Showing 276 items matching "carding wool"

-

![Photograph, Carding machinery [R S & S]](/media/collectors/510b3f7f023fd725b4cd52cc/items/5406605b9821f50e3cc9feee/item-media/5406605b9821f50e3cc9feef/item-fit-380x285.jpg) National Wool Museum

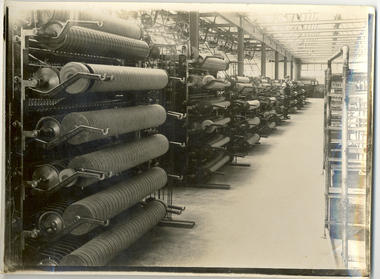

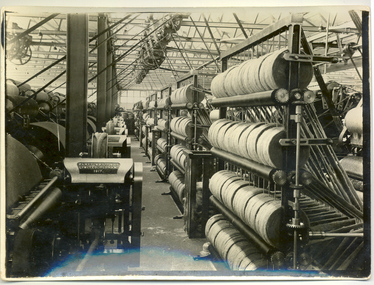

National Wool MuseumPhotograph, Carding machinery [R S & S]

Carding department, R S & S mill.2/ end of carding as carded yarn comes/ off machine for spinning/ R S & Stextile machinery textile mills - history textile mills - staff textile mills, returned soldiers and sailors mill, carding, textile machinery, textile mills - history, textile mills - staff, textile mills -

National Wool Museum

National Wool MuseumBook, Wool Year Book 1927

"Wool Year Book 1927" compiled by the editor of the 'Textile Mercury'.Mr A G .[?]textile history textile finishing wool processing textile machinery weaving, alexander lau pty ltd, carding, spinning machinery, weaving machinery, lau, mr alexander - alexander lau pty ltd, textile history, textile finishing, wool processing, textile machinery, weaving -

National Wool Museum

National Wool MuseumBook, Yarn sample, Children's wear colour card: basic range for knitwear

"Children's wear colour card: basic range for knitwear", British Colour Council, 1960.dyeing knitting yarn production, alexander lau pty ltd british colour council, lau, mr alexander - alexander lau pty ltd, dyeing, knitting, yarn production -

National Wool Museum

National Wool MuseumCard, Christmas, Albany Woollen Mills

Wishing you a Merry Xmas and a Bright and Happy New Year/ from/ The Directors, Management and Staff/ of / Albany Woollen Mills/ mAlbany and Freemantle Millstextile mills - management, alexander lau pty ltd albany woollen mills, lau, mr alexander - alexander lau pty ltd -

National Wool Museum

National Wool MuseumPhotograph

James Murgatroyd worked in textile mills in England, Victoria and NSW. His son Fred worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.The Murgatroyd CollectionF Murgatroydtextile machinery textile mills weaving mills textile mills - staff textile mills, federal woollen mills ltd tweedside woollen mills yarra falls mill collins bros mill pty ltd, carding, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills, textile mills - staff -

National Wool Museum

National Wool MuseumPhotograph, Federal Mill: dyeing room c.1918-1920

James Murgatroyd worked in the textile industry in England, and in Victoria and New South WalesF Murgatroyd Federal Mill/ Dyeing Room/ c.1918-1920textile machinery textile mills weaving mills textile mills - staff textile mills, federal woollen mills ltd tweedside woollen mills yarra falls mill collins bros mill pty ltd, carding, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills, textile mills - staff -

National Wool Museum

National Wool MuseumPhotograph

James Murgatroyd worked in textile mills in England, Victoria and NSW. His son Fred worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.F Murgatroydtextile machinery textile mills weaving mills textile mills - staff textile mills, federal woollen mills ltd tweedside woollen mills yarra falls mill collins bros mill pty ltd, carding, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills, textile mills - staff -

National Wool Museum

National Wool MuseumPhotograph, Federal Mill: winding room .c1918-1920

James Murgatroyd worked in textile mills in England, Victoria and NSW. His son Fred worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.F Murgatroyd Federal c1918-1920/ Winding Roomtextile machinery textile mills weaving mills textile mills - staff textile mills, federal woollen mills ltd tweedside woollen mills yarra falls mill collins bros mill pty ltd, carding, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills, textile mills - staff -

National Wool Museum

National Wool MuseumPhotograph

James Murgatroyd worked in textile mills in England, Victoria and NSW. His son Fred worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.F Murgatroydtextile machinery textile mills weaving mills textile mills - staff textile mills, federal woollen mills ltd tweedside woollen mills yarra falls mill collins bros mill pty ltd, carding, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills, textile mills - staff -

National Wool Museum

National Wool MuseumPhotograph

James Murgatroyd worked in textile mills in England, Victoria and NSW. His son Fred worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.F Murgatroydtextile machinery textile mills weaving mills textile mills - staff textile mills, federal woollen mills ltd tweedside woollen mills yarra falls mill collins bros mill pty ltd, carding, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills, textile mills - staff -

National Wool Museum

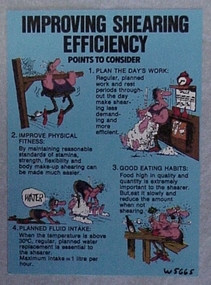

National Wool MuseumCard, Improving Shearing Efficiency

Produced by the Australian Wool Corporation and the National Rural Industry Training Committee, along with booklet, "Improving Shearing Efficiency" and poster."Improving Shearing Efficiency"shearing, national rural industry training committee street, mr tony - australian wool corporation -

![Business Card, [Squatter]](/media/collectors/510b3f7f023fd725b4cd52cc/items/54065f789821f50e3cc9f624/item-media/54065f789821f50e3cc9f625/item-fit-380x285.jpg) National Wool Museum

National Wool MuseumBusiness Card, [Squatter]

Associated documents from Mr R Lloyd provide further informationsheep stations - management wool growing squatters, lloyd, mr robert, sheep stations - management, wool growing, squatters -

National Wool Museum

National Wool MuseumPhotograph

Acquired when "Classweave Industries" closed down.H L S POTTER/ PHOTO STORES/...textile mills woollen mills textile mills - staff, classweave industries pty ltd federal woollen mills ltd, carding, scouring, textile mills, woollen mills, textile mills - staff -

National Wool Museum

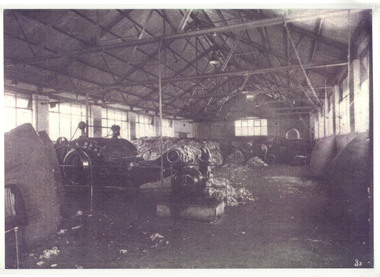

National Wool MuseumPhotograph

Acquired when "Classweave Industries" closed down.H L S POTTER/ PHOTO STORES/...textile mills woollen mills, classweave industries pty ltd federal woollen mills ltd, carding, textile mills, woollen mills -

National Wool Museum

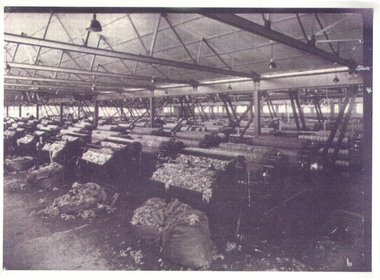

National Wool MuseumPhotograph

Acquired when "Classweave Industries" closed down.H L S POTTER/ PHOTO STORES/...textile mills woollen mills, classweave industries pty ltd federal woollen mills ltd, carding, textile mills, woollen mills -

![Photograph, [No 1 Carding Room Machines c30's]](/media/collectors/510b3f7f023fd725b4cd52cc/items/54065f599821f50e3cc9f4d6/item-media/54065f599821f50e3cc9f4d7/item-fit-380x285.jpg) National Wool Museum

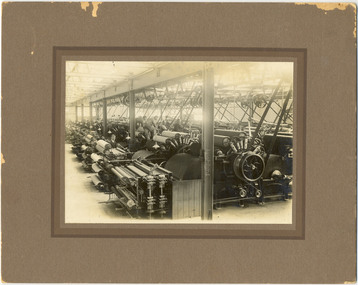

National Wool MuseumPhotograph, [No 1 Carding Room Machines c30's]

Acquired when "Classweave Industries" closed downNo 1 Carding Room Machines c30's still in use until 1960's 15 7A 14/57 74%textile machinery woollen mills, classweave industries pty ltd federal woollen mills ltd, carding, textile machinery, woollen mills -

National Wool Museum

National Wool MuseumPhotograph, No 1 carding room

Acquired when "Classweave Industries" closed down16 N01 Carding Room 13/87 p?honetextile mills - staff woollen mills, classweave industries pty ltd federal woollen mills ltd, carding, textile mills - staff, woollen mills -

Stawell Historical Society Inc

Stawell Historical Society IncArchive - Laboratory Books, W.I.R.E. Publications

Dye laboratory books. Norwellen / Aunde now closed. 10 in a bunlde 1 The WIRA DIRECTORY WIRA INST amentation 2 seperateBlue Card Covers: Grey Covers X2. 10 in a bundle 1 individualWool Industies Reseach Association. Members only Private Publication Torrindon Haeadley Leeds 6norwellen -

Stawell Historical Society Inc

Stawell Historical Society IncBook - Labratory Book, CIBA - GEIG 7X 2

Dye Laboratory Book. Aunde/ Norwellan. Now Closed North Western Woolen Mills became Norwellan Textiles then AUNDEBlue CardWool / Cotton union blends Dyeing Process -

Stawell Historical Society Inc

Stawell Historical Society IncArchive - Labratory Book, Textile Titles of the World 1995 & Publications For the Wool Industry 1963-1991

Labratory Books from Aunde / Norwellan now closed North Western Woolen Mills became Norwellan Textiles then AUNDE5257 - Orange Cardcaover with Blue Print 5257-1 Rec Card Cover With Black Orint5257 Austicks Bookshops In Association with The Testile Industry (Coat of Arms Above Print) Textiles of the World 1995 A Catalogue of Current Literature 5257-1 WRONZ (in rectangle ) Publications for the Wool Industry 1963 - 1991 May 1992 WRONZ ( in rectangle) Wool research Orginisation of New Zealand (inc) Private Bag 4749 Christchurch New Zealand. norwellan -

Yarrawonga and Mulwala Pioneer Museum

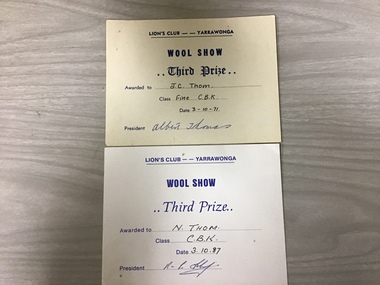

Yarrawonga and Mulwala Pioneer MuseumMemorabilia - Wool Show Prize cards, Yarrawonga Chronicle, Lions Club Wool Show

The Lions Club has been conducting their Wool Show in conjunction with the Yarrawonga Show Committee since 1985. Proceeds from the sale of fleeces donated by local farmers are donated to worthy causes in the communitySmall Third Prize cards. White card, blue print. Awarded to J.C. and N. C. Thom for fine comeback wool fleecessheep wool, agricultural show -

National Wool Museum

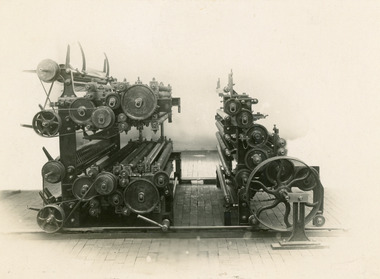

National Wool MuseumPhotograph, Carding Machine, Unknown

Photograph most likely used for promotional purposes. The machine possibly could have been manufactured by Chadwick Machine Co Ltd, a British textile machine company established in 1899.Black and white photograph of a carding machine.Rear handwritten top edge - Chadwickstextile machinery, wool manufacture, wool, spinning -

National Wool Museum

National Wool MuseumPhotograph, Carding Machine, Unknown

Photographs were most likely used for promotional purposes. The photographed machine was made by Tomlinsons (Roshdale) Limited, was British machine manufacture company based in Rochdale.Black and white photo of a Rag Puller Machine in landscape format. Location of photo looks to be in a textile mill.On machine - Tomlinsons (Roshdale) Limited.textile machinery, wool manufacture, wool, timlinsons, rag pulling -

National Wool Museum

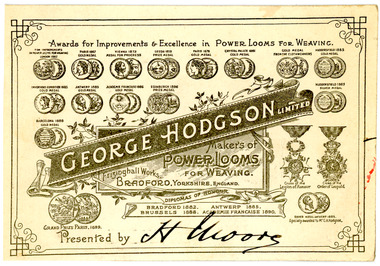

National Wool MuseumAdministrative record - Business Card, George Hodgson Limited Business Card, Unknown

George Hodgson Limited Business Card, a British loom manufacture based in Bradford England. The card showcases the awards the company as won as well as a description of one of their looms.Cream business card printed with the black ink. The front of the card lists the awards and medals the company had one in the background with an image of each award. The company logo is placed in the center. The back of the card has a drawing of a loom with a decorative border.Front top edge - Awards for Improvements & Excellence in Power Looms for Weaving. Front middle - George Hodgson Limited Makers of Power Looms for Weaving. Bradford, Yorkshire, England Front bottom edge - Presented by J T Elioors (?) Back bottom edge - One shaft heavy underpick worsted and woollen cloth loom, with 4 holed drop box on each side, fitted with positive wheel dobby.textile machinery, wool manufacture, wool, loom, george hodgson limited -

National Wool Museum

National Wool MuseumTextile - Onkaparinga Blanket, Waffle Collection, Unknown

Onkaparinga started in South Australia in 1869. Migrating from Germany, two brothers, Heinrich and Edward Kramm, both weavers, purchased and brought with them some machinery and established themselves in Hahndorf in a mud hut. Their original plant consisted of one carding machine, one spinning mule of 30 spools and 2 hand looms. The spinning mule was horse driven, the others all hand operated. The wool was washed by hand and dried in the sun then teased by hand. Now 145 years later the brand name Onkaparinga, is known all over the world, the products reflect the experience, passion and ingenuity of over a century's tradition in providing luxurious home wares. Donated to the National Wool Museum by Joyce GrayLight orange waffle weave woolen blanket, with nylon trimming. Product tag included with plastic case. On product tag - The better way to sleep. Onkaparinga onkaparinga, blanket, wool, kramm -

National Wool Museum

National Wool MuseumPicker

... before it is carded and spun. The picker opens the wool’s locks... of wool before it is carded and spun. The picker opens the wool’s ...Wool picking machine designed to separate locks of wool before it is carded and spun. The picker opens the wool’s locks which makes it easier to send the fleece through a carding machine. It does this by teasing the fibres (which can also be done by hand just by pulling the lock structure apart), but a picker does this in bulk and much quicker than what can be done by hand. It is possible to spin fibres directly after the picking stage; however, it is usually more desirable to card and blend them with other fibres. Typically, at a textile mill, a picking machine can separate enough lengths of fibre for a full day’s work after just a single hour. It will also help to remove any vegetation matter or other any unwanted elements that may be present in the wool. The quality of the casting on this machine suggest that it was made locally, either in Australia or New Zealand. Mike Leggett, the donor of the machine, acquired it from New Zealand where the seller said it had been used by his father to pick wool to make hand stuffed horse saddles. Mike attempted to used it a couple of times to pick alpaca hair, but the speed of the attached motor caused damage to the fibres. The motor is thought to be an added attachment, sometime around the 1960s judging by its age, while the machine itself is thought to be dated around the 1920s. The machine works by inserting wool through the rollers. Initially there was a conveyor belt feeder system which was powered by the handle on the side. This conveyor belt has been removed however, most likely due to age and deterioration. Wool is now fed through the initial teeth and is met by a spiked rotating drum which works to separate the fibres. The separated fibres would then complete a loop of the drum before being dispatched somewhere below, around where the motor presently sits, at a rapid rate of speed. Typically this wool will be collected in a closet or large catchment area, as can be seen from the 8:47 minute marker in the linked video (link - https://www.youtube.com/watch?v=kMjx-t3tH3A). It is not apparent how the wool is collected with this machine. Red and green machine with four green legs currently attached to a wooden pallet with wheels for easy movement. The green legs lead up to a red central circular barrel from which many attachments are present. Also present on the wooden pallet is a small black motor which is attached by a rubber belt to the central drum inside the red barrel. The belt spins the wooden drum via a dark red circular plate attached to the side of the drum. On the other side of the red barrel, a green handle extends for turning the picker’s conveyor belt feeder system. Two green walls extend forward from the central red barrel, guarding either side of where the conveyor belt would have been. At the start of these walls is a wooden cylinder, which the conveyor belt would have wrapped around, followed by two interlocking gears which rotate and accept the fed wool. The red roof extends over the central cylinder from here, securing the wool inside and protecting hands from the heavily spiked internal wooden cylinder which rotates and separates (picks) the wool. Extending over the top of this red roof is a green handle which reaches to the back of the machine (not pictured). Here it accepts a weight to ensure pressure is always present for the initial feeder interlocked gear teeth. There are two large gear cogs on the rubber belt side of the machine and 3 small gear cogs on the handle side of the machine, all coloured green. A green handle is also present at the rear of the machine, below the location from which the weight is hanging. A power cable extends from the motor and there are two adjustable metal rods on the top of the machine, the purpose of these rods is presently unknown. Black texter. On top of drum. Wording: HG3707 Wording. Imprint: BRACEWIND BLYN On motor. Wording AEIwool picking, textile manufacturing, wool processing -

National Wool Museum

National Wool MuseumClothing - Jacket, 1978

The wool for this jacket began on the back of two sheep many kilometres apart. The first fleece for the warp was shorn from a single Merino at Currotha in Moree, NSW. The wool was 21-22 micron and the bloodline is a cross between Bundemar, Rossmore and Eural. The second sheep that provided wool for the weft was shorn in Beaufort, Victoria. It was a single Corriedale fleece shorn at Niawanda. The distance between these two towns is approximately 1250kms; a 15-hour car ride between paddocks. The two fleeces were spun and weaved together by the donor’s mother, Marjorie Allnutt. A level of talent is required to spin Merino fleeces. It is easier to spin cross bred wool, such as Corriedale, because it is less dense and much easier to comb, card and then tease out for a spinning wheel. The donor Philip Allnutt had a suit tailored out of the completed fabric at Ravensdale J & Son, 37 Swanson Street, Melbourne. The tailor was then a member of the Master Tailors Federation of Victoria. The business closed around 1986. Adding to the jacket’s story is its relationship to the household board game “Squatter”. Marjorie Allnutt was the sister-in-law of Robert Crofton Lloyd, the inventor of the wool themed boardgame. With more than 500,000 games sold in Australia as of 2007, it is the most successful board game ever produced in the country. The original “Squatter” board game is located within the National Wool Museum’s Collection. Philip Allnutt donated the Jacket to the National Wool Museum Collection in 2021. Cream singled breasted jacket with a narrow overlap and one column of buttons for fastening. The jacket features notched lapels of a medium width and two buttons of a cream & brown marble. The jacket has three visible pockets. A jetted pocket with no flap is on the right breast. A further two jetted no flap pockets finish an inch above the hem, on either side of the opening. Internally, the jacket features a further two pockets and a white silk lining for comfort. At the cuffs, the jacket utilises another 2 buttons of the same cream & brown marble.merino, currotha, moree, nsw, niawanda, corriedale, beaufort, victoria, hand spun, hand weaved -

National Wool Museum

National Wool MuseumPostcard, 1910

Postcard was given to David Phillips (Donor) by a friend who was involved in the wool industry through employment at CSRIO.Postcard with black and white image on front. Image is of two men standing in front of a carding machine inside of the Warrnambool Woollen Mill. Image is printed onto postcard despite the non-straight lines suggesting the image may have been cut and pasted. Reverse of the postcard has handwritten message detailing image on the front of the postcard.Handwriting, black ink: Warrnambool Woollen Mill 1910 / First carding Machine bins / Erected b W. (Bill) + (?) / Pontefract warrnambool woollen mill, carding machine -

National Wool Museum

National Wool MuseumBook - Wool Classing Exercise Book, 1936-38

The story of 90 years of wool classing between father & son begins in 1936, when a young boy by the name of Stanley James Hucker walked through the doors of the Gordon Technical School in Geelong. Born in 1921, Stanley was 15 years of age when he began his 3-year course in Wool Classing. 30 years later, Stanley’s second son Denis completed the same 3-year wool classing course. Beginning in 1966, Denis attended the same Gordon Technical School and walked the same halls as his father before him. Stanley finished his course in 1938. He went back to the family farm in Lake Bolac for a brief period before enrolling in the Second World War. At the completion of the war, Stanley returned home and married before gaining a soldier settler allotment, north of Willaura. This enabled Stan to use his wool classing knowledge. He ran between 1,500 and 2,000 sheep for many years, while his wool classer stencil also allowed him to go out and class at various sheds around the area. He held his stencil from 1938 until he retired at the age of 60 in 1981. On retirement, his second son Denis was working in the district, managing a local property while also leasing land himself. Upon his father’s retirement, Denis had the opportunity to lease his father’s farm, an opportunity he could not refuse. Denis had finished his wool classing course at the Gordon Technical School in 1968, graduating dux of his class. He began working with a local contractor and started classing wool in his team. Denis gained a great deal of experience working as part of this team in big sheds of up to 8 stands servicing between 10 & 20,000 sheep. It was not all smooth sailing for Denis however, and he soon learnt an important lesson. Class wool the way you’re taught, don’t listen to the owner standing over your shoulder. At a clip of Corriedales near Casterton, Denis was pushing too many fleeces into the line of fine wool. This resulted in a notice from the Australian Wool Exchange (AWEX) “mixing counts too much, submit three clips for inspection”. Denis was able to submit 3 clips with no further complaints, however, this proved a valuable lesson he would never forget over his long career classing wool. In the early 1980s, when Denis was leasing two properties including his father’s, things were going well until drought struck. February 1983 was the date of the Ash Wednesday bushfires, and saw Melbourne have three days over 40 °C for only the second time on record. This period saw Denis give away farming, turning towards contracting work instead. After the difficult times of the early 1980s, the next two decades were a good time for the sheep industry. 15 micron wool was selling for prices between 4 to 5,000 cents per kilo, double what you’d expect for the same wool in 2022. In 1995 a single bale of wool sold for a million dollars. This was a good time for Denis too. His contracting work saw him employing local shearers and shed staff. His team was involved with the shearing and classing of more than 130,000 sheep. After 20 years of contracting, it was time for Denis to transition into the next phase of his life. He gave up independent contracting, preferring instead to return to being a member of someone else’s team. In 2018, having completed 50 years of wool classing, it was time to call it a day and retire completely. At the annual Gordon Wool School Old Students Association dinner held in 2018, Denis was presented with his 50 years as a registered wool classer stencil awarded by the Australian Wool Exchange (AWEX). This is a rare honour achieved by few. As of February 2020, a total of 430 wool classers had achieved this 50-year milestone. For Denis however, his proudest achievement is achieving 90 years of wool classing with his father. The National Wool Museum is proud to share the collection of objects gained from 90 years in the wool classing industry by Stanley and Denis. This ranges from Stanley’s first stencil and Wool Sample book, started when he first attended the Gordon in 1936. The collection concludes 90 years later with Denis’ 50 years of wool classing Stencil. The collection contains many more objects, all telling the story of these 90 years, and the hard work invested by this dedicated father and son duo. This is the first in a series of 5 wool classing exercise books. They were written by Stanley Hucker in his time at the Gordon Technical College from 1936-1938. This book begins in a cover of black vinyl with a strip of red tape on the spine to give added support. Some of the vinyl has been removed on the cover, revealing blue card beneath. A sticker label is also found on the front cover. It has been damaged. Part of the sticker has been removed, while blue ink can also be found obscuring the text below. Internally, the book is handwritten on yellowed pages with blue lines for the assistance in clarity of handwriting. The pages are also surrounded by a margin of red pen. The exercise book’s content is about veterinary studies relating to the diseases, injuries, and treatment of sheep. It is handwritten and accompanied by an occasional hand drawn diagram. A selection of pages have been photographed to give an impression of the information taught in classes, 90 years ago. This includes information about a sheep’s heart, hind limbs, and reproduction system in ewes. Front Cover. Wording, printed and handwritten “SERVICE / EXERCISE BOOK / NAME Stanley Hucker / GRADE wool classing / SCHOOL Gordon Technical / SUBJECT Veterinary”gordon institute geelong, wool classing, 1930s sheep farming, 90 years wool classing between father & son -

National Wool Museum

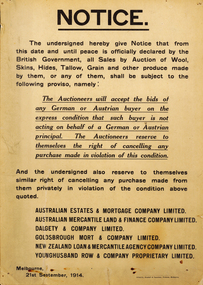

National Wool MuseumPoster, Notice, 1914

This set of two posters were displayed in the sale rooms for wool, skin, hides, and tallow at the Wool Exchange in Melbourne, on the corner of King and Little Collins Street. The posters were found in the storeroom under the white sale room in the late 1970s, when the Melbourne Woolbrokers Association moved around the corner to 530 Little Collins Street. The first poster is dated 21st of September 1914. It predates the second poster which replaced it on the 4th of December 1914. The posters detail that the Auctioneer will accept any bid from German or Austrian buyers on the condition that the buyer is not acting on behalf of any country which is at war with Great Britain. The Auctioneer also reserves the right to cancel any purchases found to be in violation of this condition. Presumably, the posters were in use until 1916, when Australia's 7th Prime Minister, Billy Hughes, negotiated the sale of Australia's entire wool clip to the British Government for the remainder of The Great War. The British government agreed to buy Australia’s entire wool production in 1916 at 55% above market price. In the end, £160,000,000 British pounds was paid by the UK Government to Australia for the nation’s entire wool clip between 1916‑1920. This would be equivalent to £7,619,760,000 in 2022 money when accounting for inflation, or $13,239,000,000 AUD.Two posters on yellowed card. The first poster is printed in black text with a title of “NOTICE”. The second poster is printed in red text with the same title, “NOTICE”. Both posters have 4 body paragraphs of text, detailing restraints put on potential wool buyers because of war with Germany in the Great War. Both Posters are finished with a date in the bottom left corner.the great war, world war one, melbourne wool exchange, melbourne wool brokers association, wool sales, 1910s