Showing 8936 items matching "flagstaff hill village"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTurnbuckle

... Flagstaff-Hill-Maritime-Village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...Turnbuckle, with hook link screws and other end missing, 12" buckle.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTurnbuckle

... flagstaff-hill-maritime-village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...Turnbuckle, with hook link screws and ring link screw, 12" buckle.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBlock

... flagstaff-hill-maritime-village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...2 sheave wood block becket and eye.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBuoyancy Box

... Flagstaff-Hill-Maritime-Village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...Buoyancy Box enclosed wooden 7 sided container with many nails along joins. Unpaintedflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBuoyancy Box

... Flagstaff-Hill-Maritime-Village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...Buoyancy Box enclosed wooden 7 sided container with many copper nails along joins. Unpaintedflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSenhouse Slip

... flagstaff-hill-maritime-village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...Senhouse Slip with square hookflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, senhouse slip, senhouse, slip -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTurnbuckle

... Flagstaff-Hill-Maritime-Village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...Turnbuckle, with hook link screws and ring link screw, 12" buckle.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTurnbuckle

... Flagstaff-Hill-Maritime-Village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...Turnbuckle, with hook link screws and ring link screw, 12" buckle.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTurnbuckle

... Flagstaff-Hill-Maritime-Village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...Turnbuckle, with hook link screws and ring link screw, 8" buckle.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageRigging Screw

... Flagstaff-Hill-Maritime-Village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...Rigging Screw, two ring link screws, 15" bottle bit.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Lamp, circa 1878

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This Flying Angel lamp bracket was recovered from the wreck site of the steam sailing ship, "Loch Ard", which sank near Port Campbell, Victoria in 1878. It formed part of the ship's cargo. The 'flying angel' lamp was, for a time, displayed in the St Nicholas Seamen's Church at Flagstaff Hill. The design was very appropriate to the Missions to Seamen, being associated with the emblem of the 'flying angel' on the Missions' to Seamen's flag. Brief history of the Loch Ard: The vessel Loch Ard was constructed on the Clyde River in Scotland in 1873 for the prestigious Loch Line of colonial clipper ships, designed for the Australian run. She sailed from England on 1 March 1878 carrying 37 crew, 17 passengers and a diverse general cargo ranging from luxury items to bulk railway iron. On 1 June 1878, emerging from fog and hearing too late the sound of breakers against the tall limestone cliffs, the vessel struck the southern foot of Mutton Bird Island and sank in 23 metres of water. Of the fifty-four people on board only two survived, one young male crewman, Tom Pearce, and one young female passenger, Eva Carmichael. A century later, despite the pounding seas and the efforts of looters, the wreck site continued to provide ample evidence of the extraordinary range of goods being imported into the Colony of Victoria in the post-Gold Rush era. Flagstaff Hill divers in the 1970s reported finds of “Bottles of champagne, window panes, rolls of zinc, barrels of cement, iron rails, clocks, lead shot, corrugated iron, lead, marble, salad oil bottles, ink bottles, copper wire, gin bottles, rolls of carpet, floor tiles, copper rivets, gas light fittings, pocket knives, toys, crystal chandeliers, beer mugs, cutlery, candles sticks, wick scissors, cow bells, and sauce bottles.” The lamp bracket is significant for its connection with the wreck of the sailing ship, Loch Ard, in 1878. Flagstaff Hill’s collection of artefacts from LOCH ARD is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. It is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417). The collection is significant because of the relationship between the objects, as together they have a high potential to interpret the story of the LOCH ARD. The LOCH ARD collection is archaeologically significant as the remains of a large international passenger and cargo ship. The LOCH ARD collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the LOCH ARD, which was one of the worst and best known shipwrecks in Victoria’s history. Gas lamp, brass, single burner, wall-mounting bracket, delicately crafted. Ornate decoration features bust of an angel with up-swept wings, or 'flying angel'. Recovered from the wreck of the Loch Ard.Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, lamp fitting, shipwreck artifact, 1878, shipwreck cargo, household effects, 19th century lighting, angel lamp, loch ard lamp, angelic lamp, lighting at sea, marine technology, ship's lighting, flying angel, gas lamp, maritime archaeology, port campbell -

Flagstaff Hill Maritime Museum and Village

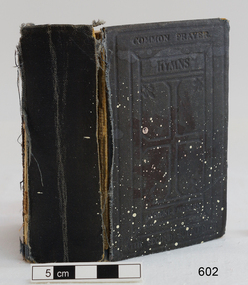

Flagstaff Hill Maritime Museum and VillageBook - Religious Book, The Book of Common Prayer, 20th century

... flagstaff-hill-maritime-village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This book was part of the original furnishings of the St Nicholas' Mission to Seamen's Church at 139 Nelson Place, Williamstown, Victoria. THE MISSIONS TO SEAMEN (Brief History: for more, see our Reg. No. 611, Set of Pews) The Missions to Seamen, an Anglican charity, has served seafarers of the world since 1856 in Great Britain. It symbol is a Flying Angel, inspired by a Bible verse. Today there are centr4es in over 200 ports world-wide where seamen of all backgrounds are offered a warm welcome and provided with a wide range of facilities. In Victoria the orgainsation began in Williamstown in 1857. It was as a Sailors’ Church, also known as ‘Bethel’ or the ‘Floating Church’. Its location was an old hulk floating in Hobson’s Bay, Port of Melbourne. It soon became part of the Missions to Seamen, Victoria. In the year 2000 the organisation, now named Mission to Seafarers, still operated locally in Melbourne, Portland, Geelong and Hastings. The Ladies’ Harbour Lights Guild was formed in 1906 to support the Missions to Seamen in Melbourne and other centres such as Williamstown. Two of the most significant ladies of the Guild were founder Ethel Augusta Godfrey and foundation member Alice Sibthorpe Tracy (who established a branch of the Guild in Warrnambool in 1920). The Guild continued its work until the 1960s. In 1943 a former Williamstown bank was purchased for the Missions to Seaman Club. The chapel was named St Nicholas’ Seamen’s Church and was supported by the Ladies’ Harbour Lights Guild, the Williamstown Lightkeepers’ Auxiliary and the League of Soldiers’ and Sailors’ Friends. It ceased operation in 1966. A Missions to Seamen Chapel and Recreation Room was a significant feature of ports during the late 1800s and into the 1900s. It seemed appropriate for Flagstaff Hill to include such a representation within the new Maritime Village, so the Melbourne Board of Management of Missions to Seamen Victoria gave its permission on 21st May 1979 for the entire furnishings of the Williamstown chapel to be transferred to Flagstaff Hill. The St Nicholas Seamen’s Church was officially opened on October 11, 1981 and closely resembles the Williamstown chapel. This book is significant through its association with the St Nicholas' Mission to Seamen Church in Williamstown, Melbourne, established in 1857. The items in our collection from the Missions to Seamen in Williamstown, Victoria, have historical and social significance. They show that people of the 1800s and 1900s cared about the seafarers’ religious, moral, and social welfare, no matter what the religion, social status or nationality. It had its origins in Bristol, England when a Seamen's Mission was formed in 1837. The first Australian branch was started in 1856 by the Rev. Kerr Johnston, a Church of England clergyman, and operated from a hulk moored in Hobson’s Bay; later the Mission occupied buildings in Williamstown and Port Melbourne. The Book of Common Prayer. Small book, dark fabric hardcovers, both embossed design on cover incorporating a cross. Owner's name written in black ink inside the cover, also four brown stamps of a cross inside cover. Titled "The Book of Common Prayer and Administration of the Sacraments and other Rules and Ceremonies of the CHURCH according to the use of The Church of England". Printed in Great Britain. Book has 730 numbered pages. Inscribed with a signature inside the front cover as well as brown stamps of images of a cross.. This is one of the original items in our St Nicholas Seamen's Church Williamstown Collection.Written in black script inside the front cover "Anne Ambrose". Stamps of a cross symbol, brown ink, on the covers and some of the pages throughout the book. Inside front cover, in pencil, "602" "CH 34" Inside the back cover in blue pen are the numbers "271 / 291 / 24"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, book, prayer book, the book of common prayer, church of england prayer book, anne ambrose, religion, religious service, sailors rest, bethel sailors’ church, bethel floating church, ladies harbour light guild, missions to seamen victoria, mission to seafarers, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, mission to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, flying angel club -

Flagstaff Hill Maritime Museum and Village

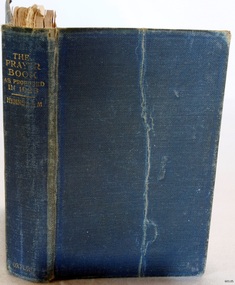

Flagstaff Hill Maritime Museum and VillageBook - Religious Book, Oxford University Press, The Book of Common Prayer, Early 20th century

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This book belongs to a set of prayer books that was part of the original furnishings of the St Nicholas' Mission to Seamen's Church at 139 Nelson Place, Williamstown, Victoria. THE MISSIONS TO SEAMEN (Brief History: for more, see our Reg. No. 611, Set of Pews) The Missions to Seamen, an Anglican charity, has served seafarers of the world since 1856 in Great Britain. It symbol is a Flying Angel, inspired by a Bible verse. Today there are centr4es in over 200 ports world-wide where seamen of all backgrounds are offered a warm welcome and provided with a wide range of facilities. In Victoria the orgainsation began in Williamstown in 1857. It was as a Sailors’ Church, also known as ‘Bethel’ or the ‘Floating Church’. Its location was an old hulk floating in Hobson’s Bay, Port of Melbourne. It soon became part of the Missions to Seamen, Victoria. In the year 2000 the organisation, now named Mission to Seafarers, still operated locally in Melbourne, Portland, Geelong and Hastings. The Ladies’ Harbour Lights Guild was formed in 1906 to support the Missions to Seamen in Melbourne and other centres such as Williamstown. Two of the most significant ladies of the Guild were founder Ethel Augusta Godfrey and foundation member Alice Sibthorpe Tracy (who established a branch of the Guild in Warrnambool in 1920). The Guild continued its work until the 1960s. In 1943 a former Williamstown bank was purchased for the Missions to Seaman Club. The chapel was named St Nicholas’ Seamen’s Church and was supported by the Ladies’ Harbour Lights Guild, the Williamstown Lightkeepers’ Auxiliary and the League of Soldiers’ and Sailors’ Friends. It ceased operation in 1966. A Missions to Seamen Chapel and Recreation Room was a significant feature of ports during the late 1800s and into the 1900s. It seemed appropriate for Flagstaff Hill to include such a representation within the new Maritime Village, so the Melbourne Board of Management of Missions to Seamen Victoria gave its permission on 21st May 1979 for the entire furnishings of the Williamstown chapel to be transferred to Flagstaff Hill. The St Nicholas Seamen’s Church was officially opened on October 11, 1981 and closely resembles the Williamstown chapel. This book is one of a set of ten books, each titled The Book of Common Prayers, and is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of books is historically significant for its connection to the Ladies Lightkeepers Auxiliary, an organisation of women, formed to support seafarers. The connection of this set of books to the Mission to Seamen and to the Ladies Lightkeepers Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. The Book of Common Prayer. Blue cloth cover. Title: The Book of Common Prayer with the Additions and Deviations proposed in 1928 Publisher: Humphrey Milford, Oxford University Press, London. Spines have gold inlay print. 244 numbered pages. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’.Red ink stamps of a symbol of a cross inside the front covers.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, preyer books, book of common prayer, anglican church prayer book, religion, religious service, sailors rest, bethel sailors’ church, bethel floating church, ladies harbour light guild, missions to seamen victoria, mission to seafarers, flying angels club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, missions to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, anglican church, religious book -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Religious Book, Oxford University Press, The Book of Common Prayer, Early 20th century

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This book belongs to a set of prayer books that was part of the original furnishings of the St Nicholas' Mission to Seamen's Church at 139 Nelson Place, Williamstown, Victoria. THE MISSIONS TO SEAMEN (Brief History: for more, see our Reg. No. 611, Set of Pews) The Missions to Seamen, an Anglican charity, has served seafarers of the world since 1856 in Great Britain. It symbol is a Flying Angel, inspired by a Bible verse. Today there are centr4es in over 200 ports world-wide where seamen of all backgrounds are offered a warm welcome and provided with a wide range of facilities. In Victoria the orgainsation began in Williamstown in 1857. It was as a Sailors’ Church, also known as ‘Bethel’ or the ‘Floating Church’. Its location was an old hulk floating in Hobson’s Bay, Port of Melbourne. It soon became part of the Missions to Seamen, Victoria. In the year 2000 the organisation, now named Mission to Seafarers, still operated locally in Melbourne, Portland, Geelong and Hastings. The Ladies’ Harbour Lights Guild was formed in 1906 to support the Missions to Seamen in Melbourne and other centres such as Williamstown. Two of the most significant ladies of the Guild were founder Ethel Augusta Godfrey and foundation member Alice Sibthorpe Tracy (who established a branch of the Guild in Warrnambool in 1920). The Guild continued its work until the 1960s. In 1943 a former Williamstown bank was purchased for the Missions to Seaman Club. The chapel was named St Nicholas’ Seamen’s Church and was supported by the Ladies’ Harbour Lights Guild, the Williamstown Lightkeepers’ Auxiliary and the League of Soldiers’ and Sailors’ Friends. It ceased operation in 1966. A Missions to Seamen Chapel and Recreation Room was a significant feature of ports during the late 1800s and into the 1900s. It seemed appropriate for Flagstaff Hill to include such a representation within the new Maritime Village, so the Melbourne Board of Management of Missions to Seamen Victoria gave its permission on 21st May 1979 for the entire furnishings of the Williamstown chapel to be transferred to Flagstaff Hill. The St Nicholas Seamen’s Church was officially opened on October 11, 1981 and closely resembles the Williamstown chapel. This book is one of a set of ten books, each titled The Book of Common Prayers, and is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of books is historically significant for its connection to the Ladies Lightkeepers Auxiliary, an organisation of women, formed to support seafarers. The connection of this set of books to the Mission to Seamen and to the Ladies Lightkeepers Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. The Book of Common Prayer. Blue cloth cover. Title: The Book of Common Prayer with the Additions and Deviations proposed in 1928 Publisher: Humphrey Milford, Oxford University Press, London. Spines have gold inlay print. 244 numbered pages. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, preyer books, book of common prayer, anglican church prayer book, religion, religious service, sailors rest, bethel sailors’ church, bethel floating church, ladies harbour light guild, missions to seamen victoria, mission to seafarers, flying angels club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, missions to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, anglican church, religious book -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Religious Book, Oxford University Press, The Book of Common Prayer, Early 20th century

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This book belongs to a set of prayer books that was part of the original furnishings of the St Nicholas' Mission to Seamen's Church at 139 Nelson Place, Williamstown, Victoria. THE MISSIONS TO SEAMEN (Brief History: for more, see our Reg. No. 611, Set of Pews) The Missions to Seamen, an Anglican charity, has served seafarers of the world since 1856 in Great Britain. It symbol is a Flying Angel, inspired by a Bible verse. Today there are centr4es in over 200 ports world-wide where seamen of all backgrounds are offered a warm welcome and provided with a wide range of facilities. In Victoria the orgainsation began in Williamstown in 1857. It was as a Sailors’ Church, also known as ‘Bethel’ or the ‘Floating Church’. Its location was an old hulk floating in Hobson’s Bay, Port of Melbourne. It soon became part of the Missions to Seamen, Victoria. In the year 2000 the organisation, now named Mission to Seafarers, still operated locally in Melbourne, Portland, Geelong and Hastings. The Ladies’ Harbour Lights Guild was formed in 1906 to support the Missions to Seamen in Melbourne and other centres such as Williamstown. Two of the most significant ladies of the Guild were founder Ethel Augusta Godfrey and foundation member Alice Sibthorpe Tracy (who established a branch of the Guild in Warrnambool in 1920). The Guild continued its work until the 1960s. In 1943 a former Williamstown bank was purchased for the Missions to Seaman Club. The chapel was named St Nicholas’ Seamen’s Church and was supported by the Ladies’ Harbour Lights Guild, the Williamstown Lightkeepers’ Auxiliary and the League of Soldiers’ and Sailors’ Friends. It ceased operation in 1966. A Missions to Seamen Chapel and Recreation Room was a significant feature of ports during the late 1800s and into the 1900s. It seemed appropriate for Flagstaff Hill to include such a representation within the new Maritime Village, so the Melbourne Board of Management of Missions to Seamen Victoria gave its permission on 21st May 1979 for the entire furnishings of the Williamstown chapel to be transferred to Flagstaff Hill. The St Nicholas Seamen’s Church was officially opened on October 11, 1981 and closely resembles the Williamstown chapel. This book is one of a set of ten books, each titled The Book of Common Prayers, and is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of books is historically significant for its connection to the Ladies Lightkeepers Auxiliary, an organisation of women, formed to support seafarers. The connection of this set of books to the Mission to Seamen and to the Ladies Lightkeepers Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. The Book of Common Prayer. Red cloth cover. Title: The Book of Common Prayer with the Additions and Deviations proposed in 1928 Publisher: Humphrey Milford, Oxford University Press, London. Spines have gold inlay print. 244 numbered pages. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’.Gold embossed text on spine: "THE / PRAYER / BOOK/ AS PROPOSED / IN 1928" "HYMS A & M" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, preyer books, book of common prayer, anglican church prayer book, religion, religious service, sailors rest, bethel sailors’ church, bethel floating church, ladies harbour light guild, missions to seamen victoria, mission to seafarers, flying angels club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, missions to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, anglican church, religious book, book -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Religious Book, Oxford University Press, The Book of Common Prayer, Early 20th century

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This book belongs to a set of prayer books that was part of the original furnishings of the St Nicholas' Mission to Seamen's Church at 139 Nelson Place, Williamstown, Victoria. THE MISSIONS TO SEAMEN (Brief History: for more, see our Reg. No. 611, Set of Pews) The Missions to Seamen, an Anglican charity, has served seafarers of the world since 1856 in Great Britain. It symbol is a Flying Angel, inspired by a Bible verse. Today there are centr4es in over 200 ports world-wide where seamen of all backgrounds are offered a warm welcome and provided with a wide range of facilities. In Victoria the orgainsation began in Williamstown in 1857. It was as a Sailors’ Church, also known as ‘Bethel’ or the ‘Floating Church’. Its location was an old hulk floating in Hobson’s Bay, Port of Melbourne. It soon became part of the Missions to Seamen, Victoria. In the year 2000 the organisation, now named Mission to Seafarers, still operated locally in Melbourne, Portland, Geelong and Hastings. The Ladies’ Harbour Lights Guild was formed in 1906 to support the Missions to Seamen in Melbourne and other centres such as Williamstown. Two of the most significant ladies of the Guild were founder Ethel Augusta Godfrey and foundation member Alice Sibthorpe Tracy (who established a branch of the Guild in Warrnambool in 1920). The Guild continued its work until the 1960s. In 1943 a former Williamstown bank was purchased for the Missions to Seaman Club. The chapel was named St Nicholas’ Seamen’s Church and was supported by the Ladies’ Harbour Lights Guild, the Williamstown Lightkeepers’ Auxiliary and the League of Soldiers’ and Sailors’ Friends. It ceased operation in 1966. A Missions to Seamen Chapel and Recreation Room was a significant feature of ports during the late 1800s and into the 1900s. It seemed appropriate for Flagstaff Hill to include such a representation within the new Maritime Village, so the Melbourne Board of Management of Missions to Seamen Victoria gave its permission on 21st May 1979 for the entire furnishings of the Williamstown chapel to be transferred to Flagstaff Hill. The St Nicholas Seamen’s Church was officially opened on October 11, 1981 and closely resembles the Williamstown chapel. This book is one of a set of ten books, each titled The Book of Common Prayers, and is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of books is historically significant for its connection to the Ladies Lightkeepers Auxiliary, an organisation of women, formed to support seafarers. The connection of this set of books to the Mission to Seamen and to the Ladies Lightkeepers Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. The Book of Common Prayer. Blue cloth cover. Title: The Book of Common Prayer with the Additions and Deviations proposed in 1928 Publisher: Humphrey Milford, Oxford University Press, London. Spines have gold inlay print. 244 numbered pages. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, preyer books, book of common prayer, anglican church prayer book, religion, religious service, sailors rest, bethel sailors’ church, bethel floating church, ladies harbour light guild, missions to seamen victoria, mission to seafarers, flying angels club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, missions to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, anglican church, religious book, book -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Religious Book, Oxford University Press, The Book of Common Prayer, Early 20th century

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This book belongs to a set of prayer books that was part of the original furnishings of the St Nicholas' Mission to Seamen's Church at 139 Nelson Place, Williamstown, Victoria. THE MISSIONS TO SEAMEN (Brief History: for more, see our Reg. No. 611, Set of Pews) The Missions to Seamen, an Anglican charity, has served seafarers of the world since 1856 in Great Britain. It symbol is a Flying Angel, inspired by a Bible verse. Today there are centr4es in over 200 ports world-wide where seamen of all backgrounds are offered a warm welcome and provided with a wide range of facilities. In Victoria the orgainsation began in Williamstown in 1857. It was as a Sailors’ Church, also known as ‘Bethel’ or the ‘Floating Church’. Its location was an old hulk floating in Hobson’s Bay, Port of Melbourne. It soon became part of the Missions to Seamen, Victoria. In the year 2000 the organisation, now named Mission to Seafarers, still operated locally in Melbourne, Portland, Geelong and Hastings. The Ladies’ Harbour Lights Guild was formed in 1906 to support the Missions to Seamen in Melbourne and other centres such as Williamstown. Two of the most significant ladies of the Guild were founder Ethel Augusta Godfrey and foundation member Alice Sibthorpe Tracy (who established a branch of the Guild in Warrnambool in 1920). The Guild continued its work until the 1960s. In 1943 a former Williamstown bank was purchased for the Missions to Seaman Club. The chapel was named St Nicholas’ Seamen’s Church and was supported by the Ladies’ Harbour Lights Guild, the Williamstown Lightkeepers’ Auxiliary and the League of Soldiers’ and Sailors’ Friends. It ceased operation in 1966. A Missions to Seamen Chapel and Recreation Room was a significant feature of ports during the late 1800s and into the 1900s. It seemed appropriate for Flagstaff Hill to include such a representation within the new Maritime Village, so the Melbourne Board of Management of Missions to Seamen Victoria gave its permission on 21st May 1979 for the entire furnishings of the Williamstown chapel to be transferred to Flagstaff Hill. The St Nicholas Seamen’s Church was officially opened on October 11, 1981 and closely resembles the Williamstown chapel. This book is one of a set of ten books, each titled The Book of Common Prayers, and is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of books is historically significant for its connection to the Ladies Lightkeepers Auxiliary, an organisation of women, formed to support seafarers. The connection of this set of books to the Mission to Seamen and to the Ladies Lightkeepers Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. The Book of Common Prayer. Blue cloth cover. Title: The Book of Common Prayer with the Additions and Deviations proposed in 1928 Publisher: Humphrey Milford, Oxford University Press, London. Spines have gold inlay print. 244 numbered pages. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, preyer books, book of common prayer, anglican church prayer book, religion, religious service, sailors rest, bethel sailors’ church, bethel floating church, ladies harbour light guild, missions to seamen victoria, mission to seafarers, flying angels club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, missions to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, anglican church, religious book, book -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Religious Book, Oxford University Press, The Book of Common Prayer, Early 20th century

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This book is part of a set of books that were from the original furnishings of the St Nicholas' Mission to Seamen's Church at 139 Nelson Place, Williamstown, Victoria. THE MISSIONS TO SEAMEN (Brief History: for more, see our Reg. No. 611, Set of Pews) The Missions to Seamen, an Anglican charity, has served seafarers of the world since 1856 in Great Britain. It symbol is a Flying Angel, inspired by a Bible verse. Today there are centr4es in over 200 ports world-wide where seamen of all backgrounds are offered a warm welcome and provided with a wide range of facilities. In Victoria the orgainsation began in Williamstown in 1857. It was as a Sailors’ Church, also known as ‘Bethel’ or the ‘Floating Church’. Its location was an old hulk floating in Hobson’s Bay, Port of Melbourne. It soon became part of the Missions to Seamen, Victoria. In the year 2000 the organisation, now named Mission to Seafarers, still operated locally in Melbourne, Portland, Geelong and Hastings. The Ladies’ Harbour Lights Guild was formed in 1906 to support the Missions to Seamen in Melbourne and other centres such as Williamstown. Two of the most significant ladies of the Guild were founder Ethel Augusta Godfrey and foundation member Alice Sibthorpe Tracy (who established a branch of the Guild in Warrnambool in 1920). The Guild continued its work until the 1960s. In 1943 a former Williamstown bank was purchased for the Missions to Seaman Club. The chapel was named St Nicholas’ Seamen’s Church and was supported by the Ladies’ Harbour Lights Guild, the Williamstown Lightkeepers’ Auxiliary and the League of Soldiers’ and Sailors’ Friends. It ceased operation in 1966. A Missions to Seamen Chapel and Recreation Room was a significant feature of ports during the late 1800s and into the 1900s. It seemed appropriate for Flagstaff Hill to include such a representation within the new Maritime Village, so the Melbourne Board of Management of Missions to Seamen Victoria gave its permission on 21st May 1979 for the entire furnishings of the Williamstown chapel to be transferred to Flagstaff Hill. The St Nicholas Seamen’s Church was officially opened on October 11, 1981 and closely resembles the Williamstown chapel. This book is one of a set of ten books, each titled The Book of Common Prayers, and is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of books is historically significant for its connection to the Ladies Lightkeepers Auxiliary, an organisation of women, formed to support seafarers. The connection of this set of books to the Mission to Seamen and to the Ladies Lightkeepers Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. The Book of Common Prayer. Red cloth cover. Title: The Book of Common Prayer with the Additions and Deviations proposed in 1928 Publisher: Humphrey Milford, Oxford University Press, London. Spines have gold inlay print. 244 numbered pages. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, religion, religious service, sailors rest, bethel sailors’ church, bethel floating church, ladies harbour light guild, lightkeepers’ auxiliary, missions to seamen victoria, mission to seafarers, flying angel’s club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, st nicholas seamen's church williamstown collection, mission to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, religious book, religious worship, anglican church, prayer book, book of common prayer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Religious Book, Oxford University Press, The Book of Common Prayer

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This book belongs to a set of prayer books that was part of the original furnishings of the St Nicholas' Mission to Seamen's Church at 139 Nelson Place, Williamstown, Victoria. THE MISSIONS TO SEAMEN (Brief History: for more, see our Reg. No. 611, Set of Pews) The Missions to Seamen, an Anglican charity, has served seafarers of the world since 1856 in Great Britain. It symbol is a Flying Angel, inspired by a Bible verse. Today there are centr4es in over 200 ports world-wide where seamen of all backgrounds are offered a warm welcome and provided with a wide range of facilities. In Victoria the orgainsation began in Williamstown in 1857. It was as a Sailors’ Church, also known as ‘Bethel’ or the ‘Floating Church’. Its location was an old hulk floating in Hobson’s Bay, Port of Melbourne. It soon became part of the Missions to Seamen, Victoria. In the year 2000 the organisation, now named Mission to Seafarers, still operated locally in Melbourne, Portland, Geelong and Hastings. The Ladies’ Harbour Lights Guild was formed in 1906 to support the Missions to Seamen in Melbourne and other centres such as Williamstown. Two of the most significant ladies of the Guild were founder Ethel Augusta Godfrey and foundation member Alice Sibthorpe Tracy (who established a branch of the Guild in Warrnambool in 1920). The Guild continued its work until the 1960s. In 1943 a former Williamstown bank was purchased for the Missions to Seaman Club. The chapel was named St Nicholas’ Seamen’s Church and was supported by the Ladies’ Harbour Lights Guild, the Williamstown Lightkeepers’ Auxiliary and the League of Soldiers’ and Sailors’ Friends. It ceased operation in 1966. A Missions to Seamen Chapel and Recreation Room was a significant feature of ports during the late 1800s and into the 1900s. It seemed appropriate for Flagstaff Hill to include such a representation within the new Maritime Village, so the Melbourne Board of Management of Missions to Seamen Victoria gave its permission on 21st May 1979 for the entire furnishings of the Williamstown chapel to be transferred to Flagstaff Hill. The St Nicholas Seamen’s Church was officially opened on October 11, 1981 and closely resembles the Williamstown chapel. This book is one of a set of ten books, each titled The Book of Common Prayers, and is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of books is historically significant for its connection to the Ladies Lightkeepers Auxiliary, an organisation of women, formed to support seafarers. The connection of this set of books to the Mission to Seamen and to the Ladies Lightkeepers Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. The Book of Common Prayer. Blue cloth cover. Title: The Book of Common Prayer with the Additions and Deviations proposed in 1928 Publisher: Humphrey Milford, Oxford University Press, London. Spines have gold inlay print. 244 numbered pages. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, preyer books, book of common prayer, anglican church prayer book, religion, religious service, sailors rest, bethel sailors’ church, bethel floating church, ladies harbour light guild, missions to seamen victoria, mission to seafarers, flying angels club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, missions to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, anglican church, religious book, book -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Pew, circa 1944

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This pew is one of a set of seventeen church pews originally used in St. Nicholas Seamen’s Church, 139 Nelson Place, Williamstown, Victoria, during religious services there. The Church was operated by the Mission to Seamen organisation. The pews were donated to the St Nicholas Seamen’s Church by the Williamstown Lightkeepers’ Auxiliary, founded by Ethel Margaret Musther, M.B.E. * for more detailed history please see our Registration Number 611, Set of Pews The set of pews is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of pews id historically significant for their connection to the Ladies Lightkeepers’ Auxiliary, an organisation of women, formed to support seafarers. The connection of these pews to the Mission to Seamen and to the Ladies Lightkeepers’ Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. Church pew, one of a set of seventeen varnished wooden church pews. The pews have a shelf fitted behind the backrest. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, religion, religious service, lightkeepers’ auxiliary, mrs musther, missions to seamen victoria, mission to seafarers, flying angel’s club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, mission to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, church furniture, church seats, church pew, religious furniture, religious worship, anglican church, set of pews -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Pew, Circa 1944

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This pew is one of a set of seventeen church pews originally used in St. Nicholas Seamen’s Church, 139 Nelson Place, Williamstown, Victoria, during religious services there. The Church was operated by the Mission to Seamen organisation. The pews were donated to the St Nicholas Seamen’s Church by the Williamstown Lightkeepers’ Auxiliary, founded by Ethel Margaret Musther, M.B.E. * for more detailed history please see our Registration Number 611, Set of Pews The set of pews is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of pews id historically significant for their connection to the Ladies Lightkeepers’ Auxiliary, an organisation of women, formed to support seafarers. The connection of these pews to the Mission to Seamen and to the Ladies Lightkeepers’ Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. Church pew, one of a set of seventeen varnished wooden church pews. The pew has a shelf fitted behind the backrest. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, religion, religious service, lightkeepers’ auxiliary, mrs musther, missions to seamen victoria, mission to seafarers, flying angel’s club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, mission to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, church furniture, church seats, church pew, religious furniture, religious worship, anglican church, set of pews -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Pew, Circa 1944

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This pew is one of a set of seventeen church pews originally used in St. Nicholas Seamen’s Church, 139 Nelson Place, Williamstown, Victoria, during religious services there. The Church was operated by the Mission to Seamen organisation. The pews were donated to the St Nicholas Seamen’s Church by the Williamstown Lightkeepers’ Auxiliary, founded by Ethel Margaret Musther, M.B.E. * for more detailed history please see our Registration Number 611, Set of Pews The set of pews is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of pews id historically significant for their connection to the Ladies Lightkeepers’ Auxiliary, an organisation of women, formed to support seafarers. The connection of these pews to the Mission to Seamen and to the Ladies Lightkeepers’ Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. Church pew, one of a set of seventeen varnished wooden church pews. The pew has a shelf fitted behind the backrest. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, religion, religious service, lightkeepers’ auxiliary, mrs musther, missions to seamen victoria, mission to seafarers, flying angel’s club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, mission to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, church furniture, church seats, church pew, religious furniture, religious worship, anglican church, set of pews -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Pew, Circa 1944

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This pew is one of a set of seventeen church pews originally used in St. Nicholas Seamen’s Church, 139 Nelson Place, Williamstown, Victoria, during religious services there. The Church was operated by the Mission to Seamen organisation. The pews were donated to the St Nicholas Seamen’s Church by the Williamstown Lightkeepers’ Auxiliary, founded by Ethel Margaret Musther, M.B.E. * for more detailed history please see our Registration Number 611, Set of Pews The set of pews is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of pews id historically significant for their connection to the Ladies Lightkeepers’ Auxiliary, an organisation of women, formed to support seafarers. The connection of these pews to the Mission to Seamen and to the Ladies Lightkeepers’ Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. Church pew, one of a set of seventeen varnished wooden church pews. The pew has a shelf fitted behind the backrest. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, religion, religious service, lightkeepers’ auxiliary, mrs musther, missions to seamen victoria, mission to seafarers, flying angel’s club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, mission to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, church furniture, church seats, church pew, religious furniture, religious worship, anglican church, set of pews -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Pew, Circa 1944

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This pew is one of a set of seventeen church pews originally used in St. Nicholas Seamen’s Church, 139 Nelson Place, Williamstown, Victoria, during religious services there. The Church was operated by the Mission to Seamen organisation. The pews were donated to the St Nicholas Seamen’s Church by the Williamstown Lightkeepers’ Auxiliary, founded by Ethel Margaret Musther, M.B.E. * for more detailed history please see our Registration Number 611, Set of Pews The set of pews is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of pews id historically significant for their connection to the Ladies Lightkeepers’ Auxiliary, an organisation of women, formed to support seafarers. The connection of these pews to the Mission to Seamen and to the Ladies Lightkeepers’ Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. Church pew, one of a set of seventeen varnished wooden church pews. The pew has a shelf fitted behind the backrest. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, religion, religious service, lightkeepers’ auxiliary, mrs musther, missions to seamen victoria, mission to seafarers, flying angel’s club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, mission to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, church furniture, church seats, church pew, religious furniture, religious worship, anglican church, set of pews -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Pew, Circa 1944

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This pew is one of a set of seventeen church pews originally used in St. Nicholas Seamen’s Church, 139 Nelson Place, Williamstown, Victoria, during religious services there. The Church was operated by the Mission to Seamen organisation. The pews were donated to the St Nicholas Seamen’s Church by the Williamstown Lightkeepers’ Auxiliary, founded by Ethel Margaret Musther, M.B.E. * for more detailed history please see our Registration Number 611, Set of Pews The set of pews is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of pews id historically significant for their connection to the Ladies Lightkeepers’ Auxiliary, an organisation of women, formed to support seafarers. The connection of these pews to the Mission to Seamen and to the Ladies Lightkeepers’ Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. Church pew, one of a set of seventeen varnished wooden church pews. The pew has a shelf fitted behind the backrest. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, religion, religious service, lightkeepers’ auxiliary, mrs musther, missions to seamen victoria, mission to seafarers, flying angel’s club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, mission to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, church furniture, church seats, church pew, religious furniture, religious worship, anglican church, set of pews -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Pew, Circa 1944

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This pew is one of a set of seventeen church pews originally used in St. Nicholas Seamen’s Church, 139 Nelson Place, Williamstown, Victoria, during religious services there. The Church was operated by the Mission to Seamen organisation. The pews were donated to the St Nicholas Seamen’s Church by the Williamstown Lightkeepers’ Auxiliary, founded by Ethel Margaret Musther, M.B.E. * for more detailed history please see our Registration Number 611, Set of Pews The set of pews is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of pews id historically significant for their connection to the Ladies Lightkeepers’ Auxiliary, an organisation of women, formed to support seafarers. The connection of these pews to the Mission to Seamen and to the Ladies Lightkeepers’ Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. Church pew, one of a set of seventeen varnished wooden church pews. The pew has a shelf fitted behind the backrest. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, religion, religious service, lightkeepers’ auxiliary, mrs musther, missions to seamen victoria, mission to seafarers, flying angel’s club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, mission to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, church furniture, church seats, church pew, religious furniture, religious worship, anglican church, set of pews -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Pew, Circa 1944

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This pew is one of a set of fifteen church pews originally used in St. Nicholas Seamen’s Church, 139 Nelson Place, Williamstown, Victoria, during religious services there. The Church was operated by the Mission to Seamen organisation. The pews were donated to the St Nicholas Seamen’s Church by the Williamstown Lightkeepers’ Auxiliary, founded by Ethel Margaret Musther, M.B.E. * for more detailed history please see our Registration Number 611, Set of Pews The set of pews is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of pews id historically significant for their connection to the Ladies Lightkeepers’ Auxiliary, an organisation of women, formed to support seafarers. The connection of these pews to the Mission to Seamen and to the Ladies Lightkeepers’ Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. Church pew, one of a set of fifteen varnished wooden church pews. The pews have a shelf fitted at the behind the backrest. Ten pews also have hinged kneeling stands attached to them underneath the seats. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, religion, religious service, lightkeepers’ auxiliary, mrs musther, missions to seamen victoria, mission to seafarers, flying angel’s club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, mission to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, church furniture, church seats, church pew, religious furniture, religious worship, anglican church, set of pews -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Pew, Circa 1944

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This pew is one of a set of fifteen church pews originally used in St. Nicholas Seamen’s Church, 139 Nelson Place, Williamstown, Victoria, during religious services there. The Church was operated by the Mission to Seamen organisation. The pews were donated to the St Nicholas Seamen’s Church by the Williamstown Lightkeepers’ Auxiliary, founded by Ethel Margaret Musther, M.B.E. * for more detailed history please see our Registration Number 611, Set of Pews The set of pews is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of pews id historically significant for their connection to the Ladies Lightkeepers’ Auxiliary, an organisation of women, formed to support seafarers. The connection of these pews to the Mission to Seamen and to the Ladies Lightkeepers’ Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. Church pew, one of a set of fifteen varnished wooden church pews. The pews have a shelf fitted at the behind the backrest. Ten pews also have hinged kneeling stands attached to them underneath the seats. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, religion, religious service, lightkeepers’ auxiliary, mrs musther, missions to seamen victoria, mission to seafarers, flying angel’s club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, mission to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, church furniture, church seats, church pew, religious furniture, religious worship, anglican church, set of pews -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Pew, Circa 1944

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This pew is one of a set of fifteen church pews originally used in St. Nicholas Seamen’s Church, 139 Nelson Place, Williamstown, Victoria, during religious services there. The Church was operated by the Mission to Seamen organisation. The pews were donated to the St Nicholas Seamen’s Church by the Williamstown Lightkeepers’ Auxiliary, founded by Ethel Margaret Musther, M.B.E. * for more detailed history please see our Registration Number 611, Set of Pews The set of pews is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of pews id historically significant for their connection to the Ladies Lightkeepers’ Auxiliary, an organisation of women, formed to support seafarers. The connection of these pews to the Mission to Seamen and to the Ladies Lightkeepers’ Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. Church pew, one of a set of fifteen varnished wooden church pews. The pews have a shelf fitted at the behind the backrest. Ten pews also have hinged kneeling stands attached to them underneath the seats. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, religion, religious service, lightkeepers’ auxiliary, mrs musther, missions to seamen victoria, mission to seafarers, flying angel’s club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, mission to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, church furniture, church seats, church pew, religious furniture, religious worship, anglican church, set of pews -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Pew, Circa 1944

... flagstaff hill maritime village...Flagstaff Hill Maritime Museum and Village 89 Merri Street ...This pew is one of a set of fifteen church pews originally used in St. Nicholas Seamen’s Church, 139 Nelson Place, Williamstown, Victoria, during religious services there. The Church was operated by the Mission to Seamen organisation. The pews were donated to the St Nicholas Seamen’s Church by the Williamstown Lightkeepers’ Auxiliary, founded by Ethel Margaret Musther, M.B.E. * for more detailed history please see our Registration Number 611, Set of Pews The set of pews is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. The set of pews id historically significant for their connection to the Ladies Lightkeepers’ Auxiliary, an organisation of women, formed to support seafarers. The connection of these pews to the Mission to Seamen and to the Ladies Lightkeepers’ Auxiliary highlights the strong community awareness of the life of people at sea, their dangers and hardships, and their need for physical, financial, spiritual and moral support. Church pew, one of a set of fifteen varnished wooden church pews. The pews have a shelf fitted at the behind the backrest. Ten pews also have hinged kneeling stands attached to them underneath the seats. This is one of a set of original items in our ‘St Nicholas Seamen's Church Williamstown Collection’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, religion, religious service, lightkeepers’ auxiliary, mrs musther, missions to seamen victoria, mission to seafarers, flying angel’s club, st nicholas seaman’s church williamstown, st nicholas mission to seamen church williamstown, mission to seamen williamstown, st nicholas seamen’s church flagstaff hill, 139 nelson place williamstown, church furniture, church seats, church pew, religious furniture, religious worship, anglican church, set of pews