Showing 923 items

matching blue paint

-

Learmonth and District Historical Society Inc.

Learmonth and District Historical Society Inc.Shire of Ballarat Crest, Circa 1963

A very large version of this crest was on the outside of the former Shire of Ballarat building in Wendouree after the Council moved there from the original Shire Hall site in Learmonth.Official Logo/Crest of the Shire of Ballarat.Crest of the Shire of Ballarat,Circular in shape,with gold edging then a white band with the words THE SHIRE OF BALLARAT in gold paint at the top,a star on either side below this and at the base the date MDCCCLX111.In the centre, on a gold painted background is the Shire Crest which shows two figures(in white) each side of the crest which is in the shape of a shield,divided into four and shows at top left a "landscape" on red background,bottom right, on red,a spade and pick crossed.Top right on gold and blue stripe,is a sheep, in white outlined in gold, and bottom left, on blue and gold stripe,is a sheath of wheat in gold.Beneath this is the word PRAEVIUS on a "ribbon"decoration.THE SHIRE OF BALLARAT.PRAEVIUS.MDCCCLXIII.shire of ballarat.crest.shire of ballarat logo -

Flagstaff Hill Maritime Museum and Village

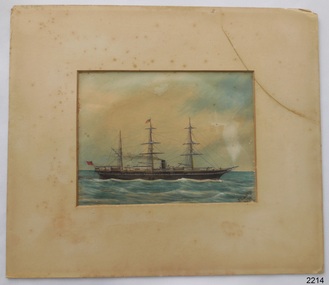

Flagstaff Hill Maritime Museum and VillagePainting - Vessel, C.K.M. (artist), S.S. Warrnambool, 1883

This oil painting is in a handmade, carved frame, dates back to the period of the old Warrnambool Museum and Art Gallery. The two-masted, sail-and-steam-powered ship has the sails and bow shape of a tall clipper ship plus the extra power of steam. It dates to the transition between the clipper ships with their billowing sails and the steam-powered ships, which happened in the late 19th to early 20th century. The flag flown from the stern is that of the British Merchant Navy that traded around the world to transport cargo, and later passengers, from one destination to another. The painting was originally catalogued as the "S.S. Warrnambool" although it has a different design. It was also attributed to the ship portrait painter, the renowned C.K.M. - Charles Keith Miller - but differs from his style. Further research is being carried out at this time. In 1966, between the closure of the old Warrnambool Museum and Art Gallery and the distribution of the painting to Flagstaff Hill, this painting was repaired by David Heysen, son of the German-born artist Hans Heysen OBE. David was born in Hahndorf (called Ambleside for a short period of time), South Australia, married Lyly Refshauge from Melbourne, and they raised a family on their property in Kalangadoo, near Penola, in South Australia.The painting's frame is an example of handmade carving and joinery created in the late 19th century. The artist has depicted the image of a historical sail-and-steam ship of the type in which cargo was traded across the world, including to and from Australia. Vessels such as this also brought migrants to Australia.Painting, oil on board, in hand carved wooden frame with floral and geometric pattern, inner border painted gold. Image of a two-masted sail and steam ship, sails raised, black funnel emitting smoke. Hull is black with white horizontal stripe and white trim around sides of deck. Three lifeboats are visible. Bow is ‘clipper shape’ with what appears to be a figurehead. A red ensign flag flies at the stern and a blue and red flag is attached to the mainmast. The frame has been assembled using Mortice and Tenon joints, one of which is exposed on the back, lower right corner. Chandelier chain has been attached for hanging. There is no visible signature, date or title on the front of the painting. The back board has empty holes spaced around the edge and is held in place by staples. The visible surface has remnants of adhesive from two rectangular attachment s. There are two small white stickers attached, one with a hand written inscription. There are pencil and pen inscriptions. The painting is protected by cardboard with inscriptions in marking pen.On back board, written in the style used by the Warrnambool Museum and Art Gallery: - On white sticker, in pen “A-P31/1-74” - Pencil “A27/1883 / Artist CKM 1883 / Title SS Warrnambool / oil on board” Written in pen by the repairer - “Repaired & re-drilled – cleaned etc. / David Heysen 11/66” Written by Flagstaff Hill’s Cataloguer - Pencil “3031” On cardboard wrapper, in marking pen: - “S.S. Warrnambool / by / C.K.M. 1883” - “A-P/31/1-74” - “3031”flagstaff hill, warrnambool, shipwrecked coast, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, s s warrnambool, charles keith miller, charles miller, steam and sail ship, british merchant navy, slipper shaped bow, 19th century sea trade, warrnambool museum and art gallery, old warrnambool art gallery, hand carved picture frame, mortice and tennon picture frame, migrants, c.k.m. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePainting - Oil painting, W. Langley-Taylor, Cape Schank [Schanck], Late 19th to early 20th century

This painting is one of a pair of large paintings by W. Langley-Taylor in our collection. Currently, no further information has been found about the artist but research is ongoing. The subjects of these paintings are seascapes of notable areas of the coast on each side of Port Phillip Bay, south of Melbourne, Victoria. The subject of this painting is Cape Schanck, Victoria, which is on the east side of Port Phillip Bay. It includes the Cape Schanck Lighthouse and its Flagstaff. The Cape Schanck Lighthouse was built in 1859 and is the second of Victoria’s coastal lights. It is 21 metres tall and made from limestone. Unusually, its stairway is made from stone rather than wrought iron. Gilded tours are available to explain its use and significance to visitors. The lighthouse keepers at Cape Schanck kept records of the ships that sailed past them along Bass Strait; ship’s names, direction, time and date and so on. The details would also be passed on to shipping agencies, Harbour Masters and newspapers, which published Arrivals and Departures into and out of shipping ports such as Port Phillip Bay and the Port of Melbourne. INSCRIPTIONS “Mrs M Irby” (and on the Eagle Rock, Warrnambool, painting “980/Regency”) The inscription “Mrs M Irby” is on the back of both paintings but the significance of the inscription has not yet been discovered. Perhaps she was connected with the ship or shipping company “Irby”. A ship named “Irby”, built in Merseyside, Liverpool in 1881 by R & J Evans, Birkenhead. It was a four-masted iron ship built for the White Star Line. Henry Wilson Hewitt bought her in 1882, then later she was owned by Chadwick & Pritchard. In 1888 she was registered under the Irby Ship Co. Ltd. (trading as J. Joyce) in Liverpool. In 1912 Galgate Co. Ltd owned her. She traded between London, England and Australia, and is recorded as being in Melbourne and Hobart. In 1919 the Irby was destroyed by a mine when on her way to England. Or perhaps her name and the inscription in pencil “980/Regency” on the Eagle Rock Warrnambool, painting could be a delivery address for the paintings, perhaps an apartment in a hotel. NOTE: The artist’s spelling of the title “Cape Schank, Vic.” is incorrect. The location in this painting is named Cape Schanck. This painting is significant geographically for its representation of the coastal scenery of Victoria, Australia. It is also significant as one of a pair of paintings of seascape, one at sites each side of Port Phillip Bay. The painting is significant historically as an example of late 19th and early 20th methods and materials used to construct a painting’s frame. Painting oil on board in a dark wooden frame, portrait orientation. Seascape of coast with cliffs, lighthouse and flagstaff, flying birds, high waves breaking onto rocks, blue sky with clouds. The title is painted on lower left corner and the Victorian artist, W. Langley-Taylor, has signed his name on lower right. The inscription on back is handwritten script in red crayon or thick red pencil. The board is held in place inside the timber frame with small, dark metal tacks around all sides. Metal eyes join the wire to the frame. Small round, dark metal nail heads are dispersed around the frame and there is a change of colour on both the board and the wood of the frame. Painted on front “W.LANGLEY-TAYLOR.” and “CAPE SCHANK, VIC.” [NOTE: correct spelling is Schanck] Handwritten on back “Mrs. M. Irby” flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, painting, oil painting, cape schanck painting, w. langley-taylor, wall decoration, seascape of victoria's coast, art, mrs m irby, victoria's coast, pair of paintings -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePainting - Oil painting, W. Langley-Taylor, Eagle Rock, Warrnambool, Vic, Late 19th to early 20th century

This painting is one of a pair of large paintings by W. Langley-Taylor in our collection. Currently, no further information has been found about the artist but research is ongoing. The subjects of these paintings are seascapes of notable areas of the coast on each side of Port Phillip Bay, south of Melbourne, Victoria. This painting is of Eagle Rock, Warrnambool, which is on the west of Port Phillip Bay. Eagle Rock is located about 400 metres west of Thunder Point, near Shelly Beach. The painting includes the rocky cliff formations looking east towards the Warrnambool Breakwater. The walk from the Thunder Point car park westwards to Shelly Beach has been popular over the decades with residents as well as tourists. Many photographs include the rock, with varying backgrounds depending on the angle of the camera. It is a popular dive site for locals and visitors, in calm weather! The site can be approached by boat from the open sea in favourable conditions, and there is plenty of native marine to be seen in this marine sanctuary. This part of Warrnambool’s rugged coastline is unprotected from the Southern Ocean with its wild icy winds and high seas. The painting’s crashing waves and the northerly direction of the smoke on the steamship sailing north show the effect of the southerly wind. INSCRIPTIONS “Mrs M Irby” and “980/Regency” The significance of the inscription “Mrs M Irby”, on the back of each of the two paintings, has not yet been discovered. Perhaps she was connected with the ship or shipping company “Irby”. A ship named “Irby”, built in Merseyside, Liverpool in 1881 by R & J Evans, Birkenhead. It was a four-masted iron ship built for the White Star Line. Henry Wilson Hewitt bought her in 1882, then later she was owned by Chadwick & Pritchard. In 1888 she was registered under the Irby Ship Co. Ltd. (trading as J. Joyce) in Liverpool. In 1912 Galgate Co. Ltd owned her. She traded between London, England and Australia, and is recorded as being in Melbourne and Hobart. In 1919 the Irby was destroyed by a mine when on her way to England. Or perhaps her name and the inscription in pencil “980/Regency” on the Eagle Rock Warrnambool, painting could be a delivery address for the paintings, perhaps an apartment in a hotel. This painting is significant geographically for its representation of the coastal scenery of Victoria, Australia. It is also significant as one of a pair of paintings of seascape, one at sites each side of Port Phillip Bay. The painting is significant historically as an example of late 19th and early 20th methods and materials used to construct a painting’s frame. Painting oil on board in a dark wooden frame, portrait orientation. Seascape of rock formation and cliffs, two yachts, a two-masted steamboat with red funnel and smoke, flying birds, high waves breaking onto rocks, blue sky with clouds, some tinted pink.. The title is painted on lower left corner and the artist, W. Langley-Taylor, has signed his name on lower right. The inscription on the back is a handwritten script in red crayon or thick red pencil. The board is held in place inside the timber frame with small, dark metal tacks around all sides. Metal eyes join the wire to the frame. Small round, dark metal nail heads are dispersed around the frame and there is a change of colour on both the board and the wood of the frame. Painted on front “W.LANGLEY-TAYLOR.” and “EAGLE ROCK, WARRNAMBOOL, VIC.” Handwritten on back “Mrs. M. Irby” and “980 [underlined] Regency”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, eagle rock warrnambool, w. langley-taylor, oil painting, wall decoration, seascape of victoria's coast, mrs m irby, art, seascape, pair of paintings -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCraft - Ship Model, Cutty Sark

ABOUT THE CUTTY SARK The CUTTY SARK, built in Britain in 1869, was one of the last historic sailing ships. She traded in tea from China for a few years then began trading with Australia in the wool industry. She held the record sailing speed from Australia to Britain for ten years! Later a Portuguese company bought her as a cargo ship (and renamed her as FERREIRA) then she was purchased by a returned sea captain for use as a training ship in Cornwall. After the captain’s death she was transferred to a training college in Greenwich in 1938. In 1954 she was placed permanently in dry dock at Greenwich for display.The sailing ship CUTTY SARK carried export cargos of wool from the Australian wool industry.Ship model Cutty Sark, a Clipper in full ship rig with raised poop deck, deck house, 3 boats on deck (1 has fallen). Two toned black and tan hull, 3 jibs set in diorama of blue sea, light house and another small yacht. Is housed in glass sided case with dark grey painted structure. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cutty sark, historic sailing ship, tea clipper, sail training vessel, cadet training ship, commercial trading vessel, cargo sail vessel, ship model cutty sark, australian wool export -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVessel, c. 1989

... Whaleboat "Flagstaff Hill" painted white with dark blue... Whaleboat "Flagstaff Hill" painted white with dark blue trim ...This whaleboat "Flagstaff Hill" is one of a set of three timber whaleboats in the whaleboat collection at Flagstaff Hill Maritime Village. The boats are designed for use in a contemporary environment. Whaleboat "Flagstaff Hill" painted white with dark blue trim and light blue interior. One of a set of 3 built by Garry Stewart c. 1989. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whaleboat, vessel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlaque - Insignia, Bank of Australasia, 16-10-1980

This plaque displays the Bank of Australia's Coat of Arms and is significant because is ts the symbol printed on the Bank Notes of the Bank of Australasia. The bank of Australasia was incorporated by Royal Charter of England in March 1834. It had its Australian beginning on 14th December 1835, opening in Sydney. The Acting Superintendent of the bank at that time was David Charters McArthur. He was Superintendent from 1867-to 1876. The Melbourne branch opened on 28th August 1838 in a two-roomed brick cottage on the north side of Little Collins Street, where two huge mastiff dogs were used at night to guard the bank. The government also provided an armed military sentinel. Due to the bank's rapid growth, a new building for the Melbourne branch was opened in 1840 at 75 Collins Street West. By 1879 the bank had been upgraded to a magnificent two-storey building on the corners of Collins and Queens Streets, with the entry on Collins Street. In 1951 the Bank of Australasia amalgamated with the Union Bank to form the Australia and New Zealand Bank, now known as the ANZ. Then in 1970, the ANZ merged with both the ES&A and the London Bank of Australia to form the ANZ Banking Group Limited. The ANZ Banking Group Ltd kindly donated a variety of historic items from the Bank of Australasia. BANK of AUSTRALASIA, WARRNAMBOOL – In 1854 Warrnambool had two banks, the Union Bank and the Bank of Australasia. Later, completely different bank businesses opened; in 1867 the National Bank of Australasia, then in 1875 the Colonial Bank of Australasia. The original Warrnambool branch of the Bank of Australasia was established in July 1854, and operated from a leased cottage on Merri Street, close to Liebig Street. The bank next bought a stone building previously erected by drapers Cramond & Dickson on the corner of Timor and Gibson Streets. Samuel Hannaford was a teller and then Manager at the Warrnambool branch from 1855 to 1856 and the Warrnambool Council chose that bank for its dealings during 1856-57. In 1859 Roberts & Co. was awarded the contract to build the new Bank of Australasia branch for the sum of £3,000; the firm built the Warrnambool Post Office in 1856 and purchased land in Timor Street in 1858. The land was on a sand hill on the northeast corner of Timor and Kepler Streets and had been bought in 1855 from investor James Cust. The new building opened on May 21, 1860. The bank continued to operate there until 1951 when it merged with the Union Bank to form the ANZ Bank, which continued operating from its Liebig Street building. Warrnambool City Council purchased the former Bank of Australasia building in 1971 and renovated it, then on 3rd December 1973 it was officially opened as the Art Gallery by Cr. Harold Stephenson and Gallery Director John Welsh. The Gallery transferred to the purpose-built building in Liebig Street in 1986 and the old bank building is now the Gallery club. Staff at the Bank of Australasia in Warrnambool included the following men but others were also involved: Samuel Hannaford, Teller then Manager from 1855-1856; Hawkins, Manager in 1856, W H Palmer, Manager from January 1857 until November 1869 when the Teller Basil Spence was promoted to Manager; H B Chomley, Manager from April 1873 and still there in 1886; A Butt, Manager in 1895-1904; J R McCleary Accountant and Acting Manager for 12 months, until 1900; A Kirk, Manager 1904; J Moore, staff until his transfer to Bendigo in December 1908; J S Bath was Manager until 1915; C C Cox, Manager until April 1923; Richard C Stanley, Manager 1923 to April 1928. The plaque with the insignia has significance through its association with the Bank of Australasia. The early Australian bank was established in 1834 by Royal Charter and opened in Sydney, Australia, in Sydney in 1835. The bank had many Australian offices in November 1877, particularly on the east and south coasts. Victoria had 45 per cent of all Offices. The plaque is locally significant for its association with the Warrnambool Bank of Australasia, which was established in 1854. It was Warrnambool Council’s first bank. The bank continued to operate until the organisation's merger in 1951 when it became the ANZ Bank Group today. The Bank was an integral part of the growth of local commerce and the community.Insignia of the Bank of Australasia. Cast metal coat of arms within a gold, shield-shaped border, painted gold and red, with blue, black and white details. Decals in each corner; upper left and lower right have a white sheep suspended by a blue ribbon, upper right and lower left have a 3-masted, square-rigged sailing ship with a black hull and red flags flying on each mast, sailing on waves with storm clouds in the sky. Between the emblems are gold stars.Decals; ships, sheep, starsflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, bank of australasia, boa, union bank, australia & new zealand bank, anz bank, david charters mcarthur, d c mcarthur, currency, banknote, commerce, banking, heraldic shield, insignia, samuel hannaford -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlaque - Insignia, Bank of Australasia, 19th Century

This decorative plaque displays the insignia of the Bank of Australasia, which was incorporated by the Royal Charter of England in March 1834. The bank began in Australia on 14th December 1835, opening in Sydney. The Acting Superintendent of the bank at that time was David Charters McArthur. He was Superintendent from 1867-to 1876. The Melbourne branch opened on 28th August 1838 in a two-roomed brick cottage on the north side of Little Collins Street, where two huge mastiff dogs were used at night to guard the bank. The government also provided an armed military sentinel. Due to the bank's rapid growth, a new building for the Melbourne branch was opened in 1840 at 75 Collins Street West. By 1879 the bank had been upgraded to a magnificent two-storey building on the corners of Collins and Queens Streets, with the entry on Collins Street. In 1951 the Bank of Australasia amalgamated with the Union Bank to form the Australia and New Zealand Bank, now known as the ANZ. Then in 1970, the ANZ merged with both the ES&A and the London Bank of Australia to form the ANZ Banking Group Limited. The ANZ Banking Group Ltd kindly donated a variety of historic items from the Bank of Australasia. BANK of AUSTRALASIA, WARRNAMBOOL – In 1854 Warrnambool had two banks, the Union Bank and the Bank of Australasia. Later, completely different bank businesses opened; in 1867 the National Bank of Australasia, then in 1875 the Colonial Bank of Australasia. The original Warrnambool branch of the Bank of Australasia was established in July 1854, and operated from a leased cottage on Merri Street, close to Liebig Street. The bank later bought a stone building previously erected by drapers Cramond & Dickson on the corner of Timor and Gibson Streets. Samuel Hannaford was a teller and then Manager at the Warrnambool branch from 1855 to 1856 and the Warrnambool Council chose that bank for its dealings during 1856-57. In 1859 Roberts & Co. was awarded the contract to build the new Bank of Australasia branch for the sum of £3,000. The land was on a sand hill on the northeast corner of Timor and Kepler Streets and had been bought in 1855 from investor James Cust. The new building opened on May 21, 1860. The bank continued to operate there until 1951 when it merged with the Union Bank to form the ANZ Bank, which continued operating from its Liebig Street building. Warrnambool City Council purchased the former Bank of Australasia building in 1971 and renovated it, then on 3rd December 1973 it was officially opened as the Art Gallery by Cr. Harold Stephenson and Gallery Director John Welsh. The Gallery transferred to the purpose-built building in Liebig Street in 1986 and the old bank building is now the Gallery club. Staff at the Bank of Australasia in Warrnambool included the following men but others were also involved: Samuel Hannaford, Teller then Manager from 1855-1856; W H Palmer, Manager from January 1857 until November 1869 when the Teller Basil Spence was promoted to Manager; H B Chomley, Manager from April 1873 and still there in 1886; A Butt, Manager in 1895-1904; J R McCleary Accountant and Acting Manager for 12 months, until 1900; A Kirk, Manager 1904; J Moore, staff until his transfer to Bendigo in December 1908; J S Bath was Manager until 1915; C C Cox, Manager until April 1923; Richard C Stanley, Manager 1923 to April 1928. The plaque has historical significance as it belonged to the Bank of Australasia which was established in Australia in 1835 by Royal Charter. The plaque is significant for its association with the Bank of Australasia in Warrnambool, the first bank in Warrnambool, established in 1854. The bank continued to operate until its merger in 1951 when it became the ANZ Bank, which is still in operation today. The Bank was an integral part of the establishment and growth of commerce in Colonial Warrnambool and throughout Australia.Plaque with insignia on glass in a rectangular varnished wooden frame. Insignia of the Bank of Australasia has been painted onto the glass in a mirror-like fashion. Insignia depicts a heraldic shield with sheep hung up by their waists and ships in full sail. Inscription on insignia. Stamp and handwritten inscription on the rectangular label with a blue border on the reverse.Insignia: "BANK OF AUSTRALASIA INCORPORATED BY ROYAL CHARTER 1835" Label's red oval stamp with "AUSTRALIA AND NEW ZEALAND BANK UNITED ARCHIVES" Label's handwritten black letters "AM1" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, commerce, banking, plaque, insignia, bank of australasia, insignia on glass, union bank, australia & new zealand bank, anz bank, david charters mcarthur, d c mcarthur, sydney, new south wales, currency, banknote, legal tender -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Federation University Historical Collection

Federation University Historical CollectionInstrument, Ballarat Junior Technical School Bass Drum, Early 20th Century

The Ballarat Junior Technical School was opened in 1913. Originally situated at the Dana Street Primary School, it was relocated to a custom built school in 1921 in the grounds of the School of Mines Ballarat. The building is now used as the Prospects Restaurant (2012). The drum was one of the BJTS school instruments and seems to have been signed by the many students who played it over period that the school was in operation. This drum appears to be the same one as is shown in a 1913 photograph of the whole school although the skins have been replaced and one of the oldest signatures on the current skins is dated 1939. A large brown bass drum with blue, green and white trim. The sides have a rope binding with leather ties.School crest painted on side. "BJTS / Win through". Signatures with class or year written on both skins. ballarat junior technical school, bass drum, school band, school of mines ballarat, musical instrument -

Bright & District Historical Society operating the Bright Museum

Bright & District Historical Society operating the Bright MuseumEgg hand painted

Handpainted egg with blossom and butterfly design, mounted on blue silk base and covered by glass box.Made in People's Republic of Chinaornaments, egg, china -

Federation University Historical Collection

Federation University Historical CollectionNewspaper, Ballarat 150 Years: Supplement to the Ballarat Courier, 1988, 17/03/1988

A supplement to celebrate 150 since the establishment of the Port Phillip Colony (Victoria).40 page newspaper published to celebrate the Sesquicentenary of Ballarat. Articles include: 1838-the pastoral period begins; First White Settlers arrive (Anderson, Winter, Yuille, Kirkland, Learmonth); Learmonths - Pioneer Settlers; The Rush to Ballarat; Last of the Aborigines; Eureka Affair Gains New Importance; Mining-After the rush; SMB - First Technical School; Clubs Play their Part; Ballarat Yuilles had Wealthy Ancestors; Town, Country Share a Close Relationship; Many Sides to Metals Industry; True Victorian City; Five Severe Recessions; Financiers to the Fore; Ready for War; City Rich in Sport Facilities; Visitors to most exciting place; No Place for a Nervous Lady; Theatres Provide Welcome Diversion for Mines; Might Achievers Among famous Citizens; Life Seemed Different After the War; Ballarat School of Mines Eastern Station Hotel; Memorial (Her Majesty's) Last of Many Theatres; Art Gallery at its Best; Pilgrimage to Yuille Cairn at Sebastopol Images include: Jelbart tractor; Sunshine Harvester; Bailey's Mansion; Pennyweight Hotel; Bridge Mall; Blue Riband Mine, Black Hill, Burrumbeet Shooting party; A wendouree rowing club; Motor Cycle Racing; Women bowlers, Queen Elizabeth; Gong Gong Methodist Church; Arbour day at Waterloo Farm, Smythes Rd; Gold panners (1890s); Ballarat Cricket Team (1902); William Peart; D'Angri's store; Sturt St Advertisements include: Rehfisch and Co.; UFS Dispensaries; Deutscher Mower Sales and Service; Haymes Paint; Cincotta's; Abraham's Sportscene; McK's; McKay Macleod; St John of God Hospital; Benjamins Real Estate; Ballarat Water Board; Cornell's Pharmacy; Laminex Industries; Coltman Mitre 10; Lal Lal Iron Mine; Heinz Bros; Crockers; Frank ford travel; S.J. Weir; Ludbrook Plumbing Service; Mars; Robert Sim Building Supplies, Frank Day; Sectrol Systems; Thornton Richardsballarat, anniversary, sydney abraham, cincotta, eureka, ballarat school of mines, mining, ballarat club, lal lal iron mine, ballarat rangers, victorian rifles, 3rd battalion victorian rifles, ballarat militia, white flat, celia scott, adelphi theatre, victoria theatre, montezuma theatre, charlie napier, juliamatthews, royal theatre, dick richards, henry sutton, eleanor lucus, martin hosking, newington estate, saleyards, g. gay & co, ballarat books, old benev' alleviated distress on goldfields -

Federation University Historical Collection

Federation University Historical CollectionSign, Sign by Keith Rash

Keith Rash was a Ballarat signwriter.Cream thick paper with blue writing in sign writers paint. The sign was created by Keith Rash.Tuesday 28th August at 8.p.m. G.S.V. Speakers, Major C. Stephen, Pres. K. Holden, V. Pres.keith rash, sighwriting, major c. stephen, k. holden -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePainting - Watercolour, J C Long, 1878

Hand painted image of a steamship with three masts.The painting is significant for its connection with Australian maritime art. Painting, watercolour, steamship at sea, flying an Australian Red Ensign flag from the bow. The centre of three masts has a flying flag of blue, red and yellow. Mounted on card. Artist J C Long, 1879. Inscription on top left corner of front and centre of back, handwritten in pencil."J R Long 1879". Inscriptions in pencil, front and back, some is indecipherable "3/" ", " - lack" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, j c long, steamship, marine art, australian vessel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVehicle - Wagon, Early 20th Century

... ", which name Stanley was known by. Also, a painted on the wage... of the original paint colours of blue and yellow show on the photograph ...This wagon is linked to Mr Stanley James Bell via his father Mr John Bell, who owned "Warrumyea" at Wangoom. It is believed that Stanley grew up and worked for his father at this property, eventuality inheriting his father's death in 1920. This wagon was likely used at Mr Stanley Bell's property “Warrumyea” at Wangoom around 1920-1940. The wagon was donated in 1984, at which time it was noted as having a brass plate inscribed "Jas", which name Stanley was known by. Also, a painted on the wage was “S J Bell Wangoom”. Remnants of the original paint colours of blue and yellow show on the photograph, which was taken at the time of cataloguing. Mr John Bell Snr from Plymouth, England, arrived in Portland, Victoria, around 1860. He had served in the British navy as a lad for a number of years. On arriving in Australia he travelled to the Wangoom district where he lived for many years. Mr J Bell worked for 20 years as herd manager at “Wangoom Park”., for Mr F Tozer (1843-1954), one of the original pioneers of the western district. He went on to pursue dairying and general farming at his property “Warrumyea” Wangoom. Bell’s son Stanley James Bell went to the Wangoom School. His first reader from this school, published in 1909, has his name inscribed in the flyleaf “Stanley J. Bell, Warrumyea, Wangoom” and is now in the collection of the Warrnambool & District Historical Society. Stanley went on working the property “Warrumyea” and eventually purchased “Wangoom Park” in 1956, where his father had been employed years before. Mr S J Bell died in 1968.The wagon is significant for its association with the farming history of Wangoom and the Warrnambool area in general. Also, the wage is significant for its association with one of the early families that settled in the Warrnambool area and their contribution to the dairying and general farming industries that sprang from their efforts. The wagon has a good provenance linking it to Mr Stanley James Bell and is also a good example of how goods were transported using horse-drawn vehicles at the beginning of the 20th century.Four-wheeled wagon or cart,12 spokes in each wheel, wooden axle with rear hub brake. Hinged and chained tailboard. Wheels have metal rims. Metal frame and wooden superstructure. Wagon has two pairs of staves. Wooden shelves, one missing with turntable. Small toolbox in front. Made by Kelly and Preston of Ballarat. Metal nameplate of the owner attached, "Jas" (S J Bell of Wangoom).. Original inscription, now obscured, was painted “Kelly and Preston Builders Ballarat”. Metal plate inscribed "Jas", and "S J Bell Wangoom". flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wagon, sj bell, stanley james bell, wangoom park, warrumyea, first reader, john bell 1830-1920, stanley james bell 1904-1968, warrnambool pioneers, f tozer, western district, kelly and preston of ballarat -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSnatch Block

Snatch Block, 1 sheave wood block with hook and locking mechanism broken on one side painted green with remnants of medium blue on mechanism near joining ring. Graham marked on side in blackflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.White earthenware dinner plate. Crazing evident all over.Backstamped ‘Made in England S LTD’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Johnson Bros