Showing 738 items

matching machine made

-

National Wool Museum

National Wool MuseumSocks

A pair of machine knitted aqua coloured woollen socks. Probably made on the "Beehive" manual benchtop sock knitting machine.A pair of machine knitted aqua coloured woollen socks. Probably made on the "Beehive" manual benchtop sock knitting machine.SOV KNITTED BY STAN FINLAYknitting textile machinery machine knitting, hosiery, knitting, textile machinery, machine knitting -

National Wool Museum

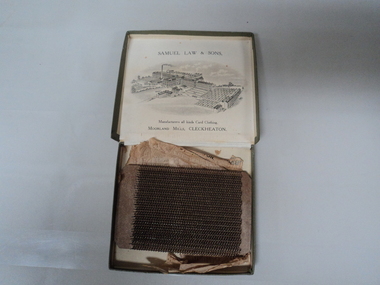

National Wool MuseumSample, Card Clothing

Card clothing sample manufactured by Samuel Law and Sons, Cleckheaton and probably sent to the Collins Bros Mill at the same time as W621. Card clothing is defined as 'the leather or other stiff material which holds the wire staples, the points of which project outwardly and form the carding teeth which operated on the fibres.' This fits into a carding machine ("The Textile Industries" vol. 8 - William S. Murphy, 1911).Card clothing sample, comprising rows of bent wires mounted on a thick rectangular leather base. Wrapped in tissue printed with an engraving of the factory where it was made and housed in an olive green lidded cardboard box, the interior of which is printed with an image of the manufacturer's factory.SAMUEL LAW & SONS, / Manufacturers all kinds Card Clothing. / Moorland Mills. / CLECKHEATON, England. SAMPLE OF CARD CLOTHING / FROM / SAMUEL LAW & SONS, / (branch of the English Card Clothing Company, Limited). / CLECKEATON. / MOORLAND MILLSsamuel law and sons collins bros mill pty ltd, carding, card clothing -

National Wool Museum

National Wool MuseumTextile - Quilt, Domestic Wagga, 1950s

Part of the Running Stitch collection, possibly made in BallaratDomestic wagga, unfilled, consisting of two machine sewn layers of woollen garment pieces both knitted and woven. The front pieces are predominantly red, blue and yellow, the back is mostly brown red and blue.WAGGA/ Maker unknown 154cm long X 90cm wide/ Made of parts of wool garments, knitted and woven.....handicrafts quilting quilting - history, running stitch collection, running stitch group, handicrafts, quilting, quilting - history -

National Wool Museum

National Wool MuseumQuilt, Medallion Quilt

Part of the Running Stitch Collection. Possibly made at Ballarat.Patchwork quilt, made with small rectangular pieces of printed cotton dress fabrics in predominant shades of blue. Machine quilted and filled with woollen handknitted garment pieces. Backing is a cream cotton fabric printed with blue and green and brown floral pattern.quilting quilting - history, running stitch group, running stitch collection, quilting, quilting - history -

National Wool Museum

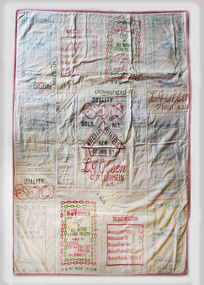

National Wool MuseumTextile - Quilt, Mrs Elizabeth Morton, c.1934

... A small knee rug made from suiting samples machine stitched... rug made from suiting samples machine stitched together ...Made by Mrs Noel (Lizzie) Morton, the donor's mother on their farm "Wanera" at Benjeroop on the Murray River. It was stitched with a treadle machine. Her sister Flora MacDonald did the running stitch and provided the silk backing. The squares were sent as samples from a firm called "Fred Hesse" who advertised in the Melbourne papers "Be smart and dressy In a suit by Fred Hesse". The buyer chose a sample and then sent it back with measurements and received a "mail order" suit.A small knee rug made from suiting samples machine stitched together. It is backed with black silk fabric and finished with a running stitch of orange wool oversewn with black wool thread.farming quilting quilting - history, wanera benjeroop, farming, quilting, quilting - history -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Stawell Post Office Cnr Wimmera and Main Streets 1875

Stawell Post Office on corner of Wimmera and Main Streets. Erected 1875. Telegraph pole and streetlamp in foreground. Akins store visible at right of photo. The building has 3 arched doors & 6 arched windows on the ground floor and 8 square windows on the top story. Two chimneys on the roof and a wrought iron square fence on the roof. The outside of the building has not changed while the interior has been remodelled several times. The early Postmasters and their families lived upstairs. The main room originally included the Telegraph office where operators worked at machines, sending and receiving Morse code messages. Later alterations were made for a telephone switchboard room downstairs, with trunk line equipment upstairs. In 1965 the telephone system was converted to automatic.Black & white photo of a two story building on the corner of Wimmera & Main St. The building the Stawell Post and Telegraph Office. Out the front of the Post office is a telegraph pole and a light post. Next door in Main St is a single story building with a sign over the building Argus Australasian, underneath Akins, Age/Leader possible a newsagent. stawell -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumWashing machine and wringer, 1920's

significant household item for a large familyWashing Machine [Metal with plunger on leve ron a three legged base with tap at base for emptying] Wringer attachedOn the wringer :Made in Great Britain Acme Wringers Ltd Glasgow Washing Machine The Lehmann, compressed air and vacuum washing machine no.30614/30 -

Yarrawonga and Mulwala Pioneer Museum

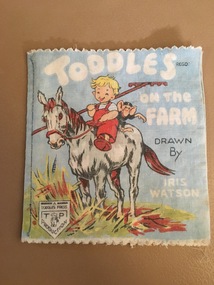

Yarrawonga and Mulwala Pioneer MuseumChild's cloth book, Toddles Press, Toddles on the farm

Small cloth book with four pages printed on both sides. Brightly coloured pictures of farm animals and their babies and "Toddles" the little boy. Spine machine sewn, each page doube thickness, top and bottom edges neatened with pinking shears.Front - A Toddles Press TP Production Toddles on the Farm Regd. Drawn by Iris Waton Back - Made in England, Copyright reserved -

Yarrawonga and Mulwala Pioneer Museum

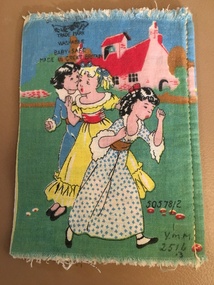

Yarrawonga and Mulwala Pioneer MuseumChild’s cloth book, Jolly Rhymes

Small cloth book with four pages printed on both sides. Contains the first line of nursery rhymes and accompanying pictures. Spine machine stitched each page double thickness. Top and bottom unfinished with fraying threads. Front page - Dean's rag book. Back page - Rag book. Trade mark Washable baby safe. Made in Great Britain 50578/2 -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumMachine - Sewing Machine, 1960

... condition and working order Machine case in good condition made ...Purchased in 1960 as "state of the art"1960 Singer sewing machine Model 411. Spare bobbins, needles, lubricant etc included. Manual also included. Still in perfect condition and working order Machine case in good condition made of wood.model number not visable any longer . In instruction book it indicates model no 411 -

Plutarch Project

Plutarch ProjectMachine - Shortwave Radio Antenna, Active Antenna, circa late 1980's

This antenna was used between 1989 and 1990 to help receive the daily news service in the Greek language directly from Athens, Greece. At the time, news from Greece for the Greek people in Australia were arriving in Melbourne a week late, on newspapers from Athens sent through air-mail. These newspapers were displayed at Salapatas and Carras newsagents at Lonsdale street in Melbourne. One thing that was a problem for this service was that the news came at least 7 days late. Using the Shortwave Antenna we could get the latest news from Athens on shortwave radio directly and within an hour these news were recorded on a cassette tape and taken to the Tricom Group P.L. offices in Melbourne (1155 Malvern Road, Malvern 3144). The tape was loaded onto a system which allowed people to call a local phone number and listen to the latest news with a cost of a local call, or a little bit more. As this was prior to the Internet being established around the globe, it was the fastest news service directly from Greece, in the Greek language. It was used for a span of about 12 months, until Tricom closed down their dial-in services, sometime in 1990. The service was captured and loaded onto the system by Iakovos Garivaldis, then an employee of the Tricom Group which was a subsidiary of Southern Cross TV.The Primary significance of this object is of its historical value, social and informative value for the first generation of Greeks in Victoria"World Tuner AT4 SW" antenna with a 920mm fully extended aerial, a tuned circuit and two transistors to prevent loading of the antenna and boost signal output. It is made of plastic, black in colour with the aerial being made of steel. The signals picked up by the antenna are fed via a 15pF ceramic capacitor to a tuned circuit consisting of either VC1a or VC1b and either L1, L2, L3 or L4. The slider switch S1 selects the band to be tuned. The band range is normally from 3 to 30MHz. When S1 is in position A, L1 and VC1a are selected and the antenna can be tuned from 3-9MHz. Similarly positions B, C, and D select higher frequencies up to 30MHz. It was purchased by Iakovos Garivaldis for this use for $119.WORLD TUNER AT4 SW "Amplituned" Shortwave Antennaantenna, radio, short-wave, language, greek -

Stawell Historical Society Inc

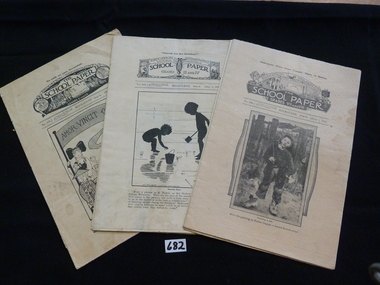

Stawell Historical Society IncBook, Education Department of Victoria, School Paper 1931 & 1933 & 3 Supplements, 1930's

The School Paper published monthly. Cost 1 Penny (2 Cents) Used in State Schools2 Paper booklets & 3, 4 page, supplements. 0682 has a photo of a boy holding a stick wearing unlaced boots, (after the painting by Bastien Lepage) 0682-1 is a supplement with a Picture of girls in a large room sitting in front of electric sewing machines. 0682-2 supplement: Contains photo of a certificate from the Victorian State Schools League of Kindness. 0682-3 Black and white drawing of two children in silhouette. on the beach with bucket and spade.0682-4 Supplement a picture of a variety of toys. 0682-5. drawing of children of different nationalities.0682: Midwinter. Days grow Longer. - Signs of Spring. Education Department. Victoria Australia The School Paper Grades VII and VIII. No 369. Melbourne Price 1d [July 1 1931. 0682-1: Supplement to the School Paper - Grades VII and VIII July 1931. 1. Made in Australia. 80. Girls and Womans Wear. 0682-2: Supplement to the School Paper - All Grades July 1931.1 The Protection of Animals. 0682-3: Hurrah for the Holidays Education Department. Victoria Australia The School Paper Grades III and IV. No 403. Melbourne Price 1d [Dec 1 1931. 0682-4: Supplement For the School Paper - Grades III and IV December 1931. 1.Made In Australia 85. Toys. 0682-5: No Cold, No Care, November Education Department. Victoria Australia The School Paper Grades V and VI. No 409. Melbourne Price 1d [Nov. 1 1931.stawell education -

National Wool Museum

National Wool MuseumPicker

Wool picking machine designed to separate locks of wool before it is carded and spun. The picker opens the wool’s locks which makes it easier to send the fleece through a carding machine. It does this by teasing the fibres (which can also be done by hand just by pulling the lock structure apart), but a picker does this in bulk and much quicker than what can be done by hand. It is possible to spin fibres directly after the picking stage; however, it is usually more desirable to card and blend them with other fibres. Typically, at a textile mill, a picking machine can separate enough lengths of fibre for a full day’s work after just a single hour. It will also help to remove any vegetation matter or other any unwanted elements that may be present in the wool. The quality of the casting on this machine suggest that it was made locally, either in Australia or New Zealand. Mike Leggett, the donor of the machine, acquired it from New Zealand where the seller said it had been used by his father to pick wool to make hand stuffed horse saddles. Mike attempted to used it a couple of times to pick alpaca hair, but the speed of the attached motor caused damage to the fibres. The motor is thought to be an added attachment, sometime around the 1960s judging by its age, while the machine itself is thought to be dated around the 1920s. The machine works by inserting wool through the rollers. Initially there was a conveyor belt feeder system which was powered by the handle on the side. This conveyor belt has been removed however, most likely due to age and deterioration. Wool is now fed through the initial teeth and is met by a spiked rotating drum which works to separate the fibres. The separated fibres would then complete a loop of the drum before being dispatched somewhere below, around where the motor presently sits, at a rapid rate of speed. Typically this wool will be collected in a closet or large catchment area, as can be seen from the 8:47 minute marker in the linked video (link - https://www.youtube.com/watch?v=kMjx-t3tH3A). It is not apparent how the wool is collected with this machine. Red and green machine with four green legs currently attached to a wooden pallet with wheels for easy movement. The green legs lead up to a red central circular barrel from which many attachments are present. Also present on the wooden pallet is a small black motor which is attached by a rubber belt to the central drum inside the red barrel. The belt spins the wooden drum via a dark red circular plate attached to the side of the drum. On the other side of the red barrel, a green handle extends for turning the picker’s conveyor belt feeder system. Two green walls extend forward from the central red barrel, guarding either side of where the conveyor belt would have been. At the start of these walls is a wooden cylinder, which the conveyor belt would have wrapped around, followed by two interlocking gears which rotate and accept the fed wool. The red roof extends over the central cylinder from here, securing the wool inside and protecting hands from the heavily spiked internal wooden cylinder which rotates and separates (picks) the wool. Extending over the top of this red roof is a green handle which reaches to the back of the machine (not pictured). Here it accepts a weight to ensure pressure is always present for the initial feeder interlocked gear teeth. There are two large gear cogs on the rubber belt side of the machine and 3 small gear cogs on the handle side of the machine, all coloured green. A green handle is also present at the rear of the machine, below the location from which the weight is hanging. A power cable extends from the motor and there are two adjustable metal rods on the top of the machine, the purpose of these rods is presently unknown. Black texter. On top of drum. Wording: HG3707 Wording. Imprint: BRACEWIND BLYN On motor. Wording AEIwool picking, textile manufacturing, wool processing -

National Wool Museum

National Wool MuseumTextile - Quilt, Judith Oke et al, Isolation Quilt, 2020-2021

In 2020 during the period of lockdown due to COVID the National Wool Museum asked their volunteers to make and donate blocks made from a variety of materials found in their homes, for an ISO quilt. The NWM reached out to the patchwork and quilter community to find a local quilter to sew the donated blocks together. The quilt is sewn together and quilted by Judith Oke, 2020-2021. Judith is a local patchwork and quilter and a member of Geelong Patchwork & Quilters Guild. Through the process she was inspired by the tradition of wagga quilts, where bits and pieces are stitched together, sometimes lined with whatever the sewer found available, such as clothing and sacking, to provide warmth. In construction of the finished quilt the challenge was combining 10 inch blocks made from a variety of materials, with uneven sizing. The aim was to combine these very different blocks into a harmonious whole. To this end a light and dark pattern was planned, with the blocks to be sewn onto a blanket. The choice to layer the blocks over each other, rather than sew an even seam was aimed at emphasizing the make do nature of these ISO blocks. Due to the weight of the blanket a decision was made to sew the blocks onto a base before the whole was stitched onto the blanket. The blanket was sourced from NWM donations. The rich, red of the blanket provides a bright, warm background for the colourful squares. Some of the light weight blocks were backed with iron-on interfacing to strengthen them for sewing. The edges of two of the woven squares were blanket stitched with knitting wool. The 10 inch donated blocks/squares were machine sewn to a cotton sheet base, with liberal use of blanket stitching, as the blanket was too heavy to sew the blocks directly onto the blanket. The base with squares was then machine sewn onto the red blanket backing.Various multi coloured and designed patchwork squares sewn onto a red woollen blanket. isolation, covid, quilt, wool -

National Wool Museum

National Wool MuseumTextile - Quilt, Mrs Beryl Andersen, Chicken Feed Wagga, 1995-2001

Norma Dessent (the donor) was cleaning out her Mother-in-law Amy Dessent’s home, after she passed away in 1995. She came across a collection of gunny sacks for chicken feed, potatoes, and flour. Norma gave the bags to her good friend Beryl Andersen, thinking she might be able to make use of the material in her quilting. Many years later in 2001, Beryl gave Norma this quilt made in a wagga style out of the bags. This was both a great surprise and a great delight for Norma. Amy Dessent was a housewife. Her chickens were her friends, keeping her company as she worked in her renowned garden and while she cooked and maintained a beautiful home. Typically, Amy would have a dozen chickens clucking around at a time. In the style of the time, everything was kept for a possible repurposing later in life, such as these gunny sacks. The Chicken Feed Wagga was created in Ballarat by Mrs Beryl Andersen. Beryl was the inaugural president of the Hamilton Quilters Guild and is a well-known quilter. Perhaps her best-known work was the “Quilt for Hope”, a living memorial for victims of institutional church-related sexual abuse. More information about this quilt can be found on the following link. https://www.nationalquiltregister.org.au/quilts/quilt-of-hope/). The wool blanket used as a backing belonged to Beryl’s mother. Beryl’s mother married in 1930 and the blanket is thought to have been a present from this wedding, making the blanket close to a century old. Norma donated the quilt to the National Wool Museum in 2021 as a result of downsizing. She no longer had room for the quilt to hang on her wall. Before downsizing, the quilt had hung in the entryway to her home for the last two decades.Wagga style quilt made with a appliqué top layer of gunny sacks that once held chicken feed, flour, and potatoes. The insulating internal material is not known. The backing fabric is made from a cream woollen blanket. The edges are bound with a material of a red and white plaid. The gunny sacks are quilted together with a machine stitch of red thread. The sacks contain imagery pertaining to their previous use. Some sacks have an image of a chicken applied with blue, red, or green ink. Other sacks contain imagery of potatoes. While other sacks contain information “Minimum Crude Protein 14%, Minimum Crude Fat 3%, Maximum Crude Fibre 7%”. One of the sacks shows a handwritten price for a bag of chicken feed in a red ink.Numerous. See multimediaquilts, wagga, gunny sacks, upcycle -

National Wool Museum

National Wool MuseumFunctional object - Typewriter, Remington Typewriter Company, c.1925

This Remington No.12 typewriter is of the typebar, front-strike class. It was made by the Remington Typewriter Company of Ilion, New York, U.S.A. in about 1925. The Model No. 12 was introduced in 1922 and was one of the first 'visible writer' machines, in which the typed characters were visible to the operator. Previous models were of the upstrike class in which the characters were typed on the underside of the platen. To see what had been typed the operator had to raise the platen, meaning the typist was typing blind much of the time. This machine was used by Margaret Ganly née Burn in the 1930s. It was purchased for her by one of the sons of William Pride, a famous saddle maker in Geelong, William was Margaret’s grandfather. The typewriter was donated with original sales receipt and servicing tools. Margaret worked at Dennys for 7 years during the 1930s. The typewriter is accompanied with a story written by Margaret about her time working at the company. Margret married Jack Ganly, a fellow employee of Dennys. The Ganly name was well known within Dennys, with three generations of the Ganly family working at the company. WORKING CONDITIONS & OFFICE WORK DUTIES. Written by Margaret Burn in 2021. Worked at Dennys Lascelles in the 1930s. In the 1930s coming out of the Depression, jobs were hard to come by and had to be clung to by efficiency and subserviency. There was no union to protect workers – bosses could be tough and rough. Dennys Lascelles revolved around fortnightly wool sales in the “season” – September to May. Sale day was always a day of suppressed excitement. Preparation from a clerical point of view was complete and we now awaited the aftermath of the actual wool auction. The building teemed with people. There were country people down to see their wool sold, buyers of many nationalities, or from the big cities, who were coming in and out of the building all day. Their role was to inspect the acres of wool bales displayed on the show floors; however, caterers were present to feed clients, and there was plenty of social interactions on top of business. The office staff did not go home but waited until the first figures came back from the wool sales and the machines went in to action, both human and mechanical, preparing the invoices for the buyers’ firms. This comprised of lists of lot numbers, weights, prices per lb., and the total prices paid. A lot of this was done by old-school typewriters, making this work a big, heavy, tiring job. Before the finished lists could be dispatched, they were collated on an “abstract”. The lists had to balance with the catalogue from which the invoices had been prepared. This never happened automatically. All the paperwork had to be split up amongst pairs of workers and checked until discrepancies were found. This would happen until midnight but occasionally went until 2 or 3 am. Once complete, the invoices could then be rushed off to the buyers’ firms usually in Melbourne, and hire cars took the staff home. It was back on the job the next morning, usually around 8.30. The office hours varied according to the size of the sale and work involved. Some days started as early as 8 and could finish around 5.30. The second phase of work began with the account sales to be prepared for the sellers of the wool. These detailed all the weights, descriptions of wool, brands, and prices. One Sales account could have multitudes of lot numbers, all needing to be individually described. Various charges needed to be deducted such as finance for woolpacks, extra stock, or farmers who were given a loan to live on during the season. Details of how payment was to be made was also noted, whether the seller was to be paid by cheque, to a bank, or credited to their account with the company (which often left the seller still in debt). For a couple of months in the winter, things were quieter when staff took holidays and were sometimes given afternoons off. But there were still weekly skin sales and stock sales around the state. The annual end of June figures to be prepared for a big company like Dennys with branches all around the state also kept the staff busy. In good years there was sometimes a bonus. On sale days there was a bar open for the clients and wool buyers. This added to the excitement for the young girls, who were strictly barred from using it, but somehow managed to sneak a gin and tonic. This is how I had my first ever, before the evening meal. There was also the romantic notion in some minds, with all the influx of males, that some of us might end up on a wealthy station, or be noticed by an exotic buyer. To my knowledge, this never happened at Dennys Lascelles Limited. Group staff photo at Dennys Lascelles Limited. Margaret Burn. Age 18 or 19. Jack Ganly (Margaret’s future husband). 22.The typewriter has a black painted metal frame. The top section of the typewriter consists of a cylindrical platen on a carriage featuring plated metal fittings. A curved folding paper guide sits behind the platen and moves on the horizontal axis when the user types on the keyboard. A horizontal semicircular type basket with typebar links the top section to the lower keyboard. The ink ribbon is carried between two spools on a horizontal axis, one on each side of the type-basket. At the rear, a paper tray features gold lettering which reads ‘Remington’. At the front, a four-row QWERTY keyboard is found with 42-character keys total. 'SHIFT LOCK' and 'SHIFT KEY' are to the left of the keyboard, 'BACK SPACER' and 'SHIFT KEY' to the right. All keys are circular, white with black lettering. At the top of the keyboard are five circular red keys with the numbers 1-5 displayed behind their respective keys. A Spacebar is found along the front of the keyboard. The typewriter is accompanied by a cardboard box. This box contains the original sales receipt, on blue paper with grey lead handwriting. It also contains spare parts, a spare ribbon stretched between two spools, and cleaning tools such as brushes of differing sizes. Serial Number. Engraved. "LX45395" Gold lettering. Paper tray. “Remington” Gold Lettering. Behind keyboard. “Made in Ilion, New York, U.S.A. Gold Lettering. Mirrored both sides of type-basket. “12”remington, dennys lascelles ltd, worker conditions 1930s -

National Wool Museum

National Wool MuseumTool - Knitting Pins, 1960-69

The donor (Lynn Fitzpatrick) purchased these knitting needles 20 years ago from an opportunity shop. Aero Knitting Pins are a discontinued brand that were popular in the 1960s, 70s and 80s. They are made of smooth, aircraft-quality anodized aluminium. To this day, they are a popular and sort after knitting needle. Being a long-lasting product, they are often given as heirlooms. Abel Morrall was a major needle manufacturer from Studley, a town near Redditch. In 1785, Michael Morrall who was taught the art of needle making by a maternal uncle, moved to Studley. He founded the Abel Morrall company with his brother Abel, and another unnamed brother-in-law. Within five years the company was producing 40% of the 2.5 million needles that were made each week in the Redditch area. In 1811 the company introduced the concept of creating the eyes by using a stamping press. Additional machines were invented by them throughout the 19th century leading to major improvements in the way needles were produced. Abel Morrall demonstrated their needle making machinery at the Great Exhibition of 1851 and Queen Victoria personally inspected it. The company selected the demi-griffin for its trademark in 1861, which can be seen on older products produced by the company. Set of four knitting needles stored within paper packaging. Packaging features black, red, and white ink, detailing the selling points of the Aero Knitting Pins. The packaging folds with 3 main sections, each providing different insights into the knitting needles. Examples of this are " CANNOT SOIL LIGHT WOOL", "...SPECIALLY TAPERED POINTS WHICH WILL NOT INJURE THE FINGERS" and "RUSTLESS-NON-GLITTER FINISH". As the packaging unfolds, the grey knitting needles become visible. The needles can be removed from the packaging by sliding them through small bands of paper that hold the needles secure while in transportation. The four knitting needles are a “NEUTRAL” grey colour finished in a double point style.Printed. Orange, White and Black Ink Numerous, see multimediaabel morrall, knitting needles, knitting pins, 1960s home knitting -

National Wool Museum

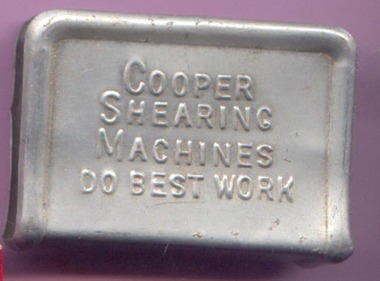

National Wool MuseumMatchbox Holder

This matchbox holder / striker was made to advertise Cooper's shears, a well known Australian brand of sheep shears. An image of a mechanical Cooper's shear can be seen on one side.Matchbox holder, advertising Cooper's Shearing Machines. Matchbox holder, advertising Cooper's Shearing Machines. Matchbox holder, advertising Cooper's Shearing Machines. The area for striking matches can be seen. Matchbox holder, advertising Cooper's Shearing Machines.COOPER / SHEARING / MACHINES / DO BEST WORK NEW MODEL / COOPER / SHEAR PROV. PAT. / 16367shearing, cooper engineering company pty ltd -

National Wool Museum

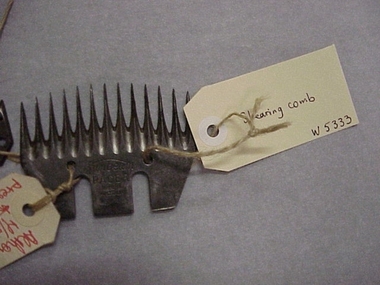

National Wool MuseumShearing comb

Shearing machine comb inscribed "Sunbeam PACER".Sunbeam PACER/ MADE IN AUSTRALIA Although the L/H/pce appears to have been presented complete/with combs and cutter/ I feel the tools are modern/ TC.3/11/93shearing animal health sheep stations - management, shearing, animal health, sheep stations - management -

National Wool Museum

National Wool MuseumTextile - Child's Quilt, 1930s - 1940s

... This wagga has been made of regular sized, machine sewn...-and-the-bellarine-peninsula This wagga has been made of regular sized ...This wagga has been made of regular sized, machine sewn patches of mens suiting fabrics. The fabrics would almost certainly have been sourced from a sample book of fabrics for mens suits, owing to their regular size and the fact that many have the same pattern but vary in colour.Wagga, made from samples of mens suiting in machine sewn patchwork.patchwork, wagga, fabrics, mens suits, pattern, necessity -

National Wool Museum

National Wool MuseumQuilt, Floral chintz quilt

Quilt made from pink patchwork curtain cloth, machine stitched and patched at a later date by hand. Part of the Wagga collection.Quilt made from pink patchwork curtain cloth, machine stitched and patched at a later date by hand.quilting history, patchwork history, running stitch group, running stitch collection, quilting - history, patchwork - history -

National Wool Museum

National Wool MuseumQuilt, Commercially made quilt

Commercially made quilt, c.1930s. Maker unknown, found in Ballarat. The Country Women's Association of Victoria had been active during the Depression in promoting the use of wool in domestic items and handcrafts in its "Handcrafts and Home Industries Committee". In 1933 during "Wool Week", a train jointly sponsored by the Wool Board, toured the state demonstrating amongst other crafts, the making of wool quilts and mattresses. Commercially made quilts much like this one marketed as 'Kosy Quilts', were used in these demonstrations.Quilt, plain light blue cotton cover with lambs wool filler. Machine sewn. Evidence of a label can be seen at one corner, however it has been removed.quilting history, textile mills, running stitch group, running stitch collection, ballarat, quilting - history -

National Wool Museum

National Wool MuseumTextile - Suitings Quilt

Origins are unknown, however it may be possible that since the creator of this quilt has used larger than usual pieces of suiting material, they may have worked as or knew of a tailor for their fabrics.Quilt made of large strips of men's suiting fabric. Machine stitched. Red flannel backing.quilting history, patchwork history, running stitch group, running stitch collection, quilting - history, patchwork - history -

National Wool Museum

National Wool MuseumTextile - Quilt, 1910 - 1940

Part of the "Wagga collection". Made from squares of patchwork suiting, machine stitched with red diamond and rectangle motifs at strategic positions. The diamonds look like they have been inserted in the fabric pieces where a dart has been cut and opened out.Quilt made of squares of patchwork suiting and fabric offcuts, machine stitched with red diamond and rectangle motifs at strategic positions.quilting history, patchwork history, running stitch group, running stitch collection, quilting - history, patchwork - history -

National Wool Museum

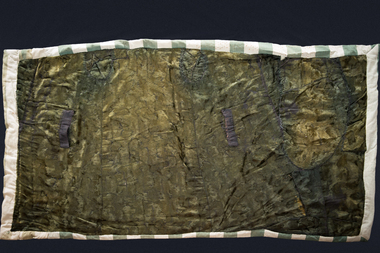

National Wool MuseumQuilt, Travelling rug

Part of the Wagga collection. Maker unknown, c. early 1940s. Possibly from South Australia. This 'travelling rug' was found in an opportunity shop in Campbell's Creek near Castlemaine in Victoria. Unfortunately, nothing is known about the maker but it could be surmised that the quilt had many uses. It is heavy and designed for warmth, lined with a woollen blanket and hessian. Its size suggests usage in an open buggy or car when travelling or as a picnic rug along the way. The sturdy canvas backing is of the type commonly used for awnings, chair coverings or tent cloth. The quality of the green velvet made it ideal for further use as a quilt after the original use as an overcoat or smoking jacket for either a man or a woman. Apart from the original machine stitched seams in the garment, it is sewn together by hand using herringbone stitch. It is not known if this quilt was designed to be used with a cover. However, the arrangement of pieces in the garment to create a shape with straight edges may suggest that this may have been a consideration.Travelling rug made of wool, cotton and green velvet.No. 27 "Travelling rug" Maker Unknown Running Stitch Collection...quilting history, handicrafts, running stitch group, blankets, running stitch collection, highlights of the national wool museum: from waggas to the wool quilt prize - exhibition (22/09/2001 - 02/12/2001), quilting - history -

National Wool Museum

National Wool MuseumTextile - Quilt, Pamela Farmer, Earth Blanket, 2000

'Earth Blanket' is a quilt made by Pamela Farmer of Shoreham, Victoria in 2000. It is made from a wool blanket with merino and alpaca felt. The techniques used to make it include: felting, applique, quilting, machine and hand embroidery and it has been dyed with eucalyptus leaves. This quilt was an entrant in "Expressions 2000: the wool quilt prize"; an acquisitive exhibition held by the National Wool Museum from 16 Sept. 2000 to 3 Dec. 2000 (extended until 2 Feb. 2001) for contemporary art quilts, with the first prize winning $2000. 'Earth Blanket' was selected as the winner of this exhibition and was purchased for $2000. It was catalogue entry no. 5.Quilt, woollen felt with appliqued, quilted, dyed and embroidered surface. This quilt is mostly in brown and brown tones.P.F.quilting handicrafts, masters of technique: creators on cloth - exhibition (15/06/2001 - 22/07/2001) expressions 2000: the wool quilt prize - exhibition (16/09/2000 - 04/02/2001) highlights of the national wool museum: from waggas to the wool quilt prize - exhibition (22/09/2001 - 02/12/2001), farmer, ms pamela, quilting, handicrafts -

National Wool Museum

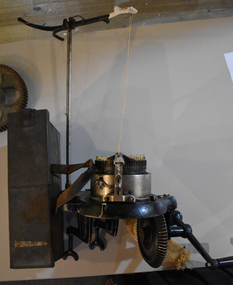

National Wool MuseumMachine - Knitting Machine, Sock

Knitted fabric is made with a single yarn or sets of yarns moving in only one direction. Whether done by hand or by machine, the process is the same. The knitting needle loops the yarn through itself to make a chain of stitches. These chains, or rows, are connected to produce the knitted cloth. There are two types of commercial knitting machine. A flat-bed has its needles, one for each loop, arranged in a straight line to produce a flat fabric. A circular machine has its needles arranged on a rotating circle. The cloth forms as a tube which can be made into seamless clothing. Personal history of Edna Harris who used the machine.knitting machine, industry, design, socks, clothing, wool -

National Wool Museum

National Wool MuseumMachine - Sock Knitting Machine, G Stibbe and Co, c.1928

Knitted fabric is made with a single yarn or sets of yarns moving in only one direction. Whether done by hand or by machine, the process is the same. The knitting needle loops the yarn through itself to make a chain of stitches. These chains, or rows, are connected to produce the knitted cloth. There are two types of commercial knitting machine. A flat-bed has its needles, one for each loop, arranged in a straight line to produce a flat fabric. A circular machine has its needles arranged on a rotating circle. The cloth forms as a tube which can be made into seamless clothing. Dellruss Pty Ltd original owner Llyold Henry Coburg. Mock ribber fitted post World War 2. In use from c.1928 until 1978.Stibbe Maxim circular sock knitting machine.sock knitting machine, manufacturing, textiles, socks, machines, circular, clothing, industry, wool -

National Wool Museum

National Wool MuseumMachine - Sock Knitting Machine

Knitted fabric is made with a single yarn or sets of yarns moving in only one direction. Whether done by hand or by machine, the process is the same. The knitting needle loops the yarn through itself to make a chain of stitches. These chains, or rows, are connected to produce the knitted cloth. There are two types of commercial knitting machine. A flat-bed has its needles, one for each loop, arranged in a straight line to produce a flat fabric. A circular machine has its needles arranged on a rotating circle. The cloth forms as a tube which can be made into seamless clothing. Griswold bench-type sock knitting machine hand operated by turning the handle.sock knitting machine, textile industry, wool, fashion, clothing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Clothing - Wedding dress, 13.5.1945

Worn by Jessie Allan for her marriage to William Thomas Kenny on 13 May 1945 at St Stephens Church, Richmond. They lived in 19 Baldwin Road, Blackburn from 1965. Jessie deceased 1.4.2010. Funeral at St Alfred's Anglican Church, Blackburn South.1945 Cream satin wedding dress with a rouched bodice to a centre panel, high neckline and pointed collar. Bead work on centre panel and edge of bodice, long sleeves to a pointed wrist and beading. Thirty covered buttons down centre back. Skirt cut on cross and three metre train at back.|.2|Champagne coloured Wedding Veil - (approx 6ft in length) - complete with orange blossom 3 1/4' headdress. Headdress is handmade, attached to a wire frame|.3|Cream satin slipper. Machine stitched half in rows. Bow with satin loop and spray of wax orange blossom attached.|.4|Horse shoe shaped wedding item to hang over bride's arm. Rouched satin with ornamental - artificial (wax) orange blossom and buds with 2 mm ribbon to hang over arm. Cream coloured to match wedding dress.|.5|Satin horse shoe, rouched, with satin ribbon handle.|.6|Cream braided horse shoe with gilded wishbone and wax orange spray attached. A bow with long loop to hang on the arm.|.7|Satin Horseshoe Good Luck charm with 'petal' flowers surrounding it, made of cut material - ribbon bow with pearls in centre.|.8|Doll in taxi - Rosy-cheeked, dark hair, blue eyes, dressed in bridal dress with veil, with pearls and 'flowers' decorating the doll. The doll stood across the back seat, under the window. Lavender in base of stand.|.9|Bridal Ring Box - 'Good Luck' horseshoe charm box - in the shape of a prayer book. Cream box with silver motifs printed on.|.10|Groom's Buttonhole of spray of wax orange blossom - 4 flowers and 3 leaves. Cream flowers with yellow stamens - green leaves. 10 Items in total..7 'Wishing you all The Best' 'Good Luckcostume, female ceremonial