Showing 870 items

matching water colour

-

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Autumn Excursion, Hume and Hovell's 1824 expedition, 26 May 1996, 26/05/1996

[article by Bettina Woodburn in EDHS Newsletter No. 109, July 1996:] ON THE TRAIL OF HUME AND HOVELL - REPORT ON THE AUTUMN EXCURSION - On a green and fresh morning (Sunday 26th May 1996) the Cobb and Co coach (driven by the most obliging Peter Tampion) set off in a north easterly direction from Eltham to connect with Hume and Hovell's route on their 1824 explorations of central Victoria. The Society would follow a series of monuments erected for the 1924 centenary of the expedition from King Parrot Creek (Tuesday 7th December 1824), through Strath Creek, over Sunday Creek (Sunday 12th December 1824) at Broadford, Tullamarine, St Albans, Deer Park, through Werribee, skirting east of the You Yangs to Lara and Avalon Beach. Because their distance-measuring wheel had broken and a one degree mistake was made in calculations, the two leaders of the original group of six convict-companions arrived at Corio Bay, instead of the expected Western Port, discovered earlier by Flinders. From below Mt. Disappointment (Hume and Hovell's difficulties in "scrambling over brush and rock", "leeches in forest, as well as no water", "cutting grass 4-5 ft. high", dreadful scrub", "devil flies") we took an easier route, saw the Strath Creek memorial in ground fog and a wonderful "field of dreams", the Hume-Hovell privately owned cricket ground with its white picket boundary fence. Now, after a steep climb, in sunshine under gums we stretched and viewed magnificent rolling hills and fog-filled valleys - not "smoke from Aborigines' bush fires". After morning tea at Broadford we followed the Sunday Creek valley beside the Hume Freeway, passed the Wallan Wallan Rest Area (more appropriately Hume and Hovell Rest Area) to tum right at Beveridge. In Gellibrand Hill Park, near the headwaters of the Moonee Ponds Creek, we experienced the landscape the first European settlers saw - huge river red gums and rolling pastures. The gardens and sheltered courtyard of the 1840s, timber, brought from .....[?] prefabricated Woodlands Homestead, provided a pleasant lunch stop. We enjoyed a private tour, panoramic views over Melbourne and surroundings and the excitement of arriving and departing aircraft. Our next river crossing was at Werribee, "in a vast treeless plain", then we drove on by-ways no coach had previously travelled, to find "an immense sheet of water" salty Corio Bay, off-course to the west. In late afternoon of a super, calm, late autumn day we headed homewards. Back at Eltham we were rather surprised to find that we had travelled a total of 347 km. Thanks again to Russell Yeoman for his research and organization. What a wonderful day! Colour photographactivities, hume and hovell -

Eltham District Historical Society Inc

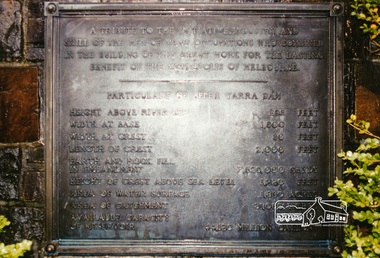

Eltham District Historical Society IncPhotograph, Peter Bassett-Smith, Upper Yarra Dam, Spring Tour, 22 Oct 1995, 22/10/1995

EXPLORING THE UPPER YARRA (Newsletter No. 105, November 1995, by Bettina Woodburn) We enjoyed the Spring Excursion, this year "Exploring the Upper Yarra" - in spite of the constant rain and the countryside under the cloud cover, especially in the valleys, being mainly shiny shades of green. The occasional fields of buttercups, clumps of arum lilies and splendid rhododendron and other flowering bushes became very special. The Cobb and Co coach was warm and a cosy retreat as we zig-zagged on the highways and byways to glimpse the Yarra River, upstream and down, its secret places, and particularly the many bridges. Russell excelled as 'Poet Laureate', reading from Dacre Smyth's book. This 1979 publication includes paintings of all the bridges along the river with poems and brief descriptions of each one. Some of the bridges are in out of the way places and are not very well known. We looked forward to hearing the poetry as much as seeing the ' constructions'…Big Pat (was he short or tall, lean or fat? He did win the two hundred pound reward for discovering gold and had the creek named after him), about the 'Eddies'?, and the disliked 'meccano' bridge in Warburton, etc. etc. The hot roast lunch in the old Reefton Hotel was also most welcome. It was easy to imagine it peopled by miners and early settlers. Starting by crossing the new (1974) concrete bridge at Warrandyte we headed through Wonga Park with views to the Christmas Hills and to the escarpment of the Yering Gorge, which causes flood waters to back up through the Yarra Glen plain, so avoiding disasters downstream. At the end of a long driveway we found the wooden, privately owned Henley Bridge (1935 after the 1934 floods). This facilitates access to different parts of Henley Farm and to Lilydale. Everard Park, named after Blanche Shallard's father, a State Member for 17 years, below the Highway Yarra crossing was in need of care. It is 10 miles from Yarra Glen by road but, as "Yarra Marra” canoeists well know, 32 winding miles down by water. After more delightful countryside scenes we joined the Warburton Highway at Woori Yallock. From the old Railway Station at Launching Place the Centennial Trail for walkers, cyclists and ' horse riders has replaced the rails. The line from Lilydale was opened in 1901, and the last diesel freight train ran to Warburton in 1965. It continued to rain as we had morning tea in Warburton in a shelter between footbridges. From here we continued upstream past the Bridge to O'Shannasy Lodge and Reservoir, Starvation Creek, and the Peninsular tunnel (miners dug it as at Pound Bend) which we visited (scrambling down those steps!) on our return after lunch. Our furthermost point was the Upper Yarra Dam Reserve (and vast catchment area). Finished in 1957 after ten years work and 100 years after Yan Yean, it supplies much of Melbourne's water. After crossing the 30m Launching Place Bridge to the Eltham side of the Yarra and Healesville, we saw in the distance the Yarra Glen Timber Trestle Bridge over the river flats "the longest for years in the land it was said!" Harry's dream of "better weather over the Divide" unfortunately didn't come true, but I'm sure we 36 members will retain happy memories of a day that was wet and green and filled with Bridges. Bettina Woodburn - October 1995 Record of the Society's history of activities - Spring 1995 excursionColour photographactivities, upper yarra dam, 1995, peter bassett-smith -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Peter Bassett-Smith, Upper Yarra Dam, Spring Tour, 22 Oct 1995, 22/10/1995

EXPLORING THE UPPER YARRA (Newsletter No. 105, November 1995, by Bettina Woodburn) We enjoyed the Spring Excursion, this year "Exploring the Upper Yarra" - in spite of the constant rain and the countryside under the cloud cover, especially in the valleys, being mainly shiny shades of green. The occasional fields of buttercups, clumps of arum lilies and splendid rhododendron and other flowering bushes became very special. The Cobb and Co coach was warm and a cosy retreat as we zig-zagged on the highways and byways to glimpse the Yarra River, upstream and down, its secret places, and particularly the many bridges. Russell excelled as 'Poet Laureate', reading from Dacre Smyth's book. This 1979 publication includes paintings of all the bridges along the river with poems and brief descriptions of each one. Some of the bridges are in out of the way places and are not very well known. We looked forward to hearing the poetry as much as seeing the ' constructions'…Big Pat (was he short or tall, lean or fat? He did win the two hundred pound reward for discovering gold and had the creek named after him), about the 'Eddies'?, and the disliked 'meccano' bridge in Warburton, etc. etc. The hot roast lunch in the old Reefton Hotel was also most welcome. It was easy to imagine it peopled by miners and early settlers. Starting by crossing the new (1974) concrete bridge at Warrandyte we headed through Wonga Park with views to the Christmas Hills and to the escarpment of the Yering Gorge, which causes flood waters to back up through the Yarra Glen plain, so avoiding disasters downstream. At the end of a long driveway we found the wooden, privately owned Henley Bridge (1935 after the 1934 floods). This facilitates access to different parts of Henley Farm and to Lilydale. Everard Park, named after Blanche Shallard's father, a State Member for 17 years, below the Highway Yarra crossing was in need of care. It is 10 miles from Yarra Glen by road but, as "Yarra Marra” canoeists well know, 32 winding miles down by water. After more delightful countryside scenes we joined the Warburton Highway at Woori Yallock. From the old Railway Station at Launching Place the Centennial Trail for walkers, cyclists and ' horse riders has replaced the rails. The line from Lilydale was opened in 1901, and the last diesel freight train ran to Warburton in 1965. It continued to rain as we had morning tea in Warburton in a shelter between footbridges. From here we continued upstream past the Bridge to O'Shannasy Lodge and Reservoir, Starvation Creek, and the Peninsular tunnel (miners dug it as at Pound Bend) which we visited (scrambling down those steps!) on our return after lunch. Our furthermost point was the Upper Yarra Dam Reserve (and vast catchment area). Finished in 1957 after ten years work and 100 years after Yan Yean, it supplies much of Melbourne's water. After crossing the 30m Launching Place Bridge to the Eltham side of the Yarra and Healesville, we saw in the distance the Yarra Glen Timber Trestle Bridge over the river flats "the longest for years in the land it was said!" Harry's dream of "better weather over the Divide" unfortunately didn't come true, but I'm sure we 36 members will retain happy memories of a day that was wet and green and filled with Bridges. Bettina Woodburn - October 1995 Record of the Society's history of activities - Spring 1995 excursionColour photographactivities, upper yarra dam, 1995 -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Peter Bassett-Smith, Upper Yarra Dam, Spring Tour, 22 Oct 1995, 22/10/1995

EXPLORING THE UPPER YARRA (Newsletter No. 105, November 1995, by Bettina Woodburn) We enjoyed the Spring Excursion, this year "Exploring the Upper Yarra" - in spite of the constant rain and the countryside under the cloud cover, especially in the valleys, being mainly shiny shades of green. The occasional fields of buttercups, clumps of arum lilies and splendid rhododendron and other flowering bushes became very special. The Cobb and Co coach was warm and a cosy retreat as we zig-zagged on the highways and byways to glimpse the Yarra River, upstream and down, its secret places, and particularly the many bridges. Russell excelled as 'Poet Laureate', reading from Dacre Smyth's book. This 1979 publication includes paintings of all the bridges along the river with poems and brief descriptions of each one. Some of the bridges are in out of the way places and are not very well known. We looked forward to hearing the poetry as much as seeing the ' constructions'…Big Pat (was he short or tall, lean or fat? He did win the two hundred pound reward for discovering gold and had the creek named after him), about the 'Eddies'?, and the disliked 'meccano' bridge in Warburton, etc. etc. The hot roast lunch in the old Reefton Hotel was also most welcome. It was easy to imagine it peopled by miners and early settlers. Starting by crossing the new (1974) concrete bridge at Warrandyte we headed through Wonga Park with views to the Christmas Hills and to the escarpment of the Yering Gorge, which causes flood waters to back up through the Yarra Glen plain, so avoiding disasters downstream. At the end of a long driveway we found the wooden, privately owned Henley Bridge (1935 after the 1934 floods). This facilitates access to different parts of Henley Farm and to Lilydale. Everard Park, named after Blanche Shallard's father, a State Member for 17 years, below the Highway Yarra crossing was in need of care. It is 10 miles from Yarra Glen by road but, as "Yarra Marra” canoeists well know, 32 winding miles down by water. After more delightful countryside scenes we joined the Warburton Highway at Woori Yallock. From the old Railway Station at Launching Place the Centennial Trail for walkers, cyclists and ' horse riders has replaced the rails. The line from Lilydale was opened in 1901, and the last diesel freight train ran to Warburton in 1965. It continued to rain as we had morning tea in Warburton in a shelter between footbridges. From here we continued upstream past the Bridge to O'Shannasy Lodge and Reservoir, Starvation Creek, and the Peninsular tunnel (miners dug it as at Pound Bend) which we visited (scrambling down those steps!) on our return after lunch. Our furthermost point was the Upper Yarra Dam Reserve (and vast catchment area). Finished in 1957 after ten years work and 100 years after Yan Yean, it supplies much of Melbourne's water. After crossing the 30m Launching Place Bridge to the Eltham side of the Yarra and Healesville, we saw in the distance the Yarra Glen Timber Trestle Bridge over the river flats "the longest for years in the land it was said!" Harry's dream of "better weather over the Divide" unfortunately didn't come true, but I'm sure we 36 members will retain happy memories of a day that was wet and green and filled with Bridges. Bettina Woodburn - October 1995 Record of the Society's history of activities - Spring 1995 excursionColour photographactivities, upper yarra dam, 1995 -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Peter Bassett-Smith, Upper Yarra Dam, Spring Tour, 22 Oct 1995, 22/10/1995

EXPLORING THE UPPER YARRA (Newsletter No. 105, November 1995, by Bettina Woodburn) We enjoyed the Spring Excursion, this year "Exploring the Upper Yarra" - in spite of the constant rain and the countryside under the cloud cover, especially in the valleys, being mainly shiny shades of green. The occasional fields of buttercups, clumps of arum lilies and splendid rhododendron and other flowering bushes became very special. The Cobb and Co coach was warm and a cosy retreat as we zig-zagged on the highways and byways to glimpse the Yarra River, upstream and down, its secret places, and particularly the many bridges. Russell excelled as 'Poet Laureate', reading from Dacre Smyth's book. This 1979 publication includes paintings of all the bridges along the river with poems and brief descriptions of each one. Some of the bridges are in out of the way places and are not very well known. We looked forward to hearing the poetry as much as seeing the ' constructions'…Big Pat (was he short or tall, lean or fat? He did win the two hundred pound reward for discovering gold and had the creek named after him), about the 'Eddies'?, and the disliked 'meccano' bridge in Warburton, etc. etc. The hot roast lunch in the old Reefton Hotel was also most welcome. It was easy to imagine it peopled by miners and early settlers. Starting by crossing the new (1974) concrete bridge at Warrandyte we headed through Wonga Park with views to the Christmas Hills and to the escarpment of the Yering Gorge, which causes flood waters to back up through the Yarra Glen plain, so avoiding disasters downstream. At the end of a long driveway we found the wooden, privately owned Henley Bridge (1935 after the 1934 floods). This facilitates access to different parts of Henley Farm and to Lilydale. Everard Park, named after Blanche Shallard's father, a State Member for 17 years, below the Highway Yarra crossing was in need of care. It is 10 miles from Yarra Glen by road but, as "Yarra Marra” canoeists well know, 32 winding miles down by water. After more delightful countryside scenes we joined the Warburton Highway at Woori Yallock. From the old Railway Station at Launching Place the Centennial Trail for walkers, cyclists and ' horse riders has replaced the rails. The line from Lilydale was opened in 1901, and the last diesel freight train ran to Warburton in 1965. It continued to rain as we had morning tea in Warburton in a shelter between footbridges. From here we continued upstream past the Bridge to O'Shannasy Lodge and Reservoir, Starvation Creek, and the Peninsular tunnel (miners dug it as at Pound Bend) which we visited (scrambling down those steps!) on our return after lunch. Our furthermost point was the Upper Yarra Dam Reserve (and vast catchment area). Finished in 1957 after ten years work and 100 years after Yan Yean, it supplies much of Melbourne's water. After crossing the 30m Launching Place Bridge to the Eltham side of the Yarra and Healesville, we saw in the distance the Yarra Glen Timber Trestle Bridge over the river flats "the longest for years in the land it was said!" Harry's dream of "better weather over the Divide" unfortunately didn't come true, but I'm sure we 36 members will retain happy memories of a day that was wet and green and filled with Bridges. Bettina Woodburn - October 1995 Record of the Society's history of activities - Spring 1995 excursionColour photographactivities, upper yarra dam, 1995 -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Peter Bassett-Smith, Upper Yarra Dam, Spring Tour, 22 Oct 1995, 22/10/1995

EXPLORING THE UPPER YARRA (Newsletter No. 105, November 1995, by Bettina Woodburn) We enjoyed the Spring Excursion, this year "Exploring the Upper Yarra" - in spite of the constant rain and the countryside under the cloud cover, especially in the valleys, being mainly shiny shades of green. The occasional fields of buttercups, clumps of arum lilies and splendid rhododendron and other flowering bushes became very special. The Cobb and Co coach was warm and a cosy retreat as we zig-zagged on the highways and byways to glimpse the Yarra River, upstream and down, its secret places, and particularly the many bridges. Russell excelled as 'Poet Laureate', reading from Dacre Smyth's book. This 1979 publication includes paintings of all the bridges along the river with poems and brief descriptions of each one. Some of the bridges are in out of the way places and are not very well known. We looked forward to hearing the poetry as much as seeing the ' constructions'…Big Pat (was he short or tall, lean or fat? He did win the two hundred pound reward for discovering gold and had the creek named after him), about the 'Eddies'?, and the disliked 'meccano' bridge in Warburton, etc. etc. The hot roast lunch in the old Reefton Hotel was also most welcome. It was easy to imagine it peopled by miners and early settlers. Starting by crossing the new (1974) concrete bridge at Warrandyte we headed through Wonga Park with views to the Christmas Hills and to the escarpment of the Yering Gorge, which causes flood waters to back up through the Yarra Glen plain, so avoiding disasters downstream. At the end of a long driveway we found the wooden, privately owned Henley Bridge (1935 after the 1934 floods). This facilitates access to different parts of Henley Farm and to Lilydale. Everard Park, named after Blanche Shallard's father, a State Member for 17 years, below the Highway Yarra crossing was in need of care. It is 10 miles from Yarra Glen by road but, as "Yarra Marra” canoeists well know, 32 winding miles down by water. After more delightful countryside scenes we joined the Warburton Highway at Woori Yallock. From the old Railway Station at Launching Place the Centennial Trail for walkers, cyclists and ' horse riders has replaced the rails. The line from Lilydale was opened in 1901, and the last diesel freight train ran to Warburton in 1965. It continued to rain as we had morning tea in Warburton in a shelter between footbridges. From here we continued upstream past the Bridge to O'Shannasy Lodge and Reservoir, Starvation Creek, and the Peninsular tunnel (miners dug it as at Pound Bend) which we visited (scrambling down those steps!) on our return after lunch. Our furthermost point was the Upper Yarra Dam Reserve (and vast catchment area). Finished in 1957 after ten years work and 100 years after Yan Yean, it supplies much of Melbourne's water. After crossing the 30m Launching Place Bridge to the Eltham side of the Yarra and Healesville, we saw in the distance the Yarra Glen Timber Trestle Bridge over the river flats "the longest for years in the land it was said!" Harry's dream of "better weather over the Divide" unfortunately didn't come true, but I'm sure we 36 members will retain happy memories of a day that was wet and green and filled with Bridges. Bettina Woodburn - October 1995 Record of the Society's history of activities - Spring 1995 excursionColour photographactivities, upper yarra dam, 1995 -

Eltham District Historical Society Inc

Eltham District Historical Society IncNegative - Photograph, Water Tower, 51 Cassells Road, Research, 1998c

... .) water tower Kodak Gold 100-5 Roll of 35mm colour negative film ...Dismantled 6 April 2017Roll of 35mm colour negative film, 8 strips and associated 10 x 15 cm colour printKodak Gold 100-5cassells road, research (vic.), water tower -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Water dip on road to Donnelly's Weir, Healesville, 1989, 1989

... Colour photograph Water dip on road to Donnelly's Weir ...Originally contained in a 'magnetic' photo album of scenic photos of Yan Yean and Warrandyte believed to be donated by Mrs Eric Stephenson, Jingalong, 110 Ryans Road, Eltham, Vic. 3095; relocated to archival safe storage.Colour photographdonnelly's weir, healesville -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, High water, Yarra River at Templestowe

... ; relocated to archival safe storage. yarra river Templestowe Colour ...Originally contained in a 'magnetic' photo album of scenic photos of Yan Yean and Warrandyte believed to be donated by Mrs Eric Stephenson, Jingalong, 110 Ryans Road, Eltham, Vic. 3095; relocated to archival safe storage.Colour photographyarra river, templestowe -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Yan Yean, 1987, 1987

Originally contained in a 'magnetic' photo album of scenic photos of Yan Yean and Warrandyte believed to be donated by Mrs Eric Stephenson, Jingalong, 110 Ryans Road, Eltham, Vic. 3095; relocated to archival safe storage. On the 20th December 1853 Lieut Governor Charles LaTrobe took his spade to turn the first sod of an embankment across the swampy bed of the Plenty River at a lonely place called Yan Yean, in order to create Melbourne’s first water supply. In the early 1850’s water had been drawn from the Yarra which even then was known as Yarra Soup. A convict by the name of James Blackburn produced the basic design for supplying water to Melbourne from a reservoir on the Plenty River at Yan Yean, and later on he was appointed consulting engineer on the project. In 1853 a contract was let for the building of the wall for 91 thousand 575 pounds, and at one stage some 400 labourers were at work in the area. A tramway was constructed to convey stone and other materials from Melbourne. So famous was this magnificent stretch of water that illustrations of the bluestone embankment and tower appeared in London journals Whittlesea Historical Society – Historic items for Diamond Valley Community Radio September 1990 Colour photographyan yean, yan yean reservoir -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Yan Yean, 1987, 1987

Originally contained in a 'magnetic' photo album of scenic photos of Yan Yean and Warrandyte believed to be donated by Mrs Eric Stephenson, Jingalong, 110 Ryans Road, Eltham, Vic. 3095; relocated to archival safe storage. On the 20th December 1853 Lieut Governor Charles LaTrobe took his spade to turn the first sod of an embankment across the swampy bed of the Plenty River at a lonely place called Yan Yean, in order to create Melbourne’s first water supply. In the early 1850’s water had been drawn from the Yarra which even then was known as Yarra Soup. A convict by the name of James Blackburn produced the basic design for supplying water to Melbourne from a reservoir on the Plenty River at Yan Yean, and later on he was appointed consulting engineer on the project. In 1853 a contract was let for the building of the wall for 91 thousand 575 pounds, and at one stage some 400 labourers were at work in the area. A tramway was constructed to convey stone and other materials from Melbourne. So famous was this magnificent stretch of water that illustrations of the bluestone embankment and tower appeared in London journals Whittlesea Historical Society – Historic items for Diamond Valley Community Radio September 1990 Colour photographyan yean, yan yean reservoir -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Yan Yean, 1987, 1987

Originally contained in a 'magnetic' photo album of scenic photos of Yan Yean and Warrandyte believed to be donated by Mrs Eric Stephenson, Jingalong, 110 Ryans Road, Eltham, Vic. 3095; relocated to archival safe storage. On the 20th December 1853 Lieut Governor Charles LaTrobe took his spade to turn the first sod of an embankment across the swampy bed of the Plenty River at a lonely place called Yan Yean, in order to create Melbourne’s first water supply. In the early 1850’s water had been drawn from the Yarra which even then was known as Yarra Soup. A convict by the name of James Blackburn produced the basic design for supplying water to Melbourne from a reservoir on the Plenty River at Yan Yean, and later on he was appointed consulting engineer on the project. In 1853 a contract was let for the building of the wall for 91 thousand 575 pounds, and at one stage some 400 labourers were at work in the area. A tramway was constructed to convey stone and other materials from Melbourne. So famous was this magnificent stretch of water that illustrations of the bluestone embankment and tower appeared in London journals Whittlesea Historical Society – Historic items for Diamond Valley Community Radio September 1990 Colour photographyan yean, yan yean reservoir -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Yan Yean, 1987, 1987

Originally contained in a 'magnetic' photo album of scenic photos of Yan Yean and Warrandyte believed to be donated by Mrs Eric Stephenson, Jingalong, 110 Ryans Road, Eltham, Vic. 3095; relocated to archival safe storage. On the 20th December 1853 Lieut Governor Charles LaTrobe took his spade to turn the first sod of an embankment across the swampy bed of the Plenty River at a lonely place called Yan Yean, in order to create Melbourne’s first water supply. In the early 1850’s water had been drawn from the Yarra which even then was known as Yarra Soup. A convict by the name of James Blackburn produced the basic design for supplying water to Melbourne from a reservoir on the Plenty River at Yan Yean, and later on he was appointed consulting engineer on the project. In 1853 a contract was let for the building of the wall for 91 thousand 575 pounds, and at one stage some 400 labourers were at work in the area. A tramway was constructed to convey stone and other materials from Melbourne. So famous was this magnificent stretch of water that illustrations of the bluestone embankment and tower appeared in London journals Whittlesea Historical Society – Historic items for Diamond Valley Community Radio September 1990 Colour photographyan yean, yan yean reservoir -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Yan Yean, 1987, 1987

Originally contained in a 'magnetic' photo album of scenic photos of Yan Yean and Warrandyte believed to be donated by Mrs Eric Stephenson, Jingalong, 110 Ryans Road, Eltham, Vic. 3095; relocated to archival safe storage. On the 20th December 1853 Lieut Governor Charles LaTrobe took his spade to turn the first sod of an embankment across the swampy bed of the Plenty River at a lonely place called Yan Yean, in order to create Melbourne’s first water supply. In the early 1850’s water had been drawn from the Yarra which even then was known as Yarra Soup. A convict by the name of James Blackburn produced the basic design for supplying water to Melbourne from a reservoir on the Plenty River at Yan Yean, and later on he was appointed consulting engineer on the project. In 1853 a contract was let for the building of the wall for 91 thousand 575 pounds, and at one stage some 400 labourers were at work in the area. A tramway was constructed to convey stone and other materials from Melbourne. So famous was this magnificent stretch of water that illustrations of the bluestone embankment and tower appeared in London journals Whittlesea Historical Society – Historic items for Diamond Valley Community Radio September 1990Colour photographyan yean, yan yean reservoir -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Yan Yean Reservoir

Originally contained in a 'magnetic' photo album of scenic photos of Yan Yean and Warrandyte believed to be donated by Mrs Eric Stephenson, Jingalong, 110 Ryans Road, Eltham, Vic. 3095; relocated to archival safe storage. On the 20th December 1853 Lieut Governor Charles LaTrobe took his spade to turn the first sod of an embankment across the swampy bed of the Plenty River at a lonely place called Yan Yean, in order to create Melbourne’s first water supply. In the early 1850’s water had been drawn from the Yarra which even then was known as Yarra Soup. A convict by the name of James Blackburn produced the basic design for supplying water to Melbourne from a reservoir on the Plenty River at Yan Yean, and later on he was appointed consulting engineer on the project. In 1853 a contract was let for the building of the wall for 91 thousand 575 pounds, and at one stage some 400 labourers were at work in the area. A tramway was constructed to convey stone and other materials from Melbourne. So famous was this magnificent stretch of water that illustrations of the bluestone embankment and tower appeared in London journals Whittlesea Historical Society – Historic items for Diamond Valley Community Radio September 1990 Colour photographyan yean, yan yean reservoir -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Yan Yean, 1988, 1988

Originally contained in a 'magnetic' photo album of scenic photos of Yan Yean and Warrandyte believed to be donated by Mrs Eric Stephenson, Jingalong, 110 Ryans Road, Eltham, Vic. 3095; relocated to archival safe storage. On the 20th December 1853 Lieut Governor Charles LaTrobe took his spade to turn the first sod of an embankment across the swampy bed of the Plenty River at a lonely place called Yan Yean, in order to create Melbourne’s first water supply. In the early 1850’s water had been drawn from the Yarra which even then was known as Yarra Soup. A convict by the name of James Blackburn produced the basic design for supplying water to Melbourne from a reservoir on the Plenty River at Yan Yean, and later on he was appointed consulting engineer on the project. In 1853 a contract was let for the building of the wall for 91 thousand 575 pounds, and at one stage some 400 labourers were at work in the area. A tramway was constructed to convey stone and other materials from Melbourne. So famous was this magnificent stretch of water that illustrations of the bluestone embankment and tower appeared in London journals Whittlesea Historical Society – Historic items for Diamond Valley Community Radio September 1990 Colour photographyan yean, yan yean reservoir -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Flowering Gum at Yan Yean, 1988, 1988

Originally contained in a 'magnetic' photo album of scenic photos of Yan Yean and Warrandyte believed to be donated by Mrs Eric Stephenson, Jingalong, 110 Ryans Road, Eltham, Vic. 3095; relocated to archival safe storage. On the 20th December 1853 Lieut Governor Charles LaTrobe took his spade to turn the first sod of an embankment across the swampy bed of the Plenty River at a lonely place called Yan Yean, in order to create Melbourne’s first water supply. In the early 1850’s water had been drawn from the Yarra which even then was known as Yarra Soup. A convict by the name of James Blackburn produced the basic design for supplying water to Melbourne from a reservoir on the Plenty River at Yan Yean, and later on he was appointed consulting engineer on the project. In 1853 a contract was let for the building of the wall for 91 thousand 575 pounds, and at one stage some 400 labourers were at work in the area. A tramway was constructed to convey stone and other materials from Melbourne. So famous was this magnificent stretch of water that illustrations of the bluestone embankment and tower appeared in London journals Whittlesea Historical Society – Historic items for Diamond Valley Community Radio September 1990 Colour photographyan yean -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Eltham Central Depot, c. Oct 1987, 1987

Now Eltham Fort Knox, previously Eltham Water Works. Date based on other similar display panels visible in images of the Shire of Eltham display at the Eltham Community Festival, 7 November 1987.Colour photographdepot, display panel, eltham festival, eltham fort knox, eltham shire council, infrastructure, shire of eltham -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Colour, Hotel Cavalletto - Doge Orseolo, Venezia, c1920

Colour postcard showing a number of Venetian buildings surrounded by water.chatham-holmes family collection, venice, lagoon -

Federation University Historical Collection

Federation University Historical CollectionBook, William Ripper, Steam-Engine Theory and Practice, 1914

Used at Ballarat School of MinesThe cover is a red brown colour with the title on the spine and the publisher Longmans & Co printed near base of the spine. The book has 496 illustrations throughout with some pull out plates. Pages 514.On the inside cover it is stamped with The School of Mines Ballarat and written in pencil is 1914 and E K.compound engines, thermodynamics of gases, properties of steam, temperature-entropy diagrams, superheated steam, steam-jacket, feed-water heaters, crank-shaft, flywheels, corliss engine, steam turbine, condensers, friction of engines, steam-engine, william ripper, steam -

Federation University Historical Collection

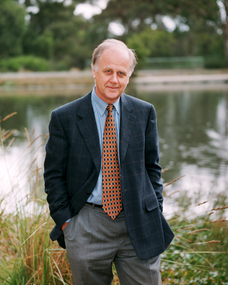

Federation University Historical CollectionPhotograph - Photograph - Colour, University of Ballarat Vice-Chancellor Professor Kerry Cox, 2001, 2001

Professor Kerry Cox was Vice Chancellor of the University of Ballarat from 01 January 2001.Digital image of Professor Kerry Cox standing in high grass in front of a body of water. The water is probably the dam near the swimming pool at Mount Helen Campusuniversity of ballarat, kerry cox, cox, vice-chancellor, mount helen -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Pulley Sheave, Russell & Co, 1888

This ship's pully sheave was part of the Antares rigging. A pulley sheave is a circle on a shaft that is manufactured to hold up movement and change of way of a cable or/and rope, or transfer of power between the shaft and cable or/and rope. A pulley is a unique mechanism that is used to leverage the lifting of heavy loads to required heights. The Italian barque Antares was an iron three-masted sailing clipper built in 1888 by Russell & Co of Port Glasgow originally named the “Sutlej” and renamed in 1907 the “Antares” when sold to the Semider Bros of Genoa Italy. The vessel left Marseilles on the 18th of December 1913 with its master captain Gazedo destined for Mullaly & Byrne of Melbourne with a cargo of roofing tiles but failed to arrive. The wreckage was found near the Bay of Islands twenty-two miles east of Warrnambool after a body had washed ashore. Some of the timbers washed up were charred by fire, and a small boat's stern board with the name "Sutlej" led to the identification of the wreck as Antares which had been reported missing. According to later reports, the Antares wrecking was overshadowed by war news at the time. A young local boy had remarked that the Germans had arrived off the coast as he had seen them firing off shells and rockets, but his story was passed off as a joke. These rockets were most likely the distress signals from the stricken ship. The Italian barque/clipper Antares was sometime later reported as overdue. The wreck of the ship was later found at the base of a cliff at the Bay of Islands near Warrnambool in November 1914, there were no survivors.The Antares is significant as it was a sail trader carrying an international inbound cargo during the early part of the 20th century. It is part of the Great Ocean Road Historic Shipwreck Trail and as such is registered as a protected wreck in the Victorian Heritage Database VHS S34.Pulley sheave; brass, with recesses full of concretion. The metal has some blue-green colouration due to exposure to sea water. Recovered from the wreak of the Antares. Noneflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, pulley sheave, antares, tall ship, peterborough, 1914 shipwreck, phillip le couteur, peter mathieson, constable stainsbury, sutlej, bay of islands, pully sheave, pulley, lifting equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSteel Sample, ca. 1876

The sample of steel from which the S.S. Julia Percy’s boiler was made has been tested, according to the attached label. The test involved heating the steel to blood red temperature (or dark red colour) then dipping it into water and bending it when it was cold. A “very severe test for quality” was written on the ticket by T.H. Osborne. (Mr Thomas Hamilton Osborne was the secretary for the Western Steam Navigation Co, established in Warrnambool in 1886. The company’s office was on the corner of Timor and Liebig Streets in Warrnambool and its north-western wall is now part of the current Warrnambool Regional Art Gallery. ) Cold bending of steel in a press or through rollers is the typical method of curving steel for construction. The steel needs to be manufactured in such a way that it is strong enough yet still flexible enough not to crack when bent or rolled. The boiler on the Julia Percy could have been a Scotch Boiler, a design introduced in the 1870’s and still being used today. This design was more robust that previous boilers, generating higher working steam pressures. The design incorporate greater ability to roll iron plates, leading to greater strength, thicker plating and fewer riveted joints. They were originally made of iron then later incorporated steel sections until they were entirely constructed of steel. Many examples of this type of boiler can be found on wreck sites. Shipping was the cheapest and most practical means of carrying produce and goods during the period 1840-1890. Regular domestic steamer services commenced in the Warrnambool district in the late 1850’s and by 1870 the passenger trade was booming. Produce was loaded from the jetty into ‘lighters’ (small boats), which took it to the ships at anchorage in the bay. Passengers were taken to the ship’s side then climbed aboard up ladders or gangways. The coming of the railway in October 1889 meant the gradual decline and end of the steam shipping era. Originally the ship was known as the SS Julia Percy and was later renamed as the Leeuwin. She was an iron passenger-cargo steam ship built in Glasgow by Thomas Wingate for the Warrnambool Steam Packet Company, which commissioned the ship for the steamship trade in Victoria’s western district. She was first registered in Warrnambool, Victoria in 1876. At one point in time the Julia Percy would sail from Warrnambool to Melbourne every Friday and return from Melbourne to Warrnambool every Tuesday. The cost of a return ticket for a Saloon Fare was £1.0.0. She would sail “if practical and weather permitting”. The Julia Percy changed hands several times. Her next owner was the Western Steam Navigaiton Co of Melbourne (1887). It was the manager of this company, Mr. T.H. Osborne, who tagged ths steel sample above. Melbourne Steamship Co became the next owners (1890), followed by William Howard Smith and Sons (1901) for use in Queensland coastal trades, then she was bought by George Turnbull in 1903 and used for local mail contract in Western Australia. She was sold to the Melbourne Steamship Company Ltd. (1906) and re-named the Leeuwi but continued in her Western Australian coastal run. She was converted into a coal hulk in Melbourne in 1910 as a result of damaged caused when she was driven against the jetty at Dongara during a gale. The ship was eventually dismantled and scuttled in Bass Strait on 28 December 1934. The steel sample is significant for its association with the wreck of the Leeuwin (Julia Percy), which is on the Victorian Heritage Register. It is historically significant for being a rare artefact that has potential to interpret aspects of western Victoria’s 19th century steamship trade and Victorian cultural history, including the testing and manufacturing process associated with steam power. Leeuwin is listed on the Victorian heritage Register as being historically significant ‘as one of only four wrecks of steamships in Victorian waters associated with the western district of Victoria’s coastal steamship trade. Her registered number is VHR S413. A sample of the steel from which the boiler of the "SS Julia Percy" (later named Leeuwin) was made. The piece of steel is a ‘C’ shape with the ends almost meeting. A luggage ticket is tied onto the steel and has an inscription on it. The steel is rusty.Ticket with typed information “Steel of which the Boiler of the “Julia Percy” (Warrnambool Steam Navigation Co) was made. TEST: Made Blood hot or Dark Red then dipped into water and bent cold. A very severe test for quality T.H. Osborne. Below these words is the hand written inscription in black “FM 151 / 9.75” julia percy, leeuwin, steel, boiler, steam ship, metal testing, western steam navigation co., flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, t.h. osborne -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.White earthenware dinner plate. Crazing evident all over.Backstamped ‘Made in England S LTD’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Johnson Bros

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.A white earthenware side plate with a gadroon edge. Has water marks and chips on front.‘Johnson Bros England Reg No 15587’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, johnson bros, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Alfred Meakin

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.Earthenware dessert plate, cream colour. Made by Alfred Meakin, England. Backstamped ‘Alfred Meakin England’. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alfred meakin, ceramics, earthenware, kitchenware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFreezer, circa 1930's

This ice cream freezer, manufactured in South Australia in the 1930's, was advertised to "keep the contents of the cream compartment frozen for many hours". It was promoted for use at picnics to keep salads cool. Its design is very similar to other freezers of The Frigid name which were made in 1939; those freezers were all one colour whereas this one is blue around the top and bottom of the barrel and cream in the centre with blue/green lettering. The process of making ice cream was to pack the outer chamber full with a combination of 3 parts ice cubes of about 1 inch (2.cm) to one part coarse salt, then pour into the chamber about 1 cup of cold water. After this, the ingredients for ice cream or sorbet were poured into the inner chamber, then attach the lid and turn The Frigid freezer upside down for about 40 minutes or until the right consistency is reached. Advice as given to open the freezer every 20 minutes and stir around the contents that were frozen against the sides of the inner chamber. The ingredients for the ice cream could include cream, sugar, vanilla and eggs. The label on the box of The Frigid shows the address of A Simpson and Son to be at Pirie Street, Adelaide. This address was used as early as 1876 and later catalogues, 1931 - 1960 still show this address. Alfred Simpson and his family emigrated from England, arriving in South Australia in 1849. He had already completed his apprenticeship as a tinplate worker but he tried various other occupations, including trying out the gold mines in Victoria, before he established himself as a tinsmith in 1853. His products included many agricultural items. His son, Alfred Muller Simpson, joined the business when he turned 21. In the 1860 Simpson's products included 'explosion proof' safes. In the late 1880's A Simpson and Son manufactured munitions and mines for the war. At the time of Alfred's death in 1891, A Simpson and Son had the largest metal manufacturing plant in Australia. From 1898 the company's reputation grew from the process of enamel plating with porcelain. During the First World War, Simpsons returned to the manufacture of munitions. Alfred M. Simpson's sons (Alfred Allen, known as Allen, and Fredrick Neighbour) joined the company when they finished their schooling. Allen was also associated with the Royal Geological Society over many years and when the CT Madigan surveyed Central Australia in 1929, the Simpson Desert was named in his honour. Cape Simpson in Antarctica is also named after him due to his assistance to Douglas Mawson. A new factory was opened at Dudley Park in the 1940s and the company began the manufacture of whitegoods. In 1963 A. Simpson and Son merged with Pope Industries to form Simpson Pope Holdings. Alfred Simpson became chairman of the board of Simpson Pope Holdings. The Simpson brand, now owned by Electrolux, continues to produce a variety of household appliances. (Reference: State Library of South Australia) A Simpson and Son was an early colonial business that has lasted well into the 20th century and the name Simpson is still associated with whitegoods. Freezer, 2 quart (1.8 litre) capacity, made by A Simpson and Son Ltd, marked "The Frigid". Cylinder shaped, constructed from enamelled sheet metal, has two catches one on the base and one on top. Inner cylinder for holding contents for freezing. Slightly rusted. Freezer is inside original cardboard box with yellow label showing manufacturer details. Circa 1930'sOutside of freezer is printed in blue"The Frigid". Box includes "THE "FRIGID" FREEZER" and branded "S & S" inside a circle.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, a. simpson & son limited, manufacturer, foundry, freezer, 2 quart freezer, portable freezer, kitchen appliance, the frigid, ice cream freezer, ice cream maker 1930's -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Jug