbethong, seventeen were facing death this day. But not till Wednesday, when Melbourne breathed again in a cool change, while the country still sweltered in temperatures up to 117 degrees, did the news come through the tree blocked roads. A woman and her little daughter, trapped on the road, were among those who died. Their bodies, and those of menfolk with them, were found strewn out at intervals along the road, where the furnace of the surrounding fire had dropped them in their tracks as they ran. Twelve died at a Rubicon mill, five on the road at Narbethong. At Alexandra, not far distant, a baby was born while the fires raged, and stretcher-bearers brought in the injured. On Thursday the State Government voted £5000 for the relief of fire victims. The Governor (Lord Huntingfield) and the Lord Mayor (Cr. Coles) visited some of the stricken areas, and dipped into their pockets personally. Later, the City Council, too, voted £5000. Friday, The 13th Friday, the Thirteenth, justified its evil name. A blistering northerly came early in the morning, presaging destruction, and forcing the mercury to a new record of 114 degrees. Racing fires killed at least ten in those terrible 12 hours. Four children were engulfed in the furnace at Colac. Panic drove them, uncontrollable, into the smoke-filled road when the fire raced down behind their home. They choked to death. In other parts fires were joining to make fronts of scores of miles. Kinglake was being menaced on two fronts, £60,000 worth of timber was going up in smoke in Ballarat district. Warburton was surrounded. Residents at Lorne, favoured resort, were being driven to the sea-front by a fire which destroyed at least 20 homes. Healewille. with flames visible from the town at one stage, was in a trough between two fires which burned four guest-houses, seven homes and left its surrounding beauty-spots wastes of bowed-over, blackened tree-fern fronds; with its famous Sanctuary, however, intact. Most of Omeo was destroyed this black day: Noojee. while 200 residents crouched in the river, was being reduced to a waste of buckled iron and smoking timber; Erica was once again saved by a change of wind. Beneath a pall of smoke, the Rubicon victims were buried at Alexandra. Friday night and the early hours of Saturday saw the streets of beleagured towns strewn with exhausted fire-fighters. Their flails beside them, ready for the next call, they lay where exhaustion overtook them-on footpaths, beside lamp-posts, in gutters, in cars, under trucks. Saturday's dawn brought clear skies and lower temperatures in many parts, and from the burnt-out areas came a great rush of tragic reports. The death-roll rushed past the fifty mark with incredible speed. Some had been trapped on roads, others at mills; some, after burying their treasures, had clung too long to the places they had made their homes for many years. Four men lost their lives because one went back for his dog. By Sunday, when the first of the saving rain came, nearly another score of names had been added to the list.Newspaper magazine, 48 pages (incl. covers). Fully digitised and searchable PDFPublished in aid of the Bush Fire Relief Fund by the Sun News-Pictorial in co-operation with its newsagents.bushfires, 1939 bushfires, black friday, warrandyte -

Eltham District Historical Society Inc

Eltham District Historical Society IncDocument - Property Binder, 1184 Main Road, Eltham

Newspaper article: A sustainable award, Diamond Valley Leader, 1 November2006, Architect and building Llewellyn Pritchard won resource Efficiency Housing Award, finalist in HIA Greensmart Building of the Year Award. House – Environmental Leader (Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p186) In 2006 environmental awareness was mushrooming in the community, which is reflected in the award-winning house at Main Road near Wattletree Road, Eltham. At first sight, the building appears a mix of a classic Eltham mud-brick house and an avant-garde building style. The crown of solar panels stretching along the width of the curved roof, indicates that this is no ordinary house. In fact it signals a new building trend of minimal impact on the environment. Yet it utilises the environment with high technical expertise to achieve comfort and cut running and maintenance costs. In recognition of this, its designer/builder, Conscious Homes, won the 2006 National HIA Greensmart Resource Efficiency Award. For Conscious Homes director, Llewellyn Pritchard, this house reflects a philosophy, strengthened by his connection with Aboriginal culture, through his foster siblings. Pritchard believes the sustainable way indigenous Australians lived and their spiritual connection with land, demonstrates how humanity is part of the ecology. His interest in environmental design stemmed from growing up in bushy Eltham Shire, with its mud-brick tradition. This was followed by studying Architecture at RMIT in the early 1980s, and learning about passive solar design. Pritchard says this house demonstrates that environmental sustainability is not about sacrifice, but about exceptional levels of occupant comfort, savings in running costs and modern fittings and appliances.1 The solar panels on the north roofs are intentionally obvious to make a statement about what the building is doing. But inside the systems are hidden and interactive with conventional services, such as the underground water tank. The house is water and energy self-sufficient and at 12 squares is much smaller than conventional houses, to minimise resources. Yet it accommodates his family of four with three bedrooms, a living/dining and kitchen area and a bathroom/laundry. Importantly the building is designed to last hundreds of years, by being able to be modified as the need arises, such as for commercial use. In this way the structure minimises its environmental impact. The solid double mud-brick walls (which are insulated) include steel beams and supporting frame, allowing the future removal or alteration of any section. The materials are local, recycled and of low toxicity where possible.2 Inside and out, the mud-brick is rendered and sealed with a combination of cement and sand and a mud-based coating in a soft golden hue increases its life. Inside, the golden-brown timber is plantation Mountain Ash and the concrete floors throughout – of local stone aggregate with a clear seal – have a natural looking random stone appearance. The house sustains a stable temperature of around 20 degrees, assisted by the concrete slab floor. The many large double-glazed windows and highlights (windows set high on walls) provide cross-flow ventilation. The north-facing living area maximises heating from the lower winter sun and is cooler in summer, because the sun is higher. Heating comes from a solar hydronic slab system. All appliances and fittings are high efficiency energy or water rated. Appliances in the timber kitchen include a gas stove and a dishwasher, using the building’s own power and water. French doors open from the living area to a deck, concealing the treatment system for all waste water. This is pumped through sub-soil drippers to the indigenous garden beds and no-dig vegetable patch. Below the carport is the 80,000-litre rainwater tank and at the back, the boiler room houses the solar boiler, water tank access, domestic water supply pump, filter gear and hydronic slab heating controls. The solar system is backed up with gas, which is needed to heat water only in winter. Gas used is less than one quarter of that for an average home with ducted heating. Excess power is fed back to the grid and the building uses about one quarter of the mains electricity of an average home. Other local builders have followed Pritchard’s lead in resource efficiency for minimal environmental impact.main road, eltham, businesses, llewellyn pritchard, hia greensmart building of the year award., efficiency housing award, conscious homes australia pty ltd -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Instruction Book, Westinghouse Brake Company of Australasia Limited and The Westinghouse Brake & Saxby Signal Co. Ltd. of 82 York Road and Kings Cross London, "Westinghouse Railway Operating Data", 2000

Photocopy of 54 data sheets published by Westinghouse Electric & Manufacturing Company of East Pittsburgh Pa, USA c1920. Consists of plastic cover, header page with Westinghouse logo, contents sheets (2 pages), forward, 67 pages (single side photocopy) and heavy rear card cover bound with a green comb binder. Original material lent by Craig Tooke of the Melbourne Tramcar Preservation Association at Haddon. Photocopied by Warren Doubleday March 2000. List of contents produced 30/6/2000 and then bound. Contains data sheets regarding motors, commutators, brushes, armatures, bearings, field coils, pinions, lubrication, air piping, axle collars, resistance grids, gear cases and other technical information. Westinghouse Railway Operating Data 30/6/2000 List of Contents Page No. Care and repair of commutators 1 Undercutting commutators 2 Railway Motor carbon brushes 3 Brush holders 4 Flashing of railway motors 5 Soldering railway armatures 6 Armature Winding 7 Banding armatures 8 Railway Motor Bearings 9 Lubrication of railway motor bearings 10 How to babbitt motor bearings 11 Oil, grease and waster for motors and gears 12 Saturation of motor bearing waste 13 Testing Polarity of Field Coils 14 Charging of storage batteries on Interurban & street rail cars 15 Precautions to be taken with blower installations on motor cars 16 Putting on Railway Motor Pinions 17 How to take armatures out of box frame motors 18 Dipping and Baking of Railway Motors 19 War time dipping and baking outfits 20 Dipping and baking railway motors will decrease troubles 21 Protection of Motor Bearings from Dust 25 Winter Operation of Railway Motor equipments 26 Installation of Air piping to prevent freezing 27 Maintenance of Traction Brake Equipment 28 Maintenance of controller fingers and contacts 29 Hand operated circuit breakers 30 Railway Motor Testing I 31 Railway Motor Testing II 33 Railway Motor Testing III 35 Railway Motor Testing IV 36 Railway Motor Testing V 37 Removing and replacing railway motor armature shaft 39 Mounting and Maintenance of car resistors 40 Lubrication of control apparatus 41 Maintenance of fuse boxes for railway service 42 Does it pay to dip and bake armatures 43 Dipping and Baking as a financial asset 44 Shop Organisation 45 Tinning Malleable Iron Bearing shells 46 Life of armature bearings or railway motors 47 The assembly of complete sets of commutator segments 48 Electric welding as a factor in reclamation 50 Metal to Metal press, shrink and clamping fit allowances 52 Life of railway motor carbon brushes 54 General information of grid resistance design for the operating man 56 Stopping a car by braking with the motors 57 Railway Motor shafts and their maintenance 58 Axle collars 59 Gear cases 60 Ventilated railway motors 62 Revamping Loose armature bearings 64 Life of axle bearings of railway motors 65 Heat-treated bolts for railway service 66 Document imaged over 7 parts 7-9-2016 - see hi res files. trams, tramways, westinghouse, motors, data sheets, technical information -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - First Aid Case, Thomas Urquhart & Son Pty Ltd (Thos. Urquhart), 1930-1939

This small, portable 1930s Sanax First Aid Case has been strongly constructed, with corners reinforced with metal to take knocks and bumps, so it could be quickly transported to the site of an emergency. Having these supplies organised into a kit made them easily accessible and reduces time to take them to the site of the accident. It was possibly designed for use in factories because the booklet in the case states that the kit complies with “Part 1, Victorian Factories Regulations”. The text of the printed brand “Sanax First Aid Case” is right-way up when the case stands vertically on its hinged side. In modern times people are well aware of the importance of quick treatment when accident and injury occur. However, before the first commercial First Aid Kit was made by Johnson & Johnson in 1888, people had little knowledge about treating injuries and lacked information about suitable supplies to keep on hand for emergencies. They were often unaware of how to help in that critical time before the doctor or other assistance arrived, a particularly important time for the many people living in remote areas. A quote from Johnson’s & Johnson’s 1888 price list explains “It is a fact, which is everywhere being recognized, that many lives are lost and much suffering entailed in such accidents on account of the lack of the simple but necessary articles required to afford prompt assistance to the wounded.” One example of the value of First Aid assistance to community groups is shown in an article from the Weekly Times, 29th November 1930. It records a report from the Annuello Branch of the Younger Set (a Country Women’s Organisation), telling that on Armistice Day their president Mrs Jamieson, presented the Annuello School with the gift of a Sanax Red Cross First Aid outfit, which was accepted as being “of great practical use to the scholars.” (Annuello is a remote wheat growing area in the Mallee region of North Western Victoria, which became a soldier settlement area after World War I. There is a strain of wheat named ‘Annuello’ due to its suitability for that area. ) The Sanax Case in our Collection contains instructions, equipment and medical items suitable for use in emergency situations. The Case was one of 42 patterns available from Sanax that conformed to ‘Part 1, Victorian Factories Regulations’. It includes items made by Sanax Company and by Burroughs Wellcome & Co. (Australia) Ltd., Sydney, NSW. A quote at the back of the First Aid Emergency Instructions booklet says: “Sanax products are made in Australia by or under the supervision of qualified chemists, from the highest quality materials. They are dependable for the purposes written on labels.” BOOKLET included in First Aid Case: “SANAX” First-Aid Emergency Instructions has orange cover and white pages, joined in the centre by two staples. Booklet contains First Aid Instructions for general events listed in alphabetical order. It also contains an indexed sections headed “Poisoning, and what to do” written by S.A. Burrows, Ph.C., Vuc and N.Z. There are instructions and diagrams on how to perform Artificial Respiration. There are advertisement for Sanax products throughout the booklet that include; - Sanax Ambulance Stretcher for timber mills, mines, ships and quarries - Saw dust masks (porous rubber) for workers in dust, paint or duco sprayers Inside cover lists Sanax’s Australian made products including - tablets and powders for headaches, neuralgia, influenza, colds - snuff for Catarrh that is “quite harmless” - First Aid Cases that come in a range of 42 patterns - sunburn preventatives and treatments - healing salve for carbuncles, pock, pimples, boils, varicose ulcers etc. - snake bite outfits and kits LEAFLETS included in First Aid Case: (1) Tannafax Tannic Acid Jelly. Tannafax should be kept at hand in every home. It should be applied direct from the tube and used with neither oil nor grease. Where a large area has to be covered the clamped end may be torn or cut off to give a wider mouth to the tube. Collapsible tubes of different sizes. Made in Australia. Burroughs Wellcome & Co. (Australia) Ltd. (Incorporated in England). Sydney, NSW. Assorted Houses, London, New York, Montreal, Cape Town, Milan, Bombay, Shanghai, Buenos Aires. Copyright A. 1817, J. 9463 (2) Tabloid. The strong thing is the just - - . Tabloid marks the wor - - Burroughs Wellcome & Comp. The use of the word is to enab – the prescriber, dispenser and patient to get the right thing with one short word, instead of the firm’s long name. If another maker apply the word to his product, the act is unlawful. Tabloid is our trade mark and brand. If a vendor disregard it in dispensing or selling, the act is unlawful for the same reason. We prosecute both offenders rigorously, in the interest of prescribers, dispensers, patients and the owners of the trade mark. Please inform us of any instance of either offence. Burroughs Wellcome & Co. (Australia) Ltd. (Incorporated in England). Telephone Number - M 4184 (4 lines) All communications to G.P.O. Box No. 1185 DD. Copyright Sy. 20. & J 9894. Medicines and Equipment included in First Aid Case: - Absorbent Cotton, Sanax, for absorbing blood or drying a wound. As a swab for washing wounds; to place above a compress to keep the heat in: or as a pad to protect wounds or fractures. The Sanax Co. Manuf. Chemists, Melbourne. Regd. Office: 5 Brunswick St, Fitzroy. N.6. - ACHE tablets, Sanax, for all aches, pains, fevers etc. Dose: 2 to 3 tablets with a draught of water, every 3 hours. Children in proportion. For influenza or colds, take the bedtime dose with a hot lemon drink or toddy. Recommended for Headaches, Colds, Influenza, Fevers, Neuralgia, Rheumatism, Nerve Pains, Sleeplessness, and Seasickness. Three Sanax Ache tablets equals one Sanax Ache powder. Each tablet contains 1.75grs. each Phenacotinum and Acety acSzilcyl, and .75grs Ammon Brom. Etc.. Sanax brand specialties are prepared by highly qualified pharmaceutical chemists and may be accepted as safe and effective for the purpose indicated on the label. The Sanax Co. Melbourne - Eye lotion, Sanax, “in eye bath full strength or diluted with equal parts of water. Sanax Co. Brunswich St, Fitzroy, Melbourne. - Iodine, Sanax, POISON, with instructions for what to do if swallowed. - Kuraburn, Sanax, Applied to the burn and allowed to dry, the pain and heat instantly disappear, and blistering is prevented. If necessary, apply again in an hours. To safeguard against burning when sunbathing, apply before exposure to the sun. If already sunburnet, use Kuraburn as directions above. Safe and harmless. Sole makers, The Sanax Co. Brunswick St. - - Vic. - Sal Volatile, Sanax, - - stimulant for - - nervous aches - - or as smelling salts Dose - - - - Solution of A- - - 5%, . The Sanax Co. Brunswick St, Melbourne. - Tannafax, Burroughs Wellcome & Co. Australia Ltd. Sydney, N.S.W., 20gm. Approx., Tannic Acid Jelly, (Tannic Acid with 0.5% Phenol in a water-soluble base) for burns and scalds. A.N. 15050, p188, logo of a unicorn. Apply lightly, allow to dry, and bandage loosely. Do not apply oil or grease. - bottle wrapped in brown paper, unknown contents, paper adhered to bottle. - dish, kidney shaped, metal, white enamel with black rim - eye bath, green, plastic or Bakelite SANAX COMPANY The Sanax Company was at the address of 5 Brunswick Street, Fitzroy [Melbourne] at least as early as November 1924, as shown by its advertisement of Ache Powder in the Weekly Times, 8th November 1924. It was still at this address in September 1951, when it advertised First Aid outfits and components in the Post Master General’s section of the Commonwealth of Australia Gazette. REFERENCES: Annuello, Victoria; Wikipedia, https://en.wikipedia.org/wiki/Annuello,_Victoria Annuello Younger Set, Branch Activities and Local Reports, Country Women’s Organisations, Weekly Times, 29 November 1930, Trove http://trove.nla.gov.au/newspaper/article/224921009?searchTerm=%22sanax%22%20and%20%22melbourne%22&searchLimits=# Commonwealth of Australia Gazette, Issue 32, 24th April 1915, https://www.legislation.gov.au/file/1915GN32 [Johnson & Johnson Price List, September 1, 1888, p. 20. From our archives], Celebrating the 125th Birthday of the First Aid Kit , The Story of Johnson & Johnson, , http://www.kilmerhouse.com/2013/06/from-1888-to-2013-celebrating-the-125th-birthday-of-the-first-aid-kit/ Post Master General’s section of the Commonwealth of Australia Gazette, Issue No. 73, Thursday 27th September 1951 http://trove.nla.gov.au/newspaper/article/232185299?searchTerm=%22sanax%22%20and%20%22fitzroy%22&searchLimits= Sanax First Aid Emergency Instructions, by S.A. Burrows, publisher Sanax Ltd. Fitzroy, Victoria, 1930-1939 English, book, Illustrated edition, Trove http://trove.nla.gov.au/version/40948895 Access to emergency medical help in early settlement days of Victoria could take quite some time, especially in remote areas. From 1888 First Aid Kits and instructions became available for work sites, offices, community groups and individuals, helping to bridge the gap between the accident and the arrival of medical assistance. This portable Sanax First Aid Case is an example of portable medical equipment made in Melbourne, Australia, in the 1930’s and available to the public. It contains a range of items plus information to be used in a variety of injuries and emergencies in in factories, households, businesses and local communities, and instructions on their use. First Aid Case, portable, Sanax First Aid Case. First Aid kit in strong black cardboard carry case with metal reinforced corners, metal hinges on lid, metal catch and leather carry handle. Inside lid is a vertical strap with narrow gap behind it. Base is divided into two compartments. Manufactured by Sanax, Fitzroy, Melbourne, C. 1930-1939 Contents include "Sanax" First Aid instructions booklet, 2 leaflets, metal kidney dish enamelled in white with black trim on edge, green plastic or Bakelite eye bath, eye lotion, Tannafax tannic acid jelly, Sal Volitile, Kuraburn, Iodine, Argyrol, ACHE tablets, absorbent cotton in cardboard box, gauze bandage, and UNKNOWN wrapped bottle. Printed in gold on lid of case “SANAX” FIRST AID CASE. Most of the contents, as well as the case, show the “SANAX” brand. Some contents are inscribed Burroughs Wellcome & Co. (Australia) Ltd., flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, first aid items, first aid kit, emergency first aid, medical emergency kit, home emergency kit, industrial emergency kit, sanax company fitzroy melbourne, burroughs wellcome & co. (australia) ltd, thos. urquhart & son pty. ltd. melbourne, sanax first aid case, sanax first-aid emergency instructions, part 1 victorian factories regulations, tabloid medical supplies -

Melton City Libraries

Melton City LibrariesPhotograph, Bruce Myers, 1931

My Story by Bruce Myers – June 2001 Arthur Bruce Myers was born on Wednesday morning on the 29/4/1925 at Kelvin Grove Hospital Bacchus Marsh. Background Information: Prepared by Niece Wendy Barrie. The early life of Bruce Myers “Burnbank” Ballarat Road Melton. The family home was built by his grandparents Ann nee Dowling and Henri Miers in 1867. His father Frederick was born in 1877 in Melton the youngest of four boys. Bruce the fourth son of Frederick and Martha, brother Frederick the eldest was followed by Marjorie and Edna. His brother Max was the youngest child. Father Frederick Myers attended Melton State School No 430 enrolling in 1881 and leaving in 1888 gaining his Merit Certificate No 116343. Bruce enrolled in July 1931 and completed and gaining his Merit Certificate in 1937. In 1938 he travelled to Melbourne Boys High School. Bruce was taught piano by his sister Marjorie, a respected Melton music teacher. He entered many Piano competitions and at the age of 10 winning the radio cup in the Junior Cavalcade at 3AW at Latrobe Street. At Melbourne Boys High School during his lunchtime was allowed to practice the piano in the basement for his recreation. He was pestered by another boy (name I have forgotten) a teacher intervened telling him to leave Myers alone. As a young child when listening to music he was able to on hearing it identify the key it was written in, due to his perfect pitch. I remember “Mum” Myers telling about the time they went to see Artur Rubeinstein at a concert, when Bruce was a small boy, it may have been on this occasion that he had noted the key of the piano composition. Bruce writes – In my early teens Max and I frequently accompanied the Williams boys, Wally and Jim on expeditions up the Toolern Creek near where the Gisborne exit now crosses it. The dogs would chase the rabbits into their burrows after placing nets over the burrows a ferret would be let in to burrow, much excitement would be involved in the rush to grab the rabbits as they bolted into the nets. In the same area I used too accompany Dad on an evening rabbit shoot (summer time). After the heat of the day the rabbits would emerge from their burrows at dusk. We would his behind the tree in silence, a mark contrast to the ferreting scene. Dad with the shotgun cocked would wait until 2 or 3 rabbits were close together then fire (Bang!). Hopefully killing two rabbits. They would have to be killed outright, otherwise they would run back into their burrows. Needless to say, one deafening shot ended the event, also it only cost one cartridge. Our only swimming pool was hole in the Toolern Creek at its junction with the blind creek at the eastern entrance to Melton. Dad swum there in the 1880’s teaching many of the youngsters to swim. Females never swum there to my knowledge. The dressing shed consisted of a 4 corrugated iron nailed to a wooden frame about 4 metres by 3 no floor or roof. We always walked the kilometre in our bathers anyway. The swimming hole once dried up leaving about 2 ft of mud. We Melton boys had so much fun fossicking around with our hands and feet and yanking out numerous eels, some very bid. I don’t know what happened to them all. No doubt Dad would have skun one or two for Mum to cook after cutting them up into short lengths. They used to jump around the pan when they were cooking. Dad accompanied by Max and I, frequently fished for eels in the Gillespie’s waterhole just below our place using a rod, line, sinker, hook baited with a worm, and a white floater so as to easily see when an eel was on the hook, so that it could quickly be pulled before it could anchor itself on and under water snag such as a tree root making it impossible to catch, or causing the line to be lost. At about the age of 8, I suddenly discovered amazingly easily means of movement. One day when I was riding the bike on rough bluestone road near the Presbyterian Church [Uniting Church] in Melton when the front fork broke and I landed on my right knee and right eye gashing both, the knee severely. I have carried the scars ever since. I started getting mobile by riding a scooter with good leg on the scooter and swinging the right leg, keeping is straight because bending it was too painful.Childhood photo of Brucelocal identities -

Eltham District Historical Society Inc

Eltham District Historical Society IncFilm - Video (VHS), Diamond Creek Fire Brigade, c.1955-1987