Showing 695 items

matching wool manufacture

-

National Wool Museum

National Wool MuseumBooklet, From the Sheep's Back

Booklet about the manufacture of woollen products, produced by Collins Bros Pty Ltd.Booklet about the manufacture of woollen products, produced by Collins Bros Pty Ltd.textile industry - education, collins bros mill pty ltd -

National Wool Museum

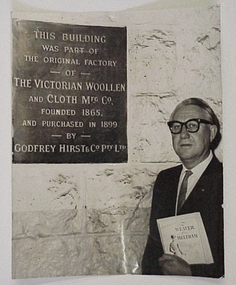

National Wool MuseumPhotograph

Photograph,of a plaque on the wall of the original Victorian Woollen Mill.Photograph,of a plaque on the wall of the original Victorian Woollen Mill.Godfrey Hirst/16/2/65 Cobb Topweaving mills, godfrey hirst and co. pty ltd victorian woollen and cloth manufacturing co. -

National Wool Museum

National Wool MuseumYarn

'Corio' brand hand knitting wool, produced in Geelong, Australia. The weight of 25 grammes indicates a date of manufacture after 1966.Three balls of 'Corio' brand woollen hand knitting yarn, produced in Geelong, Australia.Corio / 8 PLY / WOOLLEN / HAND KNITTING / YARN / MADE IN / GEELONG, AUSTRALIA. / 25 GRAMMES NET AT STANDARD CONDITIONShandicrafts -

![Photograph, [Sladen's in residence]](/media/collectors/510b3f7f023fd725b4cd52cc/items/5406604b9821f50e3cc9fe5e/item-media/5406604b9821f50e3cc9fe5f/item-fit-380x285.jpg) National Wool Museum

National Wool MuseumPhotograph, [Sladen's in residence]

Sladen House was built by Sir Charles Sladen in 1850 and it served as the amenities section of the R S & R Mill after World War 2.Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy lLimited Robert Pockley Studios/ photographers... Copy by/woollen mills - history textile mills - staff textile mills, returned soldiers and sailors mill, kidman, mr g. l., sladen house, geelong, woollen mills - history, textile mills - staff, textile mills -

National Wool Museum

National Wool MuseumAnnual Report, Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 40th Annual Report, 1960

"Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 40th Annual Report, 1960."woollen mills - history textile mills - history, returned soldiers and sailors mill, lau, mr alexander - alexander lau pty ltd, woollen mills - history, textile mills - history -

National Wool Museum

National Wool MuseumAnnual Report, Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 41st Annual Report, 1961

"Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 41st Annual Report, 1961."woollen mills - history textile mills - history, returned soldiers and sailors mill, lau, mr alexander - alexander lau pty ltd, woollen mills - history, textile mills - history -

National Wool Museum

National Wool MuseumAnnual Report, Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 42nd Annual Report, 1962

"Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 42nd Annual Report, 1962."woollen mills - history textile mills - history, returned soldiers and sailors mill, lau, mr alexander - alexander lau pty ltd, woollen mills - history, textile mills - history -

National Wool Museum

National Wool MuseumAnnual Report, Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 43rd Annual Report, 1963

"Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 43rd Annual Report, 1963"woollen mills - history textile mills - history, returned soldiers and sailors mill, lau, mr alexander - alexander lau pty ltd, woollen mills - history, textile mills - history -

National Wool Museum

National Wool MuseumAnnual Report, Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 44th Annual Report, 1964

"Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 44th Annual Report, 1964."woollen mills - history textile mills - history, returned soldiers and sailors mill, lau, mr alexander - alexander lau pty ltd, woollen mills - history, textile mills - history -

National Wool Museum

National Wool MuseumAnnual Report, Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 45th Annual Report, 1965

"Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 45th Annual Report, 1965"woollen mills - history textile mills - history, returned soldiers and sailors mill, lau, mr alexander - alexander lau pty ltd, woollen mills - history, textile mills - history -

National Wool Museum

National Wool MuseumAnnual Report, Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 46th Annual Report, 1966

"Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 46th Annual Report, 1966"woollen mills - history textile mills - history, returned soldiers and sailors mill, lau, mr alexander - alexander lau pty ltd, woollen mills - history, textile mills - history -

National Wool Museum

National Wool MuseumAnnual Report, Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 47th Annual Report, 1967

"Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 47th Annual Report, 1967"woollen mills - history textile mills - history, returned soldiers and sailors mill, lau, mr alexander - alexander lau pty ltd, woollen mills - history, textile mills - history -

National Wool Museum

National Wool MuseumAnnual Report, Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 49th Annual Report, 1969

"Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 49th Annual Report, 1969"woollen mills - history textile mills - history, returned soldiers and sailors mill, lau, mr alexander - alexander lau pty ltd, woollen mills - history, textile mills - history -

National Wool Museum

National Wool MuseumAnnual Report, Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 50th Annual Report, 1970

"Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 50th Annual Report, 1970"Back coverwoollen mills - history textile mills - history, returned soldiers and sailors mill, lau, mr alexander - alexander lau pty ltd, woollen mills - history, textile mills - history -

National Wool Museum

National Wool MuseumAnnual Report, Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 51st Annual Report, 1971

"Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 51st Annual Report, 1971"woollen mills - history textile mills - history, returned soldiers and sailors mill, lau, mr alexander - alexander lau pty ltd, woollen mills - history, textile mills - history -

National Wool Museum

National Wool MuseumAnnual Report, Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 52nd Annual Report, 1972

"Geelong R S & S Woollen & Worsted Co-operative Manufacturing Coy: 52nd Annual Report, 1972"woollen mills - history textile mills - history, returned soldiers and sailors mill, lau, mr alexander - alexander lau pty ltd, woollen mills - history, textile mills - history -

National Wool Museum

National Wool MuseumBook, Hand books of the textile industry, vol 2: manufacture of narrow woven fabrics

"Hand books of the textile industry, vol 2: manufacture of narrow woven fabrics" - E A PosseltK M Chisholm/ Denholm/ Bowenfelstextile calculations textile industry weaving textile industry - education, weaving, weaving looms, yarn - woollen, yarn - worsted, ribbon, textile calculations, textile industry, textile industry - education -

National Wool Museum

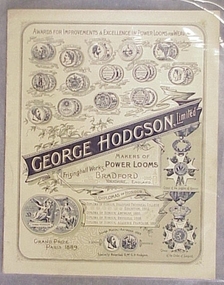

National Wool MuseumCatalogue, Illustrated catalogue of power looms for weaving, manufactured by George Hodgson Ltd: treading tappet section

"Illustrated catalogue of power looms for weaving, manufactured by George Hodgson Limited, Frizinghall Works, Bradford Yorkshire: treading tappet section". Among items from Yarra Falls Mill."Illustrated catalogue of power looms for weaving, manufactured by George Hodgson Limited, Frizinghall Works, Bradford Yorkshire: treading tappet section".textile machinery weaving, yarra falls mill george hodgson limited, weaving looms, weaving machinery, textile machinery, weaving -

National Wool Museum

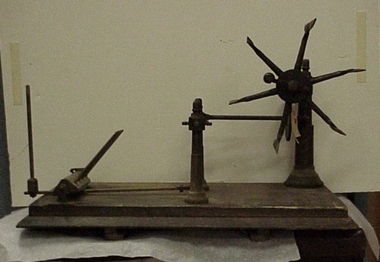

National Wool MuseumMachine - Wrap Reel

Wrap reel manufactured at Valley Worsted Mill and possibly used in the laboratory. "Wrap reels were used to check the yarn count in a spinning mill. A set length of yarn was wound off several test bobbins and weighed, if the weight was not the correct amount expected the spinning machines draft could be re calculated and the machine draft wheel ( cog ) changed to achieve the required count". - Greg AldridgeA small hand operated wrap reel. The reel is on a wooden base, the winding mechanism is metal and turned by a wooden handle. There is a metal plaque on the base inscribed MAKERS VWM. A wood and metal yarn feeder has broken off its mount.MAKERS/ VWMtextile machinery textile production weaving, valley worsted mill valley worsted mill, warping machinery, textile machinery, textile production, weaving, wrap reel, skein winder -

Stawell Historical Society Inc

Stawell Historical Society IncBook - Laboratory Reference Book, Wool an Introduction to its properties, Varieties, uses and production, W.J. Onions

Textbook. Lab Reference - Norwellan & AUNDE North Western Woolen Mills became Norwellan Textiles then AUNDELight Brown hardcover with Gold title on spineJohn T Bennett, Lyddon Hall Leeds 17/10/1968manufacturing -

Stawell Historical Society Inc

Stawell Historical Society IncBooklet - Laboratory Reference Book, The Chemistry of Wool and Related Fibres, by J.B. Speakman

Lecture Notes Reprinted from The Journal of the Textile Institute, Lab Reference - Norwellan & AUNDE North Western Woolen Mills became Norwellan Textiles then AUNDELight Green soft cover booklet with Dark Blue title on covermanufacturing -

National Wool Museum

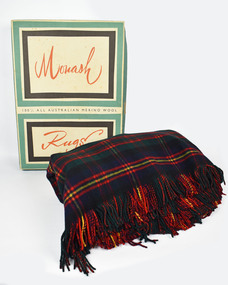

National Wool MuseumTextile - Rug, Returned Soldiers and Sailors Mill, 1963

The Returned Soldiers and Sailors Mills was located near the Barwon river on Pakington Street, Geelong, where its building still stands. The mill was established in October 1922 with capital acquired from War Gratuity Bonds. The mill produced fine grade woollen products with its speciality being ‘Retsol’ travelling rugs. The mill first began to run into financial troubles with the ‘Credit Squeeze’ or the ‘Holt Jolt’ of the early 1960s. This saw import restrictions lifted which triggered the start of a minor recession and a rise in unemployment. Included in these troubles was the RS&S Mill which saw the number of employees gradually decrease and business declining with cheaper imports beginning to grab an expanding part of the market share. The mill was eventually purchased by Godfrey Hirst in 1973 who tried to continue operations without success and in June 1975 textile production at the site ceased. Outside of financial considerations contributing to the closure of Woollen Mills in this period was the declining need for heavier fabrics as in-home heating and insulation improved. This need had been replaced for a demand for ever softer, finer and lighter worsted fabrics for more casual clothing. Modern day textile production requires fewer steps in the processing of materials for this use. This meant large factory complexes such as early woollen mills like the RS&S mills were no longer required. Compared to modern textile production which can spin a fine yarn out of synthetic fibre or imported cotton easily, spinning fine yarn from medium quality wool at a textile factory was cumbersome and no longer financially viable to suit new consumer demands. This rug provides context to this statement. It was gifted to Shirley and Gordon Green as a wedding present in November 1963 by one of Gordon's colleagues in the wool industry. Living in areas such as Neutral Bay, the Hornsby area and later in life retiring to the Central Coast, the blanket was too heavy for use in these weather conditions and hence it stayed in its original box for nearly 60 years. Top and bottom of rug has frilled edges. Pattern is titled the 'Clan Cameron' and is repeated in a 7x7 grid. Front of rug has a red background with 4 vertical and horizontal lines. All is surrounded by a yellow boarder. Label is stitched into the bottom right corner. Reverse of rug also has a repeating 7x7 grid. Blue background with thick green horizontal stripe. Yellow and red boarder to the grid with 4 red vertical and horizontal lines making up the interior. Rug measure 1550 x 2040mm, approximately the same size as a queen size mattress.Wording, Bottom right corner. THE GEELONG R.S&S. WOOLEN MILLS/ PURE/ WOOL/ AUSTRALIA/ The John Monash Rug (cursive)/ The Clan Cameron (cursive)rs&s mills, textile manufacture, rug, clan cameron, sydney greasy wool exchange -

National Wool Museum

National Wool MuseumFunctional object - Needles, W.H. Head & Son, c1895

Needles are over 100 years old. The donor obtained them from Mrs Patricia Wrench, a granddaughter of Lord Brassey, Governor of Victoria between 1985 – 1900. The needles were manufactured by W.H. Head & Son, a Trimming Manufacture and Wholesale Haberdashers company established in London.A purple leather case containing 39 steel knitting needles of varying widths.Above clip of case, gold lettering - W.H. Head & Son, Sloane st, London, S.W. Inside case, gold lettering - 10 11 12 13 14 15 16 17 18 19 20england, needles, patricia wrench, lord brassey, knitting -

National Wool Museum

National Wool MuseumTool - Metal Files, c. 1920

Selection of metal files used for cutting wool bale stencils with an accompanying box. Not all files belong to this box as some are too long to fit within. Used in Denny’s Lascelles Bow Truss building by Maurice Dalton who was the foreman of the building for 34 years. Files are ‘Cup Brand’ – ‘Best refined steel files’ and were manufactured by the no longer trading Moss & Gamble Brothers LTD at the Franklin works in Sheffield, England.12 steel files of varying length, thickness and shape. The longest and thickets are in a flat half circle with some files being fully flat, others complete cylinders, one is a complete square and others are in the shape of a triangle. Cardboard box is brown with black inscription on lid of box.stencils, denny’s lascelles bow truss building -

National Wool Museum

National Wool MuseumPicker

... is collected with this machine. Wool Picking Textile manufacturing wool ...Wool picking machine designed to separate locks of wool before it is carded and spun. The picker opens the wool’s locks which makes it easier to send the fleece through a carding machine. It does this by teasing the fibres (which can also be done by hand just by pulling the lock structure apart), but a picker does this in bulk and much quicker than what can be done by hand. It is possible to spin fibres directly after the picking stage; however, it is usually more desirable to card and blend them with other fibres. Typically, at a textile mill, a picking machine can separate enough lengths of fibre for a full day’s work after just a single hour. It will also help to remove any vegetation matter or other any unwanted elements that may be present in the wool. The quality of the casting on this machine suggest that it was made locally, either in Australia or New Zealand. Mike Leggett, the donor of the machine, acquired it from New Zealand where the seller said it had been used by his father to pick wool to make hand stuffed horse saddles. Mike attempted to used it a couple of times to pick alpaca hair, but the speed of the attached motor caused damage to the fibres. The motor is thought to be an added attachment, sometime around the 1960s judging by its age, while the machine itself is thought to be dated around the 1920s. The machine works by inserting wool through the rollers. Initially there was a conveyor belt feeder system which was powered by the handle on the side. This conveyor belt has been removed however, most likely due to age and deterioration. Wool is now fed through the initial teeth and is met by a spiked rotating drum which works to separate the fibres. The separated fibres would then complete a loop of the drum before being dispatched somewhere below, around where the motor presently sits, at a rapid rate of speed. Typically this wool will be collected in a closet or large catchment area, as can be seen from the 8:47 minute marker in the linked video (link - https://www.youtube.com/watch?v=kMjx-t3tH3A). It is not apparent how the wool is collected with this machine. Red and green machine with four green legs currently attached to a wooden pallet with wheels for easy movement. The green legs lead up to a red central circular barrel from which many attachments are present. Also present on the wooden pallet is a small black motor which is attached by a rubber belt to the central drum inside the red barrel. The belt spins the wooden drum via a dark red circular plate attached to the side of the drum. On the other side of the red barrel, a green handle extends for turning the picker’s conveyor belt feeder system. Two green walls extend forward from the central red barrel, guarding either side of where the conveyor belt would have been. At the start of these walls is a wooden cylinder, which the conveyor belt would have wrapped around, followed by two interlocking gears which rotate and accept the fed wool. The red roof extends over the central cylinder from here, securing the wool inside and protecting hands from the heavily spiked internal wooden cylinder which rotates and separates (picks) the wool. Extending over the top of this red roof is a green handle which reaches to the back of the machine (not pictured). Here it accepts a weight to ensure pressure is always present for the initial feeder interlocked gear teeth. There are two large gear cogs on the rubber belt side of the machine and 3 small gear cogs on the handle side of the machine, all coloured green. A green handle is also present at the rear of the machine, below the location from which the weight is hanging. A power cable extends from the motor and there are two adjustable metal rods on the top of the machine, the purpose of these rods is presently unknown. Black texter. On top of drum. Wording: HG3707 Wording. Imprint: BRACEWIND BLYN On motor. Wording AEIwool picking, textile manufacturing, wool processing -

National Wool Museum

National Wool MuseumCarpet Samples, Godfrey Hirst and CO. Pty Ltd, c.1990

Carpet samples created by Godfrey Hirst, a carpet mill whose history spans back to 1865 when the Victorian Woollen and Cloth Manufacturing Company began operations in Geelong and was purchased in the 1890s by the man Godfrey Hirst. Godfrey Hirst’s entrepreneurial skills and knowledge of the industry led to the great success which saw the company expand in multiple forms over the next century and a half. Today, thousands of metres of carpet are produced by Godfrey Hirst every day, and their flooring can be found in millions of homes. These 6 carpet samples date from the early 1990s and each have a unique colour pattern and design.Each carpet sample is made with a pile fibre that is 100% wool. The primary backing of the carpet is a woven polypropylene with a secondary backing a woven jute. Carpet 8102.1's colour name is Slate. It has a dark grey background with a red and blue diagonal stripe. The pattern repeats in a 10cm x 11.5cm block. Carpet 8102.2’s colour name is Terracotta. It is a mostly block pink colour with no repeating pattern. It has occasional flicks of grey. Carpet 8102.3’s colour name is Arctic Night. It has white, light blue and grey colours repeating one after another in a diagonal line. Carpet 8102.4’s colour name is Ivory. It has a brown background with a cream colour diamond. The pattern repeats in a 15cm x 15cm block. Carpet 8102.5’s colour name is Glenwood. It has a thin darker green and lighter green horizontal stripe spanning its entire width. These stripes repeat the height of the carpet. Carpet 8105.6’s colour name is also Ivory. It has a brown background with a cream colour leaf pattern. The pattern repeats in a 92cm x 92cm block.Wording on rear: Numerous. See Media.godfrey hirst, carpet, textile manufacture -

National Wool Museum

National Wool MuseumTextile - Blanket, Eagley Mill, 1955-59

... . This was the largest manufacturing plant for wool in the Southern Hemisphere... in Collingwood. This was the largest manufacturing plant for wool ...This blanket was owned by the Rosenberg family from the late 1950s onwards. It was the donor Denise’s blanket. Born May 1958, her late mother Elfie kept it safe for many decades after Denise had outgrown it. Elfie returned the blanket to Denise 20 years ago, in its current near new condition. Jacques Rosenberg and Elfie née Naparstek, Denise’s parents, met in Melbourne in the Summer of 1950. They both survived being young and Jewish in Europe during the Second World War. Jacques grew up in France and Elfie in Germany, she was a child of the Kindertransport. They married in 1952 and by 1958 had a son and two daughters. Denise, the youngest daughter, donated the blanket on behalf of the Rosenberg family to the National Wool Museum in 2021. The Kindertransport was a program designed to facilitate the immigration of Jewish children from Nazi Germany before the outbreak of the Second World War. The United Kingdom took in nearly 10,000 predominantly Jewish children from Germany, Austria, Czechoslovakia and Poland. The children were placed in British foster homes, hostels, schools and farms. Tragically, these children were often the only members of their families to survive the tragedies that were to unfold in Europe. Fortunately, Elfie’s parents did survive World War Two by sneaking out of Germany and into the south of France. After Elfie and her sister Serry were Kindertransported, they met up with Salma and Risla Naparstek in Paris in 1947 before migrating to Australia. This blanket originates from the Eagley Mill. They manufactured woollen, worsted and knitwear products from their mill located in Collingwood. Part of Foy & Gibson, the mill had frontages measuring almost two miles within the area bounded by Little Oxford, Wellington, Stanley and Peel Streets in Collingwood. This was the largest manufacturing plant for wool in the Southern Hemisphere at the time. It was also one of the oldest. The first machines for knitting men’s socks were installed in 1896. The site ultimately went into receivership while under new ownership in 1968 and is now high-end real estate. More information about the Mill can be read via Unimelb digitised collection. https://digitised-collections.unimelb.edu.au/bitstream/handle/11343/21262/269411_UDS2010852-85.pdf?sequence=18&isAllowed=y 38”x45” (965 x 1145mm) cream wool blanket. The blanket has white stitching around its edge. Embroidered in the centre of the blanket is a koala eating leaves with accompanying flowers on either side of the marsupial. In the bottom right corner of the blanket a small square label from the Eagley Mills is stitched. This label includes the images of a Sphinx head, a pyramid and a baby’s crib.Eagley / ALL / WOOL / 38”x45” / AWARDED THE CERTIFICATE OF / THE ROYAL INSTITUTE OF / PUBLIC HEALTH & HYGIENE LONDONkindertransport, eagley mill, blanket -

National Wool Museum

National Wool MuseumBook - Fabric Sample Book, c.1920

A Textile Designer’s Fabric Sample Book is an important tool for keeping a record of past designs. This is useful in order to showcase a designer’s previous work; functioning like a portfolio or a résumé. They also serve as a source of inspiration, sometimes even providing a template to re-release iconic designs. The National Wool Museum has a large collection of Fabric Sample Books. They reveal the colour and daring designs produced by textile mills across various time periods. This Fabric Sample Book is from the 1920s and gives us insights into design trends that are now over a century old.The cover of this book has a brown/grey marble. It carries many marks and oils from the hands, after more than a century of use. A strip of red tape has been added to the spine of the book in order to give it integrity. The book internally has white pages that have turned a brown/cream with age. These pages have a faint blue line printed horizontally across them, to assist with handwriting. The contents of the pages are fabric samples which have been staple to them, as well as handwriting with a blue ink. The pages also include technical drawings, relating to the fabric samples and how such samples were woven together.textile design, textile manufacture -

National Wool Museum

National Wool MuseumTextile - Travel Rug, Albany Woollen Mills, c1960s

Collector says - "I can still recall one of my earliest childhood memories, of my nana's bright aqua shoes against the checks of our family travel rug on summer picnics. Maybe that's when this collection planted its seed in me - 40 years later I start my first blanket collection after stumbling across old Onkaparinga travel rugs. I would go to a vintage market in Collingwood every month and almost always found a good one, amassing enough for the entire household. Everyone had their favourite, even the cat had his own – a small red tartan one just for him." Note from collector-"For more than 100 years blankets were made all over Australia in over 100 woollen mills. My aim, is to preserve 100 examples of these wonderful pieces of history. Ten years ago I started collecting the iconic Onkaparinga travel rugs, so that on movie nights at home there would be plenty to go around. Everyone had their favourite; even the cat had his own – a small red tartan one. Keeping an eye out for those travel rugs at op-shops and markets, collectable stores and bazaars, led to noticing vintage blankets. I'd never really thought about them before or paid much attention though of course I had grown up with them at my grandmother's. When I discovered my first Laconia cream blanket with blue stripes, my eyes just went gaga. Well that was it, I was hooked and since then over 500 blankets have passed through my hands. These common, everyday items, found in all households for so many decades, were traditional engagement gifts. Pairs were prized wedding presents turning into family heirlooms. They were fashionable dressers of beds, givers of warmth, bestowers of security and reliability. The comfort found in these objects resonates with almost all of us; we grew up with them ourselves or fondly recall them in a grandparent’s home. There is no modern replacement with the integrity of these old blankets, many of them now older than most of us. They are romantic, sensible, special, familiar, nostalgic and nothing else feels so appropriate in so many situations. No offense to the great Aussie doona, but from hippie to hipster, at a music festival, picnic, campsite or couch, a vintage blanket is something coveted by all. This industry that employed tens of thousands and must have been such a huge contributor to the economy is almost completely lost now. Blanket Fever is an ode to everything that came before: the land, the sheep, the shearers, the hands, the mills, the weavers, the designers, the distributors, the department stores. To the grandparents that gave them, the people that received them, the families that kept them; thank you. I’m passionate about my collection of Australian blankets manufactured in mostly Victoria, South Australia and Tasmania from the 1930s to the end of the 1960s. The collection has blankets from each of these four decades representing the styles and fashions of their time and includes dated advertisements which help determine the eras the blankets are from. " Tan and brown plaid fringed travel rug. Albany Woollen Mill/Travel Rug/All Pure Wool/Emblem: A, Albany blanket, blanket fever, wool, rug, albany, albany woollen mills -

National Wool Museum

National Wool MuseumTextile - Blanket, Albany Woollen Mills, Albany Woollen Mills blanket, c 1950s

Note from collector: I love the generous size and thickness of Albany blankets and know someone who collects from this Mill only. The colour shades and combinations Albany used are still so gorgeous. From Western Australia. Note from collector - "For more than 100 years blankets were made all over Australia in over 100 woollen mills. My aim, is to preserve 100 examples of these wonderful pieces of history. Ten years ago I started collecting the iconic Onkaparinga travel rugs, so that on movie nights at home there would be plenty to go around. Everyone had their favourite; even the cat had his own – a small red tartan one. Keeping an eye out for those travel rugs at op-shops and markets, collectable stores and bazaars, led to noticing vintage blankets. I'd never really thought about them before or paid much attention though of course I had grown up with them at my grandmother's. When I discovered my first Laconia cream blanket with blue stripes, my eyes just went gaga. Well that was it, I was hooked and since then over 500 blankets have passed through my hands. These common, everyday items, found in all households for so many decades, were traditional engagement gifts. Pairs were prized wedding presents turning into family heirlooms. They were fashionable dressers of beds, givers of warmth, bestowers of security and reliability. The comfort found in these objects resonates with almost all of us; we grew up with them ourselves or fondly recall them in a grandparent’s home. There is no modern replacement with the integrity of these old blankets, many of them now older than most of us. They are romantic, sensible, special, familiar, nostalgic and nothing else feels so appropriate in so many situations. No offense to the great Aussie doona, but from hippie to hipster, at a music festival, picnic, campsite or couch, a vintage blanket is something coveted by all. This industry that employed tens of thousands and must have been such a huge contributor to the economy is almost completely lost now. Blanket Fever is an ode to everything that came before: the land, the sheep, the shearers, the hands, the mills, the weavers, the designers, the distributors, the department stores. To the grandparents that gave them, the people that received them, the families that kept them; thank you. I’m passionate about my collection of Australian blankets manufactured in mostly Victoria, South Australia and Tasmania from the 1930s to the end of the 1960s. The collection has blankets from each of these four decades representing the styles and fashions of their time and includes dated advertisements which help determine the eras the blankets are from. " Checked blanket, pink, lemon and violetAlbany Woollen Mill/Blanket/All Pure Wool/Emblem: A, Albany blanket, blanket fever, wool, albany, albany woollen mills