Showing 773 items matching "mechanical"

-

Puffing Billy Railway

Puffing Billy RailwayV. R. Krupp 1888. IV. Rail, 1888

60lbs rail that was used throughout the Victorian rail network. In 1887 Gibbs, Bright and Co. had a contract with Victorian Railways for railway and canal construction and supply of Krupp Rails. Gibbs, Bright and Co were merchant bankers and shipping agents and merchants who where also Directors of the GWR ( Great Western Railway ) and the Ship The "Great Britain" in England Gibbs, Bright and Company had principally been involved in shipping and trading, mainly in the West Indies, but following the discovery of gold in Victoria they established an office in Melbourne and soon became one of the leading shipping agents and merchants in the Colony. They expanded into passenger shipping and soon established offices in Brisbane, Sydney, Newcastle, Adelaide and Perth as well as launching passenger services between England, Mauritius and New Zealand. Gibbs, Bright also held a number of financial agencies from British mortgage, finance and investment companies as well as representing several British insurance companies in Australia. In addition they conducted a growing import business as well as an export business that included livestock, dairy produce, wool and flour. Also the company played a substantial part in the development of Australia's mineral resources, starting with lead in 1895, and later venturing into tin, gold, copper, cement and super phosphates. In Australia, after WWI, many of the larger companies were managing their own import and export so Gibbs, Bright and Company tended to focus its Agency business on smaller companies while expanding their interest into other markets such as timber, wire netting, zinc, stevedoring, road transport, marine salvage, gold mining as well as mechanical, structural, electrical and marine engineering. The Company's shipping interests continued to grow as well and still formed a major part of its business. In 1948 the parent company in England took the major step from tradition when they changed the business from a partnership into a private limited company. The name was the same, Antony Gibbs and Sons Limited, and in practice the effect of the change was very little. Some of the firm's branches and departments had already become limited companies and the formation of a parent company simplified the structure. The Australian operation was in time changed to Gibbs Bright & Co Pty Ltd in 1963. In 1848 Alfred Krupp becomes the sole proprietor of the company which from 1850 experiences its first major growth surge. In 1849 his equally talented brother Hermann (1814 - 1879) takes over the hardware factory Metallwarenfabrik in Berndorf near Vienna, which Krupp had established together with Alexander Schöller six years earlier. The factory manufactures cutlery in a rolling process developed by the brothers. Krupp's main products are machinery and machine components made of high-quality cast steel, especially equipment for the railroads, most notably the seamless wheel tire, and from 1859 to an increased extent artillery. To secure raw materials and feedstock for his production, Krupp acquires ore deposits, coal mines and iron works. On Alfred Krupp's death in 1887 the company employs 20,200 people. His great business success is based on the quality of the products, systematic measures to secure sales, the use of new cost-effective steel-making techniques, good organization within the company, and the cultivation of a loyal and highly qualified workforce among other things through an extensive company welfare system. From 1878 August Thyssen starts to get involved in processing the products manufactured by Thyssen & Co., including the fabrication of pipes for gas lines. In 1882 he starts rolling sheet at Styrum, for which two years later he sets up a galvanizing shop. The foundation stone for Maschinenfabrik Thyssen & Co. is laid in 1883 with the purchase of a neighboring mechanical engineering company. In 1891 August Thyssen takes the first step toward creating a vertical company at the Gewerkschaft Deutscher Kaiser coal mine in [Duisburg-]Hamborn, which he expands to an integrated iron and steelmaking plant on the River Rhine. Just before the First World War he starts to expand his group internationally (Netherlands, UK, France, Russia, Mediterranean region, Argentina). info from The company thyssenkrupp - History https://www.thyssenkrupp.com/en/company/history/the-founding-families/alfred-krupp.htmlHistoric - Victorian Railways - Track Rail - made by Krupp in 1888Section of VR Krupp 1888 Rail mounted on a piece of varnished wood. Rail made of ironpuffing billy, krupp, rail, victorian railways -

Puffing Billy Railway

Puffing Billy RailwayPhoenix Foundry Plate

Phoenix Foundry Plate - replica Made about 2010 cast off original from locomotive Y112 The Phoenix Foundry (1857-1906) fabricated iron and brass products - including engines and pumping gear for the mining industry, locomotives, steam rollers, water pipes, water gauges and diverse small items. Throughout its operation the business was located at premises on Armstrong Street, Ballarat . Background In 1852, at the age of thirty-three and after a year of operating his own engineering business at Williamstown, Lancashire-born blacksmith and engineer George Threlfall (1819-1897) arrived on the Sebastopol gold plain and immediately undertook blacksmith work repairing picks and tools for the miners. Little did he know that this fledgling business would be the genesis of the most iconic business of nineteenth-century Ballarat. At approximately thirty-nine years of age, English mechanical engineer Richard Carter (c1814-1883) came to Australia on board the Arrogant - arriving in Melbourne on 19 April 1853. He soon travelled to the Ballarat goldfields. Born in the year 1830 in Belfast (Ireland), mechanical engineer William Henry Shaw (1830-1896) arrived in Australia in October 1853. He worked briefly with George Threlfall at Sebastopol, then moved to Geelong to manage the small foundry of Frederick Moore. Twenty-four year old English-born iron moulder Robert Holden (c1831-?) left his home in Belfast (Ireland) in late 1854 and travelled from Liverpool to Melbourne on board the James Baines - arriving in February 1855. Afterwards he joined his brother-in-law William Henry Shaw in Ballarat. History Foundation to Incorporation In March 1857 George Threlfall joined in business with Richard Carter, William Henry Shaw and Robert Holden. They relocated Threlfall's successful engineering enterprise from Sebastopol to new premises in Armstrong Street, Ballarat. This business was then known variously as the Phoenix Iron Works Company, Phoenix Foundry or Messrs Carter and Co. By 15 April 1857 they were advertising that they were open for business as engineers, millwrights, boiler makers, smiths, iron founders and brass founders. In January 1858 George Threlfall left the partnership. Incorporation to 1889 1890 to Closing locomotive Y112 Builder: Phoenix Foundry, Ballarat Builder’s Number & Year: 238 of 1889 Designer: Kitson & Co Wheel Arrangement: 0-6-0 No. in class: 31 Entered Service: 24 July 1889 Taken off Register: 11 May 1961 The origins of the Victorian Railways Y-class lay with the decision by Kitson & Co, Leeds to place a 0-6-0 freight locomotive on display at the Centennial International Exhibition, Melbourne in 1888, together with a 2-4-2T suburban passenger locomotive. This marketing initiative proved successful as the Victorian Railways were clearly impressed with these machines, with both purchased after the exhibition and becoming the patterns for new standard locomotive types. Thirty examples of the 0-6-0 heavy freight design were ordered from the Phoenix Foundry, Ballarat, becoming the Y-class for main line heavy freight duties, while the 2-4-2T design became the E-class for Melbourne suburban passenger duties (represented by preserved locomotive E 236). The Y-class prove successful in service and accrued high mileages. They were inevitably superseded by more modern and powerful steam locomotives and a number cascaded into shunting and yard pilot duties, often with the addition of shunters steps along both locomotive and tender. Y 112 was one of the last in service when withdrawn in 1961. Fortunately it was saved for preservation and plinthed in central Ballarat, ostensibly in commemoration of Phoenix Foundry. I understand it is owned by the Sovereign Hill Museums Association. During the 1980’s, Y 112 was leased to Steamrail Victoria and restored to operation at an industrial site in Ballarat. Y 112 features an attractive lined apple green livery and has performed various rail tours around Victoria since restoration. It is normally based at the Steamrail depot in Ballarat East. Y 112 is the only 19th century design in operational condition in Victoria and as such is one of the oldest working steam locomotive in Victoria . Historic - Phoenix Foundry Plate - replica Made about 2010 cast off original from locomotive Y112Phoenix Foundry Plate Oval shaped plate with an image of a phoenix centered at the top with lettering surrounding it.Phoenix Foundry No 238 Ballarat Company Limited 1889.puffing billy, phoenix foundry, ballarat, locomotive y112, phoenix foundry plate - replica -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageShip Log, 1900-1920

Thomas Walker & Son was internationally renowned in the manufacturing of ships logs. Founding father Thomas Walker (1805–1871), an engineer in Birmingham, patented a mechanical log in 1878 which was a recording instrument that attached to a rail at the stern of a vessel connected by a long cord with a rotor which was towed behind the ship. The instrument dial recorded the distance travelled. Thomas Walker first went into business to manufacture stoves at 58 Oxford Street Birmingham. Walker’s self-feeding stove was widely lauded at the Paris Exhibition of 1855, winning a prize medal and kick starting the first of many notable innovations for the Walker family's manufacturing business. However, it wasn’t until working on an earlier ships log model invented by his Uncle that Thomas Walker became interested in the further development of this device, used to ascertain a ship’s speed. Walker continued to improve on the common log for the company of Massey & Sons and these improvements were deemed revolutionary. This log became a firm favourite of the West India Association (British-based organisation promoting ties and trade with the British Caribbean) and the most common log in use for two generations. It took till 1861 for Thomas Walker and his son, Thomas Ferdinand Walker (1831-1921) to patent the first Walker log of many. Together, with the introduction of the A1 Harpoon Log two years later, they established the Walker Log Business as a force to be reckoned with. By the time of his passing in 1871, Thomas Walker Snr had not only founded a family business with considerable staying power but also instilled a tradition of public service. Having sat as a representative on the Birmingham Town Council for 15 years and played an active role in public works, he was soon given the nickname of ‘Blue Brick Walker’. Much like his father, Thomas Ferdinand Walker changed the face of the maritime industry. His patent of 1897, the ‘Cherub’ log, was a notable departure from the past providing a far more accurate reading and replacing the majority of logs of the age. They were the first to produce an electric log and the Walker factory was one of the first to introduce the 48 hour work week for employees. This ship log was invented and made by a significant marine instrument maker and innovator of machinery. It demonstrates the huge leap taken to improve navigational accuracy at sea with an instrument that was in use for decades. Ship Log, three analogue dials calibrated in increments of Miles, the Rocket Log is a nautical instrument for measuring a vessel’s speed and distance traveled. The floating log was drawn behind the ship over a fixed time period in order to measure the distance traveled. The counter could measure enough miles to cover the maximum distance traveled by a ship in one day. The log has two distinct parts; a brass register, made by Walker, showing the distance recorded and the rotator made by Reynolds, that spins in the water driving the counter. both parts are connected by a linked chain. The register has a cylindrical brass body approx 4.5 cm diameter containing registering mechanism with hardened steel bearings. Distance is indicated by the three pointers on enamel plate as follows: graduated every 10 miles from 0-100; every mile from 1-10; every 1/4 mile from 1/4 -1. A brass sling and eye secured to the body enables it to be attached to the taffrail. The original rotator would have had a cylindrical tapered wooden body, approx 4.5 cm in diameter with three metal alloy fins or could be all made from brass. A towing eye is fitted to the tapered end. The two pieces of apparatus are connected by a length of linked chain, length 22.9 cm."Walkers Rocket Ship-Log Birmingham (Patented)" printed on face-plate. "Made by Thomas Walker".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ship log, rocket log, mechanical ship log, measuring instrument, marine instrument, nautical instrument, speed recording instrument, ship log register, walker ship log, walkers rocket ship-log, thomas walker, thomas walker & son, thomas ferdinand walker, walker log business, reynolds ship log rotor, taffrail log, taff rail log, west india association -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTins - Tobacco (Lucky Hit) x4, Mid to late 1900s Possibly c1910

The British Australasian Tobacco Co. (based in Melbourne and Sydney. The parent company was founded in England, circa 1902). This item "Lucky Hit" was the fore runner of the "Lucky Strike" brand name. The ready rubbed tobacco held within the tin was mainly used by those smokers who rolled their own cigarettes. These smokers would have mainly used their palm and formed a cup then placing their choice of the amount of tobacco to be rolled. This would then be placed on the fine cigarette paper and rolled and sealed (using saliva in the mouth) into the required shape. There were mechanical "roll you own" gadgets on the market but most rural users, especially males used their palms. The quantity of tobacco used to make up the cigarette was up to the individual user. The thinner that the cigarette was rolled the longer and more economical did the supply last. The by -products of this method were nicotine stained fingers and hands. "Chain" smokers were easily identified and could therefore be discriminated against obtaining smoke sensitive employment. The two world wars (1914-18 and1939-45) produced a significant rise in the consumption of cigarette use by men and the eventual overflow to women. Cigarette smoking before the 1900s was seen as rough and uncouth (socially frowned upon), however after the introduction of overseas films (U.K. and U.S.A.) and film stars presenting smoking as socially acceptable the rise of smoking cigarettes, especially roll you own (American western movies) in rural areas was an accepted way of life. Things however started to change in the mid 1900s when medical evidence pointed to the health problems of regular smokers. Governments were now implementing non smoking education material. Restrictions on where and when smoking was permitted and acceptable started to creep into all areas of society whether city or rural. This was the era that highlighted the use of roll your own cigarettes, especially when the costs of "tailor made" cigarettes were taxed at an increasing amount. Roll your own cigarettes also provided an avenue for the consumption of illicit drug use.The significance of this ready rubbed tobacco tin to this rural region is, stems from how much influence that the Western novels and overseas films (portraying rural lifestyles) played in shaping the rural social and working mores of the Kiewa Valley. The post war depression (financially) resulted in more smokers turning away from expensive machine (tailor) made cigarettes to the roll your own, using ready rubbed tobacco. This tobacco tin relays a long ago era, when personal contact, and not something that has been written down by some "unknown", was valued as the true appraisal of a member of the community. This was especially relevant in a small regional area such as the Kiewa Valley. Although social networking was not as fast then as the internet provides now, appearances, manners, fashion and etiquette with first impressions high on the order of evaluating someone in the community. Pointer such as the brand of tobacco smoked was part of the rural assessment method. Up until the demise of the Australian Tobacco Industry, circa 2004, the Kiewa Valley and surrounding district was part of a vibrant producer of tobacco leaves. The remnants of this industry still remain today but the drying sheds (for tobacco leaves) are now used to store hay for the valley's dairy and beef cattle industries. Tins 2,3 and 4 were found (in 2009) at Wallace's Hut on the Bogong High Plains. This tobacco tin is constructed from tin plated thin rolled steel. The lid is attached by two pressed and formed (from the main frame) hinges using the nip and tuck construction method. The lid and outside frame have been gold & silver anodised. Tins 2,3 and 4 have the Union Jack on the front lid. One is too rusty to read. The other two have "A blend containing choice selected Australian grown leaf" in white across the bottom on the red border and above the "2oz net weight when packed". In the centre and on the outside of the lid and surrounded by a reproduction of the "Union Jack" is stamped, "Lucky Hit Tobacco" within these words are also stamped "Ready Rubbed". The bottom of the lid is stamped (in smaller script) "2oz NET WEIGHT WHEN PACKED" and underneath this and on the rim of the lid is "THE BRITISH AUSTRALASIAN TOBACCO CO. PTY. LTD. MELBOURNE" on the inside of the lid and stamped in black print on a gold anodised lid is " NOTICE "(underlined) "Every tin of genuine "Lucky Hit has the name of the Manufacturing Company printed on wax paper lining; also on the band or wrapper with which the tin is sealed. THE BRITISH-AUSTRALIAN TOBACCO CO. PTY. LTD., MELBOURNE" and underneath this and underlined is " None genuine without the band or wrapper" On the hinge side of the lid is "LUCKY HIT READY RUBBED TOBACCO" Tins 2,3 and 4 Vary to the above inscription.roll your own, cigarette tins, smoking accessories, personal effects, tobacco containers, tobacco -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTin Tobacco, Mid to late 1900s

The British Australasian Tobacco Co. (based in Melbourne and Sydney. The parent company was founded in England, circa 1902). This item "HAVELOCK" is one of many ready rubbed tobacco tins produced by the British Australasian Tobacco Company.The ready rubbed tobacco held within the tin was mainly used by those smokers who rolled their own cigarettes. These smokers would have mainly used their palm and formed a cup then placing their choice of the amount of tobacco to be rolled. This would then be placed on the fine cigarette paper and rolled and sealed (using saliva in the mouth) into the required shape. There were mechanical "roll you own" gadgets on the market but most rural users, especially males used their palms. The quantity of tobacco used to make up the cigarette was up to the individual user. The thinner that the cigarette was rolled the longer and more economical did the supply last. The by -products of this method were nicotine stained fingers and hands. "Chain" smokers were easily identified and could therefore be discriminated against obtaining smoke sensitive employment. The two world wars (1914-18 and1939-45) produced a significant rise in the consumption of cigarette use by men and the eventual overflow to women. Cigarette smoking before the 1900s was seen as rough and uncouth (socially frowned upon), however after the introduction of overseas films (U.K. and U.S.A.) and film stars presenting smoking as socially acceptable, the rise of smoking cigarettes, especially roll you own (American western movies) in rural areas was an accepted way of life. Things however started to change in the mid 1900s when medical evidence pointed to the health problems of regular smokers. Governments were now implementing non smoking education material. Restrictions on where and when smoking was permitted and acceptable started to creep into all areas of society whether city or rural. This was the era that highlighted the use of roll your own cigarettes, especially when the costs of "tailor made" cigarettes were taxed at an increasing amount. Roll your own cigarettes also provided an avenue for the consumption of illicit drug use.The significance of this ready rubbed tobacco tin to this rural region is, stems from how much influence that the Western novels and overseas films (portraying rural lifestyles) played in shaping the rural social and working mores of the Kiewa Valley. The post war depression (financially) resulted in more smokers turning away from expensive machine (tailor) made cigarettes to the roll your own, using ready rubbed tobacco. This tobacco tin relays a long ago era, when personal contact, and not something that has been written down by some "unknown", was valued as the true appraisal of a member of the community. This was especially relevant in a small regional area such as the Kiewa Valley. Although social networking was not as fast then as the internet provides now, appearances, manners, fashion and etiquette with first impressions high on the order of evaluating someone in the community. Pointer such as the brand of tobacco smoked was part of the rural assessment method. Up until the demise of the Australian Tobacco Industry, circa 2004, the Kiewa Valley and surrounding district was part of a vibrant producer of tobacco leaves. The remnants of this industry still remain today but the drying sheds (for tobacco leaves) are now used to store hay for the valley's dairy and beef cattle industries.This tobacco tin is constructed from tin plated thin rolled steel. The lid is attached by two pressed and formed (from the main frame) hinges using the nip and tuck construction method.The lid and outside frame have had a green "weave" pattern anodised to the metal.On the outside of the lid and at the top left is stamped, in gold coloured letters "HAVELOCK". The bottom of the lid is stamped (in smaller script) "READY RUBBED TOBACCO" and below this in smaller lettering "2oz NET WEIGHT WHEN PACKED". On the rim of the lid is "THE BRITISH AUSTRALASIAN TOBACCO CO. PTY. LTD." Inside of the lid and stamped in black print on a gold anodised lid is "Every tin of genuine HAVELOCK Ready Rubbed Tobacco has the mane Havelock printed on the paper lining, and also on the band or wrapping sealing the tin. On the hinge side of the lid is "HAVELOCK READY RUBBED"roll your own, cigarette tins, smoking accessories, personal effects, tobacco containers -

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - Submission for Approval, VIOSH: Ballarat College of Advanced Education; Submission to the Victorian Institute of Colleges, 1978

Victorian Institute of Occupational Safety and Health (VIOSH) Australia is the Asia-Pacific centre for teaching and research in occupational health and safety (OHS) and is known as one of Australia's leaders on the field. VIOSH has a global reputation for its innovative approach within the field of OHS management. VIOSH had its first intake of students in 1979. At that time the Institution was known as the Ballarat College of Advanced Education. In 1990 it became known as Ballarat University College, then in 1994 as University of Ballarat. It was 2014 that it became Federation University. VIOSH Australia students are safety managers, senior advisors and experienced OHS professionals. They come from all over Australia and industry. Students are taught active research and enquiry; rather than textbook learning and a one-size fits all approach. VIOSH accepts people into the Graduate Diploma of Occupational Hazard Management who have no undergraduate degree - on the basis of extensive work experience and knowledge. Ballarat College of Advanced Education had been trying for approval of a PG1 Graduate Diploma in Occupational Hazard Management during 1976 and 1977. This last application was 1978. They were hoping to introduce it in 1979. Present at this meeting held on Tuesday 8th August 1978 were representatives from: EAC Subcommittee; W J Robertson (Convenor), Dr K B Brown (Medical Officer}, Dr A J Christophers (Chief Industrial Hygiene Officer, Dept of Health, E O'Keefe (Secretary to the Committee) Ballarat CAE Course Advisory Committee; W Jinkins (Safety Engineer, Gas & Fuel), E Wigglesworth (Injury Research Unit, Royal College of Surgeons) Ballarat College of Advanced Education; D J Woolley (Head of School of Engineering), T D Norwood (Head of Dept Mechanical Engineering), D Viner (Course Co-ordinator}, G Fernandez (School of Business} Recommendation that the proposed course for the award of PG1 Graduate Diploma in Occupational Hazard Management at Ballarat College of Advanced Education be approved for introduction in 1979 at first year level. This still needs approval from the Tertiary Education Commission for the purposes of the expenditure of funds under the provision of the State Government.Ten A4 pages - typed. Four correspondence and six the Draft of course for the applicationLetterhead of Victoria Institute of Colleges and the Prime Minister, Canberra Signature: R I Viner - Minister assisting the Prime MInister in Public Service Matters Elizabeth O'Keefe - Secretary to the Academic Committee in Engineering, V.I.C.viosh, victorian institute of occupational safety and health, ballarat college of advanced education, pg1, graduate diploma in occupational hazard management, minister assisting prime minister, r i viner, elizabeth o'keefe, victoria institute of colleges, vic academic committee, w j robertson, k b brown, a j christophers, bcae advisory committee, w jinkins, e wigglesworth, bcad staff, d j woolley, t d norwood, d b viner, g fernandez, royal australian college of surgeons, department of health, gas and fuel corporation, medical officer olympic tyres, school of engineering, mechanical engineering, school of business, tertiary education committee, state government, state grants -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, 1903

Hugo Wertheim (1854-1919), was a merchant and manufacturer and was born on the 12th July 1854 at Lispenhausen, in the German electorate of Hesse-Kassel, son of Meyer Wertheim and his wife Minna, née Heinemann. Hugo reached Melbourne in October 1875. He soon began advertising, from premises at 39 Flinders Lane East, as agent for his father's cousin Joseph Wertheim, a well-established manufacturer of sewing machines. Hugo returned to Germany where he married Joseph Wertheim's daughter Sophie Emilie (1864-1953) on 30 August 1885 at Frankfurt. the couple then came to Melbourne. In a short time, with extensive advertising, Hugo established a substantial business, selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He also mounted elaborate displays at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. O. C. Beale worked with him before setting up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Wertheim opened a large, innovative piano factory at Richmond, Melbourne, intending to produce 2000 pianos and player pianos annually, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis on 11 July 1919 at his home at South Yarra, his wife, two daughters and three sons survived him; Herbert Joseph (1886-1972), the eldest, continued the business. Rupert became a share broker and went on to represent Victoria in inter-State tennis in 1913-27 and Australia in Davis Cup matches against Czechoslovakia in 1922. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices.Early Australians had to be self-reliant in regards to making and mending their clothes and utensils. This sewing machine was one of many items used that exhibit the skill and craftsmanship of the women in these early families. A sewing machine was a necessary part of each home and this item demonstrates how women of the time managed had to become self-reliant in the repair and making of their families clothes to make their household budgets go further.Wertheim sewing machine in carry case, hand operated with two spindles, handle with locking pin, which turns lever between spokes of main handle, hand brake. The machine is table-mounted with a Turkish walnut base. The base can be attached to a cast iron table with a foot treadle as an optional extra. The walnut base has marquetry to the front set out as a measure for material. There is also an accessory box inside the carry case containing 20 additional items for use with the machine. Wertheim brass trademark badge riveted to the body of the machine of a crouching dwarf with a hammer with the name of the company Wertheim and Frankfurt. Gold filigree decoration in gold paint adorns the main body of the machine. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand operated sewing machine, crank handle sewing machine, wertheim, dressmaking, taylor, domestic, clothing, hugo wertheim, joseph wertheim -

Flagstaff Hill Maritime Museum and Village

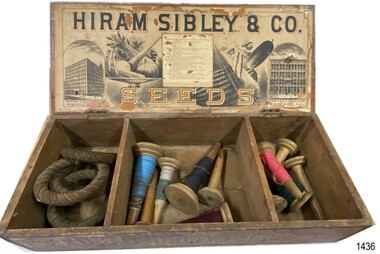

Flagstaff Hill Maritime Museum and VillageContainer - Box for seeds, ca. 1880s

This seed box was made for Hiram Sibley for his seed house business. He sold seeds priced by the weight or the space they took up e.g. bushel. This box allowed for seeds to be divided by type, size or even date. The box was strong and easy to cart and store. It was also a handy item to 'recycle' as a storage container for other items. The Sibley seed box is a desirable collectors' item. A large variety of sizes and shapes are still available today in various stages of condition. Hiram Sibley developed seeds that were strong and the plants that grew from these seeds produced many seeds. Varieties of Sibley seeds and plants are still advertised for sale in modern times. HIRAM SIBLEY (1807-1888) - Hiram Sibley was born in America. He had a natural mechanical ability and became skilled in many trades. He and his partner Don Watson opened a sawmill then a machine shop and foundry. He became involved with Alfred Vale and Samuel Morse and their work on the telegraph. Eventually he became the first president of the Western Union Telegraph Company. Later, after leaving Western Union in the early 1860s, Sibley bought and sold railroads, manufactured sold, ran timber mills, and became involved in farming and seed supply. In this area he used his skills to engineer seeds that were stronger and develop plants that produced more seeds. The production of seeds became his main business. He bought land cheaply and improved to soil so that he could produce seed and grain, and graze herds of cattle. He became the owner of 14 large farms. Hiram Sibley earned the reputation "as the most extensive farmer and seedsman in this country". The business of Hiram Sibley & Co. was conducted his warehouse in Rochester and his seed house in Chicago. One department of the business sold farming equipment, another department imported ornamental plants from overseas countries Sibley went on to invest a large amount of money in a bank, and to be financially involved in the community by making large donations to public services such as a library and a school of music. At one point he was the richest man in Monroe county.This box is significant for its historic connection with Hiram Sibley, who is famous for many reasons, among which is his very profitable business of seed engineering to improve the production of crops. This box also represents the value of containers used for selling products in the 1880s, being re-used for other useful purposes. The box is an example of goods imported for use in Australia. The text and images of the box are an example of 1880s advertisingBox, wooden, with two brass hinges joining lid to base. Base has two wooden partitions, divided into three unequal sized compartments. Lid's underside has label with drawings of buildings and produce, text with maker's name and description of vegetables. Front edge of box has stencilled text and diagrams. Outside lid, and the other three sides, have no inscriptions. Made by Hiram Sibley & Co., USA. (Box is currently used to store quoits 1436.2 and cones of cotton thread 1436.3.)Marked "HIRAM SIBLEY & CO / SEEDS", "WAREHOUSE - "ROCHESTER N.Y. ", "SEED HOUSE - CHICARGO, ILL.", "SEEDS BY WEIGHT & MEASURE", "PUT UP BY / HIRAM SIBLEY & CO. / ROCHESTER, N.Y. AND CHICARGO, ILL."flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, hiram sibley & co, rochester n.y., seeds, wooden seed box, seed box, seedsmen, arable farming, chicargo illinois, seed house, seed engineering, seed distribution, seeds by weight and measure -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine and case, Joseph Wertheim, late 19th century

Hugo Wertheim (1854-1919), was a merchant and manufacturer and was born on the 12th July 1854 at Lispenhausen, in the German electorate of Hesse-Kassel, son of Meyer Wertheim and his wife Minna, née Heinemann. Hugo reached Melbourne in October 1875. He soon began advertising, from premises at 39 Flinders Lane East, as agent for his father's cousin Joseph Wertheim, a well-established manufacturer of sewing machines. Hugo returned to Germany where he married Joseph Wertheim's daughter Sophie Emilie (1864-1953) on 30 August 1885 at Frankfurt. the couple then came to Melbourne. In a short time, with extensive advertising, Hugo established a substantial business, selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He also mounted elaborate displays at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. O. C. Beale worked with him before setting up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Wertheim opened a large, innovative piano factory at Richmond, Melbourne, intending to produce 2000 pianos and player pianos annually, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis on 11 July 1919 at his home at South Yarra, his wife, two daughters and three sons survived him; Herbert Joseph (1886-1972), the eldest, continued the business. Rupert became a share broker and went on to represent Victoria in inter-State tennis in 1913-27 and Australia in Davis Cup matches against Czechoslovakia in 1922. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices.Early Australians had to be self-reliant in regards to making and mending their clothes and utensils. This sewing machine was one of many items used that exhibit the skill and craftsmanship of the women in these early families. A sewing machine was a necessary part of each home and this item demonstrates how women of the time managed had to become self-reliant in the repair and making of their families clothes to make their household budgets go further.Sewing machine, Wertheim brand “ Syst 182” hand crank operated machine with folding handle, timber case and carry handle. Metal machine is painted black, with remnants of gold, red and green scrolls and floral decoration. Machine has base with inlaid measuring rule across front and 2 holes drilled through the base (perhaps for mounting machine to a bench). Machine tilts open, hinged on one side, after thumb screw is unwound, revealing machine’s workings and serial number. Base has a fitted round, concave, silver metal pin holder with lid that hinges open, and symbol pressed into lid; several pins are inside. Body of machine has brand name transfer across front and oval metal trademark disc on front. Metal sliding covers over footplates have stamped lettering. Timber machine case or cover includes an accessory box with sliding cover and metal hook and eye latch, and inside the box are 23 metal sewing attachments, a disc and a stick of black crayon with maker’s trademark on it paper cover. Workings of machine have seized up. The crayon wrapper has printed on it “For the wonderful Wertheim new family machine made in Germany ‘Syst. 182’”, and the maker’s symbol with “Trademark” beside it. Made for Hugo Wertheim.“WERTHEIM” transfer across front and back of machine body. Cover of pin holder has symbol ‘Wings above a shield’. Maker’s trademark on gold oval disc, “WERTHEIM / FRANCFURT” and picture of a dwarf with a hammer. Left footplate has script “Syst 182”, right footplate has stamp in oval shape “MANUFACTURED IN - - /SPECIALLY FOR / HUGO WERTHEIM” Serial Number “7501”flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand crank sewing machine, hugo wertheim, wertheim, clothing manufacturer, sewing, syst 182 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wringer/Mangle, Melvin Newton Lovell, 1898 -1900

Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers).Wringer (or mangle); portable wooden washing wringer with rubber rollers, manually driven by iron set of gears and handle. Includes iron clamps and adjusting screws for attaching. Marked on frame "382", "12 x 1 3/4" Anchor Brand "Made in USA" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mangle, clothes wringer, washing equipment, laundry, wringer, domestic, washing mangle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wash trough, Melvin Newton Lovell, Mangle was Patented June 10, 1898 by Lovell Trough is possibly of later manufacture by a local unknown cabinet maker between 1900-1920

Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers). This item is now sought by collectors and is even rarer due to it's combination with a Lovell clothes wringer. Wooden wash trough with 2 troughs & attached a Lovell wringer (or mangle Anchor Brand) Hard to make out as worn off with useflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, flagstaff-hill-maritime-village, wash trough, wringer, mangle, laundry, cleaning, washing, housework, domestic, melvin newton lovell, wooden was trough -

Puffing Billy Railway

Puffing Billy Railway1920's Station Cash Box Tin - Hobbs & Co London, 1920's

1920's Station Cash Box Tin Made by Hobbs & Co London Lever Machine Made Alfred Charles Hobbs (October 7, 1812 – November 6, 1891) was an American locksmith and inventor. Hobbs went to London as a representative of the New York company of Day & Newell, which was exhibiting at the Great Exhibition of 1851. Hobbs had brought with him his boss's (Robert Newell) Parautoptic lock, designed to compete with, and surpass, the locks available at the time in Britain. He was the first one to pick Bramah's lock and the Chubb detector lock at the Great Exhibition of 1851 and forced the lock manufacturers to improve their designs. The lock controversy continues a subject of great interest at the Crystal Palace, and, indeed, is now become of general importance. We believed before the Exhibition opened that we had the best locks in the world, and among us Bramah and Chubb were reckoned quite as impregnable as Gibraltar— more so, indeed, for the key to the Mediterranean was taken by us, but none among us could penetrate into the locks and shoot the bolts of these masters. The mechanical spirit, however, is never at rest, and if it is lulled into a false state of listlessness in one branch of industry, and in one part of the world, elsewhere it springs up suddenly to admonish and reproach us with our supineness. Our descendents on the other side of the water are every now and then administering to the mother country a wholesome filial lesson upon this very text, and recently they have been "rubbing us up" with a severity which perhaps we merited for sneering at their shortcomings in the Exhibition. In 1854 he was awarded a Telford Medal by the Institution of Civil Engineers for his paper 'On the Principles and Construction of Locks'. Sign on a strong room door. Hobbs became one of the founders of the lock making firm of Hobbs Hart & Co. Ltd. The company started in 1851 and was formally registered as Hobbs and Co. in 1852. But by 1855 it had become Hobbs, Ashley and Company. The name then changed to Hobbs, Ashley and Fortescue, with an address at 97 Cheapside in London. Then for the next ninety years the address was 76 Cheapside in London. In 1860 Hobbs returned to America and lived in Bridgeport, Connecticut, and went on to hold a dozen patents for firearm ammunition manufacturing. In 1880 he listed himself as a "Superintendent Of Cartridge Factory" Info from https://en.wikipedia.org/wiki/Alfred_Charles_HobbsHistoric - Railways - Station Cash Box Tin 1920's Station Cash Box Tin - Hobbs & Co London Metal Tin - painted Black, Gold and Red with Brass Lock and HandleHobbs & Co London Lever Machine Made1920's station cash box tin, puffing billy -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ship's Wheel, John Hastie et al, Early 20th Century

John Hastie Engineer and millwright John Hastie opened small manufacturing works in Greenock in 1845 and 1853 patented the first self-holding steering gear. The firm became known as John, Hastie and Co. Ltd. in 1898 after taking on limited liability status and their main works were at Kilblain Street, Greenock, where they specialised in ships' steering gear. The company also occupied works at Rue End Street, Greenock. Plans of this unit depict a stockyard to the east, with areas for welding; fitting and assembly; flame, cutting and fabrication; and a machine bay. The company was dissolved in 1991. Brown Brothers Brown Bros Rosebank Ironworks made the steering gears for many large ship's, including The Titanic. Andrew Betts Brown the founder was born in 1741 and closely associated with many improvements in marine engineering. He was educated in his native city and served his apprenticeship as an engineer in the locomotive works of the North British Railway Company at St. Margaret's. During his apprenticeship, he attended the evening classes at Watt College. subsequently going to Manchester to study chemistry. He went to London around 1863 and took over an old brewery, which he converted into an engineering works. During his time there he invented an overhead travelling crane, which was used on the construction of Blackfriars Bridge London. He went on to develop plant which used steam and hydraulic power for discharging ships as a result the company was contracted to install this equipment in Hamburg Docks. By around 1870 he continued to construct machinery in London but realised that conditions were more favourable in Edinburgh. He acquired land at Rosebank adjoining the North British Railway Company's line to Granton, and the necessary infrastructure was completed allowing him to finish the Hamburg contract. The works at Rosebank were eventually extended and added to until they became one of the largest engineering works in the East of Scotland. Mr Brown was a member of numerous engineering institutions, the best known at the time being the Institution of Naval Architects. He was also a Fellow of the Royal Society of Edinburgh, a member of the Institute of Mechanical Engineers and of the Institution of Marine Engineers he died in 1906 at the age of 67.An item made by two marine innovators of marine auxiliary machinery, equipment and itemsShip's wheel, brass, attached to brass pillar. The base has six holes in it for securing it in place. Top of the ship's wheel pillar has a brass, adjustable arrow pointer that is positioned over a dial etched into the flat brass surface. The dial reads " PORT STABD". Lines and degrees are marked, with '0' in centre and every 5 degrees, from 0-35, in both Port and Starboard sidesInscription to wheel hub "Brown Brothers & Co. Ltd, Rosebank Ironworks, Edinburgh"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, john hastie, john hastie, andrew betts brown, ships wheel, ship steering gear, marine equipment, instrument, navigation -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Household Chopping Machine, Mechanical Chopper, c1886

Used in kitchen to cut carrots, cheese slices, onions. boiled eggs, etc.Painted black guillotine on a wooden stand. An iron pole keeps the guillotine in vertical position at one end of the block. Driven by two wheels when a handle is turned. A tilting beam moves the guillotine up and down to cut vegetables, etc. Blade 18cm long by 6.5cm wide. Metal plate missing under blade. A rotatable drum to contain the food to be chopped, which is rotated by a cog at the base (also missing) turns the container. The upright holding chopper blade e is a modification made because of the missing container.|The following description is from Ken Turner Booklet referred to under 'Reference'. ----|The Starrett food chopper would certainly have to be considered one of the more interesting inventions, which incidentally is now considered the ultimate in kitchen collectables. Laroy Starrett in later years' told of how the design of his food chopper was inspired by the action of the walking beam engine used on the Mississippi steam boats. When the crank handle of the chopper is turned, this sets in motion a mechanism which is just fascinating to watch. The crank activates a flywheel which in turn, by a series of cogs and levers, simultaneously rotates a food holding container and raises and lowers within the rotating container, a guillotine like 'chopping blade - the action does not only look like that of a beam steam engine, it even in a way sounds like one, although somewhat noisier. Starrett produced seven different models of these choppers, ranging in size appropriate for domestic use to heavy duty models for butchers, restaurants and for hotel use. The small model was capable of chopping 3lbs in three minutes, and the largest had a capacity for chopping something like 100 lbs in an hour. The mechanical chopper, which became affectionately known as the 'hasher', was the first of some one hundred of Starrett's inventions, and these include a washing machine patented in 1865 which had a similar action to his food chopper, a food press patented in 1873, and a device for lacing shoes he patented in 1886.domestic items, food preparation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Candle Snuffer, Harris and Sheldon, circa 1840

This mechanical candle snuffer tool was made in Birmingham, England, by Harris and Sheldon Ltd. The candle snuffer was part of the original furnishings of the St Nicholas' Mission to Seamen's Church at 139 Nelson Street, Williamstown, Victoria. It was donated to Flagstaff HIll and is part of the St Nicholas Seamen's Church Collection The enterprise of Harris and Sheldon was established in 1880 by Sydney Harris. They made shop fittings such as cabinets, shelving, cupboards, tables and stationery. During WWII they made aircraft parts, ammunition boxes and pumps. THE MISSIONS TO SEAMEN (Brief History: for more, see our Reg. No. 611, Set of Pews) The Missions to Seamen, an Anglican charity, has served the world's seafarers since 1856 in Great Britain. Its symbol is a Flying Angel, inspired by a Bible verse. Today there are centres in over 200 ports worldwide where seamen of all backgrounds are offered a warm welcome and provided with a wide range of facilities. In Victoria, the orgainsation began in Williamstown in 1857. It was a Sailors’ Church, also known as ‘Bethel’ or the ‘Floating Church’. Its location was an old hulk floating in Hobson’s Bay, Port of Melbourne. It soon became part of the Missions to Seamen, Victoria. In the year 2000 the organisation, now named Mission to Seafarers, still operated locally in Melbourne, Portland, Geelong and Hastings. The Ladies’ Harbour Lights Guild was formed in 1906 to support the Missions to Seamen in Melbourne and other centres such as Williamstown. Two of the most significant ladies of the Guild were founder Ethel Augusta Godfrey and foundation member Alice Sibthorpe Tracy (who established a branch of the Guild in Warrnambool in 1920). The Guild continued its work until the 1960s. In 1943 a former Williamstown bank was purchased for the Missions to Seaman Club. The chapel was named St Nicholas’ Seamen’s Church and was supported by the Ladies’ Harbour Lights Guild, the Williamstown Lightkeepers’ Auxiliary and the League of Soldiers’ and Sailors’ Friends. It ceased operation in 1966. A Missions to Seamen Chapel and Recreation Room was a significant feature of ports during the late 1800s and into the 1900s. It seemed appropriate for Flagstaff Hill to include such a representation within the new Maritime Village, so the Melbourne Board of Management of Missions to Seamen Victoria gave its permission on 21st May 1979 for the entire furnishings of the Williamstown chapel to be transferred to Flagstaff Hill. The St Nicholas Seamen’s Church was officially opened on October 11, 1981, and closely resembles the Williamstown chapel. This candle snuffing tool is significant historically for its origin in the St Nicholas Mission to Seamen's Church in Williamstown, established in 1857 to cater for the physical, social, and spiritual needs of seafarers. It originated in Bristol, England when a Seamen's Mission was formed in 1837. Candle snuffer tool. A bamboo and brass pole with a spring-action handle that operates a brass pinching mechanism at the other end. The mechanism has been inserted into the hollow bamboo handle. Maker's inscription on the pinching mechanism. Made in Birmingham, England, by Harris & Sheldon Ltd. This is one of the original items in our st Nicholas Seamen's Church Collection."HARRIS & SHELDON LTD.", "BIRMINGHAM"religious service, harris and sheldon ltd, birmingham manufacturer, sydney harris, sailors rest, ladies harbour light guild, mission to seamen williamstown, library tool, flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, religion, bethel sailors’ church, bethel floating church, joy club for fighters, ladies lightkeepers’ auxiliary, mission to seafarers, flying angel’s club, st nicholas seamen’s church williamstown, st nicholas seamen’s church flagstaff hill, candle snuffer, candle extinguisher, flame snuffer, flame extinguisher -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAudio - Phonograph, Thomas A. Edison, Edison Laboratory, c.1909

The Edison Fireside Phonograph Combination Type A model phonograph was an open horn model. This machine was produced around 1909, just after the introduction of 4-minute record cylinders in 1908.; the selection lever on the front was either 4 or 2-minute choice. This Fireside model has a fluted octagonal horn that attaches to the reproducer on the machine and is suspended by on ring by a horn crane attachment. The phonograph machine is powered purely by mechanical means, winding the crank handle on the side of the machine to start the belt-driven, spring-loaded motor inside. The sound comes from a pre-recorded, vertical cut record cylinder, which slides over the Mandle, a smooth rotating drum. The reproducer, an all-in-one needle, amplifier and speaker, is lowered onto the cylinder, the needle picks up the sound and plays it on the speaker and the attached horn amplifies the sound. The phonograph machine was invented by Thomas Alva Edison in the late 19th century. Edison adopted the idea from the technology of the telegraph machine. He patented the phonograph in early 1878. It was able to record sound and play it back. This amazing invention opened up a whole new world of entertainment, where wax cylinders of pre-recorded sound could be purchased with a wide variety of music and played over and over. The first wax cylinders were white and used a combination of bees' wax and animal fax or tallow. By 1892 Edison was using 'brown wax' cylinders that ranged from cream through to dark brown. The Edison Phonograph Company was formed in 1887 to produce these machines. He sold the company in 1855 to the North American Phonograph Company but bought that company in 1890. He then started the Edison Spring Motor factory in 1895, and the National Phonograph Company in 1896. In 1910 the company became Thomas A. Edison Inc. In 1898 Edison produced the Edison Standard Phonograph, the first phonograph to carry his own trade mark. He began mass producing duplicate copies of his wax cylinders in 1901 using moulds instead of engraving the cylinders. The wax was black and harder than the brown wax. The ends of the cylinders were bevelled so that the title's label could be added. The last phonograph machine to use an external open horn was produced in 1912 due to the much more robust round records being invented. In 1913 Edison started producing the Edison Disc Phonograph. The company stopped trading in 1929.This Edison Fireside Phonograph model is significant for being one of the last models to have an external horn. It is also significant for its connection with the invention of the phonograph, which made music and sound available for domestic enjoyment. It was used for entertainment and education, even teaching languages. It signalled a new era of music that could be reproduced and played anywhere. It is also significant for its short time span of popularity, just a few decades, due to the growing use of records, which gave a much higher quality sound and were more robust.Phonograph; Edison Fireside Phonograph, Combination Type, Model A. It is in a wooden case with a domed lid, metal catches on each side and a folding wooden handle. It has a metal drum and a reproducer mechanism. The metal and wood crank handle starts the machine’s motor. A sliding lever at the front selects the speed for four- or two-minute cylinders. The inscribed plate has the maker, serial number, patents and other information. The reproducer also has an inscription. It has a curved metal open horn attachment. Made in Orange, New Jersey in c.1909. NOTE: the fluted octagonal horn is catalogued separately.Case front, in script, Edison’s early ‘banner’ decal “Edison” On the front of the machine “Thomas A Edison TRADE MARK” On the maker’s plate; "Edison Fireside Phonograph Combination Type" Serial number “14718” Around sound outlet; “C 4076” “REPRODUCER LICENCED FOR USE ONLY ON EDISON PHOTOGRAPHS SOLD BYT.A. EDISON INC.” At the front edge “4 MINUTES 2flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, gramophone, phonograph, music player, entertainment, audio equipment, edison, thomas a edison, horn, phonograph horn, amplifier, audio, sound recording, sound playback, phonograph machine, phonograph cylinder, external horn, edison phonograph company, wax cylinders, sound reproduction, edison spring motor factory, national phonograph company, thomas a. edison inc, crank-operated motor, open horn phonograph, 4 speed, 2 speed -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Ice Chest, 1927

This particular small ice chest was once part of the domestic furniture of Dr W.R. Angus and his young family in 1927 when they lived in the Nhill and Ballarat districts. The family relocated to Warrnambool in 1939 and brought the ice chest with them. An ice chest, also called an icebox or refrigerator, was invented by Thomas Moore in 1802 and had become a common home appliance from the mid-1800s until around the 1930s, when electric refrigerators became affordable and safe. The non-mechanical ice chest allowed perishable food to be kept fresh for longer than the food-safe or ‘Coolgardie’ used in colonial days in Australia. It required the use of ice blocks, which were delivered to households by the ‘iceman' and his horse and cart. The ice man would use an ice pick to cut the blocks into the right size for the buyer’s ice chest. The ice came from an ‘ice house’, a factory where the ice was made. The ice chest required a block of ice to be placed into the insulated top section on top of the corrugated iron stand. The ice would cool the air and the cool air would flow downwards through the oval hole under the stand and into the refrigerator compartment below. The water from the melted ice would drain from the sloping floor of the top compartment and into the hooded pipe. The pipe went through the refrigerator and ended below its floor, where the drained water would be collected in the metal bowl placed there for that purpose. The lip on the bowl allowed it to be easily removed and emptied at regular intervals before it overflowed. W.R. Angus Collection- The W R Angus Collection spans from 1885 to the mid-1900s and includes historical medical and surgical equipment and instruments from the doctors Edward and Thomas Ryan of Nhill, Victoria. Dr Angus married Gladys in 1927 at Ballarat, the nearest big city to Nhill where he began as a Medical Assistant. He was also Acting House surgeon at the Nhill hospital where their two daughters were born. He and his family moved to Warrnambool in 1939, where Dr Angus operated his own medical practice. He later added the part-time Port Medical Officer responsibility and was the last person appointed to that position. Dr Angus and his wife were very involved in the local community, including the early planning stages of the new Flagstaff Hill, where they contributed to the layout of the gardens. Dr Angus passed away in March 1970.This ice chest is significant for representing a method of refrigeration and food preservation used in the 19th to mid-20th centuries when people were beginning to afford powered domestic refrigerators. After the second world war, most households replaced their food storage cupboards and ice chests with refrigerator appliances. The ice chest is also significant for its connection with the domestic furniture of Dr W.R. Angus and his family, and its inclusion in the W.R. Angus Collection.Ice chest; single front wooden cabinet with two doors and a flap, and three accessories. The top door is a lid with a metal handle at the front and two metal hinges along the back. The front door has two metal hinges on the right-hand side and has a metal lever catch. A hinged flap fits between the front legs at bottom of the ice chest and swings upwards. The front legs have wheels. The insulated top compartment has a metal lining and its floor slopes towards the centre of the back wall. In the floor are a formed oval air-flow hole and the open end of a pipe that has a hood partly covering it. The front compartment is an insulated metal-lined cupboard with a vertical pipe down the centre of the back wall and horizontal rails in the centre of each side wall. The accessories are a rectangular corrugated iron stand, a rectangular wire grid shelf and a round aluminium bowl with a lip and two sides pushed in. The ice chest was made circa 1927 and is part of the W.R. Angus Collection.flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, dr w r angus, dr roy angus, dr ryan, doctor angus, dr angus, ice chest, ice box, antique, food preservation, refrigeration, domestic equipment, kitchen appliance, refrigerator, non-electric refrigerator, non-mechanical refrigerator, w.r. angus collection -

Geoffrey Kaye Museum of Anaesthetic History

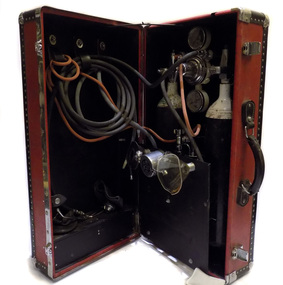

Geoffrey Kaye Museum of Anaesthetic HistoryEquipment - Resuscitator Unit, c. 1960

Mechanical resuscitation devices, such as the Pulmotor and Lungmotor, were popular in the early part of the twentieth century. Their use waned in the 1920s as significant bodies like the British Medical Research Council and American Red Cross refused to endorse them. The most popular of the resuscitators to emerge in the 1930s was the E&J (Ericson and Johnson) resuscitator. The device was soon widely available, vigorously promoted with support from many medical practitioners. They were soon to be found in hospitals, emergency services like the ambulance and fire brigade, and voluntary life-saving organisations. In Australia, Norman James, director of anaesthesia at the Royal Melbourne Hospital, developed an interest in equipment for ambulances and the resuscitation of drowning victims. Little in the way of practical, portable equipment was available to either the ambulances or the voluntary life-saving organisations, such as Surf Life Saving Australia (SLSA); American resuscitators, like the E&J, were expensive and bulky to import. James designed a simple portable resuscitation device for local use after being approached by Jack Conabere, secretary of the Elwood Life Saving Club (ELSC). The resulting Royal Melbourne Hospital resuscitator, or the R.M. resuscitator as it was marketed, was a simpler, manual version of those available overseas. It was gas driven with a plunger, marked “Press”, and a safety valve. The small working unit attached directly to the facemask. Once the patient was positioned facedown and the airway cleared of debris, the mask was placed firmly over the face. The plunger allowed gas to flow and lung inflation; releasing the plunger allowed expiration. This simple resuscitator was marketed by Commonwealth Industrial Gases (CIG) and became very popular in Australia with volunteer and professional rescue organisations. It represents one of the many innovations in resuscitation equipment that resulted from cooperation between volunteer life savers and medical practitioners. Norman James worked closely with Jack Conabere and the Government Pathologist to develop the equipment. ELSC was the first life saving club to use the resuscitator on the beach. While conducting an early training exercise on 23 December 1951, they used it to successfully resuscitate a man who had drowned after capsizing his home made yacht. The R.M. resuscitator was also used in more inventive ways. At Fairfield Hospital in Melbourne, a group of physiotherapists and doctors did some innovative work with polio patients, teaching them glossopharyngeal (or “frog”) breathing, as a means of becoming less dependent on ventilators. In 1981, the Australian Standards Association stated that the RM head failed to meet its revised standards and it was withdrawn from the market. Red leather suitcase with black leather trim with metal studs. There are clip locks for locking the suitcase in the closed position. The suitcase contains equipment for oxygen resuscitation. There is a space allocated for two oxygen cylinders, however there are no cylinders present.Embossed into metal plaque: The C.I.G. / Oxy-viva / PORTABLE UNIVERSAL OXYGEN RESUSCITATORresuscitation, portable, surf life saving australia, royal melbourne hospital, rm resuscitator -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pump, circa 1930's - 1940's

This pump is an Ajax Type L2 Series A model, made and sold by McPherson’s Pty Ltd of Melbourne circa 1930’s to 1940’s, is a mechanical, hand operated, constant flow pressure pump. It would have been used to pump fluids from one area to another, for example from a dam to a tank or used as a bilge pump on a small vessel, mounted on the vessel’s bulkhead, floor or deck. This type of hand pump is sometimes called a ‘Reciprocating Suction Pump’. It has a mechanical pumping action of the lever moves the piston inside the pump up and down. The water is lifted from below the pump through the inlet pipe and into the pump’s cylinder. This action causes the lower valve to close and the piston’s valve opens and the pressure within the pump forces the water out of the pump through the exit pipe. The limitation of this type of pump is that it can only raise the water a maximum of about 7 metres from beneath the ground and yields 24-26 Litres per minute. This type of pump could be used for many purposes such as pumping water or fuel. McPherson’s 1940’s advertisement proclaims “For all jobs on the land – irrigation, spraying, tank, plumbing, fire-fighting – there’s a suitable “Ajax” pump. Send us the details of you pumping problem. Our Expert’s advice will help you choose the right pump – the one that will give you most years of PROFITABLE PUMPING.” (The Australasian (Melbourne) Sat. 26th October 1940.) McPherson’s Pty Ltd, the manufacturer, advertised a similar pump to this one in The Australasian (Melbourne) in 1936, calling it the Ajax Double Acting Hand Pump. In 1942 another advertisement advised that a representative for a fire-fighting equipment supplier was visiting the western district of Victoria. The company could now supply double-action two-spray Ajax pumps at lower prices than similar pumps the district had recently purchased from Adelaide. McPHERSON’S FOUNDER and COMPANY TIMELINE 1860 – Thomas McPherson, a Scottish immigrant (c. 1853 ), founded McPherson’s in Melbourne, supplying pig iron (lead ingots imported as ballast in ships) to local manufacturers. 1882 – Thomas McPherson established a warehouse in Collins St Melbourne and included tools, steam fittings and machinery in his wares. The business expanded to include steam saw mills and became known as Thomas McPherson and Sons (William Murray and Edward). 1888 – Thomas passed away and his sons inherited the business. In 1896 William Murray became the sole proprietor after his brother Edward’s death. 1900 – The firm expanded, establishing Acme Bolt Company to manufacture nuts and bolts. 1912 – McPhersons Pty Ltd established a machinery warehouse and showroom in 554-556 Collins St Melbourne. McPherson’s went on to establish branches in Sydney (1911), Adelaide (1921) and Perth (1930) 1917 - McPherson’s supplied ‘dog spikes’ for the transcontinental railway, running from Eastern to Western Australia. 1918 – A tool works set up in Kensington, Melbourne, manufacturing Macson lathes and made machine tools that previously had to be imported. 1924 – The Bolt Works was transferred to a new building in Melbourne. McPhersons began making pumps. 1929 – McPherson retired. His son (Sir) William Edward McPherson (known as ‘WE’), was born in Hawthorne, Melbourne, in 1898. After his education he began work in his father’s Melbourne hardware and machinery business He took over as governing director when his father retired. 1929-1932 – McPherson’s supplied thousands of tons of rivets from its Richmond (Melbourne) Bolt Works for the construction of the Sydney Harbour Bridge. 1936 – McPherson’s Pty Ltd is advertising Ajax Pumps in newspapers 1934 – McPhersons purchased the property adjoining the warehouse in Collins Street, and during 1935-1936 built a new office and showrooms on the site of 546-445 Collins St. 1939 - McPherson’s acquired the Tool Equipment Co. Pty. Ltd and Associated Machine Tools Australia Pty Ltd was formed to separate McPherson’s machine-tool manufacturing and merchandising interests. 1939 – Ajax Pump Works, a foundry and pump manufacturing plant, was established in Tottenham, Melbourne, and the Ajax Bolt and Rivet Co Pty Ltd began manufacturing in New Zealand. 1944 - McPherson’s became a public company, McPherson’s Ltd. 1948 - The Ajax Pump Foundry opened at Kyneton, Victoria and in the post war years it grew to became a large manufacturer. 1980’s – Ajax Pumps brochure lists the address as 6 Buckhurst St, South Melbourne, Vic 3205 with the Telephone number 03 669 3588 1988 - Ajax Pumps acquired the Forrers Company, which was established in 1921. Manufacturing in Ipswich, Queensland, specialising in submersible sewage pumps. 1991 – KSB Ajax was formed, bringing together the companies KSB and Ajax Pumps 1993 – Manufacturing was moved to state-of-the-art premises in Tottenham, Victoria 2001 - The Forrers facility was moved to Tottenham. 2007 - Company name KSB Ajax Pumps was changed to KSB Australia Pty Ltd. 2009 - KSB Australia opened a branch in Townsville, Queensland. 2011 - KSB Australia moved to its dedicated Water and Waste Water Competence Centre in Bundamba, Queensland. DISPLAY OF THIS AJAX PUMP This pump was installed at Flagstaff Hill Maritime Village as part of a working display in the village by the Friends of Flagstaff Hill, in acknowledgement of the dedicated involvement of one of its long serving members, Bob Crossman. The display was officially opened 31st March 2018 and incorporates a restored Furphy Tank and Water Pipe Stand. The pump is used to draw water from the lake, through the water stand pipe and into the reconditioned Furphy Tank. This Ajax pump made by McPherson’s Pty Ltd is significant for its association with McPherson’s, a prominent manufacturer of hardware in Victoria. McPherson’s is famous for supplying ‘dog-spikes’ for the transcontinental railway (eastern to western Australia, 1917) and rivets for the Sydney Harbour Bridge (1929-1932). The Ajax pump is also of significance because of its association with McPherson’s Governing Director (Sir) William McPherson, former premier and treasurer in Victoria 1928-1929. The former McPherson’s Pty Ltd building in Collins Street Melbourne is now on the Victorian Heritage Register VHR H0942 This pump is representative of mechanical pumps popular in the early to mid-1900’s and still used today. Hand operated pressure pump, double acting. Cast metal case, painted red, with steel hose attachments and long metal lever. Pump is bolted to wooden plank. Model of pump is AJAX, Type L2, Series A pump. Embossed on lower section of pump "L2 - 10", "L2 - -1", "AJAX" “(?) –2-1” Embossed on lower handle “3-7” “L – 4” Embossed on attached plate “FOR SPARE PARTS / TYPE L2 / SERIES A / PUMP ASSEMBLED BY T R” Manufactured by McPherson’s Pty Ltd of Melbourne circa 1930’s - 1940’s.flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ajax pump works tottenham melbourne, ajax pump factory kyneton, william edward mcpherson, thomas mcpherson of melbourne, mcpherson’s pty ltd melbourne, acme bolt company, tool equipment co. pty. ltd, associated machine tools australia pty ltd, ajax bolt and rivet co. pty ltd new zealand, forrers company ipswich queensland, ksb ajax pumps, ksb australia pty ltd, macson lathes, tool manufacturer early to mid- 20th century, ajax double acting hand pump, ajax type l2 series a pump, qisjax pumps, water pump 1940’s, fuel pump 1940’s, hand operated constant flow pressure pump, reciprocating suction pump, agricultural hand pump, plumber’s hand pump, portable hand pump -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Fred Rochow Railways Collection - Bicentennial Train Locomotive 3801, 29 October 1988