Showing 525 items

matching use of machinery

-

Bendigo Historical Society Inc.

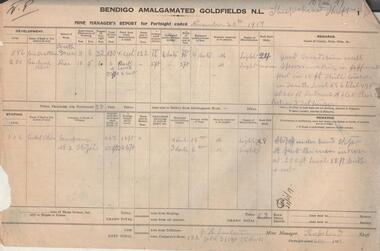

Bendigo Historical Society Inc.Administrative record - Bendigo Amalgamated Goldfields N.L. Mine Manager's Reports, 1917 - 1920

In 1917 Bendigo Amalgamated Goldfield Ltd was formed from the amalgamation of 35 companies with operations on the Garden Gully, Sheepshead, Deborah and Derby lines of reef hoping to increase profits of these existing operations through economies of scale. This was difficult to achieve as the shafts involved were spread throughout the goldfield. Diamond drilling and good geological practices were introduced (Pabst was Chief Geologist) leading to some exploration success. However costs were rising rapidly and in 1923 the directors, deciding that mining would soon become unprofitable, dissolved the company returning assets to the original vendors. J.H. Lenten, Mine Manager, received his second class Mine Manager's certificate in September, 1914 at an examination held at the Bendigo Law Courts. One hundred pages of fortnightly manager's reports for Bendigo Amalgamated Goldfields N.L., Sheepshead Shaft. Reports consist of two pages for each fortnight, signed by J.H. Lenten, Mine Manager. Dates of reports range from November 20th, 1917 to 5th May 1920. Categories reported on include: development, stoping, tons from tributors, tons Company's stone, plant and machinery, underground workings, number of rock drill shifts, firewood used, coal burnt, and general remarks. charcoal burnt., lifting waterbendigo, margaret roberts, , goldmining, bendigo amalgamated goldfields, sheepshead shaft, j.h. lenten, mine manager -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph - Entrance Beach, Bulmer H D, 1910c

... extension to western pier showing cranes and machinery in use... showing cranes and machinery in use. People on beach and piers ...One other copy slightly sepia tinted 12 x 19cmBlack and white photograph showing piers and entrance to Gippsland Lakes from ocean Bass Strait. Work in progress on concrete extension to western pier showing cranes and machinery in use. People on beach and piers. Lakes Entrance VictoriaLakes Entrancewaterways, beaches, piers, machinery -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph - Tramline, Fish Marie, 1977

Date made 18 January 1977.Colour photograph of Rex Fish standing beside the boiler which provided steam power to drive the winch to transfer rock from the tram, trucks to the barge at North Arm. This rock quarried at Mississippi Creek was used to stabilise the entrance piers, and build rock groynes around the lakes. Lakes Entrance Victoria waterways, historic sites, public works, machinery -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph, Lakes Post Newspaper, 1999c

Colour photograph showing workman using digging machine to remove sand from inside entrance pier at Lakes Entrance Victoria.waterways, jetties, machinery, public works -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph - New Works, 1910c

Also other copies, 10x13.5, 14.5x20, one of these has history of the travelling crane written on the back by Reg Schulz 11.6.1999, two of the prints have hand drawn enhancement lines.Black and white photograph of the historic travelling crane at New Works, built by Fulton Engineering Co. Melbourne in 1873 for John Carpenter, Contractor for Stage One of the construction of the entrance. Wooden piers also used by Coat Bros for Stage Two extensions in use to 1932. Lakes Entrance Victoria public works, machinery -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Photograph, Gibbons, Denis, Mobile Crusher 2

Denis Gibbons (1937 – 2011) Trained with the Australian Army, before travelling to Vietnam in January 1966, Denis stayed with the 1st Australian Task Force in Nui Dat working as a photographer. For almost five years Gibbons toured with nine Australian infantry battalions, posting compelling war images from within many combat zones before being flown out in late November 1970 after sustaining injuries. The images held within the National Vietnam Veterans Museum make up the Gibbons Collection.A black and white photograph of Engineers, from 17 Construction Squadron, use a front end loader to deliver rock into a mobile crusher used to prepare fine rock material for all types of foundation work, used in construction projects throughout Phuoc Tuy Province, South Vietnam.photograph, engineers, 17 const sqn, phuoc tuy province, gibbons collection catalogue, photographer, vietnam war, denis gibbons, front end loader, machinery -

Eltham District Historical Society Inc

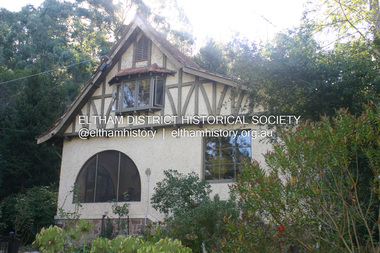

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, The Robins, 13 Kangaroo Ground-Warrandyte Road, North Warrandyte, 2 March 2008

Built by noted artist Theodore Penleigh Boyd, father of architect Robin Boyd. Covered under National Estate, National Trust of Australia (Victoria) Local Significance and Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p111 The Robins at Warrandyte,* was once home to a member of a famous family and is also one of the first reinforced concrete houses in Victoria. The builder, Theodore Penleigh Boyd, born in 1890, was a talented painter1 noted for his works of the Warrandyte bush. He was the father of architect Robin Boyd, author of the Australian Ugliness and the uncle of painter, Arthur Boyd. Penleigh Boyd’s great grandfather was Sir William A’Beckett, Victoria’s first Chief Justice. Penleigh Boyd is considered by some to be an ‘unsung hero’ overshadowed by more famous members of his family. Mornington Gallery Director Andrea May said many believed Boyd ‘had never received the national acclaim that he deserved’.2 Classified by the National Trust3 and part of the Australian National Heritage,4 The Robins is set well back near the end of Kangaroo Ground – Warrandyte Road, unobserved by passers-by. Built in 1913, The Robins has some Art Nouveau influences and is a descendant of the Queen Anne style. It is covered in stucco and has a prominent attic, which Boyd used as a studio. Some parts of the house are up to 33 centimetres thick and built in part with pisé (rammed earth) and in part with reinforced concrete. Amazingly, Boyd built The Robins without an accessible driveway, and only a narrow track along which he had to cart building materials. The journey was uphill and Boyd terraced the land with Warrandyte rock5 without the aid of machinery. At only 33 years, Boyd was killed in a car accident in 1923. He was buried in Brighton near the home of his parents. Several people have since owned the house, including political journalist, Owen Webster. Boyd was born at Penleigh House, Wiltshire, and studied at Haileybury College, Melbourne and The Hutchins School, Hobart. He attended the Melbourne National Gallery School and in his final year exhibited at the Victorian Artists’ Society. He arrived in London in 1911 and his painting Springtime was hung at the Royal Academy. He painted in several studios in England and then worked in Paris.6 There he met painter Phillips Fox through whom he met artists of the French modern school and also his wife-to-be, Edith Anderson, whom he married in Paris in 1912. After touring France and Italy, the couple returned to Melbourne. In 1913 Boyd held an exhibition and won second prize in the Federal Capital site competition, then the Wynne Prize for landscape in 1914. In 1915 Boyd joined the Australian Imperial Force, and became a sergeant in the Electrical and Mechanical Mining Company. However he was severely gassed at Ypres and invalided to England. In 1918 in London Boyd published Salvage, writing the text and illustrating it with 20 black-and-white ink-sketches of army scenes. Later that year he returned to Melbourne, and, despite suffering from the effects of gas, he held several successful one-man shows, quickly selling his water-colour and oil paintings. In his short career Penleigh Boyd was recognized as one of Australia’s finest landscape painters. He loved colour, having been influenced early by Turner and McCubbin. His works are in all Australian state galleries, the National Collection in Canberra as well as in regional galleries.7 His wife Edith was also an artist having studied at the Slade School, London, and in Paris with Phillips Fox. After her marriage she continued to paint and excelled in drawing. In later years she wrote several dramas, staged by repertory companies, and radio plays for the Australian Broadcasting Commission, in which she took part. She was the model for the beautiful red-haired woman in several of Phillips Fox’s paintings and the family hold three of his portraits of her. *Possibly named after the Aboriginal words warran, meaning ‘object’ and dyte, meaning ‘thrown at’.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, kangaroo ground-warrandyte road, north warrandyte, the robins -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, Jelbart home, 93 Arthur Street, Eltham, 11 November 2006

Situated at the top of the hill in Arthur Street, the former Jelbart residence and barn were part of a major change that transformed Eltham's character in the late 1960s. Built from the mid 1940s through mid 1950s when Eltham was a rural community, the Jelbrat residence and barn are all that remain of a family property of some 250 acres (100 ha). With growing population pressures, in the late 1960s, owners Ron and Yvonne Jelbart decided to subdivide their property creating the Woodridge Estate in the early 1970s, a major factor towards the transformation of Eltham to the suburb it is today. The Jelbarts had moved to Eltham in the early 1940s when they purchased a poultry farm in New Street, now Lavendar Park Road. (The local Black Friday bushire of January 13, 1939 had started at C.A. (Clarrie) Hurst’s Eltham Poultry Farm and Hatchery in New Street.) Jelbart was primarily a businessman importing office machinery but desired farm beef and dairy cattle so the couple purchased the virgin bushland at what was then at the end of a dirt road, Arthur Street. With post war shortages of most building materials, they followed the example of the Eltham Artists' Colony (later called Montsalvat) and built thier home from mud-bricks and recyclked materials. The barn was first to be completed in 1945 which they made their home whilst building the main residence. It took eight years to complete the two buildings. Both the main residence and the barn are now separate homes, and along with the remaining property being sub-divided further in 1998 are now part of the Kinloch Gardens Estate at 93 Arthur Street. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p139 Standing on a hilltop at Arthur Street, Eltham, the Jelbart residence and former barn were part of a major change that transformed Eltham’s character in the late 1960s. Built from the late 1940s to the mid 1950s when Eltham was a rural community, they are all that remain of what was once a family property of around 250 acres (100 ha). As population pressure increased in the late 1960s, owners Ron and Yvonne Jelbart, decided to subdivide their property. The break-up of this property into the Woodridge Estate in the early 1970s, was a major factor towards transforming Eltham into the suburb it is today.1 Although standing only a few minutes from Eltham’s busy hub and hundreds of houses in Woodridge, scarcely any urban sound disturbs the peace. Views from the two buildings are almost exclusively of trees and extend to Mt. Dandenong to the south-east, the Great Divide to the north, and Melbourne city to the south-west. The Jelbarts had lived in Eltham since the early 1940s when they bought a poultry farm in New Street, now Lavender Park Road. Although Jelbart was primarily a businessman importing office machinery, he was keen to farm dairy and beef cattle, so the couple bought rough bushland at what was then the end of Arthur Street. But a shortage of building materials following World War Two hampered their plans to build their new home, so they followed the example of the Eltham Artists’ Colony (later called Montsalvat) and used mud-bricks and recycled materials.2 With great determination the family and friends constructed their house. Massive timber frames and huge quantities of mud-bricks were made on site. The barn was built first in 1945, and two years later, while camping inside, the Jelbarts started building their house. It took eight years to construct the two buildings, even with the help of professional tradesmen. The buildings, with timber frames infilled with mud-brick and plastered, are reminiscent of the English Tudor style. The Jelbarts are of Cornish stock. Much of the timber framework came from demolished bridges or warehouses, and recycled slate was used for roofs and floors. Quality second-hand materials were readily available in the late 1940s and 1950s when there was much demolition in Melbourne and little respect for heritage. A former 19th century Toorak mansion Woorigoleen provided the magnificent stone fireplace, the timber panelling and the parquetry floor in the living room. The large stone gateposts at the entry of the property came from Melbourne University. Almost no mechanical equipment was used to build the 55 square house and the 25 square barn. Massive timber frames were erected using block and tackle pulleys and timbers were shaped, sawn and drilled by hand. Son and architect Ian, with his family, have lived in and extensively renovated both buildings since the early 1970s. Ian transformed the steep ridge of the property into a plateau, where the main house Kinloch stands, surrounded by terraces and lawns. The grounds retain many native plants, including massive yellow boxes – some nudging 80 years. Ian attached 70 metres of pergolas draped with wisteria, roses and grape vines, to three sides of the house. The beautiful garden is featured in the book Through the Rose Arbour by Rosemary Houseman. The two-storey barn – now a house – retains traces of its original use. The cow-shed with milking and feed-rooms, and the machinery-shed remain. The house, separated on the ground floor by a breeze-way, soars two storeys and includes a mezzanine. These are connected by spiral staircases, to timber-beamed and plaster-lined high-pitched ceilings. The house also descends to a wine cellar. Curiously the roof is of corrugated iron on the south and slate on the north, to save costs. Small-paned windows and three French doors open onto the front lawn, which extends to Jelbart Court.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, eltham, arthur street, jelbart barn, jelbart home, kinloch gardens -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesPhotograph - Colour, Dairy, 1985

Note by T.H. Kneen," After the transfer of the small dairy herd to Glenormiston and later Longerenong the milking shed was modified to serve as a machinery shop. Late in 1990 and early in 1991 it was converted for use as the Horticultural College Centenary Centre and as a new home for the Horticultural Shop. Half the space on ground floor level was devoted to a display "A Centenary of Horticultural Education." The old loft area was fitted out as the office for the Executive Officer for the Centenary Celebrations and the storage of archival material." (In 2009 the shop closed and the archives were removed to the Administration Building.) Colour photograph. Former dairy used as a garage prior to 1990 renovationdairy herd, glenormiston, milking shed, machinery shop, horticultural college centenary centre, horticultural shop, cows, garage, dairy, dairy shed, centenary centre, longerenong -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MARKS COLLECTION: YOUNGMAN & HARRISON PATENT BASIN PULVERISING QUARTZ TAILINGS

Blue handwritten one page document detailing 'Youngman & Harrisons Patent Basin for pulverizing quartz tailings and amalgamating fine gold with mercury'. Introductory comments the basin contains greater advantages for pulverizing quartz tailings & amalgamating than any yet constructed for that purpose; In its construction all machinery complications have been carefully avoided and yet it embodies all the best methods known for treating tailings and has besides other than advantages (both in cash and labour) that of treating puddling machine sludge and can be used as a concentrator with little or no extra expense.bendigo, mining, youngman & harrisons patent basin -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern was possibly made for casting a part for Craftman Marine, makers of engines for boats and other machines. It is part of a set that is stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block with a corner cut diagonally. A five-sided shape has been carved into the centre, with one side curved inwards and slightly shallower than the other sides. The cut-out area is painted black. Three holes are drilled in the cut-out side to align the pattern with another piece of work. A wooden slat is fixed across the diagonal side. The back of the pattern has a handwritten inscription, possibly by two writers. The pattern is part of a set of foundry patterns from Briggs Brass Foundry and is connected to Craftman Marine.In black handwriting: "1 # H AL" Handwritten in a different hand: "CRAFTMAN MARINE" Written the the first hand: BRIGGS" (or "BRICK")flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912, craftman marine, craftsman marine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; thick square mostly unopainted wooden block with a solid half-cylinder added to the top, which has rounded shoulders. A disc is added to the front, aligned with the curve at the top. The top curve has orange paint and the dial is pink. Three holes are drilled in the back, in a triangular configuration. It is similar in shape to a mantle clock or an early-style radio. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that is stored in a strong wooden crate and may be part of another similar pattern. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; unpainted, square wooden block with a semi-circle of dowel added to the centre of the side with rounded corners. Three short dowel pegs are inserted on one flat side; one below the semi-circle and one near the lower corners in an overall triangle configuration. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Baleen

A baleen whale has hard bristly baleen that hangs from its upper jaw inside its mouth instead of teeth. Baleen is made from a protein called keratin, just like human hair and fingernails, and its colour can vary between species, from black to yellow or white. The whale uses the tough, flexible baleen like a sieve to catch its food, filtering the small sea creatures out of the sea water it releases from its mouth. In the19th Century, whales were hunted for the products that could be made from their bodies, such as oil for lubricating machinery, soap making, lamps, heaters and fuel for the lighthouse lights. The flexible baleen was used for whip handles, carriage springs and umbrella ribs. It was also used for the skirt hoops, hat ribs, and rigid ‘stays’ in tightly fitting bodices to enhance their figures. The Southern Right Whales, as well as Blue Whales and Humpback Whales, are baleen whales. The Southern Rights annually visit the ocean off the southwest coast during the breeding season. In the early 1800s whalers hunted along this coastline in their dangerous pursuit of money for the precious cargoes of whale oil and bones. The population of these large animals dwindled quickly and by the late 1840s the whaling industry dwindled. Whaling recommenced from the 1940s to the 1980s when the whale products were used to make margarine and dog food. The baleen sample has been used to educate people about whaling and about the properties of baleen. The baleen sample is significant for its association with 19th century women's fashion. It helps to understand how garments were supported to shape a woman's figure. The baleen sample represents a period when whales were hunted and killed to provide income and products for for the local settlers and for the export industry.Baleen sample from a whale's jaw. Its black shiny hard yet flexible surface is slightly rippled and textured. One end is fringed and the other and a smooth cut edge. The colour varies in places, with stripy brown colouring. flagstaff hill maritime museum and village, great ocean road, shipwreck coast, baleen, whalebone, baleen whale, keratin, 19th century, whaling industry, women's fashion, stays, bodice, women's figures, fashion, clothing, whale oil, baleen colour, whale hunting, whale products, southern right whale, blue whale, humpback whale, southwest victoria, whalers, whale bones -

Kew Historical Society Inc

Kew Historical Society IncArticle, The New Electric Tramway, Malvern to Kew

... infrastructure which was used to connect Victorians in the first two ...One of a group of photographs, including three within a published photo collage , taken by Edgar James Dower in the second decade of the twentieth century. Born and raised in Olinda, Dower later moved to Surrey Hills. He worked as an adult as a clerk in the city office of the Metropolitan Gas Company, and in his role as a 'collector', he was able to photograph scenes including the construction of tramlines, railways and associated buildings in Kew, Hawthorn, Camberwell and Surrey Hills. Later he established a real estate agency with his brother - the E.J. Dower Real Estate Agency, Mount Dandenong Office.The photo collage is an historically significant record of the development of transport infrastructure which was used to connect Victorians in the first two decades of the twentieth century. This development resulted from increases in population and the consequent extension of Melbourne's suburbs. The photographs, both individually and collectively, richly detail the labour of workers and the tools and machinery used to create and extend Melbourne's public transport network in the years preceding and during World War 1.Photo collage, published in The Leader newspaper in 1913, to commemorate the opening of the Malvern to Kew Tramway. The numbered photos are: 1. Kew Railway Gates at Glenferrie. 2. Burke Road Terminus. 3. Final Stages. 4. Ladies at the Official Opening. 5. The Acting Mayoress of Kew Cutting the Ribbon at the Kew Boundary. 6. Mayor and Councillors at the Kew Terminus. 7. The Cutting the First Ribbon. 8. Guests at the Hawthorn Town Hall.Inscribed in ink by Edgar J Dower top left: "The 3 top photographs were taken by E J Dower. No.3 Cotham Road Kew near Glenferrie Road"theme -- connecting victorians by transport and communications, theme -- travelling by tram -

Bendigo Historical Society Inc.

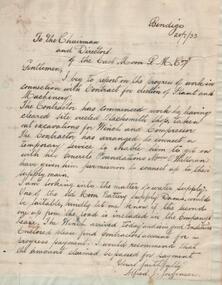

Bendigo Historical Society Inc.Administrative record - East Moon Gold Mining Company Mine Manager's Report Book, 1919 - 1920

February 1933: East Moon Gold Mining Co. N.L. has been formed with a capital of £25,000 in 36,000 shares of 10/- each issued at 1/-. The company will work an extensive lease on the Paddy’s Gully and Derby lines of reef at Eaglehawk. A shaft was sunk on the Paddy’s Gully line in the property of the New Moon Co. some years ago to a depth of 380 ft. and another shaft was sunk by the same company on the Derby line of reef to 134 ft. In the Paddy’s Gully shaft a large body of spurs 10ft wide at the 256ft plat was exposed and continued downward for 36 ft (56ft?) before passing out of the shaft to the east. A little gold was seen in the stone but no work was done. The development of this formation will be the first work undertaken by the new company. (The Sun News Pictorial Monday 20th February 1933, page 23) Black hard cover book, red binding on spine, one hundred and eighty eight pages of which sixty five are used. Label on front cover: 'East Moon G.M.C . N.L.' Book contains: a. handwritten reports from Alfred Jorgensen regarding the installation of the plant and machinery at the mine b. reports from E.G. Robertson, the Manager of the East Moon Gold Mining Company. Typed report by E.G. Robertson, 8th July 1935 reports on the Paddy's Gully shaft, the Derby shaft and the Hustlers shaft. Entries date from 20th July 1933 to 22nd. August 1935. Mine Manager's book forms part of the Margaret Roberts Collection of Mining records.bendigo, margaret roberts, legal managers, mine manager, east moon gold mining company n.l., e.g. robertson mine manager, alfred jorgensen contractor, paddy's gully shaft, derby shaft, hustler's shaft, -

Bendigo Historical Society Inc.

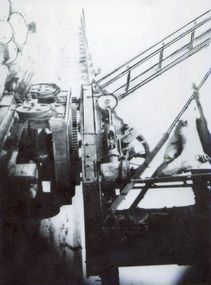

Bendigo Historical Society Inc.Slide - HORWOOD COLLECTION: DEBORAH EXTENDED, c1978

Horwood Collection. Above ground machinery at Deborah Extended. Markings: Deborah Ext'd (I think) SEP78M1. Used as a teaching aid.Kodakmine, gold, deborah extended -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block made from laminated sections of wood painted black. A half-cylinder shape was carved into the long side, and a dowel shape was placed at the lower side. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; pair of U-shaped carved blocks, unpainted. The blocks have opposing metal pins and holes to hold them together. One block has a disc shape carved into the base. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

National Wool Museum

National Wool MuseumPhotograph - C. Glover and Sons Pty. Ltd, 1890-1944

... . The men are standing in front of large machinery presumed... coming through. The men are standing in front of large machinery ...C. Glover and Sons Pty. Ltd. was founded on Brougham Street, Geelong c.1870. They operated as a wool and sheepskin storeroom situated on both sides of Brougham Street; where the current Elders building is located. The store was owned and operated by Joshua Glover with his brother Cyrus. A third brother Arthur also worked at the store. It was a very successful business and employed up to 40 men at its peak. Cyrus Glover died quite young, around 54, with his son Howard taking his place in the partnership at 23. During the Second World War the business was requisitioned by the Australian Government. Their wool was utilised to produce defence uniforms for Commonwealth personnel C. Glover and Sons was a very successful business which reluctantly closed its doors around 1975, as a result of the wool industry taking a downward turn Australia wide. It was decided by the family that this was the only option at the time. Howard Glover was Jan Glover’s (donor) father in law. Jan Glover donated these images to the National Wool Museum in 2021. Image 1 is a black and white image of a truck with 11 men standing in front. The truck is loaded with dumped bales of wool. The image is taken outside of the C. Glover and Sons' building. The reverse of the image is stamped. Image 2 is a black and white image of 2 rows of men. The first row of six men are sitting in their cricket whites. The second row of 10 men are standing in suits bar one-man 3rd from the right, who is also in his cricket whites. The image is taken on a cricket oval with the grandstand visible in the background. Image 3 is a black and white image of 12 men. The first 3 men are sitting on wool bales while the other 9 stand behind. The image shows the word 'record' spray painted on a piece of timber hanging behind the man. This is expressed in the men's faces with emotions of joy and celebration coming through. The men are standing in front of large machinery presumed to be used for wool pressing/dumping. Image 4 is a black and white image of 15 men and 5 horses in front of two large white sheds with triangular rooves. The men are all standing with the majority having their arms crossed. On the left is a cart carrying sheep skins. On the right are two smaller carts that appear to be carrying wool bales. Image 5 is a black and white image of a wool and hides storeroom. The ceiling is lined with multiple sheep skins while the floor has multiple wool bales neatly stored. In the background of the image, two men can be seen inspecting wool while sitting at a small white table. Behind this, 5 men are standing in a crowd while another man is seen to the left of the men at the table. This separate man is standing inspecting a wool bale. Image 6 is a black and white image of a wool storeroom. Numerous bales of wool can be seen open for inspection stacked semi-neatly one next to another. 6 men can be seen inspecting a bale of wool in a group. Another 5 men are present in the room performing separate duties.Image 1 Reverse. Black Stamp INTERNATION FOTO-NEWS / H. A SOETEKOUW / 52 GHERINGHAP ST., / GEELONG / PHONE X 2920 Image 2 Wording. Typed black lettering. Geelong Buyers and Brokers Cricket Team. Image 3 Wording. Blue handwriting RECORD OF PRESSING FOR ONE DAY / FORTY BALES / 1910 Image 4 Wording. Blue handwriting. 1890 Image 5 Wording. Typed black lettering. Messrs. Moss & R. Allan. / Government Sheepskin Appraisers. 1918. Image 6 Wording. Black Handwriting. C. GLOVER & SONS. APPRAISEMENT NO. 50 14/12/1944. / GOVERNMENT SHEEPSKIN APPRAISERS. MESSERS. R. BORLAND & H. V. McCALLUM / GEELONG REPRESENTATIVES. J. GLOVER & H. J. GLOVER. c. glover and sons pty. ltd, geelong 1870, brougham street, wool & sheepskin storeroom -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Foundry Patterns set, Briggs Brass Foundry, Early 20th century

The wooden crate contains a set of patterns or moulds that were once used at Briggs’ Brass Foundry for making sand moulds. The traditional method of sand casting is over 2000 years old. It is part of a crafted process used to make brass and copper alloy goods suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-corrosive and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry display was one of the early ‘working craft’ shops at Flagstaff Hill. It included a historic Cornish chimney that was set up as a working model, telling the story of heat from furnaces to smelt metal, which would then be poured into the sand moulds. This chimney is made from specially curved bricks and is about two-thirds of its full height when originally located at the Grassmere Cheese factory. HISTORY of BRIGGS BRASS FOUNDRY: - The family business was founded in 1912 by Herbert Harrison Briggs (1963-1931) with his son George Edward Briggs, trading as Briggs & Son Foundry at 70 Wellington Street, Collingwood. Younger son Cyril Falkiner McKinnon Briggs joined the foundry in 1922, and it was renamed H H Briggs & Sons Foundry. Both sons ran the firm after Herbert’s death in 1931, making products mainly for marine purposes. They became Bell Founders in 1936 and were known for their specialty of high-quality ship bells. They produced miniature varieties of these and other decorative items such as small propellers. The firm became known as Briggs Marine Foundry. The great-granddaughter of Herbert Briggs inherited the Briggs Brass Bell, similar to the one at Flagstaff Hill. Cyril became the sole family member of the firm in 1965. The Briggs Marine was an exhibitor at the 1965 Boat Show, where he advertised as “non-ferrous founders” and “Bell Specialists”. The foundry relocated to Chesterville Rd, Moorabbin. Cyril passed away in 1967. It is thought that either Cyril or his business partner Frank Lee donated the objects from the Briggs’ Foundry around the time when the business moved to Moorabbin. However, Flagstaff Hill hadn’t been thought about until 1972. The donated items were registered in the Collection in 1986 but they could have been in storage from an earlier date. In October of that same year, Briggs Marine restored Schomberg Bell, a shipwreck artefact from the collection at Flagstaff Hill. Peter Oram, who had worked for the previous owners of Briggs Marine as a fitter and turner, took over the firm in 2014, reviving some of the old casts for current use. The business is now located at Seaford in Victoria and is part of Alliance Casting & Engineering Solutions (Alliance Casting Pty Ltd). In 2016 the original Collingwood Foundry building was repurposed as a thriving business hub named The Foundry. The crate and its patterns are significant for their association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. The patterns are associated with the long-running firm, Briggs Brass Foundry, that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine is also associated with the Schomberg Bell in Flagstaff Hill, restoring the bell to is former state to show an example of the bell from a luxury mid-19th century vessel. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. Wooden rectangular crate with removable wooden lid. Inside is a set of wooden patterns of various shapes and sizes for making sand moulds in a metal foundry. The crate is made from thick wooden planks nailed together. The extended wooden struts on the long sides form a frame to hold the wooden lid. A pair of metal handles are at each short end of the crate, fixed with strong metal bolds. Between each pair of handles is an inscription stamped into the wood. The underside of the crate has red paint splashes. There are insect holes in the wood but no sign of current infestation. Stamped: "H.33 / II" (H may be N or a square B)flagstaff hill maritime museum and village, great ocean road, shipwreck coast, pattern, mould, foundry, brass foundry, metal foundry, crate, box, wooden container, briggs, traditional method, trade, sand cast, cast, brass alloy, copper alloy, marine equipment, marine tools, marine fittings, briggs' bronze, copper tin zinc lead, non-corrosive, briggs family, brassware, metalware, foundering, metalwork, maritime, casting, cornish chimney, curved bricks, grassmere cheese factory, 1912, herbert harrison briggs, h h briggs, george edward briggs, briggs & son foundry, collingwood, cyril falkiner mckinnon briggs, cyril briggs, h h briggs & sons foundry, bell founders, schomberg bell, alliance casting & engineering solutions, collingwood foundry, ship chandlers, marine products, flagstaff hill, warrnambool, maritime museum, maritime village, briggs & son brass foundry, briggs marine, moorabbin -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; hexagonal wooden shape painted orange. The thick carved wooden shape is in halves forming a hole when locked together with the dowel pegs and opposing drilled holes. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; round wooden shape with a wide concave centre and a round flat handle in the middle, painted dark brown. The underside has a large wooden disc added to the centre. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; an unpainted, rectangular wooden frame with a top and sides, similar to a small rectangular stool. A solid half-cylinder shape was added under the horizontal 'seat' with another smaller half-cylinder attached to it, end-to-end. A string is tied between two metal loops attached to the back. There are two X marks stamped into the back. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.Stamped: "X" "X"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden patterns are part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; a pair of blocks that form a rectangle with a carved centre hole and disc shape inside. The block is made from laminated pieces of wood with cut corners. Both sides have four drilled holes in a square configuration but in different positions. The cut faces and the space carved into them are painted red; one piece has two dowel pins that fit into two drilled holes on the other. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Foghorn, 20th century

A marine foghorn gives an audible navigational signal to warn vessels of dangers, hazards and the presence of other vessels in fog conditions. The foghorn signal is a series of long and short sounds with short or long pauses between them. These common signals conform to a code called the International Regulations for Preventing Collisions at Sea and provide such information as whether the vessel is under sail or motor, large or small, aground or at anchor. The designs of foghorns vary but they all use a column of air to make a loud sound. Some use vibrating plates or metal reeds, others force air through holes in a revolving cylinder or disc, sounding like a siren, and some use a clockwork mechanism to open the valves that let the air into the horn. They are usually built to meet particular specifications e.g. U.S.C.G. (US Coast Guard). This Tyfon plunger foghorn has a horizontal handle attached to a vertical rod that moves up and down inside a cylinder. When the handle is plunged down, in a similar way to a bicycle pump, the air is forced out of the bottom of the cylinder into a pipe with a bell-shaped horn on the end, making a loud, low sound. The wider base of the cylinder helps to keep it stable. The original type Tyfon foghorns were manufactured in about 1910 by Kochums Mechanical Workshop (Kockums Mechanical Werkstad, Ltd.), Malmo, Sweden. The company was established in 1840, became a Limited company in 1866, and established a shipyard at the Port of Malmo, Sweden, in 1870. The civilian ship production in Malmo ceased in 1987. As well as building ships the company built large industrial and agricultural machinery and maritime goods.this replica foghorn represents the design of a Swedish, Tyfon model 1910. It is an example of the type of safety equipment used on marine vessels to signal other vessels and signal to land. Replica foghorn; portable marine, plunger operation. It has a brass cylinder and adjustable brass horn. The plunger handle and base are wooden. Inscriptions are on the plaque on the horn and moulded into the air intake. Facsimile of a Kockums of Malmo, Sweden, Tyfon model 1910 Fog Horn.Impressed into the attached plaque "KOCKUMS MLK. VERKSTAD / MALMO SWEDEN" and "TRADE TYFON MARK" Also added to the plaque individually "288938" Molded around the circumference of the air intake "TYFON PATENT"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, foghorn, fog horn, tyfon foghorn, kockums mlk verkstad, malmo sweden, replica, warning signal, safety equipment, ship's equipment -

Melbourne Tram Museum

Melbourne Tram MuseumFunctional object - Material sample, Norm Cross, Samco Strong Machinery Pty Ltd, "Celastic Roof Covering", c1970

Material sample of "Celastic Roof covering" - a woven cloth type material, light grey which was used in the tramway rooves by the MMTB c1970? 1 - piece of timber - 73mm wide x 363 long to which the material has been applied and one side and edges painted MMTB green colour. 2 - piece of Celastic material, 125W x 330 long 3 - Hand written note by Norm Cross, undated, on the source of the material, costs, and how it was applied - 188H x 123W.trams, tramways, tramcars, materials, workshops, paint, overhauls -

Melbourne Tram Museum

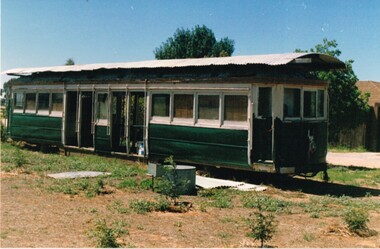

Melbourne Tram MuseumPhotograph - Set of 4 Colour Print/s, Norm Cross, 1/01/1994 12:00:00 AM

Set of four colour prints of an Ex Victorian Railways bogie tram body at Sloan NSW. Photo by Norm Cross, printed on AGFA paper. Photo dated 1/1/1994. Advised by Tony Smith - 29/3/2017 "The tram in question is VR 39. It was one of the last 4 trams disposed of from Elwood depot in 1959 after the system closed. They were purchased complete by Upton's machinery dealers of Corowa. The other cars were 29, 33 & 37. He then stripped them and sold the bodies. When we obtained VR 41 in 1977 we immediately went searching for other bodies that might yield parts to help in rebuilding 41. We located 37 on the outskirts of Wangaratta and it yielded many body items including a complete drivers bulkhead that was used to replace the one in VR 41 that had been cut out with an axle by the previous owner. You may also recall that we obtained 3 complete broad gauge 77e trucks from Upton's (they had cut up the other 5 bogies years previous). These 77E trucks are now under the Christchurch Brill tram with the 3rd as a spare as we were able to obtain standard gauge 77e's when we acquired L 105 for dismantling."Each photo has written in ink on the rear "Body of VR tram # @ Sloan NSW 1 Jan 1994, photo by Norm Cross".trams, tramways, vr trams, sale of trams, scrapped trams, tram 39 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, T & F Johnson, boilermakers, late 19th century