Showing 568 items matching "push"

-

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph

Taken some time between 1914-18, the photograph depicts an aerial view of Villers-Bretonneux in France, a region which was part of the Western Front during World War I. The image mostly shows rural landscape. The Western Front was the main theatre of war during World War I. Following the outbreak of war in August 1914, the German Army opened the Western Front by invading Luxembourg and Belgium, then gaining military control of important industrial regions in France. The German advance was halted with the Battle of the Marne. Following the Race to the Sea, both the French-British and German armies dug in along a meandering line of fortified trenches, stretching from the North Sea to the Swiss frontier with France. The First Battle of Villers-Bretonneux occurred between 30 March - 5 April 1918. It took place during Operation Michael, part of the German Spring Offensive on the Western Front. The offensive began against the British Fifth Army and the Third Army on the Somme, and pushed back the British and French reinforcements on the north side of the Somme. The capture of Villers-Bretonneux, close to Amiens, a strategically important road and rail-junction, would have brought the Germans within artillery-range. In late March, troops from the Australian Imperial Force were brought south from Belgium as reinforcements to help shore up the line. In early April, the Germans launched an attack to capture Villers-Bretonneux. After a determined defence by British and Australian troops, the attackers were close to success until a counter-attack by the 9th Australian Infantry Brigade and British troops late in the afternoon of 4 April restored the situation and halted the German advance on Amiens. The Second Battle of Villers-Bretonneux occurred between 24 - 27 April 1918, during the German Spring Offensive to the east of Amiens. It is notable for being the first occasion on which tanks fought against each other. A counter-attack by two Australian brigades and a British brigade during the night of 24 April partly surrounded Villers-Bretonneux, and on 25 April, the town was recaptured. On 26 April, the role of the Moroccan division of the French army was crucial in pushing back German units. Australian, British and French troops nearly restored the original front line by 27 April.The record is historically significant due to its connection to World War I. This conflict is integral to Australian culture as it was the single greatest loss of life and the greatest repatriation of casualties in the country's history. Australia’s involvement in the First World War began when the Australian government established the Australian Imperial Force (AIF) in August 1914. Immediately, men were recruited to serve the British Empire in the Middle East and on the Western Front. Additionally, the record's significance is enhanced by its depiction of Villers-Bretonneux. The battles that occurred in this town during World War I are especially historically significant to Australia as this is where the Australian Imperial Force had one their greatest World War I victories. An Australian flag still flies over Villers-Bretonneux in the present. Furthermore, a plaque outside the Villers-Bretonneux Town Hall recounts the battles fought to save the town in 1918. Kangaroos feature over the entrance to the Town Hall, and the main street is named Rue de Melbourne. More officially, recognition of the significance of the battle in Villers-Bretonneux is found at the Australian National Memorial, which was built just outside the town. It commemorates all Australians who fought in France and Belgium and includes the names of 10,772 who died in France and have no known grave. Each year, a small ceremony is held at the memorial to mark the sacrifice made by the soldiers. Lastly, the record has strong research potential. This is due to the ongoing public and scholarly interest in war, history, and especially the ANZAC legend, which is commemorated annually on 25 April, known as ANZAC Day.Sepia rectangular photograph printed on matte photographic paper.Obverse: yAE.2.35. / 125 / 62d.2834.35.36.VA.5. / 12.G.18-11 / F.-(?)" /military album, wwi, world war i, villers-bretonneux, australian imperial force, aif, france, war, army, conflict, germany, 1918, battle -

The Beechworth Burke Museum

The Beechworth Burke MuseumAudio - Oral History, Jennifer Williams, Max Suter, 29 June 2000

Mr Max Sutor was born in South Australia. He first began his work as a marine engineer at the Mildura Irrigation Trusts, moving later to the Melbourne Harbour Trusts. After a number of years as an engineer, he moved into farming at Gippsland and joined the prison service several years after during the late 1960s. He was first stationed at Morwell River Prison in South Gippsland, transferring to McLeod Prison in 1972 and finally to Beechworth in 1974 as senior prison and stores officer. He would assist in the organisation, obtaining and distribution of food and medication to prisoners. The prison, at the time, was of medium security and held high security prisoners, with an estimated amount of 108 prisoners to 23 staff. Mr Suter showed a great push in showing humility towards prisoners, wanting to avoid animosity against them by never looking at their records to treat them equally. His choice of kind behaviour towards prisoners had clearly influenced their own, especially during manual labor. The prison had worked cooperatively with a local farm, having their prisoners assist in the farm work. Attitudes inevitably changed positively for several prisoners. Whilst he held no control over their actions at the farm, he still became well trusted and liked amongst the prisoners, as they would continue to go to him for assistance and questions. Mr Suter had also worked as an instigator of finding drugs within each prison he has worked within. This led him to study the variations, and being a member of the Parents and Citizens Association at the high school his children attended, as well as Community Service Director of a Rotary club, he wanted to educate parents in guidance for those unsure on how to conduct actions against such behaviours. From his first seminar, a police surgeon told him that three drug users were found by their parents. This oral history recording was part of a project conducted by Jennifer Williams in the year 2000 to capture the everyday life and struggles in Beechworth during the twentieth century. This project involved recording seventy oral histories on cassette tapes of local Beechworth residents which were then published in a book titled: Listen to what they say: voices of twentieth century Beechworth. These cassette tapes were digitised in July 2021 with funds made available by the Friends of the Burke.Mr Max Suter's account on his time and experience as a senior prison officer at Beechworth Prison is historically and socially significant for the cultural heritage of the region. His recounts of his time working within the prison and out in local parent and community associations held a positive effect on the awareness and behaviours of the Beechworth area, and provides detailed information on the duties and complications working in a 20th century rural prison, as well as the lack of local awareness from adults with young influential children. This oral history account is socially and historically significant as it is a part of a broader collection of interviews conducted by Jennifer Williams which were published in the book 'Listen to what they say: voices of twentieth-century Beechworth.' While the township of Beechworth is known for its history as a gold rush town, these accounts provide a unique insight into the day-to-day life of the town's residents during the 20th century, many of which will have now been lost if they had not been preserved.This is a digital copy of a recording that was originally captured on a cassette tape. The cassette tape is black with a horizontal white strip and is currently stored in a clear flat plastic rectangular container. It holds up 40 minutes of recordings on each side.Max Suterlisten to what they say, beechworth, oral history, burke museum, max suter, beechworth prison, farming, drug awareness -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1878

This handmade black glass bottle was recovered between the late 1960s to early 1970s from the wreck of the sailing ship Loch Ard. The ship was wrecked in 1878 and its remains are located at Mutton Bird Island, near Port Campbell, Victoria and bottles of liquor were listed as part of the Loch Ard’s cargo. This bottle is now part of the John Chance collection. Black glass is one of the oldest bottle colours and dates back to the early 17th century. In the 1840s to late-1870s black glass bottles were mainly used for liquor and ale. All glass is made from silica, which is found in quartz sand. The naturally occurring sand has impurities, such as iron, that determine the colour of the glass. Residual iron leads to green or amber coloured glass, and carbon in the sand makes that glass appear as ‘black’. A strong light behind the glass will show its colour as dark green or dark amber. This handmade bottle appears to have been made in a dip mould, with the molten glass blown into a seamless shoulder-height mould to give the body a uniform symmetrical shape and size. After the body is blown, the glass blower continues blowing free-form (without the mould) to form the shoulder and neck, then the base is pushed up with a tool, and the finish for the mouth is added with his tools. The dip mould gives the body a slightly textured surface, with the free blown shoulders and neck being smoother and shinier. There is usually a line around the shoulder where the mould of the body meets the shoulder, and a lump or mark in the centre of the base, called a pontil mark, where the push-up tool was removed. The ship Loch Ard was built on the River Clyde in Scotland in 1873 for the prestigious Loch Line of colonial clipper ships, designed for the Australian run. It sailed from England on 1 March 1878 carrying 37 crew, 17 passengers and a diverse general cargo ranging from luxury items to bulk railway iron. On 1 June 1878, emerging from fog and hearing too late the sound of breakers against the tall limestone cliffs, the vessel struck the southern foot of Mutton Bird Island and sank in 23 metres of water. Of the fifty-four people on board only two survived, one young male crewman, Tom Pearce, and one young female passenger, Eva Carmichael. This bottle is historically significant as an example of liquor bottles imported into to Colonial Victoria in the mid-1800s to early-1900s. Its significance is increased by also being an artefact recovered by John Chance, a diver from the wreck of the Loch Ard and other wrecks in the late-1960s to early-1970s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. The bottle is also significant for being part of Flagstaff Hill’s collection of artefacts from the Loch Ard, which is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. The collection is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417. The collection has additional significance because of the relationship between the objects, as together they have a high potential to interpret the story of the Loch Ard. The Loch Ard collection is archaeologically significant as the remains of a large international passenger and cargo ship. The Loch Ard collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The shipwreck is one of the worst, and best known, shipwrecks in Victoria’s history.Bottle, black glass. Thick matt body, with slightly bumpy texture, areas with sheen, colour imperfections. Tooled cork-top finish with ring below, slightly bulged neck. Shoulder has some diagonal creases and a line where shoulder meets body. Body tapers inwards to base. Heel varies in width. Pushed up base has pontil mark. Base is uneven. Handmade, dip mould. No inscriptions.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, loch ard, mutton bird island, eva carmichael, tom pearce, john chance, bottle, black glass, antique bottle, bulge neck bottle, handmade, dip mould, mouth blown, pontil base, blown bottle, liquor bottle, ale bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1878

This handmade black glass bottle was recovered between the late 1960s to early 1970s from the wreck of the sailing ship Loch Ard. The ship was wrecked in 1878 and its remains are located at Mutton Bird Island, near Port Campbell, Victoria and bottles of liquor were listed as part of the Loch Ard’s cargo. This bottle is now part of the John Chance collection. Black glass is one of the oldest bottle colours and dates back to the early 17th century. In the 1840s to late-1870s black glass bottles were mainly used for liquor and ale. All glass is made from silica, which is found in quartz sand. The naturally occurring sand has impurities, such as iron, that determine the colour of the glass. Residual iron leads to green or amber coloured glass, and carbon in the sand makes that glass appear as ‘black’. A strong light behind the glass will show its colour as dark green or dark amber. This handmade bottle appears to have been made in a dip mould, with the molten glass blown into a seamless shoulder-height mould to give the body a uniform symmetrical shape and size. After the body is blown, the glass blower continues blowing free-form (without the mould) to form the shoulder and neck, then the base is pushed up with a tool, and the finish for the mouth is added with his tools. The dip mould gives the body a slightly textured surface, with the free blown shoulders and neck being smoother and shinier. There is usually a line around the shoulder where the mould of the body meets the shoulder, and a lump or mark in the centre of the base, called a pontil mark, where the push-up tool was removed. The ship Loch Ard was built on the River Clyde in Scotland in 1873 for the prestigious Loch Line of colonial clipper ships, designed for the Australian run. It sailed from England on 1 March 1878 carrying 37 crew, 17 passengers and a diverse general cargo ranging from luxury items to bulk railway iron. On 1 June 1878, emerging from fog and hearing too late the sound of breakers against the tall limestone cliffs, the vessel struck the southern foot of Mutton Bird Island and sank in 23 metres of water. Of the fifty-four people on board only two survived, one young male crewman, Tom Pearce, and one young female passenger, Eva Carmichael. This bottle is historically significant as an example of liquor bottles imported into to Colonial Victoria in the mid-1800s to early-1900s. Its significance is increased by also being an artefact recovered by John Chance, a diver from the wreck of the Loch Ard and other wrecks in the late-1960s to early-1970s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. The bottle is also significant for being part of Flagstaff Hill’s collection of artefacts from the Loch Ard, which is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. The collection is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417. The collection has additional significance because of the relationship between the objects, as together they have a high potential to interpret the story of the Loch Ard. The Loch Ard collection is archaeologically significant as the remains of a large international passenger and cargo ship. The Loch Ard collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The shipwreck is one of the worst, and best known, shipwrecks in Victoria’s history.Bottle, black glass. Thick matt body, with slightly bumpy texture, areas with sheen, colour imperfections. Tooled cork-top finish with ring below, slightly bulged neck. Shoulder has a line where shoulder meets body. Body tapers inwards to base. Heel varies in width. Pushed up base has pontil mark. Handmade, dip mould. No inscriptions.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, loch ard, mutton bird island, eva carmichael, tom pearce, john chance, bottle, black glass, antique bottle, bulge neck bottle, handmade, dip mould, mouth blown, pontil base, blown bottle, liquor bottle, ale bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1878

This handmade black glass bottle was recovered between the late 1960s to early 1970s from the wreck of the sailing ship Loch Ard. The ship was wrecked in 1878 and its remains are located at Mutton Bird Island, near Port Campbell, Victoria and bottles of liquor were listed as part of the Loch Ard’s cargo. This bottle is now part of the John Chance collection. Black glass is one of the oldest bottle colours and dates back to the early 17th century. In the 1840s to late-1870s black glass bottles were mainly used for liquor and ale. All glass is made from silica, which is found in quartz sand. The naturally occurring sand has impurities, such as iron, that determine the colour of the glass. Residual iron leads to green or amber coloured glass, and carbon in the sand makes that glass appear as ‘black’. A strong light behind the glass will show its colour as dark green or dark amber. This handmade bottle appears to have been made in a dip mould, with the molten glass blown into a seamless shoulder-height mould to give the body a uniform symmetrical shape and size. After the body is blown, the glass blower continues blowing free-form (without the mould) to form the shoulder and neck, then the base is pushed up with a tool, and the finish for the mouth is added with his tools. The dip mould gives the body a slightly textured surface, with the free blown shoulders and neck being smoother and shinier. There is usually a line around the shoulder where the mould of the body meets the shoulder, and a lump or mark in the centre of the base, called a pontil mark, where the push-up tool was removed. The ship Loch Ard was built on the River Clyde in Scotland in 1873 for the prestigious Loch Line of colonial clipper ships, designed for the Australian run. It sailed from England on 1 March 1878 carrying 37 crew, 17 passengers and a diverse general cargo ranging from luxury items to bulk railway iron. On 1 June 1878, emerging from fog and hearing too late the sound of breakers against the tall limestone cliffs, the vessel struck the southern foot of Mutton Bird Island and sank in 23 metres of water. Of the fifty-four people on board only two survived, one young male crewman, Tom Pearce, and one young female passenger, Eva Carmichael. This bottle is historically significant as an example of liquor bottles imported into to Colonial Victoria in the mid-1800s to early-1900s. Its significance is increased by also being an artefact recovered by John Chance, a diver from the wreck of the Loch Ard and other wrecks in the late-1960s to early-1970s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. The bottle is also significant for being part of Flagstaff Hill’s collection of artefacts from the Loch Ard, which is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. The collection is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417. The collection has additional significance because of the relationship between the objects, as together they have a high potential to interpret the story of the Loch Ard. The Loch Ard collection is archaeologically significant as the remains of a large international passenger and cargo ship. The Loch Ard collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The shipwreck is one of the worst, and best known, shipwrecks in Victoria’s history.Bottle, black glass. Thick matt body, with slightly bumpy texture, areas with sheen, colour imperfections. Mouth has cork seal. Tooled cork-top finish with ring below, slightly bulged neck. Shoulder a line where shoulder meets body. Body tapers inwards to base. Heel varies in width. Pushed up base has pontil mark. White discolouration in a narrow line down the body. Handmade, dip mould. No inscriptions.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, loch ard, mutton bird island, eva carmichael, tom pearce, john chance, bottle, black glass, antique bottle, bulge neck bottle, handmade, dip mould, mouth blown, pontil base, blown bottle, liquor bottle, ale bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1878

This handmade black glass bottle was recovered between the late 1960s to early 1970s from the wreck of the sailing ship Loch Ard. The ship was wrecked in 1878 and its remains are located at Mutton Bird Island, near Port Campbell, Victoria and bottles of liquor were listed as part of the Loch Ard’s cargo. This bottle is now part of the John Chance collection. Black glass is one of the oldest bottle colours and dates back to the early 17th century. In the 1840s to late-1870s black glass bottles were mainly used for liquor and ale. All glass is made from silica, which is found in quartz sand. The naturally occurring sand has impurities, such as iron, that determine the colour of the glass. Residual iron leads to green or amber coloured glass, and carbon in the sand makes that glass appear as ‘black’. A strong light behind the glass will show its colour as dark green or dark amber. This handmade bottle appears to have been made in a dip mould, with the molten glass blown into a seamless shoulder-height mould to give the body a uniform symmetrical shape and size. After the body is blown, the glass blower continues blowing free-form (without the mould) to form the shoulder and neck, then the base is pushed up with a tool, and the finish for the mouth is added with his tools. The dip mould gives the body a slightly textured surface, with the free blown shoulders and neck being smoother and shinier. There is usually a line around the shoulder where the mould of the body meets the shoulder, and a lump or mark in the centre of the base, called a pontil mark, where the push-up tool was removed. The ship Loch Ard was built on the River Clyde in Scotland in 1873 for the prestigious Loch Line of colonial clipper ships, designed for the Australian run. It sailed from England on 1 March 1878 carrying 37 crew, 17 passengers and a diverse general cargo ranging from luxury items to bulk railway iron. On 1 June 1878, emerging from fog and hearing too late the sound of breakers against the tall limestone cliffs, the vessel struck the southern foot of Mutton Bird Island and sank in 23 metres of water. Of the fifty-four people on board only two survived, one young male crewman, Tom Pearce, and one young female passenger, Eva Carmichael. This bottle is historically significant as an example of liquor bottles imported into to Colonial Victoria in the mid-1800s to early-1900s. Its significance is increased by also being an artefact recovered by John Chance, a diver from the wreck of the Loch Ard and other wrecks in the late-1960s to early-1970s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. The bottle is also significant for being part of Flagstaff Hill’s collection of artefacts from the Loch Ard, which is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. The collection is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417. The collection has additional significance because of the relationship between the objects, as together they have a high potential to interpret the story of the Loch Ard. The Loch Ard collection is archaeologically significant as the remains of a large international passenger and cargo ship. The Loch Ard collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The shipwreck is one of the worst, and best known, shipwrecks in Victoria’s history.Bottle, black glass. Thick matt body, with slightly bumpy texture, areas with sheen, colour imperfections. Mouth has cork seal. Tooled cork-top finish with ring below, slightly bulged neck. Shoulder has a line with a long bump where shoulder meets body. Body tapers inwards to base. Pushed up base has pontil mark. Handmade, dip mould. No inscriptions.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, loch ard, mutton bird island, eva carmichael, tom pearce, john chance, bottle, black glass, antique bottle, bulge neck bottle, handmade, dip mould, mouth blown, pontil base, blown bottle, liquor bottle, ale bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1878

This handmade black glass bottle was recovered between the late 1960s to early 1970s from the wreck of the sailing ship Loch Ard. The ship was wrecked in 1878 and its remains are located at Mutton Bird Island, near Port Campbell, Victoria and bottles of liquor were listed as part of the Loch Ard’s cargo. This bottle is now part of the John Chance collection. Black glass is one of the oldest bottle colours and dates back to the early 17th century. In the 1840s to late-1870s black glass bottles were mainly used for liquor and ale. All glass is made from silica, which is found in quartz sand. The naturally occurring sand has impurities, such as iron, that determine the colour of the glass. Residual iron leads to green or amber coloured glass, and carbon in the sand makes that glass appear as ‘black’. A strong light behind the glass will show its colour as dark green or dark amber. This handmade bottle appears to have been made in a dip mould, with the molten glass blown into a seamless shoulder-height mould to give the body a uniform symmetrical shape and size. After the body is blown, the glass blower continues blowing free-form (without the mould) to form the shoulder and neck, then the base is pushed up with a tool, and the finish for the mouth is added with his tools. The dip mould gives the body a slightly textured surface, with the free blown shoulders and neck being smoother and shinier. There is usually a line around the shoulder where the mould of the body meets the shoulder, and a lump or mark in the centre of the base, called a pontil mark, where the push-up tool was removed. The ship Loch Ard was built on the River Clyde in Scotland in 1873 for the prestigious Loch Line of colonial clipper ships, designed for the Australian run. It sailed from England on 1 March 1878 carrying 37 crew, 17 passengers and a diverse general cargo ranging from luxury items to bulk railway iron. On 1 June 1878, emerging from fog and hearing too late the sound of breakers against the tall limestone cliffs, the vessel struck the southern foot of Mutton Bird Island and sank in 23 metres of water. Of the fifty-four people on board only two survived, one young male crewman, Tom Pearce, and one young female passenger, Eva Carmichael. This bottle is historically significant as an example of liquor bottles imported into to Colonial Victoria in the mid-1800s to early-1900s. Its significance is increased by also being an artefact recovered by John Chance, a diver from the wreck of the Loch Ard and other wrecks in the late-1960s to early-1970s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. The bottle is also significant for being part of Flagstaff Hill’s collection of artefacts from the Loch Ard, which is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. The collection is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417. The collection has additional significance because of the relationship between the objects, as together they have a high potential to interpret the story of the Loch Ard. The Loch Ard collection is archaeologically significant as the remains of a large international passenger and cargo ship. The Loch Ard collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The shipwreck is one of the worst, and best known, shipwrecks in Victoria’s history.Bottle, black glass. Thick matt body, with slightly bumpy texture, areas with sheen, colour imperfections. Mouth has cork seal, partly removed, with content remnants inside. Tooled cork-top finish with ring below, slightly bulged neck. Shoulder a line where shoulder meets body. Body tapers inwards to base. Heel varies in width. Base is uneven. Pushed up base has pontil mark. Handmade, dip mould. No inscriptions.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, loch ard, mutton bird island, eva carmichael, tom pearce, john chance, bottle, black glass, antique bottle, bulge neck bottle, handmade, dip mould, mouth blown, pontil base, blown bottle, liquor bottle, ale bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1878

This handmade black glass bottle was recovered between the late 1960s to early 1970s from the wreck of the sailing ship Loch Ard. The ship was wrecked in 1878 and its remains are located at Mutton Bird Island, near Port Campbell, Victoria and bottles of liquor were listed as part of the Loch Ard’s cargo. This bottle is now part of the John Chance collection. Black glass is one of the oldest bottle colours and dates back to the early 17th century. In the 1840s to late-1870s black glass bottles were mainly used for liquor and ale. All glass is made from silica, which is found in quartz sand. The naturally occurring sand has impurities, such as iron, that determine the colour of the glass. Residual iron leads to green or amber coloured glass, and carbon in the sand makes that glass appear as ‘black’. A strong light behind the glass will show its colour as dark green or dark amber. This handmade bottle appears to have been made in a dip mould, with the molten glass blown into a seamless shoulder-height mould to give the body a uniform symmetrical shape and size. After the body is blown, the glass blower continues blowing free-form (without the mould) to form the shoulder and neck, then the base is pushed up with a tool, and the finish for the mouth is added with his tools. The dip mould gives the body a slightly textured surface, with the free blown shoulders and neck being smoother and shinier. There is usually a line around the shoulder where the mould of the body meets the shoulder, and a lump or mark in the centre of the base, called a pontil mark, where the push-up tool was removed. The ship Loch Ard was built on the River Clyde in Scotland in 1873 for the prestigious Loch Line of colonial clipper ships, designed for the Australian run. It sailed from England on 1 March 1878 carrying 37 crew, 17 passengers and a diverse general cargo ranging from luxury items to bulk railway iron. On 1 June 1878, emerging from fog and hearing too late the sound of breakers against the tall limestone cliffs, the vessel struck the southern foot of Mutton Bird Island and sank in 23 metres of water. Of the fifty-four people on board only two survived, one young male crewman, Tom Pearce, and one young female passenger, Eva Carmichael. This bottle is historically significant as an example of liquor bottles imported into to Colonial Victoria in the mid-1800s to early-1900s. Its significance is increased by also being an artefact recovered by John Chance, a diver from the wreck of the Loch Ard and other wrecks in the late-1960s to early-1970s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. The bottle is also significant for being part of Flagstaff Hill’s collection of artefacts from the Loch Ard, which is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. The collection is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417. The collection has additional significance because of the relationship between the objects, as together they have a high potential to interpret the story of the Loch Ard. The Loch Ard collection is archaeologically significant as the remains of a large international passenger and cargo ship. The Loch Ard collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The shipwreck is one of the worst, and best known, shipwrecks in Victoria’s history.Bottle, black glass. Thick matt body, with slightly bumpy texture, areas with sheen, colour imperfections. Mouth is sealed, and has remnants of tape on outside. Tooled cork-top finish with ring below. Slightly bulged neck. Shoulder has some diagonal creases and a distinct line where shoulder meets body. Body tapers inwards to base. It has a bubble and diagonal crease lines. Base is uneven. Pushed up base has pontil mark. Handmade, dip mould. No inscriptions.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, loch ard, mutton bird island, eva carmichael, tom pearce, john chance, bottle, black glass, antique bottle, bulge neck bottle, handmade, dip mould, mouth blown, pontil base, blown bottle, liquor bottle, ale bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1878

This handmade black glass bottle was recovered between the late 1960s to early 1970s from the wreck of the sailing ship Loch Ard. The ship was wrecked in 1878 and its remains are located at Mutton Bird Island, near Port Campbell, Victoria and bottles of liquor were listed as part of the Loch Ard’s cargo. This bottle is now part of the John Chance collection. Black glass is one of the oldest bottle colours and dates back to the early 17th century. In the 1840s to late-1870s black glass bottles were mainly used for liquor and ale. All glass is made from silica, which is found in quartz sand. The naturally occurring sand has impurities, such as iron, that determine the colour of the glass. Residual iron leads to green or amber coloured glass, and carbon in the sand makes that glass appear as ‘black’. A strong light behind the glass will show its colour as dark green or dark amber. This handmade bottle appears to have been made in a dip mould, with the molten glass blown into a seamless shoulder-height mould to give the body a uniform symmetrical shape and size. After the body is blown, the glass blower continues blowing free-form (without the mould) to form the shoulder and neck, then the base is pushed up with a tool, and the finish for the mouth is added with his tools. The dip mould gives the body a slightly textured surface, with the free blown shoulders and neck being smoother and shinier. There is usually a line around the shoulder where the mould of the body meets the shoulder, and a lump or mark in the centre of the base, called a pontil mark, where the push-up tool was removed. The ship Loch Ard was built on the River Clyde in Scotland in 1873 for the prestigious Loch Line of colonial clipper ships, designed for the Australian run. It sailed from England on 1 March 1878 carrying 37 crew, 17 passengers and a diverse general cargo ranging from luxury items to bulk railway iron. On 1 June 1878, emerging from fog and hearing too late the sound of breakers against the tall limestone cliffs, the vessel struck the southern foot of Mutton Bird Island and sank in 23 metres of water. Of the fifty-four people on board only two survived, one young male crewman, Tom Pearce, and one young female passenger, Eva Carmichael. This bottle is historically significant as an example of liquor bottles imported into to Colonial Victoria in the mid-1800s to early-1900s. Its significance is increased by also being an artefact recovered by John Chance, a diver from the wreck of the Loch Ard and other wrecks in the late-1960s to early-1970s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. The bottle is also significant for being part of Flagstaff Hill’s collection of artefacts from the Loch Ard, which is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. The collection is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417. The collection has additional significance because of the relationship between the objects, as together they have a high potential to interpret the story of the Loch Ard. The Loch Ard collection is archaeologically significant as the remains of a large international passenger and cargo ship. The Loch Ard collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The shipwreck is one of the worst, and best known, shipwrecks in Victoria’s history.Bottle, black glass. Thick matt body, with slightly bumpy texture, areas with sheen, colour imperfections, bubble in glass. Bottle has foul smelling contents inside. Mouth has hard capped cork seal with black, hard rubber capped stopper. Side of mouth has ship or mark. Tooled cork-top finish with ring below, slightly bulged neck. Shoulder has some diagonal creases and a line where shoulder meets body. Body tapers inwards to base. Heel varies in width. Base is uneven. Pushed up base has pontil mark. Handmade, dip mould. No inscriptions.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, loch ard, mutton bird island, eva carmichael, tom pearce, john chance, bottle, black glass, antique bottle, bulge neck bottle, handmade, dip mould, mouth blown, pontil base, blown bottle, liquor bottle, ale bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Corkscrew

The design of the corkscrew may have been derived from the gun worm, which was a device from at least the early 1630s, used by men to remove unspent charges from a musket's barrel in a similar fashion. The corkscrew is possibly an English invention, due to the tradition of beer and cider, and the 'Treatise on Cider' by John Worlidge in 1676 describes "binning of tightly corked cider bottles on their sides", although the earliest reference to a corkscrew is, "steel worm used for the drawing of Corks out of Bottles" from 1681. In 1795, the first corkscrew patent was granted to the Reverend Samuel Henshall, in England. The clergyman affixed a simple disc, now known as the Henshall Button, between the worm and the shank. The disc prevents the worm from going too deep into the cork, forces the cork to turn with the turning of the crosspiece, and thus breaks the adhesion between the cork and the neck of the bottle. The disc is designed and manufactured slightly concave on the underside, which compresses the top of the cork and helps keep it from breaking apart. The winged corkscrew, sometimes called a cork extractor, butterfly corkscrew, owl corkscrew, Indian corkscrew, or angel corkscrew, has two levers, one on either side of the worm. As the worm is twisted into the cork, the levers are raised. Pushing down the levers draws the cork from the bottle in one smooth motion. The most common design has a rack and pinion connecting the levers to the body. The head of the central shaft is frequently modified to form a bottle opener, or foil cutter, increasing the utility of the device. Corkscrews of this design are particularly popular in household use. In 1880, William Burton Baker was issued British Patent No. 2950 for his double lever corkscrew, with both levers sliding onto the upper end of the shank. The first American patent was in 1930 granted to the Italian Domenico Rosati who emigrated to Chicago, Illinois, to work as bartender before prohibition. Rosati's design had an exposed rack and pinion mechanism. Such design was adapted by other brands as the wine-market grew in popularity. The winged owl version, with two side-plates covering the rack and pinion mechanism, was first designed and manufactured in 1932 by the Spanish industrial designer David Olañeta for his brand BOJ and was later adopted by others, such as the 1936 US Patent No. 98,968 by Richard Smythe marked HOOTCH-OWL https://en.wikipedia.org/wiki/CorkscrewThis object is significant as an example of an item in common use in the 19th and early 20th centuries, and that was developed further in the 1930s.Winged corkscrew with a T-shaped wooden handle, metal spring and worm-wheel screw section.None.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, corkscrew, beverages, kitchen equipment, bottle opener -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph - Lantern Slide, c1900

This lantern slide shows the Ovens District Hospital (also called the Ovens Goldfields Hospital) in Beechworth in approximately 1900. The Hospital was built as part of a community push to develop the infrastructure needed for a permanent town in the 1850s. At the time there was no hospital located between Melbourne and the NSW town of Goulburn and it was recognised that the nature of mining and agricultural work predisposed people to serious injury. The community voted in 1853 to raise funds for a hospital and a voluntary committee elected from people who contributed £2 or more annually determined the organisation's management policies, which aimed to provide care for poor people at rates levied according to the person's means. Ongoing operations of the hospital were primarily supported by Government grants, however. The foundation stone was laid at a site in Church Street at a ceremony held 1st September 1856 which was attended by 2000 people using a locally crafted trowel with a tin ore handle and pure gold blade. The hospital, which was designed by J.H. Dobbyn, cost £2347. The hospital had two wards, a dispensary, apartments for a resident surgeon and the matron, an operating theatre and a board room. Further medical facilities including services to meet the cultural and health needs of the local Chinese community were later added, in addition to a Palladian-style cut-granite face built in 1862-63. It functioned as the region's primary hospital until surpassed by the Wangaratta Hospital in 1910. In the 1940s much of the building materials were salvaged and repurposed, with the exception of the facade which was restored in 1963 by the Beechworth Lions Club and still stands today. The facade featured on the covers of local history volume 'Beechworth: a Titan's Field' by Carole Woods and heritage-focused travel guide the 'Readers Digest Book of Historic Australian Towns'. Lantern slides, sometimes called 'magic lantern' slides, are glass plates on which an image has been secured for the purpose of projection. Glass slides were etched or hand-painted for this purpose from the Eighteenth Century but the process became more popular and accessible to the public with the development of photographic-emulsion slides used with a 'Magic Lantern' device in the mid-Nineteenth Century. Photographic lantern slides comprise a double-negative emulsion layer (forming a positive image) between thin glass plates that are bound together. A number of processes existed to form and bind the emulsion layer to the base plate, including the albumen, wet plate collodion, gelatine dry plate and woodburytype techniques. Lantern slides and magic lantern technologies are seen as foundational precursors to the development of modern photography and film-making techniques.This glass slide is significant because it provides insight into Beechworth's built environment and infrastructure in the early Twentieth Century, around the time of Australia's Federation. It is also an example of an early photographic and film-making technology in use in regional Victoria in the time period.Thin translucent sheet of glass with a round-edged square image printed on the front and framed in a black backing. It is held together by metal strips to secure the edges of the slide.Obverse: Y /burke museum, beechworth, lantern slide, slide, glass slide, plate, burke museum collection, photograph, monochrome, ovens district hospital, indigo shire, north-east victoria, hospital, palladian architecture, granite, community fundraising, community infrastructure, j.h. dobbyn, beechworth lions club, ovens goldfields hospital, chinese community -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Auburn Tool Company, 1870 to 1893

Moulding Plane: A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. Auburn Tool Company: The Auburn Tool Company is known to exist from 1864 to 1893. George Casey reorganized the firm of Casey, Clark and Company as a joint-stock company in 1864, under the company name of Auburn Tool Company. The 1865 New York State Census noted the firm as a manufacturer of the plane, plane irons, and skates. The production that year was listed as 30,000 pairs of skates and 35,000 planes along with 25,000 dozen plane irons. The plane irons carried the trademark "Thistle". Both skates and plane irons were made from welded wrought iron and cast steel. The Auburn Tool Company was among the five leading plane manufacturing firms existing in the mid to late 19th century USA. Others were: H. Chapin's Son; Greenfield Tool Company; and Sandusky Tool Company. Auburn Tool Company, with these others, was also a founding member of the Plane Makers Association, organized around 1858 to fix prices. Most of the companies tools were manufactured by prisoners and in 1866 the firm was outbid for prison labour by J M Easterly and Co. After losing the contract with the prison authority they constructed a new building and continued in the plane manufacturing business with private labour. The 1870 US Census reported the firm had 21 machines, driven by water power, employing 66 males, producing annual products valued at us$70, 000. After A. Howland and Company was dissolved in 1874, the Auburn Tool Company again resumed using contract labour at the State Prison until 1877. The Auburn Tool Company merged with the Ohio Tool Company of Columbus, Ohio, on Nov 14, 1893. Although plane manufacturing was continued at Auburn until after 1907, after this merger the firm went under the name of the Ohio Tool Company. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. It also gives an insight into how many manufacturing companies bid for the rights to use prison labour to make their products at this time in our history. Decorative wood Moulding, plane Round type Auburn New York. Owner A Neudt Size 14 flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Bendigo Military Museum

Bendigo Military Museumphotograph - Cartographic Squadron Production – Army Survey Regiment, Fortuna, c1980

This collection of 12 photos was most likely taken in 1980. The photos were most likely taken in Cartographic Squadron’s Ante Room, the Attic and small offices on the top floor of Fortuna Villa. The computer based Editwriter typesetting system was introduced in 1975 as a replacement to the aging Fotosetter machine. It was operated by a specialised technician, who generated a large variety of map type styles and sizes quickly and reliably, as well as text panels. CPL Richards performed this task for several years and in photo .1P and .2P is reading off a type order next to the computer monitor. Output on Copy proof adhesive backed stripping type film replaced messy wax and spray adhesives in 1978. The Editwriter capability supported all RASvy units and contractor type setting requirements. Scribing was the cartographic process of drafting features such as drainage, relief, vegetation, roads and culture on specially coated map reproduction material. The cartographic technician scribed out the map feature such as a contour to a specified line width on the map sheet, using a tool affixed with a sapphire tipped cutter. The quality control edit (Proving) stage of map production was the first opportunity to inspect a proof of the map independently and systematically. Proving tasks were carried out by technicians conversant of the map product specification and task requirement, however, was not involved in its production. Corrections were identified, marked up and sent to back to the correcting section or contractors. Terrain Embossing was a manual map production technique to produce hill shading on medium to small scale graphics and air charts. SPR John Martin is seen in photos .8P to.10P using a fine embossing metal stylus to push down on the drainage impression on a thin malleable opaque plastic material (AK Poligraphy). Ridge lines were then pushed down using the contour impression as a guide, on the opposing side of the AK Poligraphy to create a 3D plastic model terrain effect. The map impression was sprayed with white paint and photographed to create a contone tone hill shade. SPR Gina (Coore) Neilson is seen in photo .11P washing a contone positive of a land mass in a solution. The contone components were registered to the map sheet, as shown in photo .12P and masked using an air brush and a halftone negative was then created. The terrain embossing method of producing hill shading was more efficient to produce than previous specialised artistic methods such pencil/eraser and air brush. Furthermore, a more consistent enhancement of terrain on charts was achieved between technicians.This is a set of 12 photographs of Cartographic Squadron performing four map production tasks at the Army Survey Regiment, Fortuna, Bendigo c1980. The first ten photographs were on 35mm negative film and were scanned at 96 dpi. Photos .11P and .12P were on photographic paper and scanned at 300 dpi. They are part of the Army Survey Regiment’s Collection. .1) - Photo, black & white, c1980, Editwriter typesetter, CPL Paul Richards. .2) - Photo, black & white, c1980, Editwriter typesetter, CPL Paul Richards. .3) - Photo, black & white, c1980, Scribing contours on a RAAF Chart, SPR Megan (McBurney) Reynolds. .4) - Photo, black & white, c1980, Scribing contours on a RAAF Chart, SPR Megan (McBurney) Reynolds. .5) - Photo, black & white, c1980, Scribing contours on a RAAF Chart, SPR Rod Skidmore. .6) - Photo, black & white, c1980, Scribing contours on a RAAF Chart, SPR Rod Skidmore. .7) - Photo, black & white, c1980, Formal quality control edit (Proving), CPL Ian Belmont. .8) - Photo, black & white, c1980, Hill Shade Terrain Embossing, SPR John Martin. .9) - Photo, black & white, c1980, Hill Shade Terrain Embossing, SPR John Martin. .10) - Photo, black & white, c1980, Hill Shade Terrain Embossing, SPR John Martin. .11) - Photo, black & white, c1980, Hill Shade Terrain Embossing, SPR Gina (Coore) Neilson. .12) - Photo, black & white, c1980, Hill Shade Terrain Embossing, unidentified..1P to .10P No personnel are identified. .11P and .12P annotated ‘Terrain Embossing’royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr, carto -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Equipment - Barbers’ Equipment, hair clippers steel 'Brown & Sharpe", c1940

1833 Brown & Sharpe was founded in Providence, Rhode Island by David Brown and his son Joseph R. Brown. David Brown retired in 1841 and Joseph Brown formed a partnership with Lucian Sharpe in 1853. During the 19th and 20th centuries, Brown & Sharpe was one of the best-known and most influential machine tool builders and was a leading manufacturer of instruments for machinists (such as micrometers and indicators ) and helped establish: The American wire gauge (AWG) standards for wire; The Brown & Sharpe taper in machine tool spindle tapers; and The Brown & Sharpe worm threadform for worm gears. .Like most machine tool builders, Brown & Sharpe rode a business cycle roller coaster during 1920- 40. After being kept very busy during World War I, builders suffered a slump in the post–World War I recession and depression of 1920–21. The Roaring Twenties brought renewed sales, but then the Great Depression slashed them. The armament-build-up period of 1936 to 1940 again renewed machine tool activity, and then the World War II materiel effort exploded demand, pushing it to record heights and employed 11,000 workers. Brown and Sharpe machine tools were a mainstay of American metal manufacturing until the late 20th Century and could be found in most machine shops and factories that worked with metal. Brown and Sharpe made callipers and micrometers that were essential to products built to fine tolerances. Shortly after World War II, Henry D. Sharpe, Jr. succeeded his father as president of Brown & Sharpe Manufacturing Company, at which point it evolved into a new and modern company built, or at least designed, to last. The firm stopped producing its old stalwarts: sewing machines, hair clippers, and certain categories of machine tools and employment dropped to 3,500 in 1976. Due to industrial disputes in the 1980’s B&S started focusing more on developing Coordinate-Measuring Machines. The company began to lose money as it shifted production away from machine tools and toward advanced metrology equipment, losing $14.6 million in 1990 and employed only 700. In 1994 Brown & Sharpe acquired DEA of Italy, an established manufacturer of CMMs. In 2001, substantially all of the assets of the Brown & Sharpe Manufacturing Company, including the intellectual property, designs, trademarks, facilities and inventory, were acquired by Hexagon AB, Switzerland, without the acquisition of the Brown & Sharpe Manufacturing Company itself. A set of manual barbers’ hair clippers with an adjustable wing screw, from Brown and Sharpe, Manufacturing Company Ltd., Providence, Rhode Island, USA. Chrome plated, in fair condition, c1940on Right handle; MADE BY BROWN & SHARPE MFG. CO. POV. R.I. / PAT'D IN GREAT BRITAIN, EN FRANCE, S.G.D.G. / U.S.A. PATENTS JULY 1-79, JUNE 3-84, AUG 23- 92 on top blade ; BRESSANT / TRADEMARK on base of lower blade ; No. 2* barbers, hairdressers, hair clippers, brown and sharpe manufacturing company, providence rhode island, hexagon ab, switzerland, great britain, france, ww1 1914-1918, ww11 1939-1945, great depression 1930, micrometers, tools, precision instruments, brown david, brown joseph r , sharpe lucian, sharpe henry d jnr, american wire gauge standard, sewing machines, metrological tools, worm gears, spindle tapers, screw machines, moorabbin, bentleigh, cheltenham, city of moorabbin industries, -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Colour Photograph/s - set of 28, Warren Doubleday, 11/03/2002 12:00:00 AM

Set of 28 photographs of the operation of the BTM during the Begonia Festival, including the loading of the Horse Tram for Melbourne on Sunday 10/3/2002, operation in Melbourne on 11/3/2002 and reloading in Bourke St. Taken by Warren Doubleday, on Kodak paper. 2013.1 - Tram 671, Wendouree Parade, 10/3/2002 at Depot Junction .2 - 33 at Loop .3 - 40 and 33 south of the loop, heading for Carlton St. .4 - ditto .5 - 671 returning to the loop from St. Aidans Drive .6 - 40 returning to the loop from Carlton St. .7 - 33 ditto .8 - Loading horse tram at Depot Junction - Alastair Reither .9 - ditto .10 - in St. Kilda Road, 11/3/2002 at about 7.30am .11 - ditto .12 - Tram in Moomba parade, 11/3/2002 - Reg Smith, Len Millar - horse Bear. .13 - ditto .14 - ditto .15 - ditto, after passing with the Ned Kelly's. .16 - ditto - and John Clowes on rear platform .17 - the line up near Bourke St. with V214 behind the horse tram - "Tram Stop Ahead" sign .18 - the line up from Bourke St. with Hawthorn 8 alongside. .19 - Being photographed - Arthur Cook, Roma Cook, Merle Clowes and John Clowes with other visitors .20 - ditto .21 - Malcolm tram, and BTM ten in the background .22 - BTM and Sydney Tramway Museum tent in the City Square area. .23 - Pushing the horse tram across Bourke St. - John Clowes. .24 - Loaded back on the Crane Heavy Haulage (Associated Towing) truck, looking north along Swanston St. .25 - ditto .26 - ditto, general scene in Swanston St. .27 - The towing truck and tram .28 - Hawthorn 8 and Milan 1692 crossing Bourke St. Negatives held on file with documents list.horse trams, depot junction, moomba, gardens loop, swanston st, tram 1, tram 33, tram 40, tram 671, tram 8, tram 214, tram 1692 -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - HILDA HILL COLLECTION: BLACK AND WHITE PHOTOS, 1925

Hilda Hill Collection.Series of Black & White Photos Hill Family & Friends Total 5 Photos. Clem & Jim out bush, both boys are wearing dark coloured shorts and long socks boy on left has white stripes at top of the socks with braces white shirts bottom right corner shows a piece of barb fence wire. 'Babe' Noonan contemplating hatless and wearing a white dress and dark stockings, Bill Hill (lady) by lake wears round top hat with the front brim turned up white dress highlights on the lapels black belt with a black bag attached columbine pattern on her stockings standing on dam bank background is forested area. Family Group 'The Push' made up of 7 young ladies and 4 boys one of which wears a hat one girl is dressed in black all others are in white on girl is wearing a hat with another on the ground beside her girl front right has a s part black bag hanging around her neck. Hilda Hill on 2 steel wheeled apparatus with long shaft at the front being held by a man dressed in grey suit with white shirt and dark tie another man is standing rear right of the girl also wearing grey suit white shirt and dark tie, Mid left side shows a heavy wheeled cart loaded with full bags at Summer Hill March 8, 1925. rear background has large willow tree, right background shows corner of large shed and haystack Also noted in pencil -At The Pines 1919. There is also a photo of two ladies facing the camera both wearing hats one light and the other dark colours lady on left is wearing dark jacket over a white dress lady on right wearing white dress and long tress forward over her shoulder two other ladies have their backs to the camera both wearing white one has black sash at her waist and head coverings, The venue appears to be a large dam and background shows far shore and bushland.Hilda Hill Personal Collectionaustralia, history, post war life -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Saucepan

It is no secret that copper is currently experiencing a huge upsurge in popularity. This is mainly thanks to its beautiful colour featuring heavily in the ranges of countless homeware retailers. There is, however, far more to this lustrous metal than just its appearance. For example, it has a greater level of thermal conductivity than any other metal (except silver); roughly 60% higher than aluminium and 3000% higher than stainless steel. This means copper is capable of heating up very quickly when compared to other metals. Perhaps a less commonly known property of copper is it being inherently antimicrobial. A wide range of harmful microbes are unable to survive for more than a couple of hours when in contact with a surface made of copper or one of its alloys (brass and bronze). This has led to it often being used for frequently touched surfaces such as door knobs, push plates and taps. A seemingly perfect material for cooking, it is therefore no surprise that it has been used in kitchens for millennia. But exactly when did we learn to utilise copper and its valuable assets? Origins It is hard to pin down an exact date when copper cookware was first introduced. Pieces discovered in regions of the middle east were dated as far back as 9000BC, suggesting cooking with copper began during the Neolithic period (≈10000-2000BC). As civilisations became increasingly capable in metallurgical techniques, metals such as copper became more widely used. It would have been around this time that copper replaced stone as the material used for making tools and cooking vessels. The use of copper is also well documented in Ancient Egypt. Not only was it used to produce water and oil containers, but it was also used to in medical practices. The antimicrobial nature of copper was exploited long before the concept of microorganisms was fully understood. The Smith Papyrus, a medical text written between 2600 and 2200BC records the use of copper in sterilising wounds and drinking water. Tin Lining Although copper is essential to many processes within the human body, it can become toxic if consumed in excess. It was this knowledge that gave rise to lining cookware with tin, a technique used for hundreds of years to prevent copper leaching in to food. These tin linings would eventually wear out and during the 18th and 19th century, it was common for people to send pans away to be re-tinned. This practice is becoming increasingly rare, as are the craftsmen who perform it. Despite this, there are still manufactures producing tin-lined copper cookware who also offer a re-lining service. Perhaps the best known of these is Mauviel, a French manufacturer who have been making this type of cookware since 1830. Tin has now largely been replaced by stainless steel as an interior cooking surface. Not only is it more cost effective, but the high grade of stainless steel used in premium cookware (typically 18/10) is highly resistant to corrosion and more durable than tin.Copper saucepans are still used in many kitchens.Small copper saucepan with long handle and three ridges around the circumference. Extensive corrosion.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, copper, saucepans, kitchen equipment -

Federation University Historical Collection

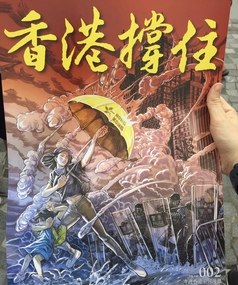

Federation University Historical CollectionPhotograph - Colour, Jarrod Watt, Hong Kong Street Flyer by an unknown artist, 2019, 06/2019

Carrie Lam, Hong Kong’s chief executive, had plenty of political support in the territory’s pro-Beijing legislature to pass a bill that would allow extraditions to mainland China. The legislators were set to begin discussing the bill in early June, and intended to vote on it just weeks later. A series of protests took place, and after a June 16 protest saw the largest turnout yet, Ms. Lam made a major concession: She postponed the bill, at least temporarily. It was an undeniable victory for the protesters — but it did little to quell the unrest. Since the bill could later be reintroduced, protesters felt they remained in danger. The police tactics to break up the demonstrations on June 12, including the use of more than 150 tear gas canisters to push protesters far away from the government office, created a new set of demands from the protesters. Now, instead of just calling for the withdrawal of the bill and Ms. Lam’s resignation, they said they wouldn’t be content unless there was an independent investigation of officers’ conduct. They also wanted the release of protesters arrested on June 12, and for the government to rescind its description of the demonstrations as a “riot,” a designation that carries legal significance. None of that has happened. Many analysts say Ms. Lam is unlikely to step down, nor would Beijing accept her resignation if she offered it. She has more wiggle room on the other demands, but has not indicated any willingness to budge. The Hong Kong Protests are a leaderless, digital movement.There is no single leader or group deciding on or steering the strategy, tactics and goals of the movement. Instead, protesters have used forums and messaging apps to decide next steps. Anyone can suggest a course of action, and others then vote on whether they support it. The most popular ideas rise to the top, and then people rally to make them happen. At its best, this structure has empowered many people to participate and have their voices heard. Protesters say it keeps them all safe by not allowing the government to target specific leaders. Their success in halting the extradition bill, which was shelved by the territory’s chief executive, speaks to the movement’s power. Despite the lack of a clear leader, protesters have shown extensive coordination at the demonstrations, having planned the specifics online beforehand. Supply stations are set up to distribute water, snacks, gloves, umbrellas and shields made of cardboard. Volunteer first aid workers wear brightly colored vests. People form assembly lines to pass supplies across long distances, with protesters communicating what they need through a series of predetermined hand signals. Anyone walking in dangerous areas without a helmet or a mask is quickly offered one. No individual can speak on behalf of the protesters, which makes negotiations difficult, if not impossible. (https://www.nytimes.com/2019/07/02/world/asia/hong-kong-protest-explained.html, accessed 07/07/2019) Hong Kong’s amended extradition law would allow the extradition of suspects to mainland China for the first time. Supporters say the amendments are key to ensuring the city does not become a criminal refuge, but critics worry Beijing will use the law to extradite political opponents and others to China where their legal protections cannot be guaranteed. The government claims the push to change the law, which would also apply to Taiwan and Macau, stems from the killing last year of a Hong Kong woman while she was in Taiwan with her boyfriend. Authorities in Taiwan suspect the woman’s boyfriend, who remains in Hong Kong, but cannot try him because no extradition agreement is in place. Under the amended law, those accused of offences punishable by seven years or more in prison could be extradited. The new legislation would give Hong Kong’s leader, known as the chief executive, authority to approve extradition requests, after review by the courts. Hong Kong’s legislature, the legislative council, would not have any oversight over the extradition process. Many Hong Kongers fear the proposed extradition law will be used by authorities to target political enemies. They worry the new legislation spells the end of the “one country, two systems” policy, eroding the civil rights enjoyed by Hong Kong residents since the handover of sovereignty from the UK to China in 1997. Many attending the protests on Sunday said they could not trust China as it had often used non-political crimes to target government critics, and said they also feared Hong Kong officials would not be able to reject Beijing’s requests. Legal professionals have also expressed concern over the rights of those sent across the border to be tried. The conviction rate in Chinese courts is as high as 99%. Arbitrary detentions, torture and denial of legal representation of one’s choosing are also common. Many in the protests on Sunday 09 June 2019 said they felt overwhelmed by a sense of helplessness in the face of mainland China’s increasing political, economic and cultural influence in Hong Kong. Hong Kong’s top political leader is not elected by ordinary voters but by a 1,200-strong election committee accountable to Beijing. Half of its legislature are chosen through indirect electoral systems that favour pro-Beijing figures. Many Hong Kongers also cited the jailing of leaders and activists from the 2014 Occupy Central movement– a 79-day mass civil disobedience movement – as well as the disqualification of young localist lawmakers as signs of the erosion of civil freedoms. Resentment towards China has been intensified by soaring property prices – with increasing numbers of mainland Chinese buying properties in the city – as well as the government’s “patriotic education” drive, and the large numbers of mainland tourists who flock to Hong Kong. Many Hong Kongers are also concerned about China’s growing control over the city’s news media, as they increasingly self-censor and follow Beijing’s tacit orders. https://www.theguardian.com/world/2019/jun/10/what-are-the-hong-kong-protests-about-explainerPhotograph of a street art poster taken on the streets of Hong Kong during the protests against legislation to allow Hong Kong suspects to be extradited to mainland Chinese carrie lam, hong kong protests, extraditions, poster art, posters -

Federation University Historical Collection

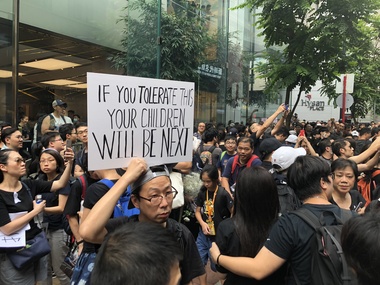

Federation University Historical CollectionPhotograph - Colour, Jarrod Watt, A thousand protestors surround Hong Kong's main police headquarters on Arsenal Street in Wan Chai on June 26th 2019, 21/06/2019