Showing 867 items matching "techniques"

-

National Wool Museum

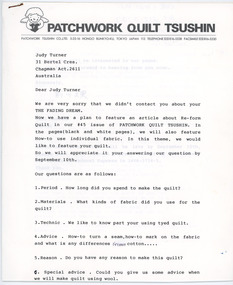

National Wool MuseumDocument - The Fading Dream of Australian Home Ownership, Letters, Judy Turner et al, 1991

‘The Fading Dream of Australian Home Ownership’ was made by Judy Turner in 1989 for her son Nicholas (then 14 years) after a family discussion about mortgages and rising interest rates (17% at the time), out of concern for his generation. “Perhaps this will keep my son warm when he can’t afford a house”, wrote Judy at the time. As a quilting teacher for over thirty years, Judy was well aware of the ‘wagga’ tradition of making do with what you have and reusing resources to make something useful. The quilt was made using approximately 270 different men’s woollen suiting samples. The fabrics in the quilt were a gift from Micheal Haze who was a travelling men’s ware salesman and friend of the artist’s late husband. The suiting samples were used just as they were, without cutting, and are stacked liked house bricks. The pieces have been machine pieced and tied. The quilt has woollen backing, with no batting. Judy’s son Nicholas, always interested in drawing, and keen to see what his mother was making, helped with the drawing and design of the house. The quilt has been exhibited in Canberra, Armidale and Sydney and featured in publications in Australian and Japan. Judy’s work has been exhibited Nationally and Internationally, including in Japan, Korea, Germany, Switzerland and the United States of America. Judy’s work has featured extensively in publications around the world, and has received many awards. Her work is held in public and private collections across Australia and the USA. As well as a successful career as an artist, Judy spent three decades imparting skills to the next generation as a patient and skilled teacher. ARTIST STATEMENT The medium of my artistic practice is quilt making and my focus is the use of colour and speedy, accurate and efficient methods of making successful quilts. In 1995 I developed an original technique of applying woollen yarn to a woollen background, focusing on the subtle blending of colour to express an idea. Author of Awash With Colour (1997) and co-author with Margaret Rolfe of Successful Scrap Quilts (2002).Two typed letters held together with a staple. The first letter has a grey printed letter head which includes a logo of a person with wings holding a heart.[printed] PATCHWORK QUILT TSUSHINquilt, wagga, home, house, housing affordability, design -

Department of Energy, Environment and Climate Action

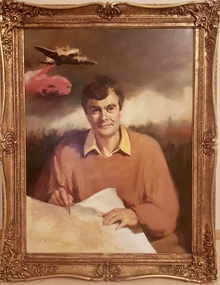

Department of Energy, Environment and Climate ActionPainting - Conrad Wood

Conrad Wood (Woody) graduated from the Victorian School of Forestry in 1957, and after postings with the Forests Commission Victoria (FCV) at Swifts Creek and Sirex surveys, he gravitated into the Forest Protection Division in Head Office in the early 1960s. He championed the setting up of proper contractual arrangements for aviation and was involved in implementing the first ongoing, organised contracts for firebombing in eastern Victoria in the 1960s. An early recipient of a prestigious Churchill Fellowship, Woody travelled extensively throughout 1969 in North America and Europe studying aviation in forestry and firefighting. Afterwards he was very active amongst the Churchill alumni. Woody had a passion for innovation and new technology and was instrumental in introducing new aircraft types and new approaches for forest firefighting and forest management. Amongst many other things, he played a major role in organising the trial of a RAAF C130 equipped with MAFFS for firebombing in south-eastern Australia in 1982-84, even piloting the lead plane. His inimitable style was crucial in successfully bringing together the cultures of the myriad organisations involved. Con advocated for the introduction of helicopters. He developed aerial fertilising and seeding techniques for forest management. He even managed to get involved in cloud seeding experiments for forest fire suppression and for improving water yield. Along with aviation, Conrad was passionate about literature, football, politics, food, drink, motorbikes, gardening and Glen Iris, to name a few. He was a committed campaigner on social justice issues and for many years read for vision-impaired people on public radio. He died in 2014. This painting of Woody by notable Australian artist Joyce McGrath OAM (also a Churchill Fellow) was done in the 1980s. Joyce asked Conrad to sit for this portrait which she planned to enter the Doug Moran National Portrait Prize. The portrait hung in Churchill House in Canberra, but when a new building was erected, it was returned to the artist/owner. The painting is now owned by Clare Harwood and is on permanent loan to the Forests Commission Retired Personnel Association (FCRPA) and is displayed at DEECA's Altona Museum.Painting of Conrad Wood by Australian artist Joyce McGrath OAMbushfire, bushfire aviation -

City of Greater Bendigo - Civic Collection

City of Greater Bendigo - Civic CollectionDecorative object - Ceramic platter, Bendigo Pottery, Strathfieldsaye Shire 1866 - 1991, 1991

Graham Masters is a potter based at Sweenies Creek, just outside Bendigo, Victoria who specialises in a patented technique of low relief stoneware depicting Australian animals and landscapes. He obtained a Diploma of Art and Design in Ceramics from the Bendigo Institute of Technology in 1973, then operated a pottery for a year in Bendigo, before becoming an employee, then a partner at Maldon Pottery, Victoria with Neville Wilson and Thomas Metcalf. He left Maldon to set up his own pottery at Sweenies Creek in 1984. (1.) (Judith Pearce). Built in 1869, the (former) Strathfieldsaye Shire Hall is one of The City of Bendigo's earliest surviving public buildings. Designed by George Steane and built by George Pallett in 1869 the Strathfieldsaye Shire Hall has aesthetic significance as a purpose built Shire Hall designed in the Free Classical manner. It is also of importance as an early example of the novel system of cavity wall construction. The building is largely intact and unaltered. Other important elements include the arched portico of the main entrance with brick arched features on either side; the brick quoining and dressings to the round arch windows; the three gabled roof; and the matching chimneys that reinforce the symmetrical design. The Hall has social significance as a temporary schooling facility in the 1870s and as a flood refuge in 1889. The Strathfieldsaye Shire Hall is a brick building designed in the Free Classical manner. This style was favoured by the Public Works Department for a number of public buildings including Shire Halls and courthouses. The form includes a central taller volume flanked by matching smaller gables. In the case of the Shire Hall these would be occupied by the Shire Secretary and Shire Engineer whilst the larger volume was the council chamber. The portico at the front is designed with a flat arch in the centre and matching smaller arches each side. The face red brick is unadorned apart from a plain string course at the roof springing point, brick quoining and dressings to the round arch windows. There are matching chimneys that are located to reinforce the symmetrical design and the original roof is believed to have been slate but is now corrugated iron. Large wheel thrown ceramic platter with a shallow well, broad flaring ledge and raised on a high foot rim. Rim decorated with slab rolled gum trees protruding on centre left and right sides of plater. which reflect the low relief image of trees and the Strathfieldsaye Shire Hall on the surface of the plate. Glazed with golden brown and cream. Front centre top; 'Shire of Strathfieldsaye'. Front lower centre '1866 - 1991 - 125 Years'. Signed 'G Master / 1991' on rim centre right. Reverse; signed 'G Master' / 1991. Bendigo Pottery stamp.shire of strathfieldsaye, bendigo pottery -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1962-1966

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. The colourwork dogs from this design are a very popular motif, and were available in both wool and Orlon in multiple styles from at least 1961-1972, including a cardigan and a pullover, selling 4346 of these in winter 1961. This example most likely dates from 1962-1966. An Illustration depicting this style is catalogued under NWM-09026. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Red children’s machine-knit jumper with white dog motif and green grass colourwork, closes with three red plastic buttons at left shoulder .2 and .3 are sample tags with manufacturing information, including sizes and colours available .4 is a swing tag with manufacturer care instructions.1) [label stitched at back neck] KATHRYN REGD. / 100% ORLON / 24 .2) STYLE: 44/OP – ORLON PULLOVER – ANIMAL MOTIF / SIZE: 18” 20” 22” 24”/ PRICE: 18/6 21/3 25/- 27/6 / COLOR: 18” PALE BLUE. LEMON. WHITE. / 20” – 24” SKY BLUE. LEMON. WHITE. REDCOAT. BOTANY BLUE. SULTRY GREEN. NUTTY BROWN. OATMEAL .3) STYLE: 44/PW – WOOL PULLOVER – ANIMAL MOTIF / SIZE: 18” 20” 22” 24”/ PRICE: 18/6 21/3 25/- 27/6 / COLOR: 18” PALE BLUE. LEMON. / 20” – 24” SKY BLUE. LEMON. REDCOAT. BOTANY BLUE. / SULTRY GREEN. NUTTY BROWN. NED KELLY GREEN. / .4) Obverse: [handwritten] 5/10 (unintelligible) Kathryn / ORLON KNITWEAR / Style : 44/OP / DESIGNED & MANUFACTURED BY / Robert Blake / MELBOURNE Reverse: STANDARD MEASUREMENTS / FIT EXACTLY / LAUNDER PERFECTLY / HOT WATER WILL DAMAGE / THIS GARMENT / WASHING INSTRUCTIONS / 1. Use lukewarm water and mild soap. / 2. Squeeze water out by hand – DO / NOT WRING. / 3. DO NOT ROLL. Hang on / Clothes hanger to dry. / To keep brushed garments like / new, brush frequently with / Nylon brush. / IRONING [m (handwritten)] ORLON garments require little / or no ironing if drip-dried. If / ironing is necessary, it may be done damp or dry, using / a warm iron. / DO NOT USE / STEAM IRON /knitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set, dog motif, animal motif, colourwork -

National Wool Museum

National Wool MuseumTextile - Children's Clothing Set, Kathryn Knitwear, c.1953-1961

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. This style of “brushed wool leginette suit” was produced by Kathryn from at least 1953-1964, though this example likely dates from before 1962. In the winter of 1961, the brand sold 4376 suits of this style. It came with an included nylon brush in order to keep the brushed finish of the garments, which can be found under NWM-09016 Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history. This style of “brushed wool leginette suit” was produced by Kathryn from at least 1953-1964, though this example likely dates from before 1962. In the winter of 1961, the brand sold 4376 suits of this style.Four-piece legging suit consisting of cardigan, leggings, hat and mittens in fuzzy yellow brushed wool. Cardigan is double breasted and closes with two rows of yellow plastic buttons, with a fifth button under the collar. Fold-over collar and cuffs are not brushed wool and provide contrasting texture. Leggings have elastic at waist and ankle to go under foot. Bottom of leg has foot flap. Hat is in a bonnet style and has turnback around face and ties under neck. Mittens are each construced in one piece with no additional thumb pocket, and tie at wrists..1) [label at back neck of cardigan] KATHRYN REGD. CREATED BY PURE WOOL / 20 / ROBERT BLAKE .5) [sample label] [OBVERSE] STYLE: LS/W. LEGGING SUIT – BRUSHED WOOL SIZE: 18” 20” PRICE: 39/9 42/6 3 PCE: 42/9 45/6 4 PCE: COLOR: BLUE. LEMON. PINK. WHITE.knitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set, brushed wool, wool, fluffy -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Crucible, The Patent Plumbago Crucible Company, circa 1873

This crucible was raised from the wreck of the Loch Ard. It is one of six similar relics, in a range of sizes, now in the Flagstaff Hill collection. All were manufactured by the Morgan brothers who founded the Patent Plumbago Crucible Company in 1856, making crucibles in a small factory in Battersea London. A crucible is a container used for purifying and melting metals so that they can be cast in a mold to a predetermined shape and use. They must withstand extremely high temperatures, abrupt cooling, and shed their contents with minimal adherence. The addition of graphite to the traditional firing clays greatly enhanced the durability of industrial crucibles this technique was pioneered by the Morgan Bros thereby making a significant technological advance in foundry technology and metallurgy. The Morgans first noticed the advantages of graphite crucibles at the Great Exhibition held in London in 1851. Initially, they contracted to be sole selling agents for the American-made products of Joseph Dixon and Co. from New Jersey, but in 1856 they obtained that firm's manufacturing rights and began producing their graphite crucibles from the South London site. The Morgans imported crystalline graphite in 4-5 cwt casks from the British colony of Ceylon (now Sri Lanka) and mixed it with conventional English (Stourbridge) clays to be fired in kilns. Their products were purchased by the Royal Mints in London and India and exported to official mints in France and Germany. They were successful exhibitors of their crucibles and furnaces at the London Exhibition held in 1861 (Class 1, Mining, quarrying, metallurgy and mineral products, Exhibit 265, Patent Plumbago Crucible Co). The range of sizes represented by the six crucibles retrieved from the Loch Ard suggests they may have been part of a sample shipment intended for similar promotion in the Australian colonies or at Melbourne's International Exhibition to be held in 1880. A newspaper account of an 1864 tour of the Morgan brothers' 'Black Potteries' at Battersea indicates: "All the pots were numbered according to their contents, each number standing for one kilogram, or a little over two pounds; a No. 2 crucible contains two kilograms; a No. 3, three kilograms, and so on." These numbers are obscured by marine sediment on three of the crucibles in the Flagstaff Hill collection, but those legible on the remaining three are 5, 6, and 8. None of the six is of the same size. (For more information on the Loch Ard wreck see note sec this document) The shipwreck of the Loch Ard is of significance for Victoria and is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefacts from Loch Ard and its collection is significant for being one of the largest accumulation of artefacts from this notable Victorian shipwreck of which the crucible is a small part. The collections objects give us a snapshot of how we can interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time. Through is associated with the worst and best-known shipwreck in Victoria's history.A medium size crucible, or fluxing pot, for heating and pouring molten metal. The container rises in a slight curve from a smaller flat base to a wider open top with a lip for pouring. It was recovered from the wreck of the LOCH ARD. The crucible has a coating of sediment that obscures its numerical specifications of size and capacity. The markings that remain visible indicate it is a Morgan’s crucible, made with graphite to prevent cracking and provide a smooth non-adhesive inner surface. .On base: “…ORGAN’S …ENT”flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, graphite crucible, plumbago crucible, morgan's crucible company, loch ard, morgan potteries, crucible, fluxing pot -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking Tool, William Marple & Sons, Early 20th century

Caulking is the traditional technique used on wooden vessels built with butted or clinker-built planks to fill the gaps between these planks while still allowing the wood to flex and move. This involved driving the irons, hammered in with the mallet, deep into the seams to open them up. After this, spun yarn, oakum (hemp) or cotton was driven deep into the gaps. The hemp or cotton was soaked in creosote or pine tar to make the joins watertight. Caulking also played a structural role in tightening up the hull or deck by reducing the longitudinal movement of the neighbouring planks. William Marples junior joined his father's joinery making business in 1821. In 1860 William's sons joined him and the firm became William Marples and sons. Over the years they acquired John Moseley & Sons a London plane maker and Thomas Ibbotson & Co a Sheffield edge tool maker. Growing to become the most prolific and best known Sheffield tool maker. Their large factory was known as the Hibernia Works. Their trademark was a shamrock that appeared on some of their tools, in 1961 they had about 400 employees. In 1962 the record Tool Company and William Ridgway acquired a fifty percent interest in the company and in 1972 the companies merged with several others to form Ridgway Tools Ltd. After 116 years at its Hibernia Works, the company was moved to Dronfield. A 1982 takeover by A G Bahco of Sweden was short-lived and in 1985 Record Ridgway returned to British ownership first as Record Marples Woodworking Tools Ltd. In 1988 then as Record Holdings PLC in 1993. In 1998 the company accepted a bid from American Tool Corporation, subsequently trading as Record Irwin. The Irwin company itself was acquired by Newell Rubbermaid in 2002 and renamed Irwin Industrial Tool Co. Both the Marples and Record names were re-branded "Irwin" However the name has since been resurrected as Irwin/Marples and applied to wood chisels and table saw blades now made at their new facility in Udine, Italy. As a footnote, William Marples was the uncle of Robert Marples and Joseph Marples, both of whom established competing tool making businesses in Sheffield. The Robert Marples firm disappeared early in the 20th century. After several changes in the company's ownership tools are now made under the Ridgway name but in China. A tool made by a company with a long family history of tool making in Sheffield England, with a member of the Marples family, Joseph Marples establishing a competing tool company which continues today to manufacture quality products for the joinery and shipwrights trades.Caulking tool straight wide blade, Stamped "W Marples & Sons" & James S Steele tool box.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, caulking tool, caulking iron, james s steele -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, Late 19th century or early 20th century

Glass manufacturing has evolved over thousands of years. Glass making has been traced back to 3500 BC in Mesopotamia. The earliest known glass objects were beads, perhaps made by accident while working with metal. In the late Bronze Age, several civilizations discovered how to make vessels and glass bottles by wrapping threads of melted glass around cores of sand or clay. Later, moulds were used to form dishes and table wares. Around the 1st century BC, glassblowing was discovered. This made glass containers less expensive than pottery. Mould-blown glass, the process of blowing a piece of molten glass into a wooden or metal mould, was invented during the 1st century AD. This technique was faster with more consistent results. It paved the way for mass production. It wasn’t until the late 1800s that the production process to become more efficient. In 1887, a company in England created a semi-automatic process that could produce up to 200 bottles an hour. This process has been refined to the point where modern machines can yield more than 600 containers per minute. Blown vs. Manufactured Glass Bottles Nowadays, glass bottles, jars, and cups are usually manufactured on a bigger scale than is found in individual glassblowing studios. If we still depended on hand-blown glass for all of our glass containers, we would see some major differences in the process of creating bottles and jars. First, there's the time. Hand blowing glass takes a significant amount of time, even for one simple container. In contrast, hundreds of jars per minute can be made using modern technology. This leads to the second advantage: price. Because of the automated and streamlined process, the price for manufactured containers is much lower than that of hand-blown glass. Third, manufactured bottles will be much more consistently uniform than bottles blown by hand. Automated glass manufacturing produces nearly identical batches of jars. Glass blowing is awesome for unique, beautiful pieces of art. But for lots of lower priced and uniformly shaped containers, automatic manufacturing is the preferred method to create glass bottles and jars. https://www.containerandpackaging.com/resources/glass-bottles-brief-history The invention and development of glass for domestic items including bottles, has been nothing short of revolutionary. The use of glass bottles, that could be easily washed, led to improved hygiene, and mass manufacturing of drinks of all types, including milk, cordial and alcoholic beverages.Green Glass Bottle Possibly a ginger beer bottle.Concave indentation at the base. Also on base are two raised lumps. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, glass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Tatting craft book, Paragon Art Needlecraft Pty Ltd, Tatting Designs, circa 1940's

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots. The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century. Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". It looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. Paragon knitting, crochet and tatting books have been distributed throughout Australia since the 1930's, originally by "Paragon Art Needlework Pty Ltd" of Sydney, N.S.W. From 1946 these books were designed and printed in Australia from patterns provided by British and Australian thread companies. Consequently these patterns may also appear in similar British and American publications. Paragon Book No. 104 is an instruction book designed for the "beginner" whilst Paragon book No. 105 is designed for the more experienced tatter. The layout of these books was typical of the 1940s period when paper was in short supply. Most of the pattern books were approximately 18 cms wide by 24 cms high and some were smaller at about 13cm by 21 cms. The type used was small (about four lines of text per centimetre) which was difficult to read. This item is an excellent example of a needle work pattern book available to women in the 1940's in Australia.A soft covered, 16 page instruction book titled "Tatting Designs". It has black and white photographs and detailed patterns for tatted doilies, a tray mat, a chairback and arm rests, a cheval set, a luncheon set, collars and edgings for an underskirt, gloves and handkerchief. It is published by Paragon Art Needlecraft of Sydney.Front cover - "Paragon's No 105" "PRICE 1/3" "Tatting Designs" "Household Linens * Personal Wear" Plus a stylized drawing of a deerflagstaff hill maritime museum and village, great ocean road, warrnambool, shipwreck coast, tatting book, tatting patterns, craft, handiwork, handcraft, needlework, shuttle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Tatting craft book, Paragon Art Needlecraft Pty Ltd, Learn to Tat, circa 1940's

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots. The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century. Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". It looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. Paragon knitting, crochet and tatting books have been distributed throughout Australia since the 1930's, originally by "Paragon Art Needlework Pty Ltd" of Sydney, N.S.W. From 1946 these books were designed and printed in Australia from patterns provided by British and Australian thread companies. Consequently these patterns may also appear in similar British and American publications. Paragon Book No. 104 is an instruction book designed for the "beginner" whilst Paragon book No. 105 is designed for the more experienced tatter. The layout of these books was typical of the 1940s period when paper was in short supply. Most of the pattern books were approximately 18 cms wide by 24 cms high and some were smaller at about 13cm by 21 cms. The type used was small (about four lines of text per centimetre) which was difficult to read.This item is an excellent example of a needle work pattern book available to women in the 1940's in Australia.A soft covered 16 page instruction book with black and white photographs and detailed instructions explaining how to tat and eight tatting projects including how to make a collar and handkerchief edgings, published by Paragon Art Needlecraft of Sydney.Front cover - "PARAGON BOOK NO. 104" "PRICE 1/3" "Learn to/ TAT' Back Cover - "36/D5 E/A DO2" - handwritten in pencil flagstaff hill maritime museum and village, warrnambool, great ocean road, shipwreck coast, tatting, tatting pattern book, tatting instructions, handicraft, needlework, shuttle, tatting shuttle, paragon needlecraft, paragon craft book -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionRakehoe (McLeod Tool)

Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts. However, its believed the now common Rakehoe is an Australian variation of the American McLeod Tool which was developed in 1905 by forest ranger Malcolm McLeod of the Sierra National Forest. The late Athol Hodgson advised that predecessors, Reg Torbet who had been the Chief Fire Officer for the Forests Commission from 1948-1956, along with his QLD counterpart Clive Price, went in late 1951 as Australian delegates on a 10 week fire study tour of Nth America organised by the United Nations. They came back with a couple of McLeod tools from Canada. Cam MacLeod (different spelling) had been the Head of Fire Research for the Canadian Forest Service at the time and had supplied them. The tools were ideal for deciduous forests in the eastern provinces and Clive arranged to have them manufactured in QLD. The Rakho, as it was then spelled, was first issued to FCV crews 65 years ago in 1955-56. The American Pulaski had been trialled, but never found favour with Australian firefighters.Rakhoeforests commission victoria (fcv), hand tools, forest harvesting, bushfire -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionFire beater (canvas)

Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts. However, its believed the now common Rakehoe is an Australian variation of the American McLeod Tool which was developed in 1905 by forest ranger Malcolm McLeod of the Sierra National Forest. The late Athol Hodgson advised that predecessors, Reg Torbet who had been the Chief Fire Officer for the Forests Commission from 1948-1956, along with his QLD counterpart Clive Price, went in late 1951 as Australian delegates on a 10 week fire study tour of Nth America organised by the United Nations. They came back with a couple of McLeod tools from Canada. Cam MacLeod (different spelling) had been the Head of Fire Research for the Canadian Forest Service at the time and had supplied them. The tools were ideal for deciduous forests in the eastern provinces and Clive arranged to have them manufactured in QLD. The Rakho, as it was then spelled, was first issued to FCV crews 65 years ago in 1955-56. The American Pulaski had been trialled, but never found favour with Australian firefighters.Fire Beater (canvas) 1930s designforests commission victoria (fcv), hand tools, forest harvesting, bushfire -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionPulaski

Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts. However, its believed the now common Rakehoe is an Australian variation of the American McLeod Tool which was developed in 1905 by forest ranger Malcolm McLeod of the Sierra National Forest. The late Athol Hodgson advised that predecessors, Reg Torbet who had been the Chief Fire Officer for the Forests Commission from 1948-1956, along with his QLD counterpart Clive Price, went in late 1951 as Australian delegates on a 10 week fire study tour of Nth America organised by the United Nations. They came back with a couple of McLeod tools from Canada. Cam MacLeod (different spelling) had been the Head of Fire Research for the Canadian Forest Service at the time and had supplied them. The tools were ideal for deciduous forests in the eastern provinces and Clive arranged to have them manufactured in QLD. The Rakho, as it was then spelled, was first issued to FCV crews 65 years ago in 1955-56. The American Pulaski had been trialled, but never found favour with Australian firefighters.Pulaski Fire Tool Combines an axe and a grubbing hoe. Digging end and cutting end with short wooden handleforests commission victoria (fcv), hand tools, forest harvesting, bushfire -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Rakehoe, McLeod Tool (American)

Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts. However, its believed the now common Rakehoe is an Australian variation of the American McLeod Tool which was developed in 1905 by forest ranger Malcolm McLeod of the Sierra National Forest. The late Athol Hodgson advised that predecessors, Reg Torbet who had been the Chief Fire Officer for the Forests Commission from 1948-1956, along with his QLD counterpart Clive Price, went in late 1951 as Australian delegates on a 10 week fire study tour of Nth America organised by the United Nations. They came back with a couple of McLeod tools from Canada. Cam MacLeod (different spelling) had been the Head of Fire Research for the Canadian Forest Service at the time and had supplied them. The tools were ideal for deciduous forests in the eastern provinces and Clive arranged to have them manufactured in QLD. The Rakho, as it was then spelled, was first issued to FCV crews 65 years ago in 1955-56. The American Pulaski had been trialled, but never found favour with Australian firefighters.First used in 1955Rakehoe Combination of a heavy-duty six-toothed (each 9cm long) rake with a large, sturdy (25cm) hoe.bushfire, forests commission victoria (fcv) -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Forceps, 20th century

Surgical forceps have been used in various forms from ancient times and have evolved into a indispensable instrument for modern surgeries. Forceps are surgical instruments for the practice of medicine which are used for grasping, holding, and manipulating tissues and objects during surgical procedures. Ancient Origins Surgical instruments, including forceps, have been use since man first started working with tools. Ancient civilizations, like Egypt, Greece, and Rome, had physicians who used rudimentary forceps made of bronze or iron. The forceps of the ancient world were often simple in design, with two arms that could be squeezed together to grasp objects. They were primarily used for tasks like extracting foreign bodies or handling tissues. Middle Ages and Renaissance During the Middle Ages, medical knowledge and surgical techniques experienced a decline in Europe. While the Roman empire enjoyed remarkably advanced medical care and practices, its collapse left a vacuum that led to a loss of a centralized medical knowledge and a disruption of education and trade. At the same time, religious superstitions suppressed medical inquiry. With many of the medical texts of Hippocrates and Galen and others lost, the medical practice experienced a decline. However, surgical forceps continued to be used in various forms, albeit with limited advancements. With the Renaissance period came a revival in medical knowledge and innovation. Ambroise Paré, a French surgeon of the 16th century, is credited with introducing improvements to the forceps design, making them more versatile and effective. 18th and 19th Centuries Innovators The 18th and 19th centuries marked a significant period of advancement in surgical instruments, including forceps. The famous French Surgeon Jean-Louis Petit introduced forceps with curved tips, making them more suitable for specific procedures. John Hunter, a Scottish surgeon, designed forceps with fine tips, allowing for more delicate and precise manipulation during surgeries. Joseph Lister, a pioneer of antiseptic surgery, emphasized the importance of cleanliness and sterile instruments during surgical procedures. This led to advancements in forceps sterilization techniques, which greatly improved patient outcomes. Modern Era The late 19th and early 20th centuries saw the development of a wide variety of specialized forceps for different surgical procedures. Advances in metallurgy and manufacturing techniques allowed for more intricate and delicate designs. As surgery became more specialized, forceps were tailored to suit specific procedures, such as neurosurgery, ophthalmology, and gynecology. Contemporary Advances In recent decades, surgical technology evolves continuously. Many surgical procedures are now performed using minimally invasive techniques, which require specialized instruments. Modern surgical forceps are typically made of high-quality stainless steel, stainless steel alloy, or titanium. They come in various shapes, sizes, and designs, each suited to specific surgical tasks. Some forceps have serrated jaws for a better grip, while others have delicate tips for fine tissue manipulation. Modern Forceps The history of surgical forceps is a story of innovation, adaptation, and continuous refinement. From ancient origins to the modern era, these instruments have evolved alongside medical knowledge and surgical techniques, playing a crucial role in improving patient outcomes and advancing the field of surgery. https://www.wpiinc.com/blog/post/history-evolution-of-forceps These forceps were donated to Flagstaff Hill Maritime Village by the family of Doctor William Roy Angus, Surgeon and Oculist. It is part of the “W.R. Angus Collection” that includes historical medical equipment, surgical instruments and material once belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) as well as Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. ABOUT THE “W.R.ANGUS COLLECTION” Doctor William Roy Angus M.B., B.S., Adel., 1923, F.R.C.S. Edin.,1928 (also known as Dr Roy Angus) was born in Murrumbeena, Victoria in 1901 and lived until 1970. He qualified as a doctor in 1923 at University of Adelaide, was Resident Medical Officer at the Royal Adelaide Hospital in 1924 and for a period was house surgeon to Sir (then Mr.) Henry Simpson Newland. Dr Angus was briefly an Assistant to Dr Riddell of Kapunda, then commenced private practice at Curramulka, Yorke Peninsula, SA, where he was physician, surgeon and chemist. In 1926, he was appointed as new Medical Assistant to Dr Thomas Francis Ryan (T.F. Ryan, or Tom), in Nhill, Victoria, where his experiences included radiology and pharmacy. In 1927 he was Acting House Surgeon in Dr Tom Ryan’s absence. Dr Angus had become engaged to Gladys Forsyth and they decided he further his studies overseas in the UK in 1927. He studied at London University College Hospital and at Edinburgh Royal Infirmary and in 1928, was awarded FRCS (Fellow from the Royal College of Surgeons), Edinburgh. He worked his passage back to Australia as a Ship’s Surgeon on the on the Australian Commonwealth Line’s T.S.S. Largs Bay. Dr Angus married Gladys in 1929, in Ballarat. (They went on to have one son (Graham 1932, born in SA) and two daughters (Helen (died 12/07/1996) and Berenice (Berry), both born at Mira, Nhill According to Berry, her mother Gladys made a lot of their clothes. She was very talented and did some lovely embroidery including lingerie for her trousseau and beautifully handmade baby clothes. Dr Angus was a ‘flying doctor’ for the A.I.M. (Australian Inland Ministry) Aerial Medical Service in 1928. Its first station was in the remote town of Oodnadatta, where Dr Angus was stationed. He was locum tenens there on North-South Railway at 21 Mile Camp. He took up this ‘flying doctor’ position in response to a call from Dr John Flynn; the organisation was later known as the Flying Doctor Service, then the Royal Flying Doctor Service. A lot of his work during this time involved dental surgery also. Between 1928-1932 he was surgeon at the Curramulka Hospital, Yorke Peninsula, South Australia. In 1933 Dr Angus returned to Nhill and purchased a share of the Nelson Street practice and Mira hospital (a 2 bed ward at the Nelson Street Practice) from Dr Les Middleton one of the Middleton Brothers, the current owners of what previously once Dr Tom Ryan’s practice. Dr Tom and his brother had worked as surgeons included eye surgery. Dr Tom Ryan performed many of his operations in the Mira private hospital on his premises. He had been House Surgeon at the Nhill Hospital 1902-1926. Dr Tom Ryan had one of the only two pieces of radiology equipment in Victoria during his practicing years – The Royal Melbourne Hospital had the other one. Over the years Dr Tom Ryan had gradually set up what was effectively a training school for country general-practitioner-surgeons. Each patient was carefully examined, including using the X-ray machine, and any surgery was discussed and planned with Dr Ryan’s assistants several days in advance. Dr Angus gained experience in using the X-ray machine there during his time as assistant to Dr Ryan. When Dr Angus bought into the Nelson Street premises in Nhill he was also appointed as the Nhill Hospital’s Honorary House Surgeon 1933-1938. His practitioner’s plate from his Nhill surgery is now mounted on the doorway to the Port Medical Office at Flagstaff Hill Maritime Village, Warrnambool. When Dr Angus took up practice in the Dr Edward and Dr Tom Ryan’s old premises he obtained their extensive collection of historical medical equipment and materials spanning 1884-1926. A large part of this collection is now on display at the Port Medical Office at Flagstaff Hill Maritime Village in Warrnambool. In 1939 Dr Angus and his family moved to Warrnambool where he purchased “Birchwood,” the 1852 home and medical practice of Dr John Hunter Henderson, at 214 Koroit Street. (This property was sold in1965 to the State Government and is now the site of the Warrnambool Police Station and an ALDI sore is on the land that was once their tennis court). The Angus family was able to afford gardeners, cooks and maids; their home was a popular place for visiting dignitaries to stay whilst visiting Warrnambool. Dr Angus had his own silk worm farm at home in a Mulberry tree. His young daughter used his centrifuge for spinning the silk. Dr Angus was appointed on a part-time basis as Port Medical Officer (Health Officer) in Warrnambool and held this position until the 1940’s when the government no longer required the service of a Port Medical Officer in Warrnambool; he was thus Warrnambool’s last serving Port Medical Officer. (Masters of immigrant ships arriving in port reported incidents of diseases, illness and death and the Port Medical Officer made a decision on whether the ship required Quarantine and for how long, in this way preventing contagious illness from spreading from new immigrants to the residents already in the colony.) Dr Angus was a member of the Australian Medical Association, for 35 years and surgeon at the Warrnambool Base Hospital 1939-1942, He served with the Australian Department of Defence as a Surgeon Captain during WWII 1942-45, in Ballarat, Victoria, and in Bonegilla, N.S.W., completing his service just before the end of the war due to suffering from a heart attack. During his convalescence he carved an intricate and ‘most artistic’ chess set from the material that dentures were made from. He then studied ophthalmology at the Royal Melbourne Eye and Ear Hospital and created cosmetically superior artificial eyes by pioneering using the intrascleral cartilage. Angus received accolades from the Ophthalmological Society of Australasia for this work. He returned to Warrnambool to commence practice as an ophthalmologist, pioneering in artificial eye improvements. He was Honorary Consultant Ophthalmologist to Warrnambool Base Hospital for 31 years. He made monthly visits to Portland as a visiting surgeon, to perform eye surgery. He represented the Victorian South-West subdivision of the Australian Medical Association as its secretary between 1949 and 1956 and as chairman from 1956 to 1958. In 1968 Dr Angus was elected member of Spain’s Barraquer Institute of Barcelona after his research work in Intrasclearal cartilage grafting, becoming one of the few Australian ophthalmologists to receive this honour, and in the following year presented his final paper on Living Intrasclearal Cartilage Implants at the Inaugural Meeting of the Australian College of Ophthalmologists in Melbourne In his personal life Dr Angus was a Presbyterian and treated Sunday as a Sabbath, a day of rest. He would visit 3 or 4 country patients on a Sunday, taking his children along ‘for the ride’ and to visit with him. Sunday evenings he would play the pianola and sing Scottish songs to his family. One of Dr Angus’ patients was Margaret MacKenzie, author of a book on local shipwrecks that she’d seen as an eye witness from the late 1880’s in Peterborough, Victoria. In the early 1950’s Dr Angus, painted a picture of a shipwreck for the cover jacket of Margaret’s book, Shipwrecks and More Shipwrecks. She was blind in later life and her daughter wrote the actual book for her. Dr Angus and his wife Gladys were very involved in Warrnambool’s society with a strong interest in civic affairs. He had an interest in people and the community. They were both involved in the creation of Flagstaff Hill, including the layout of the gardens. After his death (28th March 1970) his family requested his practitioner’s plate, medical instruments and some personal belongings be displayed in the Port Medical Office surgery at Flagstaff Hill Maritime Village, and be called the “W. R. Angus Collection”. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The collection of medical instruments and other equipment is culturally significant, being an historical example of medicine, administration, household equipment and clothing from late 19th to mid-20th century. Dr Angus assisted Dr Tom Ryan, a pioneer in the use of X-rays and in ocular surgery. Forceps from W.R. Angus Collection. Stainless steel, elbow shape in middle, hollow claw shape ends, one handle is open circle, handles clip together. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dr w r angus, dr ryan, surgical instrument, t.s.s. largs bay, warrnambool base hospital, nhill base hospital, mira hospital, flying doctor, department of defence australia, australian army, army uniform, medical treatment, medical history, medical education, forceps, surgery -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1975

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. In a world where wool garments all had to be washed by hand, the invention of machine-washable acrylic fibres and widespread adoption of washing machines in ordinary Australian homes in the 1950s and 60s posed a major risk to the wool industry, and by extension the entire Australian economy. With the price of wool falling, the CSIRO and the Australian Wool Board worked together from the 1950s on a number of developments to keep Australian wool competitive and desirable to the public, many of which came out of the Geelong research labs. While progress had been made in the preceding decades, 1970 saw a major breakthrough; the invention of a new method of making wool washable and shrink-proof, most commonly known as ‘Superwash’. It is a technology that is still highly used to this day, and is very recognisable to those who use commercial wool yarn to knit or crochet. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Blue wool turtleneck ‘skivvy’ jumper in all over rib pattern with long sleeves. .2) swing tag with woolmark logo for ‘Superwash Wool’1.)[white label at back neck with blue writing] KATHRYN REGD. (Woolmark Logo) PURE NEW WOOL Superwash SIZE 2 HGT. 92cm MADE IN AUSTRALIA 2.)[retail swing tag for ‘Superwash Wool’] [OBVERSE] [woolmark logo] [handwritten in blue pen] 314 [printed] PURE NEW WOOL [handwritten] 2 Superwash Wool Machine Washable [INTERNAL] [woolmark logo] PURE NEW WOOL YOU ARE NOW THE OWNER OF A SUPERWASH WOOL GARMENT That has been specially treated to withstand a lifetime of machine washing. SUPERWASH WOOL has all the desirable qualities of wool – soft handle, comfort, warmth and style. Not all wool knitwear has the SUPERWASH treatment so remember always to look for the special “SUPERWASH” label and swing ticket. To was SUPERWASH WOOL just follow the instructions of the garment label. [woolmark logo] PURE NEW WOOL SUPERWASH WOOL THE WOOL YOU WASH IN THE MACHINE.knitwear, children's knitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting, csiro, national wool board, superwash, australian wool innovation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTatting Shuttle

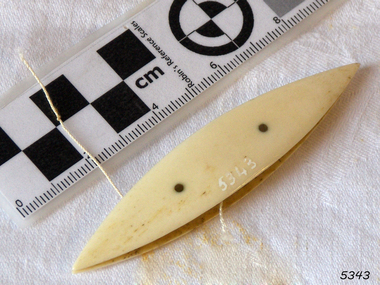

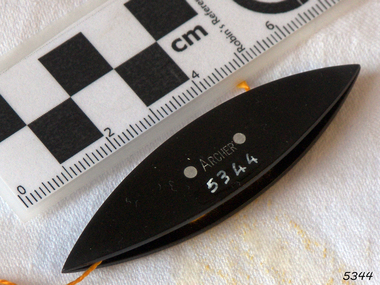

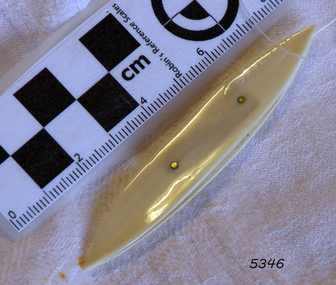

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots. The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century. Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". Tatting looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. A shuttle is a small tool that looks like a small boat "sailing" in and out of the thread. Tatting is called "schiffchenarbeit" in German, which means "the work of a little boat". There are two popular types of shuttles. The first has closed ends and a removable bobbin where the thread is wound around - often made from metal or plastic. The second type has a post in the center where the thread is wound. The ends of this bobbin are open but snug. Because it is constructed in two pieces, it can be made from materials like bone, ivory or mother of pearl. Shuttles hold a larger amount of thread (as compared with needles) which means fewer ends to weave in. Fishermen in the past are thought to have used large shuttles to weave cord into certain knots whilst making their fishing nets. Their methods were copied by weavers, who innovated by using threads and smaller shuttles to make lace.Tatting Shuttle, Ivoryflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tatting shuttle, handcraft, needlework -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTatting Shuttle

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots. The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century. Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". Tatting looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. A shuttle is a small tool that looks like a small boat "sailing" in and out of the thread. Tatting is called "schiffchenarbeit" in German, which means "the work of a little boat". There are two popular types of shuttles. The first has closed ends and a removable bobbin where the thread is wound around - often made from metal or plastic. The second type has a post in the center where the thread is wound. The ends of this bobbin are open but snug. Because it is constructed in two pieces, it can be made from materials like bone, ivory or mother of pearl. Shuttles hold a larger amount of thread (as compared with needles) which means fewer ends to weave in. Fishermen in the past are thought to have used large shuttles to weave cord into certain knots whilst making their fishing nets. Their methods were copied by weavers, who innovated by using threads and smaller shuttles to make lace.Tatting Shuttle, Black plastic, "ARCHER" inscribed. "ARCHER" inscribed.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tatting shuttle, handcraft, needlework -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTatting Shuttle

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots. The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century. Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". Tatting looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. A shuttle is a small tool that looks like a small boat "sailing" in and out of the thread. Tatting is called "schiffchenarbeit" in German, which means "the work of a little boat". There are two popular types of shuttles. The first has closed ends and a removable bobbin where the thread is wound around - often made from metal or plastic. The second type has a post in the center where the thread is wound. The ends of this bobbin are open but snug. Because it is constructed in two pieces, it can be made from materials like bone, ivory or mother of pearl. Shuttles hold a larger amount of thread (as compared with needles) which means fewer ends to weave in. Fishermen in the past are thought to have used large shuttles to weave cord into certain knots whilst making their fishing nets. Their methods were copied by weavers, who innovated by using threads and smaller shuttles to make lace.Tatting Shuttle, tortoise-shellflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tatting shuttle, handcraft, needlework -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTatting Shuttle

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots. The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century. Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". Tatting looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. A shuttle is a small tool that looks like a small boat "sailing" in and out of the thread. Tatting is called "schiffchenarbeit" in German, which means "the work of a little boat". There are two popular types of shuttles. The first has closed ends and a removable bobbin where the thread is wound around - often made from metal or plastic. The second type has a post in the center where the thread is wound. The ends of this bobbin are open but snug. Because it is constructed in two pieces, it can be made from materials like bone, ivory or mother of pearl. Shuttles hold a larger amount of thread (as compared with needles) which means fewer ends to weave in. Fishermen in the past are thought to have used large shuttles to weave cord into certain knots whilst making their fishing nets. Their methods were copied by weavers, who innovated by using threads and smaller shuttles to make lace.Tatting Shuttle, ivory, flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tatting shuttle, handcraft, needlework -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTatting Shuttle

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots. The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century. Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". Tatting looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. A shuttle is a small tool that looks like a small boat "sailing" in and out of the thread. Tatting is called "schiffchenarbeit" in German, which means "the work of a little boat". There are two popular types of shuttles. The first has closed ends and a removable bobbin where the thread is wound around - often made from metal or plastic. The second type has a post in the center where the thread is wound. The ends of this bobbin are open but snug. Because it is constructed in two pieces, it can be made from materials like bone, ivory or mother of pearl. Shuttles hold a larger amount of thread (as compared with needles) which means fewer ends to weave in. Fishermen in the past are thought to have used large shuttles to weave cord into certain knots whilst making their fishing nets. Their methods were copied by weavers, who innovated by using threads and smaller shuttles to make lace.Tatting Shuttle, black plastic flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tatting shuttle, handcraft, needlework -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Serving Mallet, Unknown